Installazzjoni u Aġġustament ta' Vakjuum Circuit Breakers

1. Requisiti għall-Installazzjoni

Kull parte u komponenti għandhom jiġu esaminati u approvati qabel l-installazzjoni.

Il-fissiluri u l-instrumenti maħdumin għal installazzjoni għandhom ikunu ċarigi u jissodisfaw ir-riżerwat tal-assenzja. Il-fissiluri stabbili għandhom jiġu miftuħa bil-użu ta' spannoli fixi, ring jew socket. L-aċċessori (open-end) mhux għandhom jiġu użati meta jiġu miftuħa is-sruġġiet bl-àrea tal-arc extinguishing chamber.

Is-sekwenz tal-installazzjoni għandha tsegwi s-silġ assenjatur. It-tip u s-speċifikazzjonijiet tal-fissiluri għandhom jissodisfaw il-requisiti tad-din. Partikularment, il-lunghezz tas-sruġġiet li jiffissaw it-terminal statwar tal-arc extinguishing chamber mhux ser tkun sbagliata.

Doppo l-assenzja, id-distanza bejn ip-polji u l-posizzjonali tal-terminals superjuri u infeżħur għandhom ikonformaw mal-speċifikazzjonijiet tad-drawings.

Kull komponenti rotanti u slissanti għandhom jiġu moħbija wara l-assenzja. Grez tal-lubrikant għandu jiġi applicat fuq is-surfiċi tal-frizzjoni.

Doppo l-aġġustament u l-prova b'suċċess, iċċanella u spilla kwalunkwe parti. Marka l-punti tal-konezzjoni aġġustabili b'vermiż scarlata biex tindika l-pożizzjoni, u metti petrol jelly fuq it-terminals, u agħṭilhom protezzjoni bl-użu ta' karta ċara.

2. Proċedura tal-Assenzja

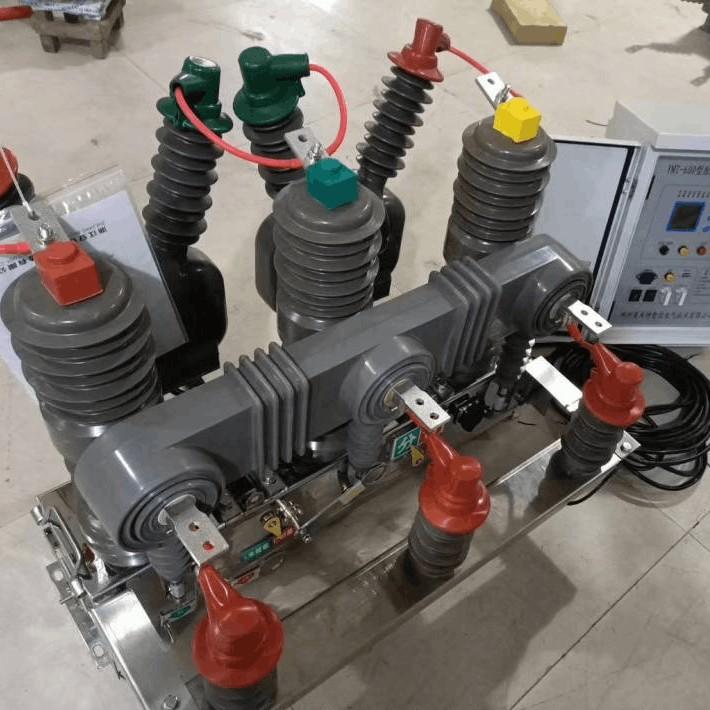

Bħala eżempju tal-vakjuum circuit breaker ta' tip ZN39, l-assenzja huwa ġeneralemente divisa f'tlisien: frontali, superjuri, u reġgħali.

Sekwenz tal-Assenzja tal-Front:

Posizzjoni tal-frame → Support insulators → Horizontal insulators → Support bracket → Lower busbar → Arc extinguishing chamber u parallel insulating rods → Upper busbar → Conductive clamp b'konezzjoni flissa → Contact spring seat u sleeve → Triangular crank arm.

Sekwenz tal-Assenzja ta' Fuq:

Main shaft u bearing housing → Oil damper → Insulating push rod.

Sekwenz tal-Assenzja tal-Lanġas:

Operating mechanism → Opening spring → Counter, open/close indicator, grounding mark.

Integrazzjoni tat-Tlisien:

Konnessjoni bejn it-tliet frontali u superjuri: link the adjustable joint of the insulating push rod to the triangular crank arm with a pin.

Konnessjoni bejn it-tliet lanġas u superjuri: link the adjustable drive rod of the operating mechanism to the main shaft crank arm with a pin.

Il-proċess tal-assenzja huwa senpliċi, intuitiv, u konvenjenti.

3. Aġġustament tal-Karatteristiċi Meċkanika

3.1 Aġġustament Preliminari

L-aġġustament preliminari għall-bażi involvi l-aġġustament grez tal-contact gap (opening distance) u contact travel (overtravel) għal kull pol wara l-assenzja kompletta.

Iċċanella l-breaker skontament biex tverifika l-installazzjoni u l-konezzjoni korretta tal-komponenti kollha. Evita l-settjar ta' contact travel żgħir, li dawk jistgħu jkompressjaw il-closing spring kemm huwa possibli (spring binding), potenzjalment saqaf il-komponenti. Biex tivita dan, fis-silġ, setta l-adjustable joint tal-insulating push rod iktar qas (screwed in). Wara l-konferma tal-operazzjoni manwali moħbija, proċedi biex timmodda u tagġusta l-opening distance u contact travel.

3.2 Aġġustament tal-Opening Distance u Contact Travel

Il-vakjuum circuit breakers jistgħu jiġu klassifikati f'żewġ tipi bażi tas-silġ relattiv tal-moving contact rod axis u closing spring axis:

Tip I: Coaxial Structure - Moving contact cup axis coincides with the closing spring axis.

Tip II: Offset (Non-coaxial) Structure - Moving contact rod axis huwa separatu mill-closing spring axis, bil-spring mounted on the insulating push rod shaft, quasi perpendikulari lil contact rod.

It-talbiet u metodi ta' aġġustament huma diffarenti flimkien milli dawn żewġ tipi.

It-tabelli tal-karatteristiċi meċkanika għal diversi vakjuum circuit breakers specifikaw il-valuri nominali għal opening distance u contact travel. Wara l-operazzjonijiet ta' open/close manwali u l-modda tal-valuri reali, aġġusta skont il-mudell segwan biex ikun imqassam il-specifikazzjonijiet tekniki.

(1) Aġġustament għal Strutturi Coaxiali

Paġna 1: Aġġusta l-Total Travel

Total travel = Opening distance + Contact travel.

Jekk it-total travel huwa inqas mill-summa tal-valuri nominali, il-rotazzjoni tal-main shaft mhux sufficienti. Allunga l-adjustable connecting rod bejn il-operating mechanism u main shaft crank arm. Jekk huwa twil wisq, qas il-rodd. Dan se ssigura li l-total travel jkonforma mal-requisiti.

Paġna 2: Aġġusta l-Distribuzzjoni Bejn l-Opening Distance u Contact Travel

Aġġusta l-threaded connection fil-front end ta' kull pole tal-insulating rod.

Aġġustament minimu: nifs pitch tal-thread (biex turn the joint 180°).

Dan il-threaded joint aġġusta ukoll it-triphasic synchronization. L-aġġustamenti għandhom ibdulaw il-valuri tal-travel u synchronization tal-phase. Ripeti s-silġ ta' open/close manuali sakemm kollox jagħmlu parte minn tolleranza. Ebda tmexxi l-maximum allowable contact travel biex ivita l-spring binding u saqaf il-komponenti.

Allunga l-konnessjoni (screw out): Opening distance ↑, Contact travel ↓

Qas l-konnessjoni (screw in): Opening distance ↓, Contact travel ↑

(2) Aġġustament għal Strutturi Offset (Non-coaxial)

Fiż-disign din, l-axis tal-closing spring u moving contact mhux allini, għalhekk it-total travel ma jkollu ebda significat fiziku dirett. Il-metodi ta' aġġustament huma diffarenti:

Aġġustament tal-Opening Distance:

Aragħġat permezz ta' "opening distance adjustment shim" montat fuq il-frame. Il-għoli tal-shim huwa aġġustat biex zid jew nieqes layers. Il-top huwa pressed bl-cranks arm tal-main shaft. Il-biddel tal-għoli tal-shim ibdel il-angle inizjali tal-main shaft fiż-posizzjoni tal-open, bl-ħolok ibdel il-contact opening distance permezz tal-insulating push rod.

Aġġustament tal-Contact Travel:

Il-pre-compression height (B1) tal-contact spring huwa fixed permezz tal-diameter tal-roller u mhux possibli li jiġi biddel. Il-final compression height (B2) wara l-closing huwa aġġustat permezz ta':

Fil-mod ta' aġġustament, optymizza l-triphasic synchronization, u fa' aġġustamenti fini ripetuta sakemm kollox il-parametri ikunu minn tolleranza.

Allunga l-rodd: B2 decreases → Contact travel increases

Qas l-rodd: B2 increases → Contact travel decreases

Screw in (qas l-rodd): B2 increases → Contact travel decreases

Screw out (allunga l-rodd): B2 decreases → Contact travel increases

A. Aġġustament tal-threaded joint fil-front end tal-insulating push rod:

B. Aġġustament tal-length tal-connecting rod bejn l-operating mechanism u main shaft crank arm:

(3) Aġġustament tal-Auxiliary Switch Interlock

Wara l-aġġustament manuali tal-opening distance u contact travel, il-pożizzjoni tal-auxiliary switch interlock għandha tkun settjeta sew bħal qabel l-operazzjoni elektrika - inkella, il-komponenti elektrika jistgħu jiġu saqajn.

Proċedura tal-Aġġustament:

Disconnect the pin between the auxiliary switch and the main shaft crank arm linkage.

Manually close the breaker while rotating the auxiliary switch to the point just before it trips. Adjust the length of the adjustable rod and bolt so that the pin holes align approximately.

Manually open the breaker and rotate the auxiliary switch to its trip point again, ensuring pin holes align.

Repeat the process until alignment is achieved in both open and close positions, then insert the pin.

Ensure the auxiliary switch contacts open slightly before the main contacts fully close or open.

4. Testjar tal-Karatteristiċi Meċkanika, Aġġustament Fini, u Tests ta' Factory

4.1 Testjar tal-Karatteristiċi

Wara l-aġġustament preliminari tal-opening distance, contact travel, u auxiliary switch, efettua l-operazzjonijiet ta' open/close elektrika u mmaddej l-karatteristiċi meċkanika segwan:

Instruments ta' Testjar:

Optical oscillograph - highly accurate and visual

Circuit breaker analyzer - simple, fast, and sufficiently accurate for field use

(Specific test methods are not detailed here.)

4.2 Aġġustament Fini tal-Karatteristiċi Meċkanika

Wara l-testjar, efettua l-aġġustament fini suvviax il-parametri out-of-spec biex tagħmel performanża ottimali.

(1) Aġġustament Fini tal-Synchronization

Identify the phase with the greatest timing deviation. If one pole closes too early (or late), slightly increase (or decrease) its opening distance by turning the insulating rod’s adjustable joint in (for earlier closure) or out (for later closure) by about half a turn. Typically, this can reduce synchronization error to within 1 ms.

(2) Aġġustament Fini tal-Opening/Closing Speed

The speed is influenced by multiple factors, but key adjustable elements are the opening spring tension and contact travel.

Closing speed too high, opening speed too low:

Increase contact travel or tighten the opening spring.

Closing speed acceptable, opening speed too low:

Increase total travel by 0.1–0.2 mm, which increases contact travel and improves opening speed.

Opening speed too high:

Reduce contact travel by 0.1–0.2 mm to lower speed.

After adjustment, re-measure opening distance and contact travel to ensure they remain within specified ranges.

(3) Elimination of Closing Bounce

Closing bounce may result from:

Excessive closing impact rigidity, causing axial rebound of the moving contact.

Poor guidance of the moving contact rod, resulting in excessive wobble.

Excessive clearance in transmission links, especially between the contact spring and the conductive rod.

Poor perpendicularity between the contact surface and the central axis, causing lateral slip upon contact (appears as "bounce" on oscillograms).

Mitigation Measures:

Design should avoid excessive mechanical rigidity (not adjustable post-manufacture).

Ensure proper guidance clearance for the moving contact rod.

In coaxial designs, the contact spring connects directly to the conductive rod—no intermediate links, hence less bounce.

In offset designs, a triangular crank arm with three pins introduces three potential clearances, increasing bounce risk.

If bounce is caused by poor perpendicularity of the arc extinguishing chamber contact surface, try rotating the chamber by 90°, 180°, or 270° during assembly to find the optimal alignment. If ineffective, replace the arc extinguishing chamber.

Ensure all screws are fully tightened during adjustment to avoid vibration interference.

(4) Factory Acceptance Tests

After all mechanical characteristics meet specifications, perform 50 operation cycles (open/close and reclose) at maximum, minimum, and rated control voltage as per factory requirements.

After 50 operations, re-measure all mechanical parameters. Results should closely match initial measurements to pass.

Finally, perform:

Only units passing all tests are approved for shipment.