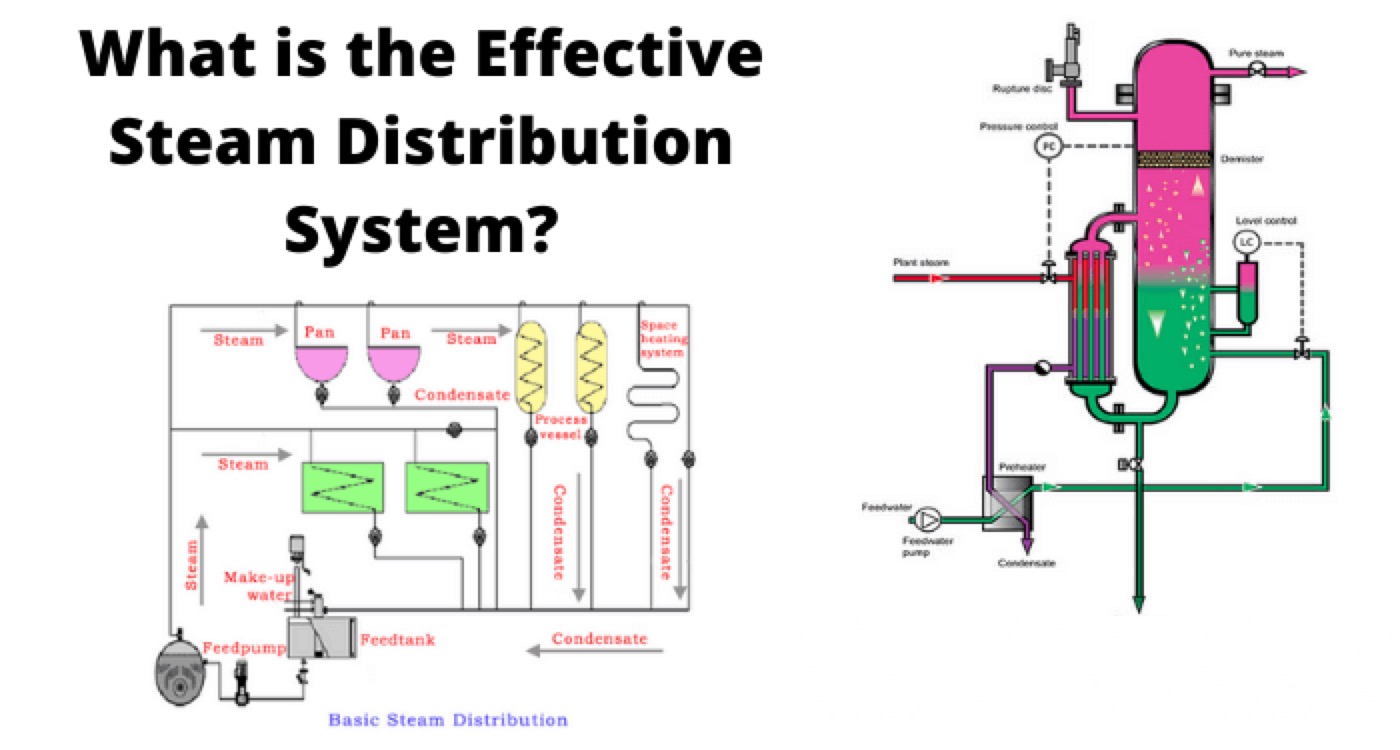

A steam distribution system is a vital link between the steam generator and the steam user in any process plant. It carries steam from the central source to the point of use with the right quality, quantity, and pressure. This tutorial will look at the methods of designing, operating, and maintaining an efficient and safe steam distribution system.

What is a Steam Distribution System?

A steam distribution system is defined as a network of pipes, valves, fittings, and accessories that transport steam from the boiler or the co-generation plant to the steam-consuming equipment in the process plant.

The steam distribution system can be divided into two parts: the steam mains and the branch pipes. The steam mains are the large pipes that carry steam from the boiler to the general direction of the plant. The branch pipes are the smaller pipes that carry steam from the mains to the individual pieces of equipment.

The main objectives of a steam distribution system are:

To deliver dry and saturated steam to the process at the required pressure and temperature.

To minimize heat losses and condensation in the pipes and fittings.

To prevent water hammer, erosion, corrosion, noise, and other problems caused by improper design or operation.

To reduce capital and operating costs by optimizing pipe size, insulation, support, and layout.

Design of Steam Distribution System

The design of a steam distribution system involves several factors, such as:

Steam-generating working pressure: This is the maximum pressure at which the boiler or the co-generation plant can produce steam. It depends on the type and capacity of the boiler, the fuel used, and the process requirements.

Minimum pressure requirement at process end: This is the minimum pressure at which the steam-consuming equipment can operate efficiently and safely. It depends on the type and capacity of the equipment, the process conditions, and the safety margins.

Pressure loss in the system: This is the difference between the steam-generating pressure and the process pressure. It is caused by frictional resistance in the pipes and fittings, condensation in the pipes due to heat transfer to the surroundings, and pressure-reducing valves (PRVs) if used.

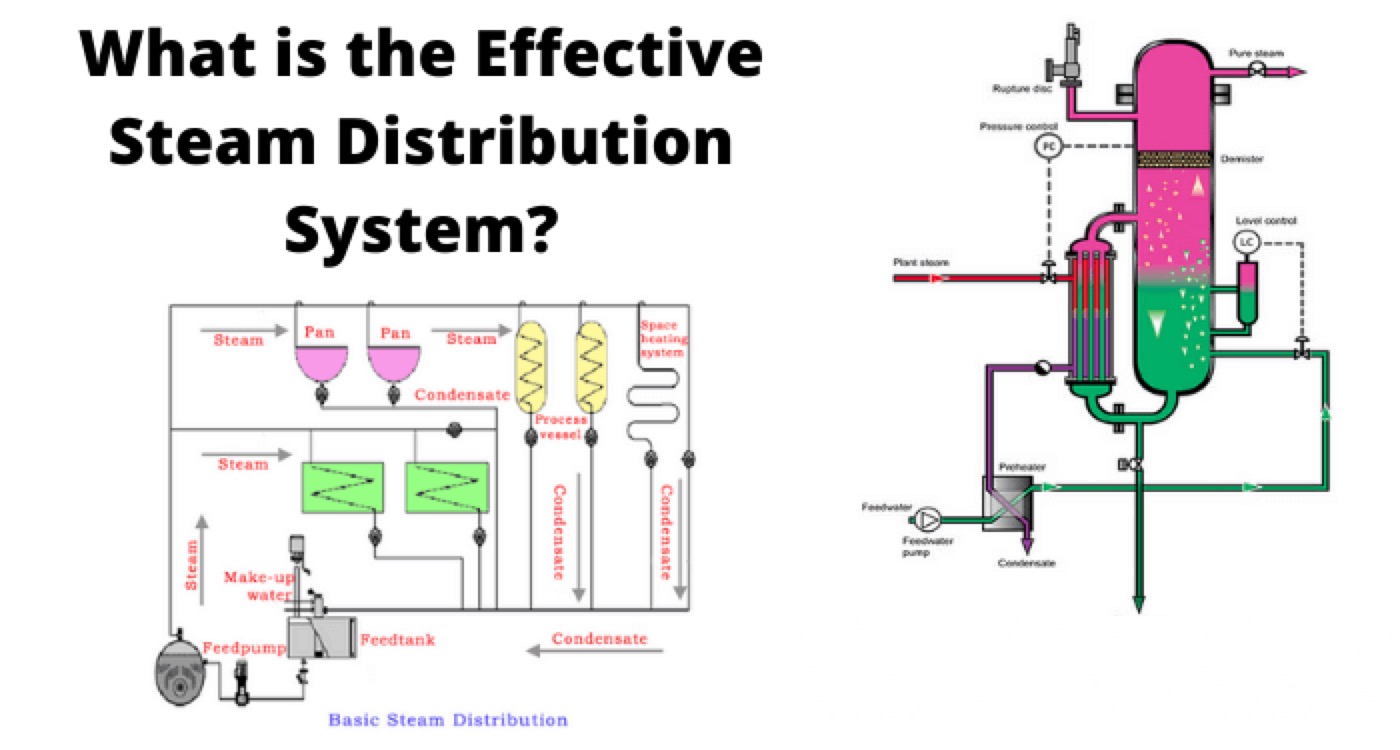

Steam quality: This is a measure of how dry and saturated the steam is. It depends on the boiler design, operation, and maintenance, as well as on the condensate removal system. Poor steam quality can lead to wet steam, which can cause problems such as erosion, corrosion, water hammer, reduced heat transfer efficiency, and damage to equipment.

To design a steam distribution system that meets these objectives and factors, some basic steps are:

Determine the steam demand of each piece of equipment in terms of mass flow rate, pressure, temperature, and quality.

Select a suitable steam-generating pressure that can satisfy the minimum pressure requirement at the process end with an adequate margin for pressure loss in the system.

Calculate the pressure loss in each section of the system using empirical formulas or software tools. Consider factors such as pipe diameter, length, roughness, bends, fittings, valves, insulation thickness, ambient temperature, etc.

Select a suitable pipe size for each section of the system that can carry the required steam flow with minimal pressure loss and cost. Use standard pipe sizes and avoid unnecessary changes in diameter.

Install PRVs where necessary to reduce the steam pressure to suit different process zones or equipment. Use separators upstream of PRVs to remove entrained condensate and ensure high-quality steam. Use safety valves downstream of PRVs to protect the system from overpressure if PRVs fail.

Install adequate condensate removal devices such as steam traps, drain valves, and condensate pumps along the system to prevent the accumulation of condensate and ensure dry steam delivery. Use different types of steam traps depending on the application, such as thermal or mechanical traps. Consider factors such as installation type (individual or group drainage), condensate load (continuous or intermittent), operating pressure and temperature (high or low), etc.

Provide proper pipe expansion and support systems to accommodate thermal expansion and contraction of pipes due to temperature changes. Use expansion joints or loops where necessary to allow for pipe movement without causing stress or leakage. Use pipe hangers or supports at regular intervals to prevent sagging or vibration of pipes.

Provide adequate insulation for all pipes and fittings to reduce heat losses and condensation. Use appropriate insulation materials depending on temperature, moisture resistance, fire resistance, etc. Avoid gaps or damage in insulation that can expose pipes to ambient air.

Provide proper ventilation for all enclosed spaces where pipes are located to prevent overheating or moisture accumulation. Use vents or fans where necessary to ensure air circulation.

Operation and Maintenance of Steam Distribution System

The operation and maintenance of a steam distribution system are essential for ensuring its efficiency, safety, and reliability. Some common practices are:

Monitor and control key parameters such as steam flow rate, pressure, temperature, and quality using instruments such as flow meters, pressure gauges, thermometers, and conductivity meters. Adjust boiler operation, PRVs, or other devices as needed to maintain optimal conditions.

Inspect and test all components regularly for proper functioning, leakage, wear, or damage. Replace or repair any faulty parts as soon as possible.

Clean and flush all pipes and fittings periodically to remove scale, corrosion, or debris that can cause blockage, reduced heat transfer efficiency, or increased pressure loss.

Lubricate all moving parts, such as valves, steam traps, or pumps, according to the manufacturer’s recommendations to prevent friction, noise, or seizure.

Check and replenish insulation materials as needed to prevent deterioration or loss due to exposure, moisture, or mechanical damage.

Advantages and Disadvantages of Steam Generation at High Pressure

Steam generation at high pressure has some advantages and disadvantages compared to low or medium pressure.

Some advantages are:

Steam generation at high pressure occupies relatively less volume than at lower pressure, which reduces pipe size, cost, and heat loss.

Steam generation at high pressure improves steam quality by reducing moisture content and increasing superheat.

Steam generation at high pressure allows for greater flexibility in PRV settings for different process zones or equipment.

Some disadvantages are:

Steam generation at high pressure increases flue gas losses due to higher stack temperature and lower combustion efficiency.

Steam generation at high pressure increases running losses due to higher blowdown rates and higher feedwater treatment costs.

Steam generation at high pressure requires more expensive boiler design, construction, and maintenance due to higher stress levels.

However, the fuel consumption of a boiler depends on its connected load rather than its output pressure.

Therefore, steam generation at high pressure should be balanced with its benefits and drawbacks for each specific application.

Conclusion

A steam distribution system is a critical component of any process plant that uses steam as a heating medium. It requires careful design, operation, and maintenance to ensure optimal performance, safety, and cost-effectiveness. By following some basic principles and best practices, a steam distribution system can deliver dry and saturated steam to meet various process requirements with minimal losses and problems.

Statement: Respect the original, good articles worth sharing, if there is infringement please contact delete.