Mai suna Centrifugal Switch?

A centrifugal switch itace da aiki mai gaba tare da kisan jirgin samun zama. Wannan kisa na jirgin samun zama yana daidaita da yanayin ko mota tsakiyar bature. Aikinsu na centrifugal switches suna da shawarar kuɗi da koyar samun zama ta shaft.

Yadda Centrifugal Switches ke Tafiya?

Aikin centrifugal switch itace da aiki mai gaba tare da yanayin tsakiyar bature da split-phase induction motors.

Aikin ya kunna don bayar da aiki mai gaba tare da yanayin tsakiyar bature idan samun zama masu shawarar kuɗi a yi.

Aikin centrifugal switch tana da muhimmanci ga jirgin samun zama. Itace da aiki mai gaba tare da yanayin tsakiyar bature da split-phase induction motors.

Saboda hakan, aikin centrifugal switch ana kira da 'clutch' saboda yadda ake amfani da shi wajen yanayin tsakiyar bature.

Tsakiyar bature da phase daban-daban tana da aikin centrifugal switch a cikin kyautar, wanda ya karkashin shaft ta tsakiya. Idan tsakiya ba a yi, aikin ya ci gaba.

Idan tsakiya a yi, aikin ya bayar da tsarin tsakiya da capacitor don bayar da starting torque. Idan samun zama ya saukar, aikin ya ci gaba saboda tsakiya ba da shawarar kuɗi a yi.

Aikin centrifugal switch tana da shawarar kuɗi ga single-phase AC electric motors. Tsakiyoyin da suka ba su da shawarar kuɗi a yi don bayar da starting torque.

Circuit ya ci gaba aikin centrifugal switch, bayar da shawarar kuɗi don bayar da starting torque. Aikin ya ci gaba circuit idan tsakiya ya samu samun zama, kuma tsakiya ya yi aiki da ma'ana.

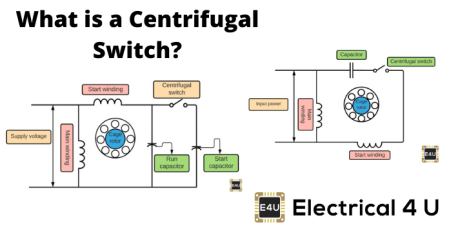

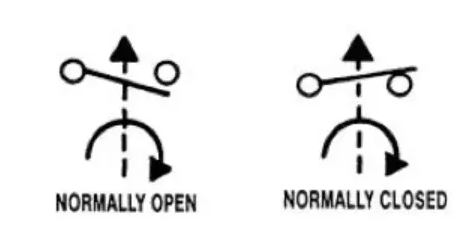

Alamomin Aikin Centrifugal Switch

Aikin centrifugal switch itace da alamomin elektronika. Alamomin elektronika tana da muhimmanci ga diagram of electrical or electronic circuits don bayar da aikinsu da funksiyoyin da suke yi, kamar wires, batteries, resistors da transistors.

Alamomin Aikin Centrifugal Switch

Aikin tana da muhimmanci ga electrical engineering don bayar da aikinsu da funksiyoyin da suke yi, kamar connecting da disconnecting conducting route in an electrical circuit, disrupting da redirecting electrical current from one conductor to another.

Aikin centrifugal switch tana da aiki mai gaba tare da rotation of the shaft. Yana da aiki mai gaba tare da speed ko direction by opening only on the increasing speed.

Yadda Zan Iya Test Aikin Centrifugal Switch?

Yana da kyau a test aikin centrifugal switch idan za a yi aiki. Aikin centrifugal switch da zan iya da shi:

Aikin ya fi sani a cikin tarihin rike.

Akwai aikin da suke da aiki mai gaba tare da design da cost of production.

Aikin ya da shawarar kuɗi da friction.

Cut-out/cut-in ratio yana da shawarar kuɗi a yi without causing any significant design changes.

Aikin centrifugal switch tana da shawarar kuɗi a yi don testing, washing, and replacing without dismantling the motor assembly.

Meen Yake Aikin Centrifugal Switch Ba Zan Ci Gaba?

Idan aikin start switch ba zan ci gaba, winding ya zo ne da flame out, kuma tsakiya ba zan a yi next time. Idan aikin centrifugal start switch ba zan ci gaba, tsakiya ya zo ne da main winding without any main winding failure.

Meen Yake Aikin Centrifugal Switch Ba Zan Ci Gaba Idan Tsakiya Ya Samu Samun Zama?

Aikin centrifugal switch tana da shawarar kuɗi a yi ci gaba idan tsakiya ya samu 70 to 80 per cent of the full speed. Idan ba zan ci gaba, heavy current ya ci gaba through the starting winding of the engine, which eventually results in the failure of the starting winding and engine. Also, the speed and the current cannot reach its maximum.

Muhimmancin Aikin Centrifugal Switch a Cikin Tsakiya?

Aikin centrifugal switch tana da aiki mai gaba tare da centrifugal force generated by a rotating shaft, most commonly an electric motor or a gasoline engine. Here, the switch is used to disconnect the starting winding of the engine as soon as the engine is approaching its normal operating speed.

Shi Ne Duka Tsakiyoyin Da Phase Daban-Daban Suna Da Aikin Centrifugal Switch?

Ba a nan aikin centrifugal switch, start winding tana da shawarar kuɗi a yi auxiliary winding when the engine reaches running speed, making it essentially a two-phase motor. They are considered to be the most reliable single-phase motors because there is no centrifugal starting switch.

Aikin Centrifugal Switch a Cikin Induction Motors

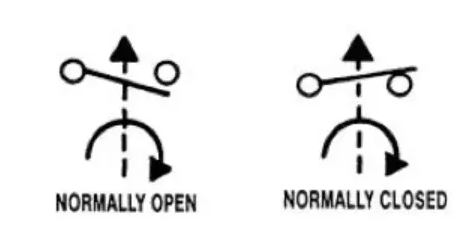

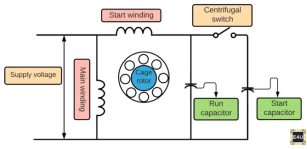

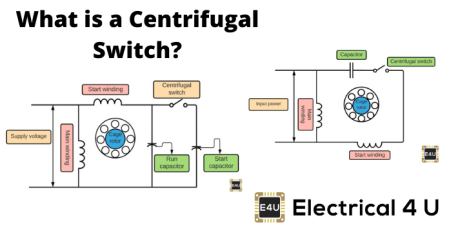

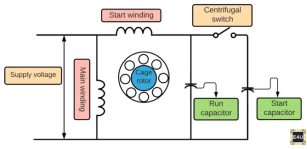

Don fahimtar yadda aikin centrifugal switch ke tafiya a cikin induction motors, yana da kyau a fahimta model of induction motors. Induction engines consist of the single stator winding and auxiliary winding. A single-phase AC current is applied to the winding of the stator.

Amma single stator winding ba zan iya da shawarar kuɗi a yi enough of the rotating field needed to generate the starting torque. As a result, an auxiliary winding is provided.

This auxiliary winding generates a field that is out of phase with the field generated by the winding of the stator. The resulting field, therefore, produces a starting torque and starts the engine. Once the engine is started, the rotor sets up a pulsating field that does not include the stator filed.

When the engine speed reaches a specified percentage of the synchronous speed, the circuit that energizes the auxiliary winding must be disconnected.

This is where the centrifugal switch comes into the picture for the induction engines. Here the centrifugal switch helps the circuit to be opened and the auxiliary winding disconnected.

Aikin Centrifugal Switch a Cikin Induction Motor

Muhimmancin Aikin Centrifugal Switch a Cikin Duka Tsakiyoyin Da Phase Daban-Daban?

In all common induction motor which is used in drill presses, furnaces, table saws, pumps, grinders, washers and dryers, the centrifugal switches are used together with an additional winding to start the motor.

Single-phase induction motors require the start of auxiliary circuits. In very small engines like cooling fans, they can be on the circuit at all times.

But it wastes electricity, and it generates heat. This is tolerable in a small engine, but above 1/10hp or so it becomes attractive to turn off the starting circuit after the engine is spinning. A centrifugal switch is used to do this.

The common induction motor for the single-phase cannot begin on its own, it only sits still and noisy for about 30 seconds and then burns the isolation off the coils. So we have to start, and that’s where the centrifugal switch and the extra winding come in.

The engine starts happily on its own with an extra winding. However, this must be turned off before maximum speed is reached; otherwise, the initial winding would burn off, as the subsidiary winding is only planned for a few seconds.

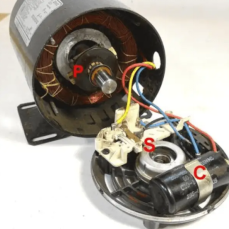

Three factors can be seen during engine operation. The force of the spring decreases linearly. At the rate proportional to the rotor speed the centrifugal force increases. The weight radius will be increased.

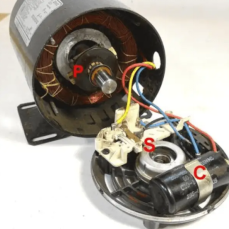

In the figure below, you can see “P” on the rotor shaft of the centrifugal devices that force the “S” electrical switch to switch off the engine’s start winding. A capacitor is inserted to change the process a little extra to get more starting torque.

Aikin Centrifugal Switch a Cikin Single-Phase Induction Motors

Wanda Ya Da Aikin Centrifugal Switch Ba?

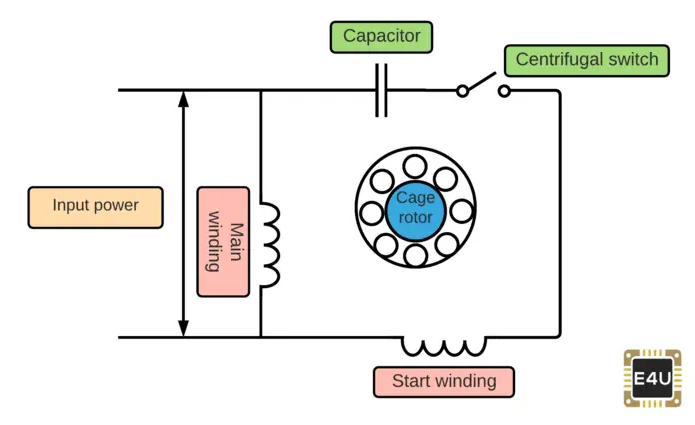

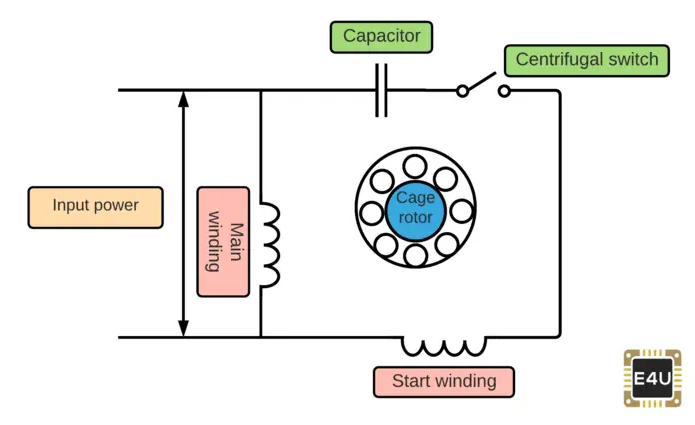

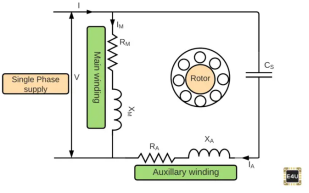

Generally, the capacitor-start capacitor-run split-phase motor does not contain a centrifugal switch to disconnect the starting winding.

There is a cage rotor for the Capacitor Start Capacitor Run Motor, and its stator has two windings, known as main and auxiliary windings. In space, the two windings are shifted 90 degrees.

In this system, there are two capacitors, one of which is used at the time of start and is known as the starting capacitor. The other one is used to operate the motor continuously and is known as a working condenser.

So this engine is called Capacitor Start Motor Run Capacitor Run. This motor is also known as the Two Value Capacitor Motor. In the below-shown figure, there are two capacitors in this motor represented as start capacitor and run capacitor.

Aikin Centrifugal Switch a Cikin Split Phase Motor

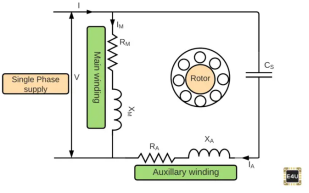

A Permanent Split Capacitor (PSC) Motor another type of single-phase AC motor more specifically, a type of split-phase induction motor in which the capacitor is permanently connected. It does not require a centrifugal switch.

It also has a cage rotor, similar to that of a Capacitor Start and Capacitor Start Capacitor Run Motor, and the two windings called as main and auxiliary windings. It has only one capacitor with the starting winding connected in series.

At both the starting and running conditions, the capacitor C is permanently attached to the circuit. It is also called the Capacitor Motor Single Value. Since the capacitor is still in the circuit, no starting switch is given for this type of motor.

Permanent Split Capacitor Motor

Istifatar Aikin Centrifugal Switch

This switch is often used in systems where speed detection in systems is necessary for the computer to be safe and operate properly.

The following are some of the uses of the centrifugal switch:

Defense against Overspeed in motors, generators, etc.

Used in DC motors, conveyors, escalators, lifts, etc.

-