Muhtasari

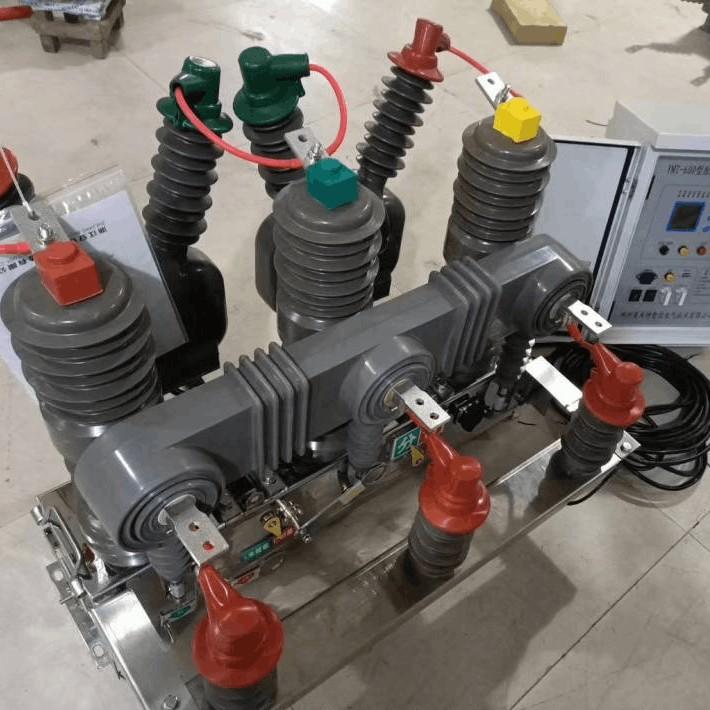

Kitaa cha kifuko cha 10kV kinatumia tabia ya kutumia ukiwa kama chombo cha kutengeneza insulation na kutukua arc kati ya contacts, ambayo hii inafanya iwe yenye upatikanaji mkubwa katika substations na distribution networks. Hata hivyo, idadi ya matatizo yanayofanyika wakati wa utumi wake ni imeongezeka. Maandiko haya yanaelezea na kusambaza matatizo yasiyofanikiwa yanayotokea katika mchakato wake, kujadili tofauti za njia za kutibu matatizo, na kuwasilisha hatua za huduma ya kawaida.

Matatizo na Njia za Kutibu Matatizo ya Kitaa Chake Mwenyewe

Urefu wa ukimya uliyoko chini katika interrupter wa ukimya ni matatizo yanayotokana mara zaidi katika kitaa cha 10kV. Kitaa cha ukimya hutukua current na arcs ndani ya interrupter wa ukimya. Mara nyingi, kitaa cha ukimya hakina vifaa au programu za kutathmini sifatisho na hesabu refu wa ukimya.

Kwa hiyo, matatizo ya refu wa ukimya uliyoko chini mara nyingi yanaonekana vigumu kupata, na ni vigumu kupata wakati wa huduma na majaribio ya utendaji. Uwezo wake wa kuchanganya ni mkubwa zaidi kuliko matatizo mengine yoyote yenye ubora. Wakati refu wa ukimya unapoganda hadi kitaa hakawezi kutukua arcs kwa kutosha, inaweza hata kuleta matukio magumu kama burning au explosion ya breaking point.

Sababu za Refu wa Ukimya Uliyoko Chini Katika Interrupter wa Ukimya

Kuna matatizo ya chombo cha interrupter wa ukimya, kufanya interrupter wa ukimya kukosa ukimya, au mchakato wa kutengeneza ukawa usio mzuri, kusababisha kuna maeneo yenye leakage katika interrupter wa ukimya mwenyewe, kwa hivyo kuathiri refu wake wa ukimya.

Baada ya muda mrefu wa kutumika, wakati kitaa kifanya kitendo fulani, gongo linalotokana linaweza pia kufanya sehemu ya sealing ya interrupter wa ukimya kuwa chache, kwa hivyo kunyongeza refu wa ukimya wa interrupter wa ukimya. Vipimo vya kitaa cha ukimya vilivyotengenezwa na CD10, wakati kitaa kifanya opening na closing operations, inaweza kuunda impact mkubwa kwenye sehemu ya sealing connection ya interrupter wa ukimya, kusababisha sealing isiyofaa na kupunguza refu wa ukimya.

Kuna matatizo ya chombo au kutengeneza bellows katika interrupter wa ukimya, na maeneo yenye leakage yanavyoonekana baada ya mikakati mengi.

Interrupter wa ukimya unaweza kupotelewa kwa hasira wakati wa huduma ya kawaida.

Njia za Kutibu Refu wa Ukimya Uliyoko Chini Katika Interrupter wa Ukimya

Tafiti za kuzuia zinapaswa kufanyika, na refu wa ukimya wa interrupter wa ukimya lazima liwekezwe kwa miaka. Wakati wa tafuta na huduma ya vyombo, mitihani ya AC withstand voltage (kati ya breaking points) yanapaswa kutekelezwa mara kwa mara. Wakiwa na namba, vacuum tester unaweza kutumika kufanya mtihani wa sifa kwa refu wa ukimya wa interrupter wa ukimya ili kuhakikisha refu wa ukimya wa interrupter wa ukimya unaendelea kuwa kwenye kiwango fulani ili kufanikiwa kwa utendaji wa kitaa.

Wakati wa kuchagua na kutengeneza kitaa cha ukimya, ni muhimu kuchagua bidhaa za watengenezaji wenye shahidi na ubora, na mekanizmi wake wa kusaidia unapaswa kuwa una impact mdogo kwa kitaa. Wakiwa wanajitazama vyombo, watalii wa huduma wanapaswa kuangalia kama shieldi ya metali ya interrupter wa ukimya imebadilika rangi au kufanya sauti asilia wakati wa utendaji.

Kwa vyombo vilivyopo vilivyopewa uvunja mkubwa, lazima tuhakikishe kutoa huduma na safisha vyombo kwa haraka ili kuepusha dust au contaminants mingine kutokusumbuliwa kwa insulation performance ya kitaa. Ikiwa itakuwa imetathmini kwamba interrupter wa ukimya una maeneo yasiyofaa, lazima interrupter wa ukimya uwekezwe kwa haraka.

Matatizo na Njia za Kutibu Matatizo ya Circuit ya Control

Fuses katika signal circuit kuganda na opening na closing coils kuganda ni katika matatizo yanayotokea kwa kawaida katika operating circuit. Dalili ni kitaa hakawezi kutumika electrically wakati ina state ya opening au closing, na indicator light haingefanya chochote. Wakiwa hivi, microcomputer anaweza kutuma taarifa ya "control circuit open-circuit". Matatizo haya yanaonekana rahisi kupata na kutibu. Mtu anaweza kutafuta kwa moja kama opening na closing coils yameganda na ukubwa wa resistance deviation. Kurekebisha coil yenye tatizo inaweza kuelekea kuvunjika fault katika operating circuit.

Contacts za auxiliary za energy-storage travel switch (CK) hayajaunganishwa, kwa sababu ya travel switch haijawekwa vizuri au imeharibika, kusababisha mechanism siwezi kupata energy kamili. Hivi, energy-storage lamp (marani yellow) haingefanya chochote. Fault inaweza kutatuliwa kwa kurekebisha position ya travel switch au kubadilisha travel switch ili kuhakikisha mechanism inapata energy kamili.

Kuhakikisha ubora wa travel switch na kuboresha installation reliability ni katika njia muhimu za kupunguza kutokuka matatizo ya circuit. Tafiti za utendaji, defects za energy-storage travel switch ya CT19 mechanism ni zinazowakilishwa. Wakati wa closing process ya 10kV circuit breaker, air switch ya control power supply iliganda, kwa mwisho kuleta control circuit open-circuit.

Wakiwa hivi, tripping protection action ilifanyika, na faulty line ilikuwa na override trip,kuboresha mazingira ya umeme-kupunguza na kutokana na athari kubwa. Tafiti zinazoweza kutathmini kwamba wakati travel switch haijafanya chochote, current loop haiwezi kufungwa kwa kutosha, kusababisha easy kwa travel switch kufanya arc wakati anafanya chochote, kusababisha loop current mkubwa kusababisha tripping. Kwa kubadilisha na vifaa vingine vya modeli, matatizo haya ya circuit yanaweza kutokuka kwa kutosha.

Switch (contacts) za auxiliary za circuit breaker yameharibika au haijawekwa vizuri, kusababisha circuit haujanaganishwi au contact si mzuri. Hii mara nyingi inaonekana kama control circuit open-circuit, na opening na closing indicator lights haingefanya chochote au flicker. Wakiwa hivi, ni lazima kurekebisha length ya rotating pull rod ya auxiliary switch au kubadilisha switch yenye tatizo.

Fault inayotokana na electrical interlocking ambayo inawezesha kitaa kutoka au kutoka, inaonekana kama ifuatavyo: components ya mechanical ya mechanism yanafanya kazi vizuri, lakini haiwezi kutoka au kutoka electrically, na positive na negative power supplies hazitoshi kuwasilishwa kwa opening na closing coils.

Hii kindi ya defect mara nyingi inatokea katika vyombo vilivyotengenezwa na electrical interlocking, kama vile circuit breakers of capacitor banks, circuit breakers with ground knife interlocking, na kadhalika. Ni lazima kutathmini kama mesh doors ya capacitor, travel (auxiliary) switches ya maintenance ground knife zimebadilishwa vizuri au zimeharibika, na kama contacts zinafanya kazi vizuri, basi kutatuliwa kulingana na hali.

Zaidi, draw-out switch cabinets, burning out ya components kama vile energy-storage motors, Y3 relays, na rectifier bridges mara nyingi inatokea, kusababisha faults za control circuit open-circuited.

Kuna matatizo mengi katika control ya operating circuit. Terminal connections zenye upungufu, contact zenye upungufu, na insulation problems za vyombo zote zinaweza kusababisha defects, kusababisha kitaa kutokuwa inaweza kutumika vizuri kwa opening na closing. Wakiwa operating circuit fault inatokea, lazima tupelekee kwanza kuthibitisha jinsi itakayotokana, basi kutatuliwa kwa njia zinazofaa kulingana na hali.

Matatizo na Njia za Kutibu Matatizo ya Mechanical Failures katika Auxiliary na Actuating Mechanisms

Wakati kitaa hakawezi kutoka au kutoka electrically au manually, mechanically, hatua ya kwanza ni kutathmini kama mechanism imepatikana kwa energy. Ikiwa energy storage inafaa, tatizo linaweza kutokana na stop piece katika opening na closing half-shaft inachacheka, stroke insufficient ya opening na closing push rod, au deformation ya opening na closing push rod, ambayo inasababisha jamming au sticking wakati wa opening na closing process, kusababisha kitaa kutokuwa inaweza kutumika vizuri.

Fault inaweza kutatuliwa kwa kurekebisha stroke ya push rod ya opening na closing coil, fixing stop piece ya opening na closing half-shaft, na replacing au repairing defective push rod (changing copper opening na closing push rod kwa steel one kutokana na deformation). Ikiwa energy storage ina tatizo au kuna tatizo katika secondary circuit, energy-storage motor, travel switch, na control circuit lazima zitathmini kwa ajili ya troubleshooting.

Actuating mechanism haiwezi patikana electrically au manually. Sababu muhimu ni damage ya one-way bearing katika energy-storage mechanism au failure ya energy-storage latch kurekebisha (reset spring si ngumu kwa kutosha au foreign objects zimejamiana reset spring), kusababisha energy-storage gear kukosa kufanya chochote. Matatizo haya yanaweza kutokana mara nyingi katika CT19-type mechanisms. Tatizo linaweza kutatuliwa kwa kubadilisha one-way bearing katika energy-storage mechanism au kubadilisha (cleaning) reset spring ili kurudi kwa normal energy storage.

Ikiwa opening na closing indication katika actuating mechanism haijafanana na actual opening na closing position ya kitaa body, inaweza kutokana na disconnection ya connecting rod kati ya mechanism na main transmission shaft ya kitaa. Kurekebisha manual kwa kulingana na position ya mechanism na ya kitaa, basi reconnect na fix transmission pull rod.

Katika characteristic test, inapatikana low-voltage operation ya kitaa inafanya kazi isiyofaa. Wakati rated operating voltage ni juu ya 65%, kitaa haiwezi kutenda opening reliable (haitawezi kutoka wakati voltage ni chini ya 30%, na inaweza au hautawezi kutoka wakati voltage inaingia kati ya 30% na 65%), na inapaswa kufanya closing reliable kati ya 85% - 110% ya rated voltage.

Wakiwa hivi, kwanza tathmini kama resistance ya coil inafaa kwenye range qualified. Ikiwa inafaa, safisha mechanism, ongeza lubricant kwenye rotating parts, basi tathmini engaging depth ya opening na closing half-shaft. Ikiwa haijafanana na mahitaji, rekebisha adjusting screw kwa engaging (inserting) depth ya opening na closing half-shaft (kama inavyoonekana Figure 1) ili kufanikiwa kwa mahitaji (engaging depth ya CT19-type mechanism ni mara nyingi 1 - 2mm).

Zaidi, increase in the resistance of the closing coil leading to a decrease in the opening and closing coils, as well as deformation of the opening and closing push rods causing jamming or sticking during opening and closing, will all affect the opening and closing voltage. When dealing with problems, specific handling should be carried out according to the fault situation.

In the draw-out switch equipment, the draw-out switch cannot be moved from the test position to the operating position. The possible causes of such a fault include ground knife interlock failure, deformation of the ground knife interlock linkage plate, failure of the ground knife operation hole linkage plate to reset, and faults in the draw-out switch chassis. The draw-out switch can be moved to the maintenance position.

Check whether the tongue-shaped interlock plate of the ground knife is deformed or whether this tongue-shaped plate corresponds to the position of the ground knife; check whether the operation hole linkage plate is fully reset; remove the chassis of the draw-out switch and check whether all internal components are in good condition.

Routine Maintenance Measures for Circuit Breakers

When dealing with faults in the circuit breaker mechanism, first analyze the type of fault to determine whether it belongs to an electrical or secondary circuit problem or a mechanical fault, and then proceed with the next-step handling. The method for judging faults is relatively simple. First, make the mechanism fully energized.

If the circuit breaker can be reliably opened and closed manually, mechanical faults can be basically excluded. Then, perform electrical opening and closing. If the opening and closing electromagnets operate but the switch fails to open and close, and the secondary control voltage is normal, it indicates that there are no problems with the secondary circuit.

For more concealed faults such as reduced vacuum degree, out-of-synchronism in opening and closing, insufficient opening and closing speed, and large bounce, relevant scientific instruments must be used for testing and measurement during maintenance. Problems should be solved through the analysis and judgment of actual measurement data.

In addition to fault repair, certain maintenance work should also be carried out on vacuum circuit breakers in daily work. This includes cleaning the transmission mechanism and insulating support columns to avoid increasing rotational friction, and appropriately adding lubricant to ensure flexible operation. When the vacuum circuit breaker is under outage for maintenance, loop resistance and mechanical characteristic tests should be conducted, and damaged components caused by overheating, etc. of the circuit breaker should be dealt with in a timely manner.

The fault repair and maintenance work of 10kV circuit breakers has similarities with that of circuit breakers or transformers of other voltage levels in terms of mechanical and secondary circuit fault repair principles. By continuously accumulating experience, technical means can be continuously improved to achieve a better fault elimination rate and maintenance level.

Conclusion

With the rapid development of society, the demand for power supply in all walks of life is constantly increasing, and higher requirements are also put forward for the quality of power supply equipment and the operational stability of the power system. Technical levels and the ability to handle defects need to be continuously improved to meet the needs of development, satisfy the requirements of the majority of users, shorten the time for equipment defect handling and maintenance, and ensure the safe operation of the power grid.

Therefore, during the process of equipment maintenance and renovation, we should strengthen the study of the characteristics of system equipment itself, comprehensively understand the operational characteristics of equipment and the existing problems and potential hazards, strengthen learning and communication, take preventive measures in a timely manner, continuously improve equipment, eliminate safety hazards, prevent accidents, and ensure the safe operation of equipment and the reliability of power supply.