Unsa ang Spring Operating Mechanism sa High- ug Medium-Voltage Circuit Breakers?

Ang spring operating mechanism usa ka kritikal nga komponente sa high- ug medium-voltage circuit breakers. Iya kini gamiton ang elastic potential energy nga naka-store sa mga springs aron mapasabot ang pagbukas ug pagsara sa breaker. Ang spring gicharge pinaagi sa electric motor. Kapag operasyon na ang breaker, ang naka-store nga energia gibuto aron mobati ang moving contacts.

Key Features:

Ang spring mechanism nagamit ang elastic energy nga naka-store sa springs.

Iya kini pasabot ang pagbukas ug pagsara sa circuit breaker.

Ang spring gicharge pinaagi sa motor ug gi-release ang iyang naka-store nga energia samtang operasyon aron mobati ang moving contacts.

Asa Padayon ang Hydraulic Operating Mechanism sa High-Voltage Circuit Breakers?

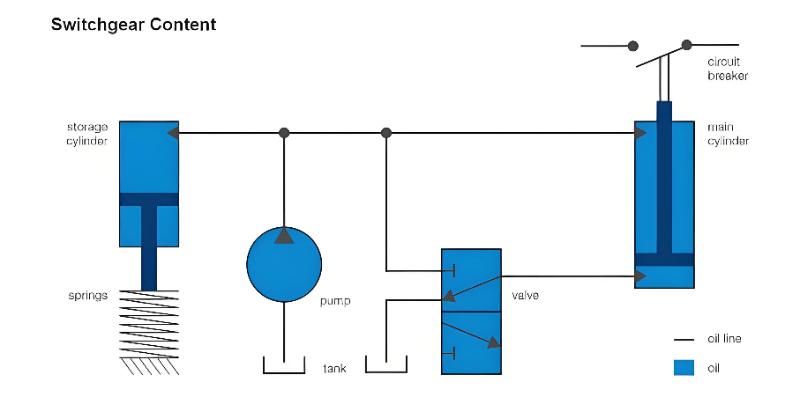

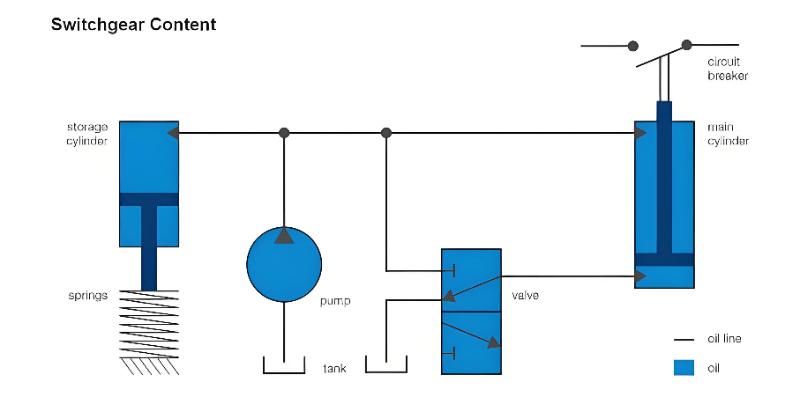

Ang hydraulic operating mechanism sa high-voltage circuit breakers gigamit aron mobukas o mosa ang breaker contacts. Iya kini operasyon batas sa hydraulic fluid dynamics aron kontrolhon ang movement sa breaker. Kapag kinahanglan na ang operasyon, gi-release ang hydraulic pressure, mosunod ang contacts mobukas o mosa basehan sa panginahanglan. Ang incompressibility ug fluidity sa hydraulic systems mahimong ideal para sa paghatag og fast, powerful motion nga gikinahanglan sa high-voltage switching.

Note: Ang diagram sa ubos nagpakita sa principle sa hydraulic-spring mechanism. Ang HMB series usa ka maayo nga pioneer niining teknolohiya.

Key Features:

Ang hydraulic mechanism nagamit ang fluid dynamics aron kontrolhon ang operasyon sa breaker.

Gi-release ang hydraulic pressure aron mobukas o mosa ang contacts kapag kinahanglan.

Ang incompressibility ug flow characteristics sa sistema mahimong suitable para sa fast, high-force operations sa HV applications.

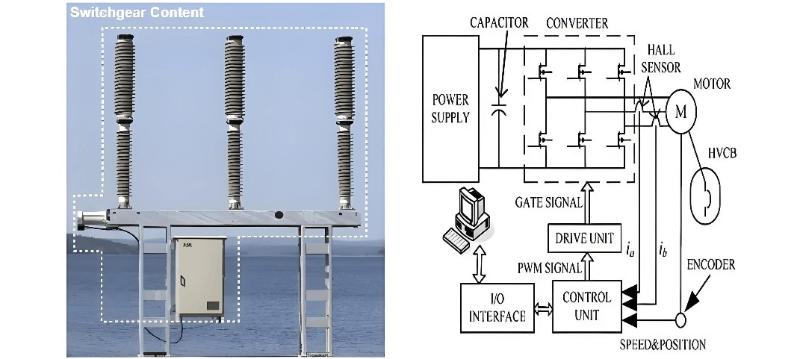

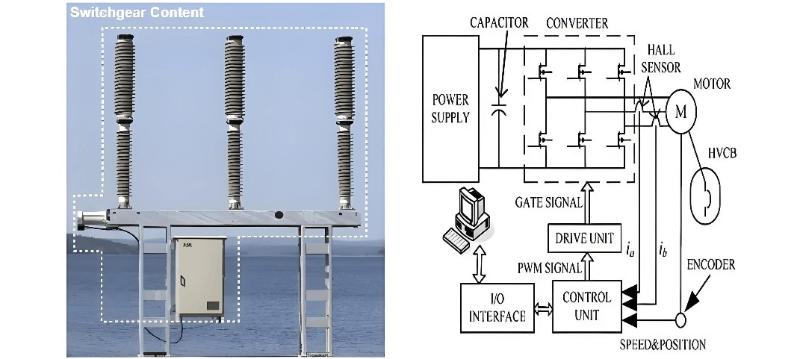

Unsa ang Role sa Motor-Driven Operating Mechanisms sa High-Voltage Circuit Breakers?

Ang motor-driven operating mechanisms gigamit sa high-voltage circuit breakers aron kontrolhon ang switching operations. Kini nga mekanismo nagamit og electric motor aron chargehon ang spring o direkta mopabilin sa moving parts. Ang motor molihok aron windhon ang spring o mobili sa mga komponente, samtang mobukas o mosa ang circuit. Kini nga disenyo naghatag og high precision ug control, essential para sa pagmaneho sa high-voltage systems.

Note: Pagkahuman nga ABB miintroduce ang motor-driven mechanism, daghang domestic companies (e.g., PG) migamit usab niining parehas nga disenyo higayon pa sa dekada. Pero, daghan sa mga proyekto mao ra gyud nahuman ug kasagaran wala na makita karon.

Key Features:

Ang motor-driven mechanism nagamit og electric motor aron kontrolhon ang operasyon sa breaker.

Ang motor chargehon ang spring o direkta mobili sa mga komponente aron mobukas o mosa ang circuit.

Iya kini naghatag og high precision ug control, necessary para sa high-voltage applications.

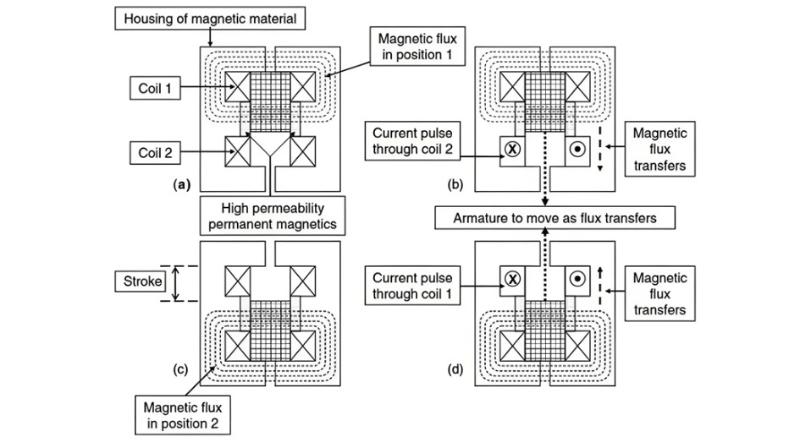

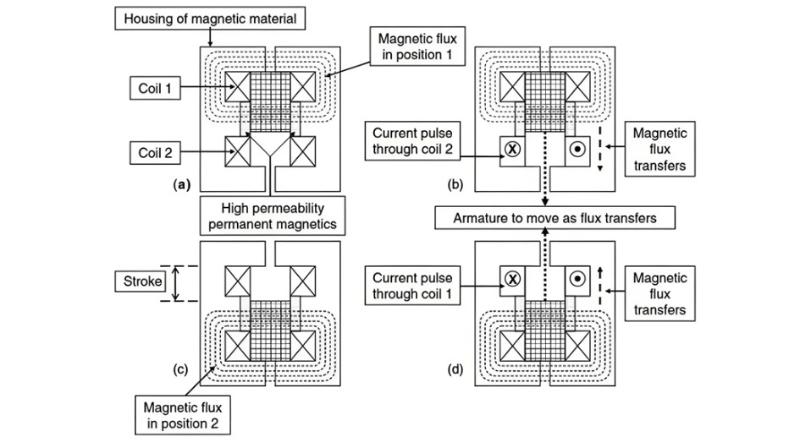

Magnetic Operating Mechanisms sa Medium-Voltage Circuit Breakers

Ang magnetic operating mechanism sa medium-voltage circuit breakers nagamit og magnetic force aron operarhon ang breaker. Kini involba ang solenoid — usa ka coil nga generate og magnetic field samtang adunay current nga molihok didto. Kapag energized, ang magnetic field dali-dali moghatag og puli sa contacts, interrupting ang circuit. Kini nga mekanismo labi ka reliable ug naghatag og fast actuation, making it particularly suitable for MV applications.

Key Features:

Ang magnetic mechanism nagamit ang force generated by a magnetic field aron operarhon ang breaker.

Kini involba ang solenoid (coil) nga produce og magnetic field samtang energized.

Ang magnetic force dali-dali mag-separate sa contacts, enabling fast, reliable operation ideal for MV systems.

Asa Padayon ang Choice sa Operating Mechanism Affect Breaker Performance?

Ang choice sa operating mechanism significantly impacts circuit breaker performance. Each type — spring, hydraulic, motor-driven, ug magnetic — adunay unique advantages ug suits different voltage levels ug applications.

Spring mechanisms adunay wide use tungod sa ilang simplicity ug reliability.

Hydraulic mechanisms offer precise, high-power control, ideal for high-voltage applications.

Motor-driven mechanisms provide high accuracy ug programmability.

Magnetic mechanisms highly reliable with fast response times, ideal for MV vacuum breakers.

Ultimately, ang selection depends sa specific application requirements, including voltage level, load conditions, ug environmental factors.

Summary:

Operating mechanism choice significantly affects breaker performance.

Each type (spring, hydraulic, motor-driven, magnetic) adunay distinct advantages for different voltages ug uses.

Selection should be based sa application-specific needs, not just cost.

Future Trends sa Circuit Breaker Operating Mechanisms

As technology advances, we can expect innovations that will shape the future of operating mechanisms:

Materials science may lead to more durable, efficient springs for spring mechanisms.

Hydraulic technology improvements could yield more precise and reliable systems.

Motor technology may enable smaller, more energy-efficient motor-driven mechanisms.

Magnetic technology could be enhanced for faster, more robust actuation.

These advancements will lead to more efficient, compact, and reliable operating mechanisms.

Summary:

Technological progress will shape the future of operating mechanisms.

Advances in materials, hydraulics, motors, and magnetics will improve performance.

Future mechanisms will be more efficient, reliable, and compact.

Maintenance Requirements for Different Circuit Breaker Operating Mechanisms

Maintenance needs vary by mechanism type:

Spring mechanisms: Require regular inspection and lubrication to ensure spring integrity and mechanical smoothness.

Hydraulic mechanisms: Need periodic checks for oil leaks and fluid condition; seals and valves may degrade over time.

Motor-driven mechanisms: Require inspection of motor health, brushes (if applicable), and electrical connections.

Magnetic mechanisms: Generally low maintenance, but the solenoid and electrical connections should be inspected periodically.

Summary:

Maintenance requirements depend on the mechanism type.

Spring and hydraulic mechanisms require more mechanical upkeep; motor-driven units need electrical checks.

Magnetic mechanisms are low-maintenance but still require periodic inspection.

How Does the Operating Mechanism Affect Circuit Breaker Cost?

The mechanism type directly impacts the cost of the circuit breaker:

Spring mechanisms are typically lower cost due to their simple, robust design.

Hydraulic, motor-driven, and magnetic mechanisms are more complex and generally more expensive.

However, selection should not be based solely on cost. Factors such as voltage level, load profile, environmental conditions, and reliability requirements must be considered. Spring mechanisms generally have lower operating energy, while hydraulic mechanisms deliver higher operating force.

Summary:

Mechanism type affects overall cost.

Spring mechanisms are cost-effective; hydraulic, motor-driven, and magnetic types are more expensive.

Choice should be based on technical requirements, not just initial cost.

Environmental Impact of Different Circuit Breaker Operating Mechanisms

Different mechanisms have varying environmental impacts:

Spring mechanisms: Minimal environmental impact — they rely on mechanical energy with no fluids or emissions.

Hydraulic mechanisms: Risk of oil leakage, which can cause soil and water contamination. Hydraulic fluid disposal must be managed carefully.

Motor-driven mechanisms: Consume electrical energy, contributing to operational energy use and carbon footprint.

Magnetic mechanisms: Generally eco-friendly, but energy is required to generate the magnetic field.

Summary:

Environmental impact varies by mechanism.

Hydraulic systems pose leakage risks; motor-driven systems increase energy consumption.

Magnetic mechanisms are environmentally friendly, though energy use should be considered.

Summary: Reliability of Spring Mechanisms in High-Voltage Applications (35kV and Above)

For high-voltage circuit breakers (35kV and above), spring mechanisms are structurally simple and theoretically more reliable. However, recent power grid operation experience shows that spring mechanisms are not without issues, including:

Spring fatigue leading to incomplete opening/closing

Latching component jamming causing failure to operate

Shaft-hole deformation altering tripping characteristics, resulting in maloperation or failure

Additionally, BLK-series coiled springs have shown cases of spring fracture due to poor environmental tolerance (e.g., temperature, humidity).

To detect defects in breakers and their mechanisms during routine testing, extensive research has been conducted worldwide. While many testing devices and analytical methods exist, using test signals and advanced analytics to assess and improve mechanism reliability remains a challenging and ongoing task.