This article introduces a case of 35kV ring main unit busbar insulation breakdown failure, analyzes the failure causes and proposes solutions [3], providing reference for the construction and operation of new energy power stations.

1 Accident Overview

On March 17, 2023, a photovoltaic desertification control project site reported a ground fault trip accident in the 35kV ring main unit [4]. The equipment manufacturer arranged a team of technical experts to rush to the site to investigate the cause of the failure. Upon inspection, it was found that the four-way connector at the top of the cabinet had experienced ground breakdown. Figure 1 shows the condition of Phase B busbar at the accident site. As can be seen from Figure 1, there was white powdery substance on Phase B busbar, suspected to be traces left after electrical breakdown of the busbar. This system had only been in energized operation for 8 days.

According to on-site inspections and tests, it was found that the construction team did not strictly follow the requirements in the equipment installation and operation manual for installation and inspection, resulting in poor conductor contact and overheating, which subsequently triggered busbar insulation breakdown.

2 On-site Testing and Inspection

2.1 Insulation Testing

First, the external incoming power supply was disconnected to de-energize the entire substation in order to locate the fault position. The switchgear was adjusted to the conductive state (disconnector closed, circuit breaker closed, grounding switch open). Insulation resistance was measured on phases A, B, and C respectively at the outgoing terminals of the equipment. The test revealed that the megohmmeter readings for phases A and C of the equipment approached infinity (good insulation), while the megohmmeter reading for phase B was less than 5MΩ, indicating poor insulation performance in phase B of the equipment. This initially suggested an insulation problem at some location in phase B of the equipment.

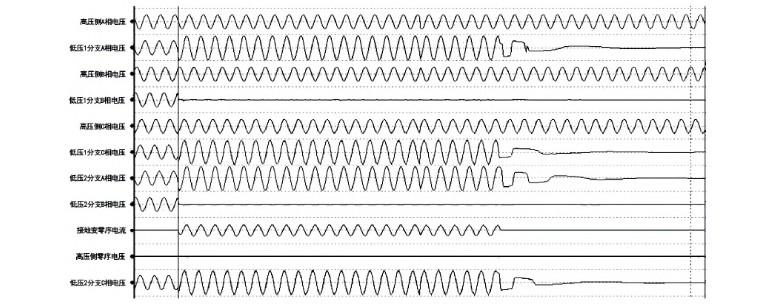

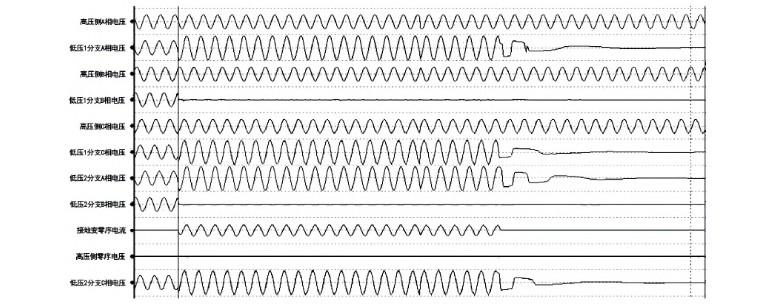

2.2 Fault Recording Inspection

The on-site fault recording is shown in Figure 2. As can be seen from Figure 2, at the time of the fault occurrence, the voltage of phases A and C on the 35kV busbar No.1 rose to line voltage, while the voltage of phase B was close to zero.

2.3 On-site Equipment Visual Inspection

Section I busbar has 9 cabinets. Through on-site visual inspection of the equipment, white powdery substance was found on phase B busbar, suspected to be traces left after electrical breakdown of the busbar. This identified that the busbar insulation breakdown accident occurred at cabinet 1AH8 of Section I busbar.

2.4 Disassembly and Inspection of Fault Location

After opening the insulation cover of phase B busbar, it was found that the insulation plug was not properly secured as shown in Figure 3, and the busbar tile conductor segments were not tightly pressed together as shown in Figure 4.

2.5 Secondary Disassembly and Inspection of Insulated Busbar

The damaged busbar four-way connector was cut open for analysis. It was found that the internal structure of the four-way connector exhibited severe high-temperature ablation as shown in Figure 5. The insulation plug near the conductor area also showed severe high-temperature ablation as shown in Figure 6.

2.6 Inspection of Phase A and Phase C Cabinet-top Insulated Busbars

Through inspection of the remaining insulated busbars of phases A and C, their installation workmanship was found to be correct, with no discoloration or ablation observed at the current-carrying positions of the equipment conductors.

3 Analysis of Busbar Insulation Breakdown Causes

3.1 Determination of Fault Scope

Insulation resistance tests were conducted on the equipment at the site. It was found that phases A and C passed the insulation test, whereas phase B failed. Additionally, data from the on-site fault recording showed that phase B busbar experienced a ground short circuit. When the fault occurred, the voltage of phases A and C on the 35kV busbar No.1 rose to line voltage while the voltage of phase B approached zero. This is characteristic of a typical single-phase metallic ground short circuit fault (phase B busbar insulation breakdown to ground). Through investigation, the fault location was identified at the phase B busbar joint in cabinet 1AH8.

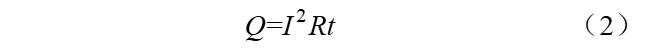

3.2 Zero Sequence Current and Busbar Current Values

419 milliseconds after the fault occurred, the zero-sequence overcurrent protection of the grounding transformer operated 452 milliseconds after the fault, the fault current disappeared. Checking the microcomputer of the grounding transformer, it recorded an operation of zero-sequence current protection, as shown in Figure 7. The operating value was 0.552A (with a zero-sequence CT current ratio of 100/1), which matched the fault recording values, as shown in Figure 8.

According to the fault recording, the RMS value of the secondary current of the low-voltage branch busbar No. 1 was 0.5-0.6A. Since the CT current ratio was 2000/1, it was calculated that the current of Section I busbar at that time reached 1000-1200A.

3.3 Impact of Installation Workmanship

Through disassembly and inspection of the phase B insulated busbar at the fault location (cabinet 1AH8), it was found that the phase B insulation plug was not properly locked and tightened, which led to the tile conductors inside the four-way connector not being pressed tightly together. This resulted in reduced contact area at the main busbar connection point, causing increased resistance at this location.

where: R is the circuit resistance (Ω); ρ is the resistivity of the conductor (Ω·m); L is the length of the conductor (m); S is the cross-sectional area of the conductor (m²). From formula (1), it can be seen that when the contact area is smaller, the equipment circuit resistance becomes larger. According to formula (2), more heat is generated per unit time during operation. When the heat dissipation is less than the heat generation, heat continuously accumulates at this location. After reaching a certain degree (critical point), the insulation at this location is damaged, resulting in insulation breakdown and triggering a ground fault.

where: Q is heat (J); I is current (A); R is resistance (Ω); t is time (s).

In summary, high temperature caused the deterioration of the busbar's insulation performance, thereby triggering busbar insulation breakdown. When the four-way connector from cabinet 1AH8 was removed on-site, its nut and bolt had already melted together due to electrical discharge and high-temperature ablation, making them impossible to disassemble, as shown in Figure 9.

4 Fault Handling and Recommendations

4.1 Fault Handling Measures

Prepare relevant materials, equipment, and tools, complete on-site work permit procedures, replace the damaged insulated busbars on site, such as three-way insulated bushings, four-way insulated bushings, and insulated straight tubes, replace the F-type bushings discolored due to high temperature, conduct relevant tests, and finally restore power supply.

4.2 Preventive Recommendations

Before equipment installation, technical personnel from the equipment manufacturer should provide professional training to on-site construction team members and explain relevant precautions. During busbar installation, the construction team should strictly follow the installation procedures in the manufacturer's operation manual. After on-site installation is completed, a torque wrench should be used for verification to ensure the busbar installation is properly tightened.

After equipment installation is completed, on-site test personnel need to perform circuit resistance tests and power frequency withstand voltage tests on the equipment. These tests can identify problems in advance and prevent accidents from escalating. The equipment can only be officially put into operation after passing acceptance inspection. During equipment operation, distribution stations can consider implementing a time-space distributed inspection strategy for distribution station rooms to identify potential equipment operation hazards as early as possible.

5 Conclusion

This paper introduces a 35kV ring main unit busbar insulation breakdown fault, conducted on-site fault inspection, fault waveform analysis, and fault cause analysis. The switchgear tripped because the busbar insulation layer broke down, causing a ground fault that triggered protective action tripping. This incident demonstrates that installation quality has a significant impact on the long-term operation of equipment.

Although the quality and service of relevant domestic power products in China have greatly improved in recent years, accidents caused by construction and installation problems, such as abnormal heating and even breakdown explosions at equipment terminals, still occur from time to time. With the continuous development of China's power industry, strengthening professional training for relevant personnel is of great significance to the rapid development of China's power industry.