Ustawi na Ubadilisho wa Vifaa vya Kuchoma Mzunguko wa Kimapaza

1. Maagizo ya Ustawi

Yote ya sehemu na vifaa lazima zitathibitishwe na kuthibitishwa kabla ya ustawi.

Vifaa na zana zinazotumika kwa ustawi lazima ziwe safi na zikubalike kwa maagizo ya kuandaa. Vifaa vinavyokubalika kwa kutumia zana ni zina mwisho mwenye magamba, ring au socket. Zana zenye magamba zinaweza kutumika wakati wa kutumia visafu karibu na chumba cha kuchoma mzunguko.

Mfano wa ustawi lazima ufuelewe kwa utaratibu uliyotakribishwa. Aina na viwango vya vifaa vinavyoungwa lazima viwekwe kwa usahihi kulingana na maagizo ya ujenzi. Kwa ujuzi, urefu wa visafu vya kusimamia kituo cha kusimamia cha chumba cha kuchoma mzunguko usiwe upungufu.

Baada ya kuandaa, umbali wa pole-to-pole na umbali wa namba za tofauti za matumizi ya juu na chini lazima ukubalike kwa michango ya ramani.

Yote ya kukuruka na kusogeza lazima yajazeze kwa uhuru baada ya kuandaa. Tegemewa lala kwa maeneo yanayosogeza.

Baada ya kubadilisha na kutest kwa usafi, safisha na sigelea yote kwa usahihi. Endelea kwenye maeneo yenye majanga na rangi ya nyekundu ili kudainisha namba, na kushika matumizi ya juu na chini kwa petroleum jelly, basi zifuatiliwe na karatasi safi kwa ajili ya usalama.

2. Mfano wa Kuandaa

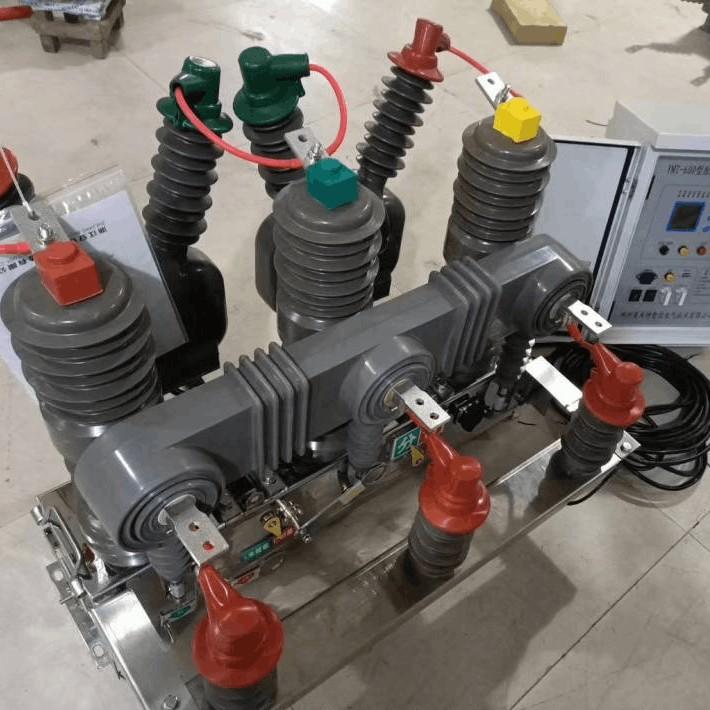

Kwa mfano wa vifaa vya kuchoma mzunguko aina ya ZN39, kuandaa kinaweza kugawanyika kwa tatu sehemu: mbele, juu, na nyuma.

Mfano wa Kutengeneza Sehemu ya Mbele:

Umbali wa mzunguko → Vitambaa vyenye umbo la vitambaa → Vitambaa vyenye umbo la vitambaa → Kituo cha kupiga → Busbar ya chini → Chumba cha kuchoma mzunguko na vitambaa vya kutambaa → Busbar ya juu → Kifundo cha kusimamia na usambazaji wa ura → Kituo cha kusogeza na kituo cha kupiga → Migongo ya triangular.

Mfano wa Kutengeneza Sehemu ya Juu:

Mzunguko mkuu na nyumba ya bearing → Oil damper → Vitambaa vyenye umbo la vitambaa.

Mfano wa Kutengeneza Sehemu ya Nyuma:

Mechanizmo ya kutumia → Spring ya kutumia → Counter, indicator ya kutumia/kutoka, alama ya kutumia.

Uunganisho wa Tatu Sehemu:

Husika sehemu ya mbele na juu: husika joint ya kutengeneza kwenye vitambaa vyenye umbo la vitambaa na migongo ya triangular kwa pin.

Husika sehemu ya nyuma na juu: husika rod ya kutengeneza kwenye mechanizmo ya kutumia na crank arm ya mzunguko mkuu kwa pin.

Mchakato wa kutengeneza unafaa kuwa rahisi, kuona na rahisi kutumika.

3. Kubadilisha Sifa za Kiujingine

3.1 Badiliko ya Mapema

Badiliko ya mapema yanahusu kubadilisha gap ya majanga (umbali wa kufungua) na safari ya majanga (overtravel) kwa kila pole baada ya kutengeneza kamili.

Funga vifaa kwa polepole kwa mkono kuhakikisha kwamba yote yameingizwa na huhusika vizuri. Usisite kubadilisha safari ya majanga kwa wingi, kwa sababu hii inaweza kuvunjika spring ya kutumia (spring binding), ambayo inaweza kuvunja vifaa. Kuhakikisha haya, anza kwa kutengeneza joint ya kutengeneza kwenye vitambaa vyenye umbo la vitambaa kuwa fupi (screwed in). Baada ya kutambua kwamba kutumia mkono kwa usawa, endelea kutathmini na kubadilisha umbali wa kufungua na safari ya majanga.

3.2 Kubadilisha Umbali wa Kufungua na Safari ya Majanga

Vifaa vya kuchoma mzunguko vinaweza kugawanyika kwa mbili kulingana na mahali pa axis ya moving contact rod na axis ya closing spring:

Aina I: Coaxial Structure - Axis ya moving contact cup inaonekana kwa axis ya closing spring.

Aina II: Offset (Non-coaxial) Structure - Axis ya moving contact rod inaonekana kwa axis ya closing spring, na spring imepatikana kwenye shaft ya vitambaa vyenye umbo la vitambaa, kubwa kwa kutosha kwa moving contact rod.

Mfano wa hesabu na badiliko unabadilika kidogo kati ya aina hizi mbili.

Tables za sifa za kiujingine za vifaa vingine vya kuchoma mzunguko vinazoelezea nominal values za umbali wa kufungua na safari ya majanga. Baada ya kutumia manual na kutathmini thamani halisi, bora kubadilisha kama ifuatavyo ili kufanikiwa na miundombinu.

(1) Kubadilisha kwa Aina Coaxial

Hatua 1: Kubadilisha Safari Kamili

Safari kamili = Umbali wa kufungua + Safari ya majanga.

Ikiwa safari kamili ni chache kuliko jumla ya nominal values, mzunguko mkuu unaweza kutofanya kazi vizuri. Ongeza length ya adjustable connecting rod kati ya mechanizmo ya kutumia na crank arm ya mzunguko mkuu. Ikiwa ni zaidi, punguza rod. Hii itasaidia safari kamili ikubalike kwa miundombinu.

Hatua 2: Kubadilisha Upatikanaji wa Umbali wa Kufungua na Safari ya Majanga

Badilisha threaded connection kwenye enda ya mbele kwa kila pole ya vitambaa vyenye umbo la vitambaa.

Badiliko chache: thread pitch moja (kwa kudondoka joint 180°).

Hii threaded joint pia hukubadilisha three-phase synchronization. Badiliko lazima yakubalike travel values na phase synchronization. Endelea kutumia manual open/close cycles hadi kumpata miundombinu. Usisite kubadilisha safari ya majanga kwa wingi ili kutokufanya spring binding na kuvunja vifaa.

Ongeza uzima (screw out): Umbali wa kufungua ↑, Safari ya majanga ↓

Punguza uzima (screw in): Umbali wa kufungua ↓, Safari ya majanga ↑

(2) Kubadilisha kwa Aina Offset (Non-coaxial)

Katika ujenzi huu, axis ya closing spring na axis ya moving contact hazijaelezane, hivyo safari kamili hauna maana ya kimataifa. Mfano wa badiliko unabadilika:

Kubadilisha Umbali wa Kufungua:

Kufanyika kwa "opening distance adjustment shim" ulioingizwa kwenye mzunguko. Urefu wa shim unaongezeka au kupunguzwa. Pembeni mpya inapigwa na crank arm ya mzunguko mkuu. Kubadilisha refu wa shim unabadilisha angle ya mwanzo wa mzunguko mkuu katika namba ya kufungua, kwa hivyo kubadilisha umbali wa kufungua kwa vitambaa vyenye umbo la vitambaa.

Kubadilisha Safari ya Majanga:

Pre-compression height (B1) ya contact spring inafanikiwa kwa diameter ya roller na haiwezi kubadilishwa. Height ya compression (B2) baada ya kutumia inabadilishwa kwa:

Wakati wa badiliko, pia ubadilishe three-phase synchronization, kufanya mara kwa mara badiliko machache mpaka kumpata miundombinu.

Ongeza rod: B2 inapungua → Safari ya majanga inongezeka

Punguza rod: B2 inongezeka → Safari ya majanga inapungua

Screw in (punguza rod): B2 inongezeka → Safari ya majanga inapungua

Screw out (ongeza rod): B2 inapungua → Safari ya majanga inongezeka

A. Kubadilisha threaded joint kwenye enda ya vitambaa vyenye umbo la vitambaa:

B. Kubadilisha uzima wa connecting rod kati ya mechanizmo ya kutumia na crank arm ya mzunguko mkuu:

(3) Kubadilisha Interlock Switch ya Auxiliary

Baada ya kubadilisha manual ya umbali wa kufungua na safari ya majanga, interlock switch ya auxiliary lazima iwe kubwa kabla ya kutumia electrically—vile vile, vifaa vya umeme vinaweza kuvunjika.

Mfano wa badiliko:

Tenga pin kati ya auxiliary switch na linkage ya crank arm ya mzunguko mkuu.

Funga vifaa kwa mkono wakati wa kutumia auxiliary switch hadi point iliyopangwa kabla ya kutumia. Kubadilisha uzima wa adjustable rod na bolt ili pin holes zikubalike zaidi.

Fungua vifaa kwa mkono na kutumia auxiliary switch tena hadi point iliyopangwa kabla ya kutumia, kuhakikisha pin holes zikubalike.

Endelea kufanya mchakato huu hadi kumpata miundombinu katika namba za kufungua na kutumia, basi ingiza pin.

Hakikisha contacts za auxiliary switch zinafungua kidogo kabla ya main contacts kufungua au kutumia.

4. Kutest Sifa za Kiujingine, Kubadilisha Machache, na Kutest ya Factory

4.1 Kutest Sifa

Baada ya kubadilisha mapema ya umbali wa kufungua, safari ya majanga, na auxiliary switch, fanya kutumia electric open/close operations na kutathmini sifa zifuatazo za kiujingine:

Testing Instruments:

Optical oscillograph - highly accurate and visual

Circuit breaker analyzer - simple, fast, and sufficiently accurate for field use

(Specific test methods are not detailed here.)

4.2 Fine Adjustment of Mechanical Characteristics

After testing, perform fine adjustments on any out-of-spec parameters to achieve optimal performance.

(1) Fine Adjustment of Synchronization

Identify the phase with the greatest timing deviation. If one pole closes too early (or late), slightly increase (or decrease) its opening distance by turning the insulating rod’s adjustable joint in (for earlier closure) or out (for later closure) by about half a turn. Typically, this can reduce synchronization error to within 1 ms.

(2) Fine Adjustment of Opening/Closing Speed

Speed is influenced by multiple factors, but key adjustable elements are the opening spring tension and contact travel.

Closing speed too high, opening speed too low:

Increase contact travel or tighten the opening spring.

Closing speed acceptable, opening speed too low:

Increase total travel by 0.1–0.2 mm, which increases contact travel and improves opening speed.

Opening speed too high:

Reduce contact travel by 0.1–0.2 mm to lower speed.

After adjustment, re-measure opening distance and contact travel to ensure they remain within specified ranges.

(3) Elimination of Closing Bounce

Closing bounce may result from:

Excessive closing impact rigidity, causing axial rebound of the moving contact.

Poor guidance of the moving contact rod, resulting in excessive wobble.

Excessive clearance in transmission links, especially between the contact spring and the conductive rod.

Poor perpendicularity between the contact surface and the central axis, causing lateral slip upon contact (appears as "bounce" on oscillograms).

Mitigation Measures:

Design should avoid excessive mechanical rigidity (not adjustable post-manufacture).

Ensure proper guidance clearance for the moving contact rod.

In coaxial designs, the contact spring connects directly to the conductive rod—no intermediate links, hence less bounce.

In offset designs, a triangular crank arm with three pins introduces three potential clearances, increasing bounce risk.

If bounce is caused by poor perpendicularity of the arc extinguishing chamber contact surface, try rotating the chamber by 90°, 180°, or 270° during assembly to find the optimal alignment. If ineffective, replace the arc extinguishing chamber.

Ensure all screws are fully tightened during adjustment to avoid vibration interference.

(4) Factory Acceptance Tests

After all mechanical characteristics meet specifications, perform 50 operation cycles (open/close and reclose) at maximum, minimum, and rated control voltage as per factory requirements.

After 50 operations, re-measure all mechanical parameters. Results should closely match initial measurements to pass.

Finally, perform:

Only units passing all tests are approved for shipment.