Installatio et Regulatio Interruptorum Vacui

1. Requirimenta Installationis

Omnis pars et componentia debent inspectari et approbari priusquam installantur.

Fixturae et instrumenta ad installationem usitata debent esse mundae et convenire requisitis assembly. Fixitores fixi debent stringi per claves box-end, ring, vel socket. Claves adjustable (open-end) non debent uti quando stringuntur clavi prope camera extinguendi arcum.

Sequentia installationis debet sequi processum assembly specificatum. Typi et specificationes fixitorum debent stricto adhaerere requisitis design. Praecipue, longitudo clavorum fixantium terminalem contactum stationarium camerae extinguendi arcum non debet esse incorrecta.

Post assembly, distantia inter polos et distantiae positionales terminorum output superioris et inferioris debent conformari specificationibus drawing.

Omnes partes rotantes et volubiles debent moveri libere post assembly. Unguentum lubricans debet applicari superficibus frictionis.

Post regulam et testationem feliciter effectam, omnia membra diligenter expurgentur et terguntur. Puncta connectionis adjustabilia notentur cum pinctura rubra ad indicandum locum, et termini output ungantur cum vaselina, deinde involventur cum charta munda pro protectione.

2. Processus Assembly

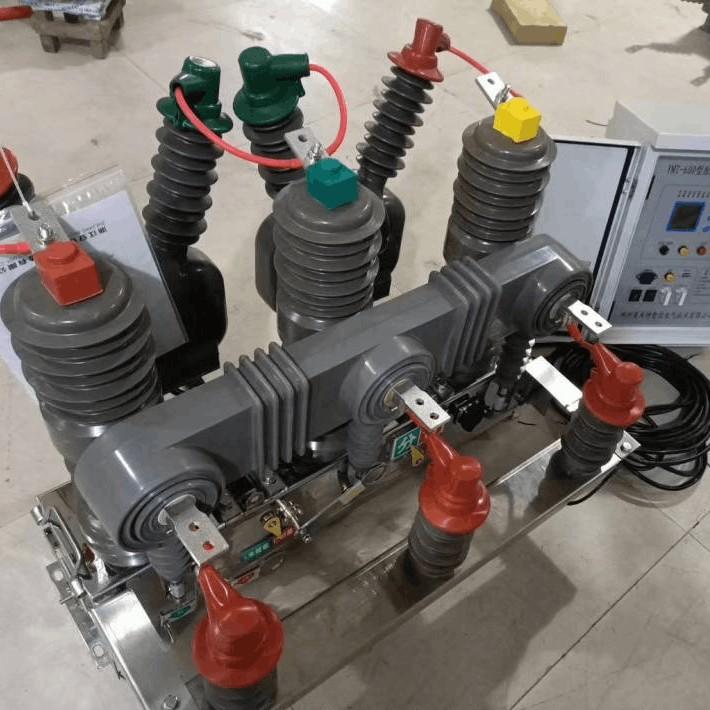

Exempli gratia, in interruptore vacuo ZN39-typus, assembly generaliter dividitur in tres partes: frontem, superiorem, et posteriorem.

Sequentia Assembly Frontalis:

Positionem frame → Support insulators → Horizontal insulators → Support bracket → Lower busbar → Arc extinguishing chamber and parallel insulating rods → Upper busbar → Conductive clamp with flexible connection → Contact spring seat and sleeve → Triangular crank arm.

Sequentia Assembly Superioris:

Main shaft and bearing housing → Oil damper → Insulating push rod.

Sequentia Assembly Posterioris:

Operating mechanism → Opening spring → Counter, open/close indicator, grounding mark.

Integratio Tres Sectionum:

Conectio sectionum frontalis et superioris: iunctura adjustabilis baculi insulantis coniungatur ad brachium triangulare crancum per pin.

Conectio sectionum posterioris et superioris: iunctura drive rod adjustabilis mechanici operativi coniungatur ad brachium crancum main shaft per pin.

Processus assembly est simplex, intuitivus, et commodus.

3. Regulatio Characteristicarum Mechanicarum

3.1 Regulatio Praeparatoria

Regulatio praeparatoria primum involvit regulam grossam intervalli contactus (distantiam apertionis) et itineris contactus (overtravel) pro singulis polis post totam assembly.

Manu clausit breaker lentissime ad verificandum correctam installationem et connexionem omnium componentium. Vito excedere itinera contactus, quod potest comprimere closing spring plene (spring binding), possibiliter laedens componentia. Ad hoc prohibendum, initio iuncturam adjustabilem baculi insulantis breviorem fac (screwed in). Post confirmationem operationis manu lenis, procede ad mensurandum et regulandum distantiam apertionis et iter contactus.

3.2 Regulatio Distantiae Apertionis et Iter Contactus

Interruptores vacui possunt latius classificari in duos typus secundum positionem relativam axis moving contact rod et axis closing spring:

Typus I: Structura Coaxialis – Axis moving contact cup coincidit cum axis closing spring.

Typus II: Structura Offsets (Non-coaxialis) – Axis moving contact rod separatur ab axis closing spring, cum spring montetur in axis baculi insulantis, fere perpendicularis ad contact rod.

Methodi calculi et regulationis paululum differunt inter hos duos typos.

Tabulae characteristicarum mechanicarum variis interruptoribus vacuis nominant valores nominates pro distantia apertionis et iter contactus. Post manuale operando apertionis et clausurae et mensurando valores actuales, regula sicut sequitur ad satisfaciendum specificationibus technicis.

(1) Regulatio pro Structuris Coaxialibus

Step 1: Regulatio Itineris Totius

Iter totum = Distantia apertionis + Iter contactus.

Si iter totum minor est quam summa valorum nominatorum, rotatio main shaft est insufficiens. Longe fac iuncturam connecting rod adjustabilem inter mechanica operativa et bracchium crancum main shaft. Si nimis longa, brevius fac baculum. Hoc certificat iter totum ad satisfaciendum requisitis.

Step 2: Regulatio Distributionis Inter Distantiam Apertionis et Iter Contactus

Regula iuncturam thread at fronte capitis uniuscuiusque poli insulantis.

Minimum adjustment: dimidium pitch thread (by turning the joint 180°).

Hac iunctura thread etiam regulat synchronizationem triphasica. Adjustmentes debent bilanciare valores itinerum et synchronizationem phasica. Repete cycles manuales apertionis et clausurae donec ambo sint intra tolerantiam. Numquam excede maximum permittibile iter contactus ad evitandum spring binding et laesionem componentium.

Longe fac connectionem (screw out): Distantia apertionis ↑, Iter contactus ↓

Brevius fac connectionem (screw in): Distantia apertionis ↓, Iter contactus ↑

(2) Regulatio pro Structuris Offsets (Non-coaxialibus)

In hac design, axis closing spring et axis moving contact non sunt alignati, itaque iter totum non habet directam significationem physicam. Methodi regulationis differunt:

Regulatio Distantiae Apertionis:

Achieved via an "opening distance adjustment shim" mounted on the frame. The shim’s height is adjusted by adding or removing layers. The top is pressed by the main shaft’s crank arm. Changing the shim height alters the main shaft’s initial angle in the open position, thereby changing the contact opening distance through the insulating push rod.

Contact Travel Adjustment:

The pre-compression height (B1) of the contact spring is fixed by the roller diameter and cannot be changed. The final compression height (B2) after closing is adjusted by:

During adjustment, simultaneously optimize three-phase synchronization, making repeated fine adjustments until all parameters are within tolerance.

Lengthen rod: B2 decreases → Contact travel increases

Shorten rod: B2 increases → Contact travel decreases

Screw in (shorten rod): B2 increases → Contact travel decreases

Screw out (lengthen rod): B2 decreases → Contact travel increases

A. Adjusting the threaded joint at the end of the insulating push rod:

B. Adjusting the length of the connecting rod between the operating mechanism and the main shaft crank arm:

(3) Regulatio Interlock Switch Auxiliaris

Post manualia adjustmentes distantiae apertionis et iter contactus, positio interlock switch auxiliaris debet recte setta fieri priusquam electrica operatio—alioqui, componentia electrica possunt laedi.

Processus Regulationis:

Disconecta pin inter switch auxiliaris et linkage bracchii cranci main shaft.

Manu clausit breaker dum roto switch auxiliaris ad punctum justum ante trip. Adjusta longitudo rod adjustabilis et bolt ut foramina pin alignentur fere.

Manu aperiit breaker et roto switch auxiliaris ad punctum trip iterum, assecurans foramina pin alignentur.

Repete processum donec alignment sit effecta in utroque statu apertionis et clausurae, deinde inserta pin.

Assecura ut contactus switch auxiliaris aperiantur modice ante contactus principales plene clauduntur aut aperiuntur.

4. Testationes Characteristicarum Mechanicarum, Regulatio Fina, et Testationes Factory

4.1 Testationes Characteristicarum

Post prima adjustmentes distantiae apertionis, iter contactus, et switch auxiliaris, opera electrica apertionis et clausurae et mensura characteristica mechanicam sequentia:

Instrumenta Testationis:

Optical oscillograph – accurate valde et visualiter

Circuit breaker analyzer – simplex, celeriter, et sufficiens accurate pro usu field

(Methodi testationis specificae non deteguntur hic.)

4.2 Regulatio Fina Characteristicarum Mechanicarum

Post testationem, perfice fines adjustmentes super omnes parametri extra spec ad optima performance.

(1) Regulatio Fina Synchronizationis

Identifica phase cum maxima deviatione temporis. Si unus polus claudit nimis cito (vel tarde), paululum aumenta (vel diminua) distantiam apertionis eius vertendo iuncturam adjustabilem baculi insulantis in (pro clausura priori) vel out (pro clausura posteriore) circa dimidium turn. Generaliter, hoc potest reducere error synchronismus intra 1 ms.

(2) Regulatio Fina Celeritatis Apertionis/Clausurae

Celeritas influetur a multis factoribus, sed elementa key adjustabilia sunt tensionem opening spring et iter contactus.

Celeritas clausurae nimis alta, celeritas apertionis nimis bassa:

Aumenta iter contactus vel stringe opening spring.

Celeritas clausurae acceptabilis, celeritas apertionis nimis bassa:

Aumenta iter totum per 0.1–0.2 mm, quod aumentat iter contactus et meliorat celeritatem apertionis.

Celeritas apertionis nimis alta:

Diminua iter contactus per 0.1–0.2 mm ad reprimendam celeritatem.

Post adjustmentem, remensura distantiam apertionis et iter contactus ad assecurandum eos remanere intra limites specificatos.

(3) Eliminatio Bounce Clausurae

Bounce clausurae posset resultare ex:

Rigiditas impactus clausurae nimis magna, causans rebound axiale contactus movens.

Guidance pauperis baculi contactus movens, resultans in wobble nimis magnum.

Clearance nimis magnus in transmission link, praecipue inter contact spring et conductive rod.

Perpendicularitas pauperrima inter superficiem contactus et axis centrale, causans slip laterale in contactu (apparet ut "bounce" in oscillogram).

Mediamenta Mitigationis:

Design debet vitare rigiditatem mechanicam nimis magnam (non adjustabile post manufacturam).

Assecura clearance guidance propria pro baculo contactus movens.

In structuris coaxialibus, contact spring connectat directe ad conductive rod—nulli links intermedi, ergo minus bounce.

In structuris offsets, bracchium crancum triangulare cum tribus pin introducit tres potential clearances, aumentans risk bounce.

Si bounce est causatus per perpendicularitatem pauperrimam superficiei contactus camerae extinguendi arcum, conare rotare cameram per 90°, 180°, vel 270° in assembly ad inveniendum alignment optimam. Si inefficax, substitue camera extinguendi arcum.

Assecura ut omnes clavi sint stringite duranter in adjustmente ad vitandam vibrationem interference.

(4) Testationes Acceptationis Factory

Post omnes characteristica mechanicam satisfacere specificationibus, opera 50 cycles (apertionis/clausurae et reclosure) ad maximum, minimum, et rated control voltage secundum requirementa factory.

Post 50 operationes, remensura omnia parametra mechanicam. Resultata debent appropinquare mensurationibus initiis ad passandum.

Denique, perfice:

Solis unitates transiens omnes testes approbantur ad shipment.