In a certain region, after maintenance of ultra-high-voltage (UHV) transmission lines, the following issues were identified: existing drones lack sufficient performance to meet the current large-scale and extensive inspection and maintenance demands of UHV lines. In practical operations, drones exhibit inadequate endurance, limited image acquisition capability, and poor electromagnetic interference (EMI) resistance, which negatively impacts inspection effectiveness and prevents accurate identification of UHV line defects.

Due to the considerable length of UHV transmission lines and the influence of local natural environments, drones equipped with detection devices cannot sustain prolonged flight, reducing inspection efficiency. In the cited case, even oil-electric hybrid drones achieved a flight duration of less than 3 hours, necessitating frequent battery replacements during inspections. Moreover, current drone-based inspection systems lack functional completeness—they do not support multi-dimensional, multi-functional inspection capabilities—resulting in insufficient inspection accuracy. This may delay the detection and handling of line faults or other defects, directly affecting normal power transmission.

To address these challenges, our company has developed a novel UHV transmission line inspection technology that integrates a robotic manipulator mounted on a drone. This solution is tailored to the specific UHV infrastructure in the region and informed by current drone application performance in line maintenance. It aims to resolve the aforementioned issues while meeting key requirements: low power consumption, extended endurance, low cost, high payload capacity, and strong environmental perception.

1.Technical Solution: Drone-Mounted Robotic Arm for UHV Line Maintenance

1.1 Design Concept

Critical considerations for this technology include insulation design, robotic arm motion control, and supporting subsystems. Ensuring rational technical design is essential to effectively resolve existing UHV maintenance challenges and overcome implementation bottlenecks.

Our company comprehensively evaluated the insulation requirements imposed by the UHV maintenance environment on the robotic arm. Based on this, we calculated the maximum electric field strength and voltage variations experienced by the arm, rotors, frame, and fuselage at various distances from live conductors. Targeted performance tests were then designed to inform subsequent refinements of the technical solution.

We selected representative UHV maintenance scenarios to define standard operating procedures and safety protocols. The multi-degree-of-freedom structure of the robotic arm was optimized to identify the most compatible drone–manipulator configuration. Given the unique operational environment, we also proposed upgrading the original image acquisition hardware and data transmission software/hardware in the case study to enhance real-time image quality.

1.2 Electromagnetic Interference (EMI) Mitigation Measures

The UHV lines in the case involve long spans and crossings, creating a complex and dynamic electromagnetic environment. Strong electromagnetic fields around the lines and intense signals from nearby communication base stations can severely interfere with the drone–manipulator system’s communications. Additionally, long-distance data transmission during manipulator operations may cause crosstalk, compromising operational safety.

To counter this, our company proposes the following EMI shielding measures:

Analyze potential damage from high-intensity electromagnetic fields near UHV lines to the drone’s internal circuitry.

Apply shielding treatments to the airframe surface, signal cables, and all housing seams.

Uniformly spray a conductive coating of specified thickness onto the drone’s exterior to mitigate electromagnetic interference. For components unsuitable for coating, copper wire bonding is used to achieve equivalent shielding effectiveness.

1.3 Robotic Arm Structural Design

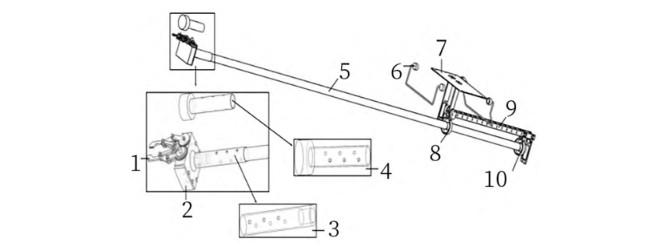

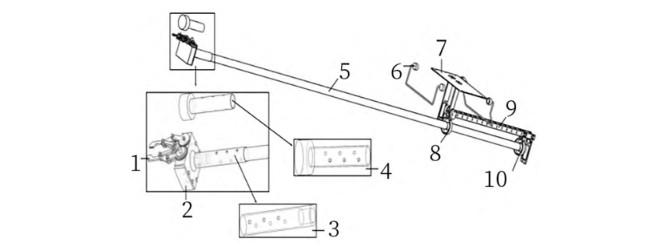

As shown in Figure 1, the robotic arm comprises:

(1) Gripper; (2) Servo protection box; (3) Zero-value detector adapter; (4) High-voltage tester adapter; (5) Insulating rod; (6) Limiting rod; (7) Epoxy resin insulating layer; (8) Pitch-specific bearing sleeve; (9) Linkage rod; (10) Roll-specific bearing sleeve.

Considering insulation requirements in UHV environments, our company proposes installing insulating bolts between the drone’s underside and landing gear. A steel frame connects the lower side of the insulating layer to the pitch-specific bearing sleeve, which is fixed externally around a metal bearing. The pitch servo motor is mounted on the right side of the bearing, driving the pitch mechanism to enable up-and-down movement of the robotic arm.

Considering the interference caused by the high-intensity electromagnetic fields in the space surrounding the transmission lines, our company proposes installing servo motor drive lines inside the insulating rod and equipping the servo with a dedicated insulated protective enclosure. This effectively isolates the servo from electromagnetic surges generated by the external high-voltage environment. Additionally, copper wire bonding is applied to the gaps around the servo to achieve equipotential bonding, thereby reducing the risk of electromagnetic wave-induced breakdown in the servo’s internal circuitry.

2.Simulation Experiment of UHV Transmission Line Inspection Using a Drone-Mounted Robotic Arm

2.1 Simulation Design

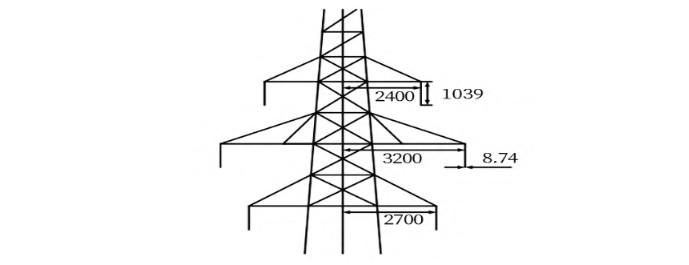

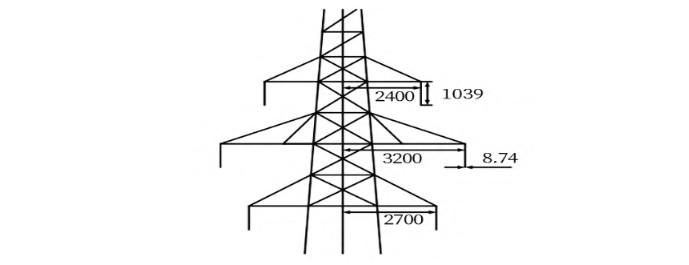

Based on maintenance records of the UHV transmission lines in the case study, the following structural parameters were obtained: the total height of the straight-line tower is 3200 mm; the large shed radius is 2400 mm; the medium shed radius is 3200 mm; the small shed radius is 2700 mm; and the conductor diameter is 17.48 mm, as shown in Figure 2.

In the simulation experiment, the drone system selected features carbon fiber materials for the propellers, frame, and fuselage to enhance its overall performance.

Taking into account the influence of the surrounding spatial electric field on drone-based maintenance operations for ultra-high-voltage (UHV) transmission lines, our company first developed a simulation model of the drone-mounted robotic arm inspection system. Using finite element analysis, we determined the specific impact of the electric field around UHV lines on drone maintenance operations. Additionally, we analyzed the maximum electric field strength and voltage variations experienced by the robotic arm, airframe, rotors, and fuselage under different distances between the left side of the robotic arm and the conductor. This allows us to assess whether potential safety hazards exist during close-proximity inspection tasks.

2.2 Simulation Process

2.2.1 Inspection System Performance at 0.84 m from UHV Transmission Line

Our company conducted simulation experiments on the drone-mounted robotic arm inspection system to further analyze its operational status and the spatial electric field distribution near the conductor when positioned 0.84 m away from the UHV transmission line.

Simulation results showed that, under this working condition, no significant adverse electric field effects were observed on the overall inspection system. However, a slight increase in electric field intensity was detected on the left side of the robotic arm. Generally, if the local electric field strength exceeds the dielectric breakdown strength of air (30 kV/cm), the risk of component breakdown increases, compromising system stability and safety.

Furthermore, by examining the potential (voltage) distribution across system components, we found that as the distance between the drone-mounted inspection system and the UHV line increases, the electric potential of all components decreases accordingly. Based on these potential variations, we determined the voltage levels and maximum electric field strengths each component experiences in the maintenance environment.

As shown in Table 1, when the inspection system is 0.84 m from the UHV line, the robotic arm experiences an electric field strength of 3712 V/m and a voltage of 2069 V. A comparison between the left and right rotors revealed that the left rotor consistently endures higher electric field strength and voltage than the right rotor. All data indicate that, under this 0.84 m operating distance, the electric field remains well below the air breakdown threshold, posing no risk of electrical discharge and ensuring safe operation of the drone-mounted robotic arm inspection system.

2.2.2 Inspection System Performance at 0.34 m from UHV Transmission Line

Our company also conducted simulation experiments to analyze the operational state of the drone-mounted robotic arm inspection system and the spatial electric field distribution near the conductor when positioned only 0.34 m away from the UHV transmission line.

Table 1: Maximum Electric Field Strength and Voltage Values Corresponding to Each Component of the Drone-Mounted Robotic Arm Inspection System

| UAV Component |

Maximum Electric Field Intensity |

Voltage Value |

| Mechanical Arm |

3712V/m |

2069V |

| Rotor |

Left Rotor |

1838V/m |

224V |

| Right Rotor |

1371V/m |

193V |

| Fuselage |

720V/m |

166V |

| Frame |

1730V/m |

470V |

The simulation results showed that, under this separation distance maintenance condition, the spatial electric field distribution around the transmission line on the left side of the robotic arm changed. Due to the unique environment of ultra-high-voltage (UHV) transmission lines, high-voltage electric fields are highly prone to causing arcing and surface flashover issues.

At the same time, by analyzing the potential variations of various components in the system, it was found that as the distance between the drone-mounted robotic arm inspection system and the UHV transmission line increases, the electric potential of all components correspondingly decreases.

According to the data in Table 2, when the inspection system is positioned 0.34 m away from the UHV transmission line, the maximum electric field strength experienced by any component in the system does not exceed the dielectric breakdown strength of air. Therefore, it is concluded that no breakdown risk will occur during the maintenance operation, ensuring the safety and reliability of the drone-mounted robotic arm inspection system in practical applications.

Table 2: Maximum Electric Field Strength and Voltage Values Corresponding to Each Component of the Drone-Mounted Robotic Arm Inspection System

| UAV Component |

Maximum Electric Field Intensity |

Voltage Value |

| Mechanical Arm |

4656/m |

3352V |

| Rotor |

Left Rotor |

2334V/m |

338V |

| Right Rotor |

2360V/m |

236V |

| Fuselage |

940V/m |

228V |

| Frame |

1337V/m |

700V |

2.3 Anti-Interference Capability Tests of the Drone-Mounted Robotic Arm in Transmission Line Maintenance

For the drone shielding performance test, the test equipment included a conductive-paint-coated drone and a multimeter. The conductive paint was uniformly sprayed onto the drone’s surface with a thickness not exceeding 0.05 mm. Under normal environmental conditions, the internal resistance between two points on the drone’s surface was measured; a value less than 1 Ω indicates compliance with the specified standard.

Image distortion test: When applying the drone-mounted robotic arm technology for line inspection, image distortion may occur due to factors such as the inherent accuracy of the gimbal camera lens and the quality of assembly processes. Such distortion causes discrepancies between the captured images and the actual scene, potentially impairing maintenance personnel’s ability to accurately identify faults or defects on UHV transmission lines.

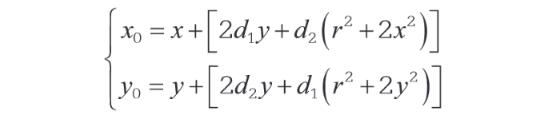

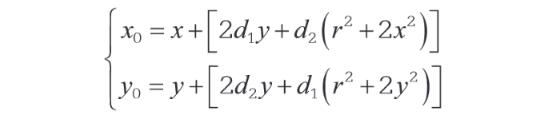

To address this issue, our technical team developed an image distortion correction model based on the distortion characteristics of the gimbal camera lens. This model is expressed by the following formula:

In the formula:

x,y are the original coordinates of a tangential distortion point in the imaging system;

x′,y′ are the new coordinates of the point after distortion correction;

p1,p2 are the tangential distortion parameters;

r is the radial distance from the image center.

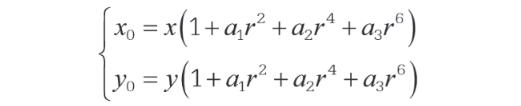

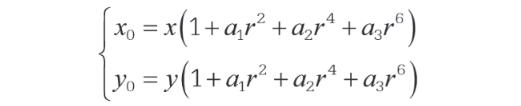

Camera lens distortion is primarily categorized into two types: tangential and radial distortion. Tangential distortion mainly arises because the lens elements and the camera’s image plane are not perfectly parallel. Radial distortion, on the other hand, occurs because light rays bend more significantly at positions farther from the optical center of the lens, resulting in distortion distributed along the radial direction of the lens. Radial distortion can be expressed by the following formula:

In the formula:

x,y are the original coordinates of a radially distorted point in the imaging system;

x′,y′ are the new coordinates of the point after distortion correction;

k1,k2,k3 are the radial distortion parameters;

r is the radial distance from the image center.

On this basis, our company proposes using Zhang’s calibration method to identify the radial distortion components that most significantly affect image formation, and to reconstruct the model parameters. This enables mutual mapping between object coordinates in a defined world coordinate system and pixel coordinates in the image plane, thereby completing the calibration of the gimbal camera. This approach effectively mitigates the impact of lens manufacturing tolerances and assembly processes on image accuracy, enhances image clarity, and ensures that high-definition images of ultra-high-voltage (UHV) transmission lines are transmitted back to the system in real time without delay. This provides maintenance personnel with reliable visual data for accurately assessing whether faults or defects exist on the lines.

In summary, the drone-mounted robotic arm inspection technology proposed in this paper fulfills current UHV transmission line maintenance requirements for low power consumption, long endurance, low cost, high payload capacity, and strong environmental perception. It overcomes key technical bottlenecks in replacing traditional manual inspection methods with drones, elevates the overall level of maintenance operations, and strengthens the safety and reliability of power transmission and supply.