Test dry, short-time power frequency voltage dikin, bi test voltage ku ji navbera values yên nîşan kirin di tabloya duyem de û bi standardên IEC relevant. Herêm îro ku effect of altitude di voltage values de hesab bikiyê. Ev test tenha ji bo wext ku circuit breaker di open position de ye û ji bo circuit breakers bi unitên yek an multi-unit适用的翻译如下:

```html

Bila her bir AC circuit breakerê ji bo malbat, disayn û bingehkirina li ser parastina kalitiya û performansa herî bi yekîniyê biguhezîne, karkerên testên demdemî li her vareyê dikin. Testeyan yekemîn ne ku hewlêkariya û ewlehîya circuit breakerên biafirîsin, û destûrên wan ya ku di şertên nîşan kirin de veqet bikin taybet bikin.

Ji bo circuit breakerên bi fazayên derbas (wek V-type an T-type), testên demdemî li ser unitên transport yên guhertina fulla dikin. Unitên transport yên guhertina column insulators û unitên circuit breaker di frame-ê specially designed de nehatiye girtin bi talabê ku bi mechanism-ê operasyon biguherine. Frame-ê custom ne divê ji bo guhezîna electrical connections di dawiyê testan de pêk bibe, lê heta destnîşan bi şertên wekî hilkiyan ên çalakan dijî rast be, ku testên bi rastî û hewlêkarî re biceribin.

Itemên testên demdemî yên AC High voltage circuit breaker bi standard IEC 62271-1, IEC 62271-100:

Test Dry, Short-Time Power Frequency Voltage

Test dry, short-time power frequency voltage dikin, bi test voltage ku ji navbera values yên nîşan kirin di tabloya duyem de û bi standardên IEC relevant. Herêm îro ku effect of altitude di voltage values de hesab bikiyê. Ev test tenha ji bo wext ku circuit breaker di open position de ye û ji bo circuit breakers bi unitên yek an multi-unit.

Bi guhezîna ev test, insulation performance û dielectric strength û circuit breaker di şertên wekî hilkiyan ên çalakan de biceribin, ku hewlêkariya û ewlehîya wan di environmentên high-voltage de biafirîsin.

Key Points:

Test Type: Test dry, short-time power frequency voltage.

Voltage Reference: Values specified in the second column of the table.

Standards: Must comply with relevant IEC standards.

Altitude Consideration: Voltage values should account for altitude effects.

Test Condition: Performed only when the circuit breaker is in the open position.

Applicability: Applies to both single-unit and multi-unit circuit breakers.

For Circuit Breakers with Serially Connected Identical Interrupting and Closing Units

Ji bo circuit breakers bi unitên interrupting û closing identical û connected in series, test voltage applied to each individual unit during the open state should correspond to the higher portion of the total withstand voltage generated by the actual power frequency voltage distribution when the circuit breaker is fully open and one terminal is grounded.

Test Connection Diagram

The above tests for single and multi-unit circuit breakers should be conducted according to the following connection diagram:

2. Dielectric Testing of Auxiliary and Control Circuits

A. Inspection and Verification

Material and Assembly Inspection: Thoroughly inspect the materials, assembly quality, surface treatment, and, if necessary, corrosion protection coatings of the auxiliary and control circuits to ensure they comply with relevant standards and specifications. Conduct a visual inspection to confirm that insulation layers are properly installed and that the wiring of conductors and cables is accurate, ensuring high-quality installation.

Diagram Compliance Verification: Verify that the physical installation of the auxiliary and control circuits exactly matches the circuit diagrams and wiring diagrams, ensuring all connections and components are accurately installed according to the design documents. This step is crucial for ensuring system reliability.

B. Functional Testing

Low-Voltage Circuit Function Verification: Perform comprehensive functional tests on all low-voltage circuits to ensure that the auxiliary and control circuits operate correctly in conjunction with other components of the circuit breaker. Adjust the test procedures based on the nature and complexity of the low-voltage circuits, including:

Counter Check: Verify the operating status and accuracy of counters.

Auxiliary Contact Check: Ensure reliable and responsive operation of auxiliary contacts.

Thermostat Setting Check: Confirm the set points and actual operation of thermostats.

Local/Remote Operation Function Test: Verify the functionality of local and remote operation modes to ensure operational flexibility and safety.

C. Electrical Safety Verification

Direct Contact Protection Check: Conduct a visual inspection to ensure adequate protection against direct contact with the main circuit, preventing accidental electric shock. Additionally, check the accessibility of auxiliary and control equipment components that may be touched during normal operation to ensure they are safe and accessible, protecting operators from harm. This ensures electrical safety during routine operations.

D. Dielectric Testing

Power Frequency Dielectric Testing: Only perform power frequency dielectric testing. The test voltage should be 1 kV or 2 kV, with a duration of 1 second and a frequency of 50 Hz or 60 Hz. This test should be conducted on terminals, motors, auxiliary switches, and control circuits to verify their insulation performance and withstand voltage capability. This ensures the electrical safety and reliability of the system.

3. Measurement of Main Circuit Resistance

For routine testing, measure the DC voltage drop or resistance of each pole of the main circuit under conditions as similar as possible to those used in type testing (including ambient air temperature and measurement points). The measured resistance must not exceed 1.2 times Ru, where Ru is the resistance measured before the temperature rise test. This ensures that the main circuit's resistance remains within acceptable limits, guaranteeing the long-term stable operation of the circuit breaker and enhancing system reliability.

4. Sealing Test

Routine Sealing Test: Sealing tests should be conducted at normal ambient air temperatures, with the component's charging pressure (or density) following the manufacturer's specified testing methods. For gas-insulated systems, sniffing techniques can be used for leak detection, ensuring that the gas seal is intact and preventing leaks that could affect the device's normal operation. This ensures the integrity and safety of the sealing system.

A: Controlled pressure systems for gas:

Find the relative leakage rate F re by measuring the pressure drop over a time period.

B: Closed pressure systems for gas:

The test may be performed at different stages of the manufacturing process or of assembling on site, on parts, components and subassemblies. For gas-filled systems, leakage detection by using a sniffing device may be used.

C. Sealing Pressure Systems

Gas-Insulated Switchgear:

Sealing tests should be conducted on gas-insulated switchgear and control equipment to determine the expected service life of the sealing pressure system. These tests ensure the integrity of the gas sealing system, preventing gas leaks and ensuring long-term reliable operation.

Vacuum Switchgear:

Each vacuum interrupter should be uniquely identified by its serial number. The vacuum pressure level of each vacuum interrupter should be tested by the manufacturer of the vacuum arc chamber, and the test results should be documented. After assembly, an important routine dielectric test should be performed to verify the vacuum pressure level of the vacuum interrupters. This test is conducted across the open contacts, and the test voltage should be specified by the manufacturer. The dielectric test should be carried out after the mechanical routine tests required by relevant product standards to ensure the insulation performance and withstand voltage capability of the vacuum interrupters.

5. Design and Visual Inspection

Switchgear and control equipment should be inspected to verify compliance with the purchase specifications. The following items must be checked:

Language and Data on Nameplates: Ensure that the information on the nameplates (such as model numbers, rated parameters, etc.) is accurate.

Identification of Auxiliary Equipment: Confirm that all auxiliary equipment (such as sensors, relays, etc.) is correctly identified.

Paint Color and Quality, and Corrosion Protection of Metal Surfaces: Check that the paint color meets specifications, the coating quality is good, and metal surfaces have appropriate corrosion protection.

Values of Resistors and Capacitors Connected to the Main Circuit (if applicable): Verify that the nominal values of resistors and capacitors connected to the main circuit meet design requirements.

6. Mechanical Operation Testing (Timed Testing via Semi-Automatic Test Program)

A complete mechanical operation test should be performed on the circuit breaker. For all required operating sequences, the following procedures should be executed, and the operating times for closing and opening operations should be recorded:

Operating Time Measurement: Record the time for each closing and opening operation to ensure it falls within the specified time range.

Mechanical Travel Characteristics: Use a travel sensor installed on the circuit breaker's contact system or a similar device, or a device located at a convenient position on the driver with a direct connection to the contact system, to record representative images of the contact travel. This provides detailed information about the contact movement, helping to evaluate mechanical performance.

The following diagram shows a typical mechanical contact curve, illustrating the characteristic features of contact movement:

Mechanical Operation Testing

The mechanical operation testing should ensure that the number of recorded points is sufficient to accurately determine the contact time, contact speed, contact closing and separation times, as well as the total travel time. The test should include the following components:

a) Testing at Maximum Supply Voltage

Five Closing Operations: Perform five closing operations at the maximum supply voltage for the operating device and auxiliary and control circuits.

Five Opening Operations: Perform five opening operations under the same conditions.

b) Testing at Minimum Supply Voltage

Five Closing Operations: Perform five closing operations at the minimum supply voltage specified for the operating device and auxiliary and control circuits.

Five Opening Operations: Perform five opening operations under the same conditions.

c) Testing at Rated Supply Voltage

Five Close-Open Operation Cycles: Perform five "close-open" operation cycles at the rated supply voltage for the operating device, auxiliary circuits, and control circuits. The tripping mechanism should be energized by the closing action of the main contacts.

Fast Automatic Reclosing Test (if applicable): For circuit breakers designed for fast automatic reclosing, perform five "open-time-close" (O – t – C) operation cycles, where t does not exceed the time interval specified in the rated operating sequence.

Additional checks should include:

After completing the required operating sequences, the following tests and inspections should be performed (where applicable):

Connection Inspection: Ensure all connections are secure and correct.

Control and/or Auxiliary Switch Indication: Confirm that control and/or auxiliary switches correctly indicate the open and closed positions of the circuit breaker.

Auxiliary Equipment Operation: Ensure all auxiliary equipment operates normally within the working supply voltage limits.

Heater and Control Coil Resistance Measurement: Measure the resistance of heaters (if installed) and control coils.

Wiring Inspection: Verify the wiring of control, heater, and auxiliary equipment circuits according to the order specifications and check the number of auxiliary contacts.

Control Room Inspection: Inspect the electrical, mechanical, pneumatic, and hydraulic systems in the control room.

Charging Duration: Record the charging time.

Pressure Relief Valve Functionality: Verify the performance of pressure relief valves.

Interlock and Signal Device Operation: Check the operation of electrical, mechanical, pneumatic, or hydraulic interlocks and signaling devices.

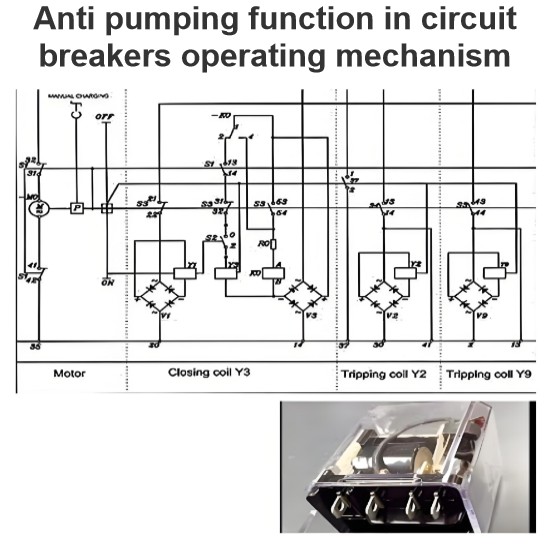

Anti-Jump Device Operation: Verify the operation of anti-jump devices.

General Performance: Ensure the equipment operates correctly within the specified supply voltage tolerances.

Grounding Terminal Inspection: Check the installation and connection of the circuit breaker's grounding terminal.

Special Tests

For circuit breakers equipped with undervoltage trip units, it should be verified that the circuit breaker can reliably trip and close when the voltage applied to the trip unit is within the specified limits.

```