Mga Kinahanglan sa Pag-install

Ang tanang bahin ug komponente kinahanglan na ma-inspeksyonon sa dili pa ang pag-install.

Ang mga kagamitan ug tool nga gamiton sa pag-install kinahanglan na malinis ug makasunod sa mga requirement sa assembly. Sa pag-tighten sa mga fasteners, gamiton ang fixed wrenches, box wrenches, o socket wrenches. Dili gamiton ang adjustable wrenches sa pag-tighten sa mga screw nga adto sa duol sa arc-extinguishing chamber.

Ang sequence sa pag-install kinahanglan na mokasunod sa regulations sa installation process, ug ang specifications sa fasteners alang sa pag-install sa matag komponente kinahanglan na mokasunod sa design requirements. Partikular, ang length specification sa mga bolts nga nag-fix sa static contact end sa arc-extinguishing chamber kinahanglan na tama.

Pagkahuman sa assembly, ang pole-to-pole distance ug ang position distances sa upper ug lower outgoing lines kinahanglan na mokasunod sa requirements sa drawing dimensions.

Pagkahuman sa assembly, ang tanang rotating ug sliding parts kinahanglan na molihok ng libre. I-apply ang lubricating grease sa areas nga subject sa motion-induced friction.

Pagkahuman sa pag-adjust test, i-clean ug i-wipe ang equipment. Marka ang adjustable connection parts sa tanang komponente pinaagi sa red paint dots. I-apply ang Vaseline sa outgoing terminals ug i-protect sila pinaagi sa clean paper wrapping.

Installation

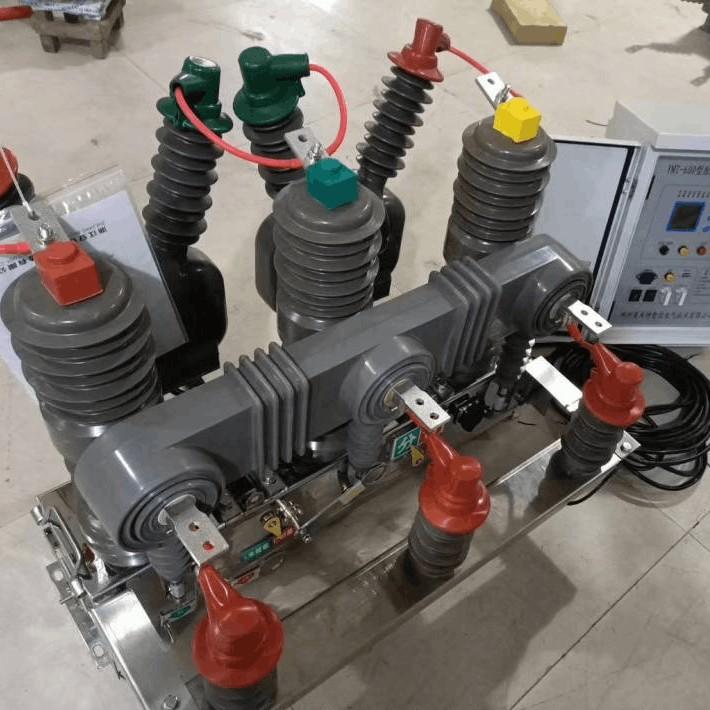

Isip ehenplo, ang ZN39 vacuum circuit breaker, ang iyang assembly naga-include og tulo ka parte: ang front part, ang upper part, ug ang rear part.

Sequence sa Pag-install sa Front Part:

Unsa man, iposition ang framework.

Pagkahuman, i-install ang post insulators, sumala sa horizontal insulators.

Sunod, i-attach ang bracket, ang lower busbar, ang arc-extinguishing chamber, ug ang parallel insulating rods.

Pagkahuman, i-install ang upper busbar, ang flexible connection sa conductive clamp, ang contact spring seat sliding sleeve, ug finally ang triangular toggle arm.

Sequence sa Pag-install sa Upper Part:

I-install ang main shaft ug ang bearing seat unang-unang.

Pagkahuman, i-mount ang oil buffer.

Finally, i-attach ang insulating push rod.

Sequence sa Pag-install sa Rear Part:

I-install ang operating mechanism unang-unang.

Pagkahuman, i-attach ang opening spring, ang counter, ang closing and opening indicators, ug ang grounding mark.

Iconnect kini tulo ka major parts pinaagi niining mosunod:

Pag-adjust sa Mga Mechanical Characteristics

Preliminary Adjustment

Ang preliminary adjustment nagfokus sa pag-roughly adjust sa contact opening distance ug contact travel para sa matag pole sa assembled vacuum circuit breaker. Sa panahon sa preliminary adjustment, i-close ang circuit breaker bisan pa manual ug i-check kung ang tanang bahin kay gi-install ug giconnect sa husto. Sa panahon sa pag-adjust, importante nga dili mas sayop ang contact travel aron dili mapressure ang contact closing spring labi na. Busa, sa panahon sa installation, maayo nga ishorten (iscrew in) ang adjustable joint sa insulating push rod. Pagkahuman sa normal na manual operation, mahimo na ang measurement ug adjustment sa opening distance ug contact travel, ang mao kini ang iintrodukta sa ubos.

Adjustment sa Opening Distance ug Contact Travel

Para sa iba't ibang tipo sa vacuum circuit breakers, batasan sa relative positions sa moving contact rod's movement axis ug ang contact closing spring axis, sila mahimong magbahin og duha ka tipo:

Coaxial type: Ang axis sa moving contact cup coincides sa axis sa closing spring.

Hetero-axial type: Ang axis sa moving contact rod separated gikan sa axis sa closing spring. Ang closing spring gigamit sa axis sa insulating push rod, ug ang positions sa duha ka axes maoy almost perpendicular. (Refer to our company's ZN28A type split-type vacuum circuit breaker, as shown in Figures 1 and 2.)

Ang calculation methods sa opening distance ug contact travel sa duha ka types sa circuit breakers lisud lisud.

Ang mechanical characteristic tables sa iba't ibang vacuum circuit breakers maghatag og data sa nominal opening distance ug contact travel. Pagkahuman sa manual closing ug opening sa circuit breaker aron sukuhan ang opening distance ug contact travel, ang mosunod nga adjustment methods mahimo gamiton aron sigurado nga mopasabot sila sa technical specifications.

Adjustment sa Coaxial Structure

Kon ang total stroke (na sama sa sum sa opening distance ug contact travel) menor sa sum sa ilang nominal values, ini nanggiingana nga ang rotational movement sa switch main shaft wala sufficient. Sa kasagaran, ang adjustable connecting rod nga iconnect ang operating mechanism sa main-shaft toggle arm kinahanglan i-adjust nga mas long; conversely, kon ang total stroke mas grande, i-adjust shorter aron ang total stroke basically mokasunod sa requirements. Ini ang unang step.

Sa ikaduha nga step, i-adjust ang distribution sa opening distance ug contact travel sa loob sa total stroke. Karon, ang length sa threaded connection sa front end sa insulating push rod sa matag pole kinahanglan i-adjust. Kon imong paglengthen ang connection, ang opening distance fo increases while ang compression stroke Jc decreases; kon imong pagshorten, ang opening distance fo decreases while ang contact travel Jc increases. Ang minimum adjustment range sa threaded joint usa ka half turn (either screwing in, which is equivalent sa pagshorten sa length sa insulating push rod, or screwing out, which is equivalent sa pagincrease sa iyang length), meaning half of the pitch.

Ang threaded joint sa insulating push rod gamiton usab aron i-adjust ang three-pole synchronism. Busa, sa panahon sa adjustment process, kinahanglan sigurado nga ang opening distance ug contact travel mokasunod sa tolerance range, samantalang i-consider usab ang three-pole synchronism. Kasagaran, mahimo ang multiple manual closing ug opening operations aron matapos ang adjustment. Sa buhat sa adjustment process, special attention must be paid so as not to exceed the maximum allowable range of the contact travel, so as to prevent the contact closing spring from being over-compressed and causing damage to the components.

Adjustment sa Hetero-axial Structure

Sa kini nga tipo sa circuit breaker, tungod kay ang contact spring axis ug ang moving contact axis wala sa same straight line, ang nabanggit nga total stroke calculation wala physical meaning dinhi, ug ang adjustment method lisud lisud.

Opening distance: Kini nga tipo sa circuit breaker equipped with a component called the "opening distance adjusting pad". Its base plate is fixed on the framework. The number of shims can be increased or decreased to change its height. The top is pressed by a toggle arm welded from the main shaft. By changing the height of the adjusting pad, the initial angle of the main shaft in the open-circuit state can be changed. After being transmitted through the insulating push rod, the contact opening distance is thus changed.

Contact travel: Ang pre-compression height B1 sa contact spring determinado gikan sa diameter sa compression roller ug wala mousab. Pagkahuman sa closing, ang final compression height B2 sa contact spring mahimo i-adjust sa mosunod nga duha ka ways:

Method A: Rotate the threaded connection joint at the end of the insulating push rod in or out. When screwing in (that is, when the distance between the pin holes at both ends of the insulating push rod is shortened), B2 increases and the contact travel decreases; when screwing out, the opposite occurs and the contact travel increases.

Method B: Adjust the length of the adjustable connecting rod between the operating mechanism and the driving toggle arm of the circuit breaker main shaft, which can also change B2. When the connecting rod is extended, B2 decreases and the contact travel increases; conversely, when it is shortened, the contact travel decreases.

Sa panahon sa adjustment process sa opening distance ug contact travel, kinahanglan usab i-adjust ang three-pole non-synchronism simultaneously. Make mutual compromises and repeatedly adjust to ensure that all are within the allowable tolerance range.

Adjustment sa Auxiliary Switch Interlock

Pagkahuman sa manual adjustment sa opening distance ug contact travel, kinahanglan i-adjust ang interlock position sa auxiliary switch bago ang electric closing ug opening operations. Otherwise, ang electrical components mahimo masunog.

Sa panahon sa adjustment, disconnect ang interlock sa usa ka end sa connecting rod between the auxiliary switch ug ang main-shaft toggle arm. I-close ang circuit breaker manually, ug simultaneously i-turn ang auxiliary switch sa just-tripped position. I-adjust ang length sa adjusting bolt ug connecting rod aron ang pin holes sa connecting rod ug adjusting bolt approximately aligned. Pagkahuman, i-open ang circuit breaker manually ug i-turn ang auxiliary switch sa just-tripped position again. Ensure usab nga ang pin holes sa connecting rod ug adjusting bolt approximately aligned. Repeat the adjustment multiple times until the above requirements are met, and then insert the pin. Ang goal mao ang ensure nga ang electrical contacts sa auxiliary switch mahimo cut off slightly in advance sa end sa closing or opening stroke sa circuit breaker.

Mechanical Characteristic Parameter Testing, Adjustment, ug Factory-acceptance Tests

Characteristic Testing

Pagkahuman sa preliminary adjustment sa opening distance, contact travel, ug auxiliary switch, mahimo na ang electric closing ug opening operations, ug i-measure ang mechanical characteristic parameters sama sa closing ug opening time, speed, non-synchronism, ug closing bounce.

Adunay duha ka types sa testing instruments para sa mechanical characteristic parameters: ang optical oscilloscope ug ang switch characteristic measuring instrument. Ang una mas accurate ug intuitive; ang ikaduha simple ug quick to operate, ug ang accuracy nia mokasunod sa operational requirements, making it suitable for on-site use. Ang specific testing methods wala describe diri.

Fine-tuning sa Mechanical Characteristics

Pagkahuman sa testing, fine-tune ang non-compliant parameters aron optimize ang tanang mechanical characteristic parameters unom-unom.

Fine-tuning sa Non-synchronism:Identify the phase with the greatest difference in closing and opening times through measurement. If this pole closes too early (late), slightly increase (decrease) its opening distance. Since the opening distances of the three poles have been adjusted to be approximately the same, at this time, the adjustment can be achieved by screwing in (out) the adjustable joint of the insulating pull rod of this pole by half a turn. Generally, the non-synchronism of closing and opening can be adjusted to within 1ms.

Fine-tuning sa Closing ug Opening Speeds:The closing and opening speeds are affected by various factors. However, the main adjustable components are generally the opening spring and the contact travel. The tightness of the opening spring affects the opening speed, while the contact travel (the compression amount of the contact pressure spring) has a major influence on the opening speed.

For example, when the closing speed is too high and the opening speed is too low, the contact travel can be increased or the opening spring can be tightened; conversely, it can be loosened. Another example is when the closing speed is appropriate but the opening speed is low. In this case, the total stroke can be adjusted to increase it by approximately 0.1 - 0.2mm. At this time, the contact travel of each pole will increase by 0.1 - 0.2mm, and the opening speed will also increase. Conversely, if the opening speed is too high, the contact travel can be adjusted to decrease by 0.1 - 0.2mm, and the speed will decrease accordingly.

After adjusting the non-synchronism and speed, the opening distance and contact travel data of each pole should be re-measured and corrected. The data should be within the specified range of the product.

Elimination sa Closing Bounce

Adunay apat ka possible causes sa closing bounce sa vacuum circuit breaker:

First, the closing impact rigidity is too high, causing the moving contact to axially rebound.

Second, the guiding of the moving contact rod is poor, resulting in excessive shaking.

Third, the gap in the transmission link is too large, especially the transmission gap between the initial compression end of the contact spring and the conductive rod.

Fourth, the perpendicularity between the contact surface and the central axis is insufficient, causing lateral slippage during contact, which is reflected as "bounce" in the oscillogram or testing instrument.

To reduce or eliminate closing bounce, in the structural design, it is necessary to ensure that the overall structural impact rigidity is not too high (but this cannot be changed for a finished product), and the gap in the guiding structure of the moving contact rod should not be too large.

In a coaxial structure, since the contact pressure spring is directly connected to the conductive rod without intermediate transmission parts, there is no gap. However, in a hetero-axial structure, there is a triangular toggle arm for direction change between the contact spring and the moving contact rod, which is connected by three pins. This creates three gaps, making bounce more likely to occur compared to the former. If bounce (slippage) occurs due to insufficient perpendicularity of the contact end face of the arc-extinguishing chamber, the arc-extinguishing chamber can be rotated by 90°, 180°, and 270° for trial assembly to find the position where the upper and lower contact surfaces fit well.

Usually, this can solve the problem. If it doesn't work, the arc-extinguishing chamber needs to be replaced. During the process of dealing with closing bounce, all screws should be tightened to avoid the interference of vibration.

Factory-acceptance Test

After all the aforementioned mechanical characteristic tests are qualified, the opening, closing, and reclosing operation tests at the maximum, minimum, and rated operating voltages shall be carried out according to the factory requirements, with a cumulative total of 50 operations. After 50 operations, measure all mechanical characteristic parameters again. They should be approximately consistent with the previously measured mechanical characteristic parameters to be considered qualified. Finally, conduct the loop resistance test and the power-frequency withstand voltage test for the primary and secondary circuits. The product can be released from the factory only when all tests are qualified.

Connect the rear part and the upper part: Use a pin to connect the adjustable transmission connecting rod of the operating mechanism to the main-shaft toggle arm. The assembly process is simple, intuitive, and convenient.