Mukadimci

Vacuum circuit breaker na 10kV ya yi amfani da yadda ake amfani da vacuum a matsayin mai kawo karfi da kuma mai hana tashin jiki a kan mazauna. Wannan ya ba shi damar amfani da shi a cikin substation da kuma network ta distribution. Amma, suna da wata take da ci gaba a kan sarautar da suka faruwa a cikin amfani da shi. Wannan makaranta ya kirkiro da kuma yin bayanin sarautun da suka faruwa a cikin amfani da shi, tafi masu yin maganganin lissafin sarauta, kuma ta bayyana masu yin ingantaccen lissafin sarauta.

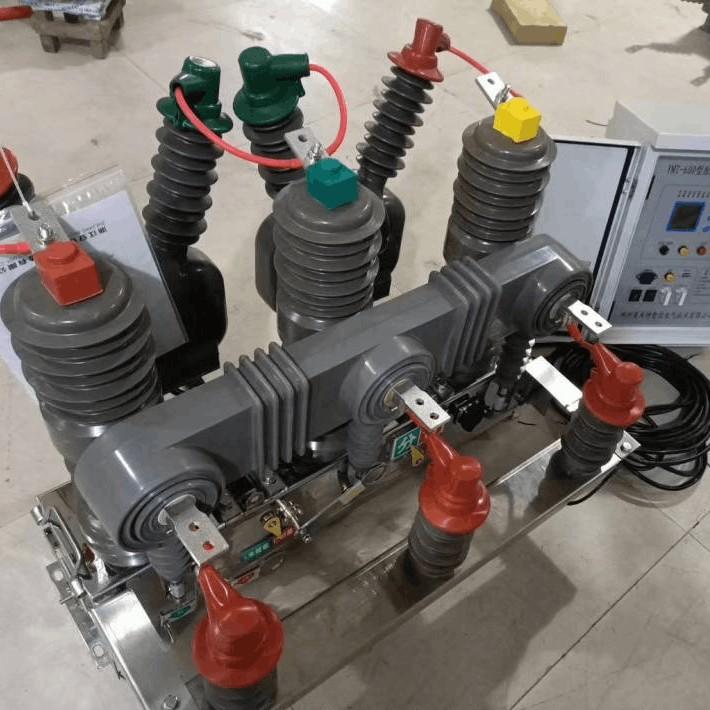

Tsunufin Sarauta da Kuma Maganganin Lissafin Vacuum Circuit Breaker Da Yake

Tsunufin da ke tsakiya a kan vacuum interrupter na 10kV vacuum circuit breaker shine sarautar da ke faruwa a kan shi. Vacuum circuit breaker ya hana tashin jiki a cikin vacuum interrupter. Duk da haka, babu wurare da kuma kayan aiki da za a iya amfani da su don in bincike da kuma in yanayi vacuum-degree characteristics na kwayoyi.

Saboda haka, sarautar da ke nuna tsunufin vacuum-degree yana da abubuwan da suka da dace, kuma ita ce da ba a zama da muhimmanci a cikin binciken da kuma testin amfani. Farkon da ya ba shi da sauraron sarauta masu fahimta ga shi. Idan vacuum degree ya zama lafiya da kuma circuit breaker ya ba da kyau a hana tashin jiki, zai iya haifar da abubuwan da suka da dace kamar burning ko explosion na breaking point.

Dalilai da Tsunufin Vacuum Degree Na Vacuum Interrupter

Akwai matsalolin da ke nuna material da ke amfani a kan vacuum interrupter, wanda ke ba shi da gas leak, ko kuma takamatsayin production ba ta da sahihi, saboda haka akwai leakage points a kan vacuum interrupter, wanda ke iya haifar da vacuum degree.

Ba aiki da lokacin da circuit breaker ya yi aiki da rike, vibration da ya faruwa ita ce da zai iya haifar da sealing part na vacuum interrupter, kuma zai iya rage vacuum degree na vacuum interrupter. Hasisa game da vacuum circuit breakers da CD10 mechanisms, lokacin da circuit breaker ya yi opening and closing operations na current, zai iya faruwar da impact na sealing connection part na vacuum interrupter, saboda haka zai rage vacuum degree.

Akwiya bellows a kan vacuum interrupter ko kuma takamatsayin production ba ta da sahihi, da kuma leakage points zai faruwa ba aiki da rike.

Akwai damage da ke faruwa a kan vacuum interrupter a lokacin da ake yi routine maintenance work.

Maganganin Lissafin Tsunufin Vacuum Degree Na Vacuum Interrupter

Yana da kyau a yi preventive tests, da kuma a bincika vacuum degree na vacuum interrupter da rike. A lokacin da ake yi inspection da kuma maintenance na equipment, yana da kyau a yi AC withstand voltage tests (between breaking points) da rike. Idan an yi shiga, ake iya amfani da vacuum tester don in yi qualitative test na vacuum degree na vacuum interrupter, domin in tabbatar da vacuum degree na vacuum interrupter ya kasance da level da ya ba shi da kyau don in samar da operational requirements na circuit breaker.

Idan ake zabi da kuma a yi installation na vacuum circuit breaker, yana da kyau a zabi mature products na manufacturers da ma'adani da quality, da kuma supporting mechanism da ke da impact na yanki a kan circuit breaker. Lokacin da ake yi patrol na equipment, maintenance personnel ya kamata a yi bincika cewa metal shield na vacuum interrupter ba a yi change color ko kuma make abnormal sounds a lokacin da ake yi operation.

Game da vacuum circuit breakers da ke da pollution na yanki, yana da kyau a yi cleaning da kuma maintenance na equipment da rike, domin in rage dust ko kuma contaminants da ke iya haifar da insulation performance na circuit breaker. Idan ake tabbatar da vacuum interrupter na da defects, vacuum interrupter ya kamata a zama da rike.

Tsunufin Sarauta da Kuma Maganganin Lissafin Control Circuit

Fuses na signal circuit blowing da kuma opening and closing coils burning out suna cikin sarautun da ke faruwa a kan operating circuit. Symptom shine cewa circuit breaker ba zan iya yi amfani a cikin opening ko closing state, da kuma indicator light ba zan faɗa. A wannan lokaci, microcomputer ya kamata a yi signal na "control circuit open-circuit". Wannan defects suna da kyau a bincike da kuma a yi lissafi. Ana iya yi bincikan da opening and closing coils da kuma resistance deviation, da kuma replacement of the problematic coil zai iya lissafin fault na operating circuit.

Auxiliary contacts na energy-storage travel switch (CK) ba su da connections, domin travel switch ba a yi adjustment da rike ko kuma an yi damage, saboda haka mechanism ba zan iya samar da energy storage da rike. A wannan lokaci, energy-storage lamp (usually yellow) ba zan faɗa. Fault ya kamata a lissafin da kuma replacement of the travel switch don in tabbatar da mechanism ya samar da energy storage da rike.

Ensuring the quality of the travel switch and improving its installation reliability are among the main ways to reduce the occurrence of circuit faults. In practical operation experience, the defects of the energy-storage travel switch of the CT19 mechanism are relatively obvious. During the closing process of a 10kV circuit breaker, the air switch of the control power supply tripped, ultimately leading to a control circuit open-circuit.

At this time, the line's tripping protection action occurred, and the faulty line experienced override trip, expanding the power-outage range and causing serious impacts. Inspection revealed that when the travel switch fails to operate, the current loop cannot be effectively turned off, making it easy for the travel switch to arc when it acts, resulting in a large loop current that causes tripping. By replacing it with equipment of other models, this type of circuit fault can be effectively avoided.

The auxiliary switch (contacts) of the circuit breaker is damaged or not adjusted in place, causing the circuit to be unconnected or have poor contact. This generally manifests as a control circuit open-circuit, and the opening and closing indicator lights do not light up or flicker. When this situation occurs, it is necessary to readjust the length of the rotating pull rod of the auxiliary switch or replace the damaged auxiliary switch.

The fault caused by electrical interlocking that prevents the circuit breaker from opening or closing is manifested as follows: the mechanical components of the mechanism work normally, but it cannot be electrically opened or closed, and the positive and negative power supplies cannot be simultaneously supplied to the opening and closing coils.

This kind of defect generally occurs in equipment with electrical interlocking, such as circuit breakers of capacitor banks, circuit breakers with ground knife interlocking, etc. It is necessary to check whether the mesh doors of the capacitor, the travel (auxiliary) switches of the maintenance ground knife are correctly switched or damaged, and whether the contacts are in good contact, and then carry out corresponding handling.

Additionally, in draw-out switch cabinets, the burning out of components such as energy-storage motors, Y3 relays, and rectifier bridges often occurs, which in turn leads to faults of the control circuit being open-circuited.

There are numerous issues in the control of the operating circuit. Loose terminal connections, poor contacts, and insulation problems of equipment can all cause defects, preventing the circuit breaker from operating properly for opening and closing. When an operating circuit fault occurs, the fault should first be located to identify its source, and then appropriate solutions should be implemented based on the specific situation.

Fault Phenomena and Treatment Methods of Mechanical Failures in Auxiliary and Actuating Mechanisms

When the circuit breaker cannot be opened or closed either electrically or manually, mechanically, the first step is to check whether the mechanism is properly energized. If the energy storage is normal, the problem may be caused by the loosening of the stop piece on the opening and closing half-shaft, insufficient stroke of the opening and closing push rod, or deformation of the opening and closing push rod, which results in jamming or sticking during the opening and closing process, preventing the circuit breaker from operating normally.

The fault can be addressed by readjusting the stroke of the push rod of the opening and closing coil, fixing the stop piece of the opening and closing half-shaft, and replacing or repairing the defective push rod (changing the copper opening and closing push rod to a steel one to avoid deformation). When the energy storage is abnormal or there are problems in the secondary circuit, the energy-storage motor, travel switch, and control circuit should be inspected for troubleshooting.

The actuating mechanism cannot be energized either electrically or manually. The main reasons are the damage of the one-way bearing in the energy-storage mechanism or the failure of the energy-storage latch to reset (the reset spring is not strong enough or foreign objects jam the reset spring), causing the energy-storage gear to idle. Such faults are prone to occur in CT19-type mechanisms. The problem can be resolved by replacing the one-way bearing in the energy-storage mechanism or replacing (cleaning) the reset spring to restore normal energy storage.

If the opening and closing indication in the actuating mechanism does not match the actual opening and closing position of the circuit breaker body, it may be due to the disconnection of the connecting rod between the mechanism and the main transmission shaft of the circuit breaker. Manually adjust to align the position of the mechanism with that of the circuit breaker, and then reconnect and fix the transmission pull rod.

During the characteristic test, it is found that the low-voltage operation of the circuit breaker is unqualified. When the rated operating voltage is above 65%, the circuit breaker cannot perform reliable opening (it cannot open when the voltage is below 30%, and it may or may not open when the voltage is between 30% and 65%), and it should be able to close reliably at 85% - 110% of the rated voltage.

When this situation occurs, first check whether the resistance of the coil is within the qualified range. If it is qualified, clean the mechanism, add lubricant to the rotating parts, and then check the engaging depth of the opening and closing half-shaft. If it does not meet the requirements, adjust the adjusting screw for the engaging (inserting) depth of the opening and closing half-shaft (as shown in Figure 1) to meet the requirements (the engaging depth of the CT19-type mechanism is generally 1 - 2mm).

In addition, an increase in the resistance of the closing coil leading to a decrease in the opening and closing coils, as well as deformation of the opening and closing push rods causing jamming or sticking during opening and closing, will all affect the opening and closing voltage. When dealing with problems, specific handling should be carried out according to the fault situation.

In the draw-out switch equipment, the draw-out switch cannot be moved from the test position to the operating position. The possible causes of such a fault include ground knife interlock failure, deformation of the ground knife interlock linkage plate, failure of the ground knife operation hole linkage plate to reset, and faults in the draw-out switch chassis. The draw-out switch can be moved to the maintenance position.

Check whether the tongue-shaped interlock plate of the ground knife is deformed or whether this tongue-shaped plate corresponds to the position of the ground knife; check whether the operation hole linkage plate is fully reset; remove the chassis of the draw-out switch and check whether all internal components are in good condition.

Routine Maintenance Measures for Circuit Breakers

When dealing with faults in the circuit breaker mechanism, first analyze the type of fault to determine whether it belongs to an electrical or secondary circuit problem or a mechanical fault, and then proceed with the next-step handling. The method for judging faults is relatively simple. First, make the mechanism fully energized.

If the circuit breaker can be reliably opened and closed manually, mechanical faults can be basically excluded. Then, perform electrical opening and closing. If the opening and closing electromagnets operate but the switch fails to open and close, and the secondary control voltage is normal, it indicates that there are no problems with the secondary circuit.

For more concealed faults such as reduced vacuum degree, out-of-synchronism in opening and closing, insufficient opening and closing speed, and large bounce, relevant scientific instruments must be used for testing and measurement during maintenance. Problems should be solved through the analysis and judgment of actual measurement data.

In addition to fault repair, certain maintenance work should also be carried out on vacuum circuit breakers in daily work. This includes cleaning the transmission mechanism and insulating support columns to avoid increasing rotational friction, and appropriately adding lubricant to ensure flexible operation. When the vacuum circuit breaker is under outage for maintenance, loop resistance and mechanical characteristic tests should be conducted, and damaged components caused by overheating, etc. of the circuit breaker should be dealt with in a timely manner.

The fault repair and maintenance work of 10kV circuit breakers has similarities with that of circuit breakers or transformers of other voltage levels in terms of mechanical and secondary circuit fault repair principles. By continuously accumulating experience, technical means can be continuously improved to achieve a better fault elimination rate and maintenance level.

Kalmomi

Daga bakin tattalin al'ummar, talabinta masu kafofin kasa a duk tushen mutane ya zama da rike, kuma talauci masu kafofin kasa da kuma operational stability na system ta kafofin kasa. Technical levels da kuma ability to handle defects suna da kyau a zama da rike, domin in tabbatar da talabinta development, satisfy the requirements of the majority of users, shorten the time for equipment defect handling and maintenance, and ensure the safe operation of the power grid.

Saboda haka, a lokacin da ake yi maintenance da kuma renovation na equipment, yana da kyau a yi study na characteristics na system equipment itself, comprehensive understanding of the operational characteristics of equipment and the existing problems and potential hazards, strengthening learning and communication, taking preventive measures in a timely manner, continuously improving equipment, eliminating safety hazards, preventing accidents, and ensuring the safe operation of equipment and the reliability of power supply.