Unsa ang Centrifugal Switch?

Ang centrifugal switch usa ka electrical switch nga gibigay kini sa centrifugal force nga gipasabot sa usa ka rotating shaft. Kini nga centrifugal force kasagaran gigikanan sa gasoline engine o electric motor. Ang mga centrifugal switch gihimo aron mopasabot o mobati sa rotational speed sa shaft.

Kung asa ang Mga Centrifugal Switch magtrabaho?

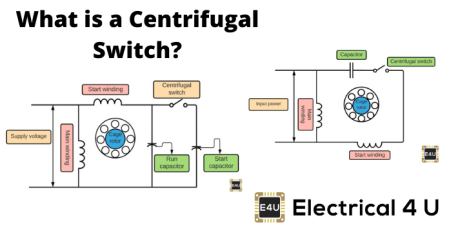

Ang centrifugal switch usa ka electrical switch nga kasagaran makita sa signal phase induction motors ug split-phase induction motors.

Kini nga switch gamiton aron mopasabot og controlled switching operation nga required sa engine bisan ang specified engine speed mahitabo.

Ang centrifugal switch based sa concept sa centrifugal force. Kini ra usa ka electric switch. Ang mga switch niini specially designed para sa induction motors sa single ug split phases.

Tungod kay ang iyang operasyon sama sa centrifugal clutch nga gisagol sa mga sasakyan, ang centrifugal switch kasagaran gitawag og ‘clutch’.

Ang single-phase AC engine adunay centrifugal switch sulod sa iyang case, nga gisulok sa engine shaft. Bisang ang engine wala nagtrabaho ug motionless, ang switch naka-close.

Bisan ang engine naka-on, ang switch nagdrive sa electricity sa capacitor ug extra coil winding sa engine, pag-increase sa iyang starting torque. Tungod kay ang revolutions sa engine increase per minute, ang switch naka-open, tungod kay ang engine wala na nagkinahanglan og boost.

Ang centrifugal switch matabangan sa problema nga associated sa single-phase AC electric motors. Wala sila mogenerate og enough torque on their own aron mohatag og starting torque.

Ang circuit naka-on sa centrifugal switch, providing the requisite boost to start the motor. The switch turns off the boost circuit until the motor reaches its running speed, and the motor runs normally.

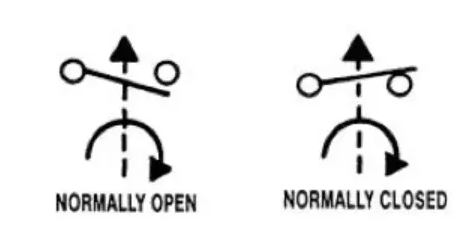

Centrifugal Switch Symbol

Ang centrifugal switch usa ka tipo sa switch ug mahimong ma-represent niini pinaagi sa electronic symbol. Ang electronic symbol usa ka pictogram nga gisagol sa schematic diagram sa electrical or electronic circuit aron represent various electrical and electronic devices or functions, such as wires, batteries, resistors and transistors.

Centrifugal Switch Symbol

Ang switch usa ka electrical feature sa electrical engineering nga mahimo mopasabot o mobati sa conducting route sa electrical circuit, disrupt or redirect the electrical current from one conductor to another.

Ang centrifugal switch usa ka switch nga gisagol pinaagi sa shaft rotation. Responsive kini sa speed or direction pinaagi sa opening only on the increasing speed.

Paano I-test ang Centrifugal Switch?

Mas maayo nga itest ang centrifugal switch bago isagol sa aplikasyon. Ang sumusunod nga criteria dili bayi ang ideal centrifugal switch:

Sa iyang buong life cycle, ang proseso dapat uniform.

Para sa simplicity of design ug low production cost, ang number of components sa equipment dapat minimal.

Dapat adunay marginal elements of friction.

Without causing any significant design changes, ang cut-out/cut-in ratio dapat readily modifiable.

Accessible ang switch tungod kay ang communication unit sa switch present sa outside of the motor frame. So, without dismantling the motor assembly, ang switch mahimo itest, wash, ug replace.

Unsa ang mahitabo kung ang centrifugal switch wala open?

Kon ang start switch wala open bisan ang gi-need, ang start winding mag-overheat ug flame out, ug ang engine wala na mogana next time. Kon ang centrifugal start switch wala closed, ang engine mag-overheat sa main winding without any main winding failure.

Unsa ang effect kon ang centrifugal switch wala disconnected after the motor starts?

Ang centrifugal switch dapat disconnected sa about 70 to 80 per cent of the full speed of the engine. Kon wala siya disconnected, ang heavy current magpadayon sa flow through the starting winding of the engine, which eventually results in the failure of the starting winding and engine. Also, ang speed ug ang current wala makaabot sa maximum.

Unsa ang purpose sa centrifugal switch sa end of an open motor?

Ang centrifugal switch usa ka electrical switch nga operate using the centrifugal force generated by a rotating shaft, most commonly an electric motor or a gasoline engine. Here, ang switch gisagol aron mopasabot sa starting winding of the engine as soon as the engine is approaching its normal operating speed.

Adunay centrifugal switch ang tanang single phase motors?

Wala centrifugal switch so that the start winding becomes an auxiliary winding when the engine reaches running speed, making it essentially a two-phase motor. Gi-consider sila nga ang most reliable single-phase motors tungod kay wala centrifugal starting switch.

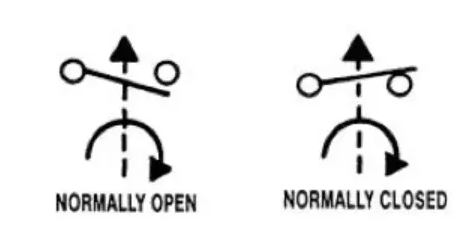

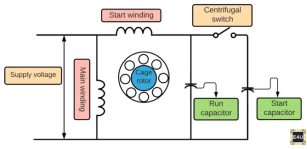

Centrifugal Switch in Induction Motors

Arong matud-an kung unsa ang switch works in induction motors, unta first understand the model of induction motors. Ang induction engines consist of the single stator winding ug auxiliary winding. A single-phase AC current is applied to the winding of the stator.

But the single stator winding cannot produce enough of the rotating field needed to generate the starting torque. As a result, an auxiliary winding is provided.

This auxiliary winding generates a field that is out of phase with the field generated by the winding of the stator. The resulting field, therefore, produces a starting torque and starts the engine. Once the engine is started, the rotor sets up a pulsating field that does not include the stator filed.

When the engine speed reaches a specified percentage of the synchronous speed, the circuit that energizes the auxiliary winding must be disconnected.

This is where the centrifugal switch comes into the picture for the induction engines. Here the centrifugal switch helps the circuit to be opened and the auxiliary winding disconnected.

Centrifugal Switch in Induction Motor

Why is the Centrifugal Switch Used in Most Single-Phase Induction Motors?

In all common induction motor which is used in drill presses, furnaces, table saws, pumps, grinders, washers and dryers, the centrifugal switches are used together with an additional winding to start the motor.

Single-phase induction motors require the start of auxiliary circuits. In very small engines like cooling fans, they can be on the circuit at all times.

But it wastes electricity, and it generates heat. This is tolerable in a small engine, but above 1/10hp or so it becomes attractive to turn off the starting circuit after the engine is spinning. A centrifugal switch is used to do this.

The common induction motor for the single-phase cannot begin on its own, it only sits still and noisy for about 30 seconds and then burns the isolation off the coils. So we have to start, and that’s where the centrifugal switch and the extra winding come in.

The engine starts happily on its own with an extra winding. However, this must be turned off before maximum speed is reached; otherwise, the initial winding would burn off, as the subsidiary winding is only planned for a few seconds.

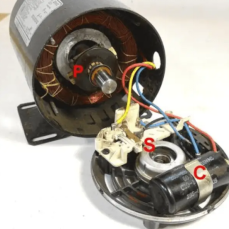

Three factors can be seen during engine operation. The force of the spring decreases linearly. At the rate proportional to the rotor speed the centrifugal force increases. The weight radius will be increased.

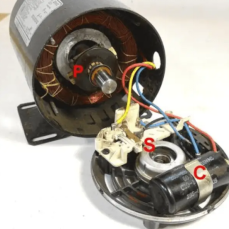

In the figure below, you can see “P” on the rotor shaft of the centrifugal devices that force the “S” electrical switch to switch off the engine’s start winding. A capacitor is inserted to change the process a little extra to get more starting torque.

Centrifugal Switch in Single-Phase Induction Motors

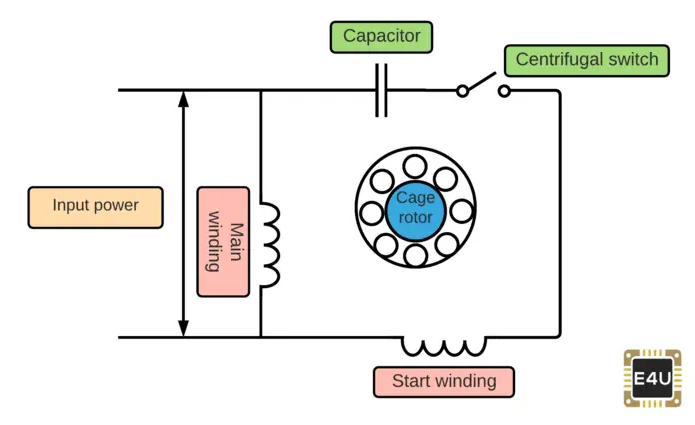

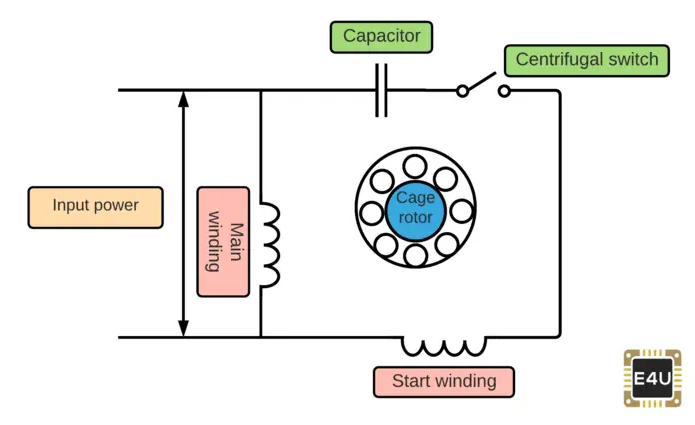

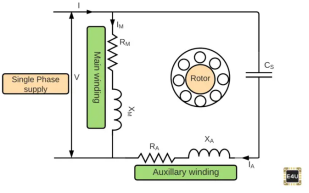

What Type of Split Phase Motor Does Not Generally Contain a Centrifugal Switch?

Generally, the capacitor-start capacitor-run split-phase motor does not contain a centrifugal switch to disconnect the starting winding.

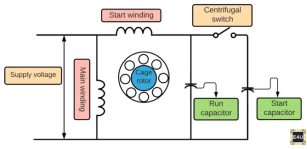

There is a cage rotor for the Capacitor Start Capacitor Run Motor, and its stator has two windings, known as main and auxiliary windings. In space, the two windings are shifted 90 degrees.

In this system, there are two capacitors, one of which is used at the time of start and is known as the starting capacitor. The other one is used to operate the motor continuously and is known as a working condenser.

So this engine is called Capacitor Start Motor Run Capacitor Run. This motor is also known as the Two Value Capacitor Motor. In the below-shown figure, there are two capacitors in this motor represented as start capacitor and run capacitor.

Centrifugal Switch in Split Phase Motor

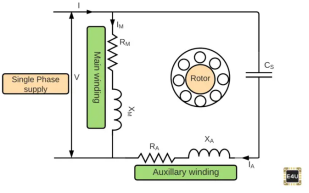

A Permanent Split Capacitor (PSC) Motor another type of single-phase AC motor more specifically, a type of split-phase induction motor in which the capacitor is permanently connected. It does not require a centrifugal switch.

It also has a cage rotor, similar to that of a Capacitor Start and Capacitor Start Capacitor Run Motor, and the two windings called as main and auxiliary windings. It has only one capacitor with the starting winding connected in series.

At both the starting and running conditions, the capacitor C is permanently attached to the circuit. It is also called the Capacitor Motor Single Value. Since the capacitor is still in the circuit, no starting switch is given for this type of motor.

Permanent Split Capacitor Motor

Applications of a Centrifugal Switch

This switch is often used in systems where speed detection in systems is necessary for the computer to be safe and operate properly.

The following are some of the uses of the centrifugal switch:

Defense against Overspeed in motors, generators, etc.

Used in DC motors, conveyors, escalators, lifts, etc.

These are also used in devices such as blowers, fans as well as conveyors to detect under-speed.

Material losses are often used in systems where the loss of speed could lead to damage of the device.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.