Isolaithe high-voltage (HVDs) is iad chriticiúla comhshaoil sa chóras grid leictreach, ag úsáid go príomha chun foinse reicte a shainéadh in éineacht le circuit breakers. Leis an bhfeachtaíocht "digital grids," forbairt leanúnach teicneolaíochta haisleachta high-voltage, agus síorshuíomh na grid reicte in China, tá feidhmíocht HVD tar éis ardú go mór i suim agus éagsúlacht. Is gníomh deacra controllaí HVD switching movements, ag iarraidh ionchur ar leith as diongbháilteacht agus stiobartacht.

Tá ráta airde meabhair a bheith ag HVDs idir uirlisí high-voltage, agus is é gníomh deacra a bhfuil mar phríomhcháinscéal. Samplaí coitianta de fhillteoireachtaí gníomh deacra ná dícheallú switch, mífhreagracht, agus oscailt/colgú neamhiomlán. Tá sé féidir go mbeadh runaway de gníomh deacra—nuair a leanann an motor ar aghaidh—ag déanamh maorúcháin móra i gcóras grid. Ina measc seo, tá fillteoireachtaí oscailt/colgú (lena n-áirítear dícheallú switch, gníomh neamhiomlán, agus cúlúide switch íosta) ag cur tionchar suntasach ar stiobartacht na grid.

Léiríonn taighde go forbríonn HVD failures tarsna gníomh deacra leictreach go príomha ó cheisteanna circuit deacra, cosúil le mífhreagracht rialú de bharr compónntaí leictreach íosta-chaolacha nó ceangail sciorradh san circuit deacra. Do gníomh deacra CJx-type leictreach, atá in úsáid go forleathan, tá motors binn-bhréige á dtosú agus devices rianú motor leictreach á dtosú. Tar éis tuilleadh blianta trína chéile, tá na gníomharthaí seo ag cothú postúir gníomhach, ach tá a cmhainní rialú leictreach íosta-saolach agus an-tábhachtach do thorthaí comhshaoil.

D’fhéadfadh tuilleadh gníomhaíochta switches limit agus bolts a dhéanamh, agus más faoi dheara nach bhfuil an switch iomlán (mar shampla, an 5° fuair-shuíomh in Figure 1 a chur isteach i gcóras grid). Tá switches travel, atá tábhachtach do thrasnsitions switching process, ag fulaingt ó contacts oxidized agus beatha ghearr de bharr tionchair comhshaoil.

I gcoitinne, is féidir fillteoireachtaí oscailt/colgú high-voltage disconnect switch (HVD) a chur i catagóir dá theanga: fillteoireachtaí circuit rialú leictreach agus fillteoireachtaí cogaimeach. Tá an páipéar seo dírithe ar an gcomhshaoil rialú leictreach, atá a bhfuil go príomha motor circuit failures, limit switch malfunctions, agus issues circuit deacra. Léireann anailís go bhfuil ráta airde fillteoireachtaí switching go príomha le motor agus circuit deacra failures, ag cur tionchar suntasach ar oibriú HVD. Mar sin, tá sé gaolmhar an diongbháilteacht agus stiobartacht gníomh deacra HVD a réiteach.

1. Stádas Taighde ar High-Voltage Disconnect Switches

Tá taighde forleathan déanta ag lucht taighde agus inoiseoirí ar na ceisteanna thuas agus roghnúmháin constructives cuimsithe, a aonródaítear in dhá thaobh príomha:

1.1 Stádas Taighde ar Fillteoireachtaí Circuit Deacra

Tá go leor staidéar déanta ar cheisteanna compónntaí leictreach san circuit deacra. Níos íosta sealú box gníomh deacra a ligean rainge ingreas, ag déanamh corrosion compónntaí, auxiliary switch/relay failure, ceangail button sciorradh, agus jams cogaimeacha—ag cur dícheallú switch nó gníomh neamhiomlán. Tá roghnúmháin cuimsitheach go raibh sé a dhéanamh maintenance rialta, protection moisture, agus fault flowcharts chun troubleshooting a dhéanamh go tapa.

Do wear cogaimeach cosúil le pins deformed, limit bolts sciorradh, nó screws worn de bharr inertia motor, molaimíd measúnuithe freastail agus éadú laighe de feamainn. Tá materials anti-oxidation molta chun joints wire corroded, agus methods testing voltage/resistance chun diagnósú fillteoireachtaí circuit deacra—buailte le logging defect chun feabhsú eficiúlacht troubleshooting. Tá heating devices molta chun dealú le ceisteanna humidity cosúil le auxiliary switch misalignment agus poor contact i gníomh deacra leictreach.

Áfach, tá staidéar reatha ag liostáil points fault agus béim a chur ar maintenance gan roghnúmháin bunúsacha, ag léiriú aire íosta chuige circuit deacra. Tá personnel maintenance go minic ag brath orthu compónntaí leictreach níos lú ná compónntaí cogaimeacha, agus unfaimiríocht le structures/principles component deacra—comhcheangailte le inspections rialta neamhshainithe—agus is iad an t-ábhar díreach fillteoireachtaí.

1.2 Stádas Taighde ar Issues Accuracy Switching

Chun accuracy switching agus inertia cogaimeach a dhéileáil leis, tá scholars ag feabhsú rialú motor trí brushless DC motor (BLDC) agus permanent magnet synchronous motor (PMSM) gníomh deacra a dearadh. Tá BLDC-based mechanism HVD le DSP core agus dual closed-loop control strategy leis an speed regulation switching effective. Chomh maith lena chéile, mothód eile chun monitoring speed real-time chun cinntiú oibriú smooth agus improved closing accuracy, ag tarraingt a bhunáil don smart grid development. Tá sé tábhachtach a lua, go bhfuil na dearadh seo fós in aghaidh theoretical research agus laboratory simulation stages, gan diongbháilteacht proifisiúnta in applications práctacha.

2 Distributed Electric Operating Mechanism Design Scheme

Ar a bonn anailísi thuas, is é an príomhcháinscéal fillteoireachtaí gníomh deacra ná diongbháilteacht íosta an circuit rialú leictreach, atá an-tábhachtach do thorthaí comhshaoil. Maintenance delayed nó ceisteanna eile is féidir damáiste a dhéanamh ar compónntaí leictreach, ag cur dícheallú switching. I gceist leis, tá an páipéar seo ag mol distributed design do gníomh deacra leictreach.

2.1 Concept Rialú Scattered do Gníomh Deacra Leictreach

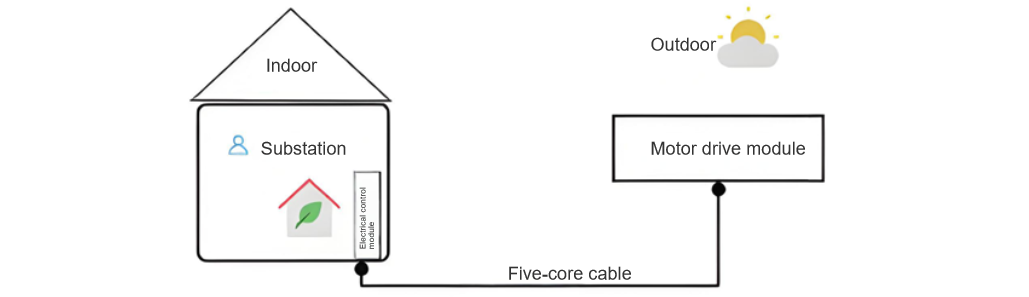

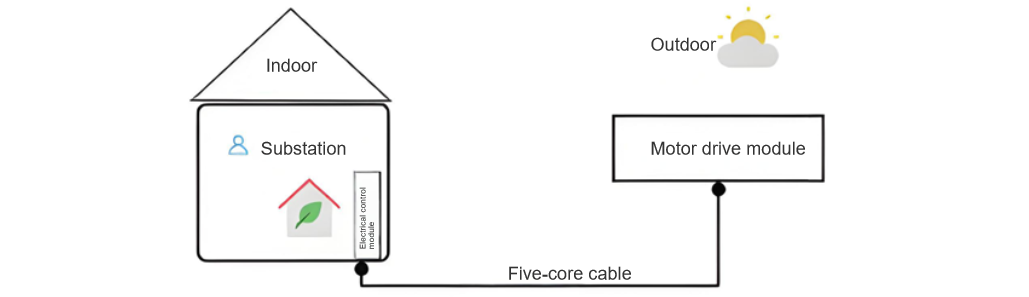

Rialú scattered roinnte an córas iomlán i segments sainiúil, gach aontas agus aontas rialú rialú príomha. An dearadh seo roinnte an module rialú leictreach ón module drive motor:

An module rialú leictreach, a chomhdhéantar as electronic components le go leor contacts wiring, atá íosta-saolach don tionchar comhshaoil. Tá sé suite in a substation le temperature stable room.

An module drive motor, níos bríomhar i ndáiríre do thorthaí comhshaoil, is suite i gcomhcheangaltacht le high-voltage disconnect switch.

Ag smaoineamh ar an environment variable outdoors agus susceptibility cable, tá strategy time-division shared cable glacadh bunaithe ar TRIZ's principle of multi-usage. Ó motor control circuits agus switching status indicator circuits níl an riachtanas chun gníomhú ar an am céanna, tá an approach seo a dhéanamh signal transmission do both motor control agus position indication disconnect switch using only 5 cables. Tá sé seo ag cur go mór le tionchar comhshaoil externa ar an gníomh deacra leictreach. Tá an concept rialú iomlán den gníomh deacra leictreach scattered léirithe in Figure 2.

2.2 Dearadh Modules Rialú Scattered

Tá gníomh deacra CJx-series leictreach, atá in úsáid go forleathan, deartha le electrical agus mechanical components integrated, ag oibriú outdoors year-round in a fixed configuration since commissioning. Tá an integration seo a chéad factor a chuir isteach ina ráta airde meabhair. Tá an dearadh modular ag briseadh an all-in-one setup outdoors seo trí an mécanisme a roinnt i dhá module sainiúil: an module rialú leictreach agus an module drive mechanical.

Tá na tairbheanna dearadh modular go príomha: a chur an module rialú leictreach suite in a temperature-stabilized environment, ag cur go mór le tionchar comhshaoil ar oibriú HVD switching; agus é a chur inter-module wiring go mion, a dhéanamh a chur faulty modules ar ais go tapa—"replace-first, repair-later" chun feabhsú eficiúlacht maintenance agus laghdú downtime grid.

2.2.1 Module Rialú Leictreach

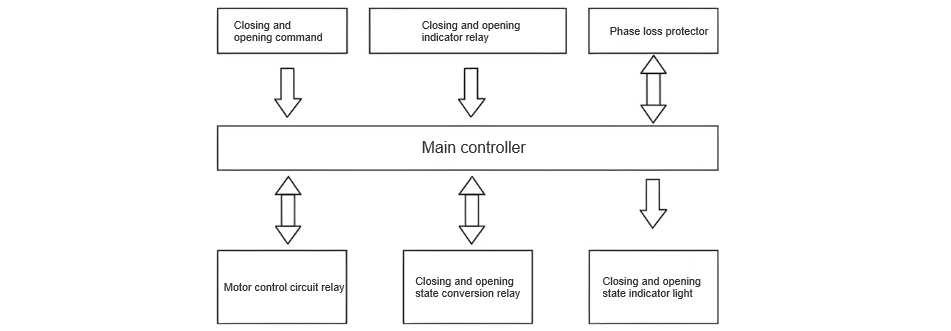

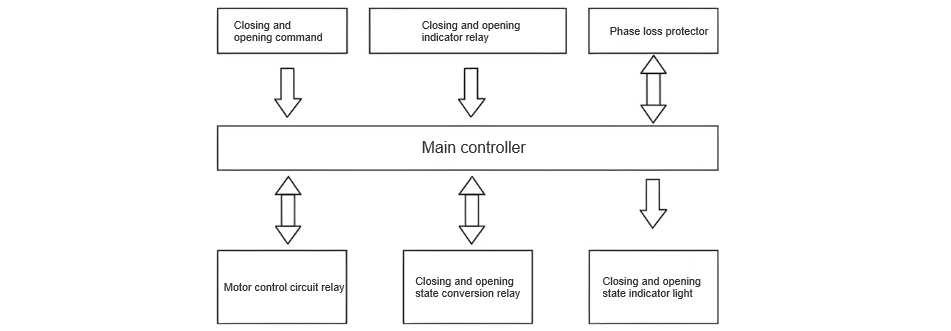

Tá an module rialú leictreach a chomhdéantar as a main controller, open/close transfer switch, relays, position indication circuits, agus a phase-loss protector, mar a léirítear in the design concept of Figure 3.

Tá an logic rialú mar seo: a signal switching (open/close) ón button a sheoladh go dtí an controller, a rialaíonn oibriú motor de réir an ordóid. Nuair a bhfuil an HVD in the open state, an circuit open-position a chur i bhfeidhm, ag lasadh an indicator. Nuair a bhrú an close button, triggers an controller to engage the main motor relay and close-circuit transfer relay, driving the HVD to close. Upon completion, the motor relay de-energizes, activating the close-position circuit and indicator. The phase-loss protector safeguards the motor circuit with timer functionality, disconnecting the main circuit within a specified time frame in the event of faults.

2.2.2 Module Drive Motor

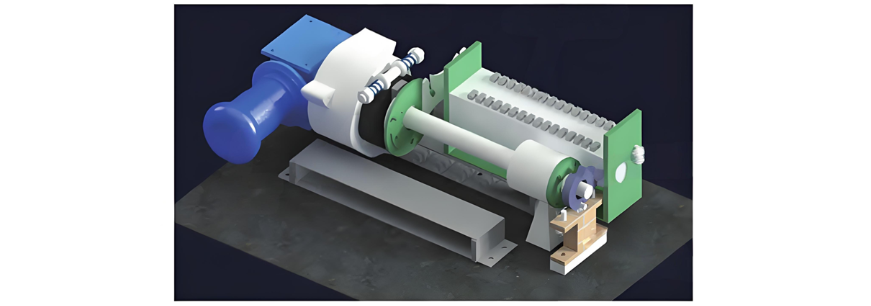

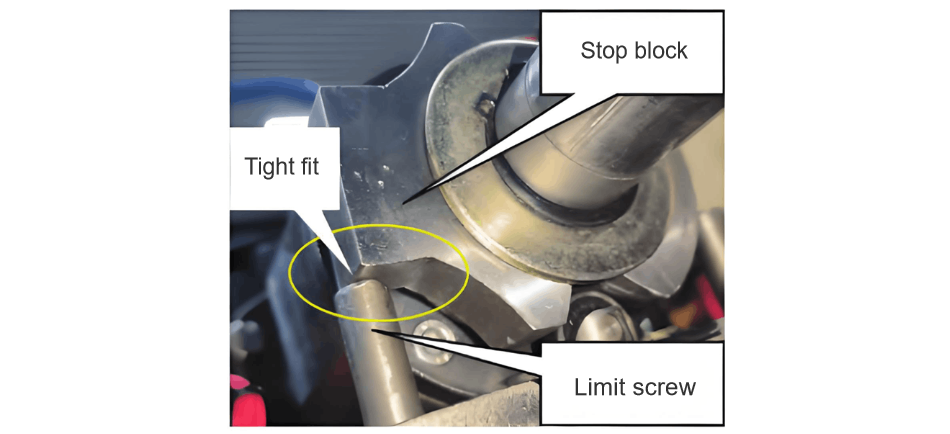

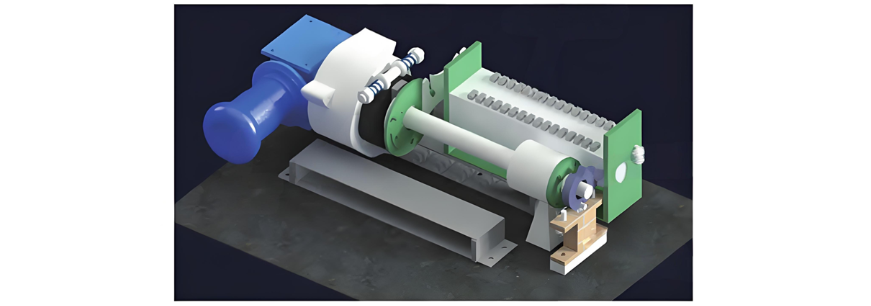

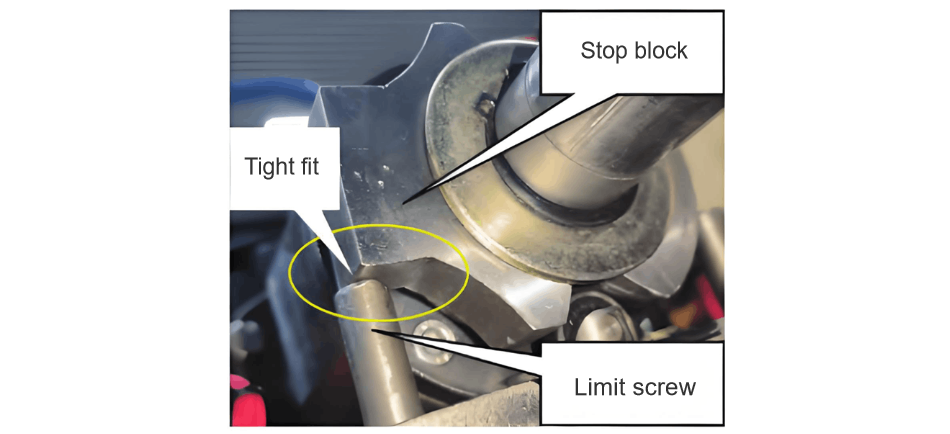

Tá an module drive motor a chomhdéantar as an AC motor, speed reducer, friction coupling, Siemens auxiliary switch, thyristor arc-suppression circuit, limit stops, agus device locking mechanical. Nuair a sheolann an main controller an open/close command, the motor control circuit is activated, driving the speed reducer and main shaft via the motor for switching operations. Limit stops at the top of the main shaft, in conjunction with the mechanical locking device, control the switching position accuracy. Meanwhile, the Siemens auxiliary switch works with the thyristor arc-suppression circuit to disconnect the motor control circuit, halting motor operation. A 90-degree rotational margin at the connection between the speed reducer and main shaft enables no-load starting of the motor. The appearance of the motor drive module is shown in Figure 4.

2.3 Solution for Disconnect Switch Closing Accuracy

Tá an closing action a step cruinn do high-voltage switchgear. Inadequate closing accuracy can affect the stable operation of the entire power system. To further enhance the opening and closing accuracy of the electric operating mechanism, this design employs a mechanical locking device, in conjunction with a Siemens auxiliary switch and a friction coupler, to improve the accuracy to a certain extent.

2.3.1 Siemens Auxiliary Switch and Thyristor Arc - Suppression Circuit

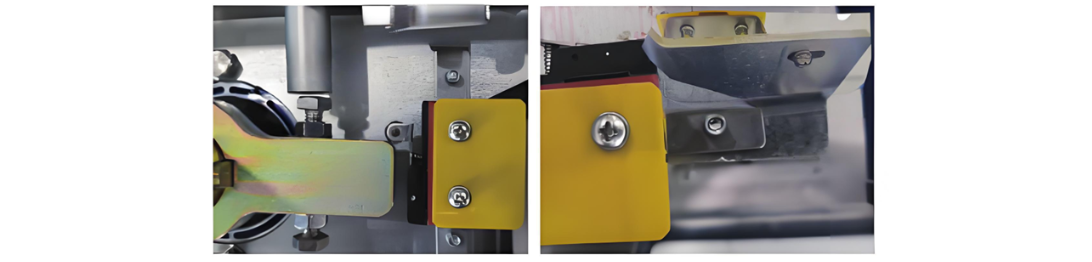

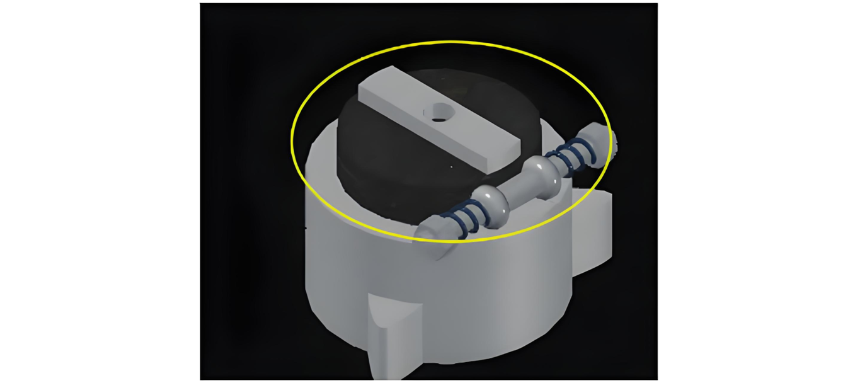

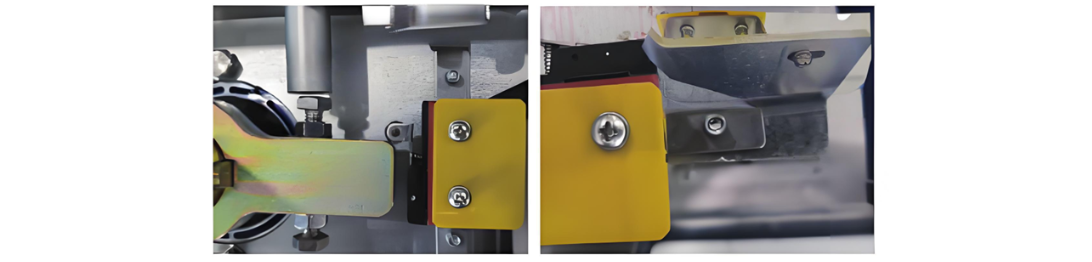

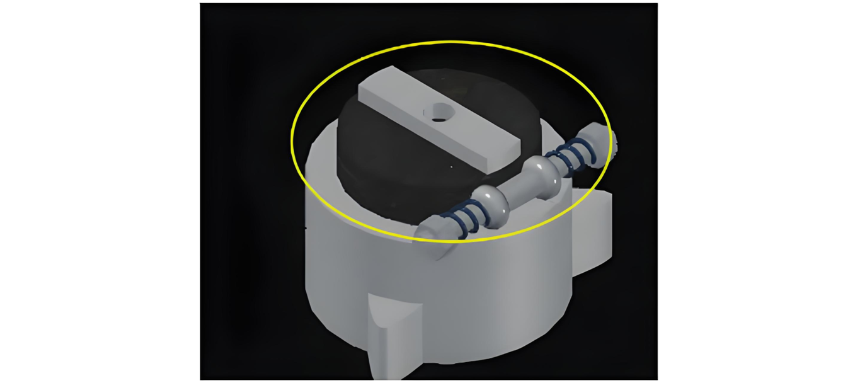

The auxiliary switch is connected to the main motor circuit to control the on - off of the motor circuit. The auxiliary switch is not prone to rust due to external environmental influences, and its internal friction mechanism prevents accidental closures. The contacts use a spring - loaded pin and a hard sheath to ensure stable and reliable connections. The specific structure is shown in Figure 6.

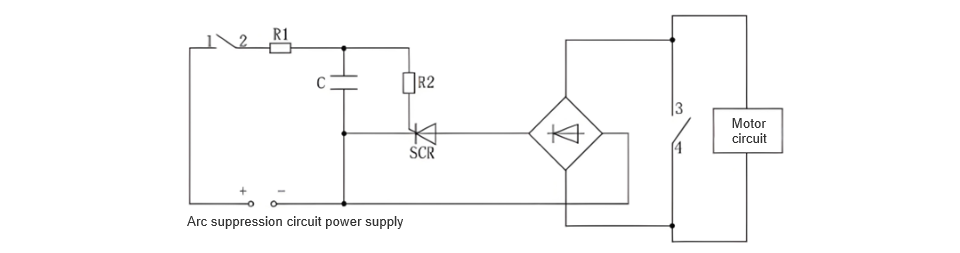

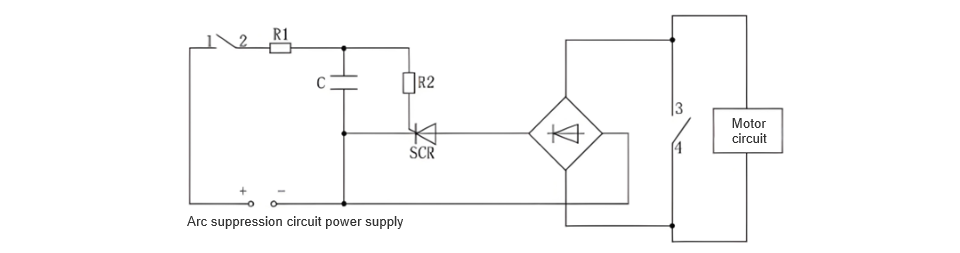

Design Principle of Thyristor Arc - Suppression Circuit: During the disconnection of the auxiliary switch, an arc is generated. To prevent the arc from being too large and damaging the switch, a thyristor arc - suppression circuit is connected in parallel with the auxiliary switch to absorb the arc. The specific circuit design is shown in Figure 7, where contacts 1, 2, 3, and 4 are all auxiliary switch contacts. (Contacts 1 and 2 are used to control the on - off of the thyristor arc - suppression circuit, and contacts 3 and 4 are used to control the on - off of the main motor circuit. It is set that contacts 1 and 2 disconnect after contacts 3 and 4 to achieve the purpose of arc suppression).

2.3.2 Function of the Friction Coupler

The friction coupler safeguards the motor under any abnormal operating conditions. Once the high - voltage disconnect switch is in place after closing, the main motor circuit is rapidly disconnected. However, due to mechanical rotational inertia, the motor cannot stop immediately. At this moment, the friction coupler acts as a force - relieving component. It enables the friction gear to idle, dissipating the motor's mechanical inertia and ensuring the precise positioning of the high - voltage disconnect switch during opening and closing operations. Additionally, by adjusting the tightness of the spring, the friction torque can be modified to suit the opening and closing operations of various disconnect switches. The friction coupler is shown in Figure 8.

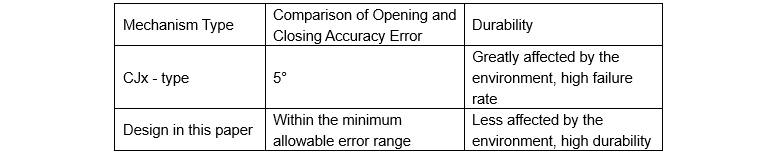

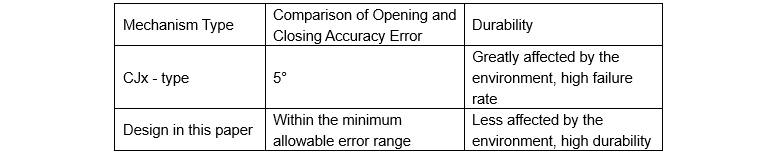

Advantages of the Designed Scheme over CJx - type Electric Operating Mechanisms

The proposed design eliminates electrical components like travel switches and limit switches, reducing instability factors and enhancing the reliability of the electric operating mechanism. It also removes the terminal block with numerous contacts, simplifying the wiring circuit. With a modular design, only five cables connect the two modules, greatly improving fault - repair efficiency. Additionally, it can form multiple protection layers with thermomagnetic circuit breakers and existing electronic motor protection devices. Even if the electrical control circuit malfunctions, the mechanical locking device and friction coupler ensure motor safety. The friction coupler counteracts the force from motor mechanical inertia, and the mechanical locking device prevents the limit stop from "rebounding", ensuring accurate opening and closing of the high - voltage disconnect switch and protecting its integrity. Moreover, the motor's no - load starting minimizes the starting current, avoiding equipment shock and extending the operating mechanism's service life.

3 Experimental Verification

Adhering to relevant standards such as "High - Voltage AC Disconnect Switches and Earthing Switches" and "Common Technical Requirements for High - Voltage AC Switchgear and Controlgear", the combination of a mechanical locking device and a friction coupler further improves the opening and closing accuracy of the disconnect switch. Compared with the CJx series electric operating mechanisms, it offers higher reliability and safety. Error detection, through multiple opening and closing tests and angular deviation measurements between the limit stop and limit screw, shows that they are closely aligned, with an actual machining error within 1°, fully meeting the technological standards. The actual position is shown in Figure 9.

4 Conclusion

As one of the key equipment in the power grid, the reliability and safety of the operating mechanism of high - voltage disconnect switches are of utmost importance. This paper takes the electric operating mechanism as the research object, conducts a detailed design and analysis of its distributed control method, and verifies it through experiments, achieving the expected results.Based on the concept of distributed control, the motor is driven by the main controller to safely and accurately control the opening and closing operations of high - voltage disconnect switches.

With a modular design approach, the electric operating mechanism is mainly divided into an electrical control module and a motor drive module, reducing the complexity of wiring and improving the maintenance speed.A mechanical locking device is set up. Combined with the special structures of the Siemens auxiliary switch and the friction coupler, the opening and closing accuracy of the disconnect switch has been improved.