Mwanzo

Gesi la SF6 linatumika kwa ukuaji katika mifumo ya umeme yenye kiwango cha juu na zaidi ya juu kutokana na ufanisi wake wa kukataa umeme, ufanisi wa kuzuia magazia, na ustawi wa kimikakia. Nguvu ya kukataa umeme na uwezo wa kuzuia magazia wa mifumo ya umeme huwasilishwa kwa ukunguaji wa gesi la SF6. Kupungua kiasi cha gesi la SF6 inaweza kupeleka kwa hatari mbili muhimu:

Zaidi hizi, upungufu wa gesi unaweza kusababisha maudhui ya maji kupanda, kuboresha sadaka ya maji katika gesi la SF6 na kuboresha uasi wa kukataa umeme. Kwa hivyo, kutambua kiasi cha gesi la SF6 ni muhimu kwa ajili ya usalama wa mifumo.

Relay ya ukunguaji wa gesi la SF6 (inayojulikana pia kama mtambuli wa ukunguaji, msimamizi, au mwanga) linapatikana kwenye mifumo ya umeme ambayo yameandaliwa na gesi la SF6 ili kushow kubadiliko kwa ukunguaji wa gesi ndani. Inachukua kubadiliko za viwango vya gesi ili kushow kubadiliko kwa ukunguaji, kunatuma ishara ya taarifa wakati ukunguaji unapopungua hadi kile ambacho kilichotengenezwa, na kuchukua hatua ya kuzuia matumizi ikiwa ukunguaji unapopungua zaidi. Tangu ufanisi wake unaelekea usalama wa mifumo, utaratibu wa kutathmini asilimia na uwiano wake unahitajika mara kwa mara.

1. Aina na Mfano wa Kazi ya Relays za Ukunguaji wa Gesi la SF6

1.1 Relays za Uchumi

Relays zinaweza kugawanyika kulingana na muundo katika aina ya bellows na aiana ya bourdon-tube, na kulingana na kazi katika na onyesha viwango na hapana. Mbadala wote hutumia malipo ya joto kwa ajili ya kutambua ukunguaji wa gesi.

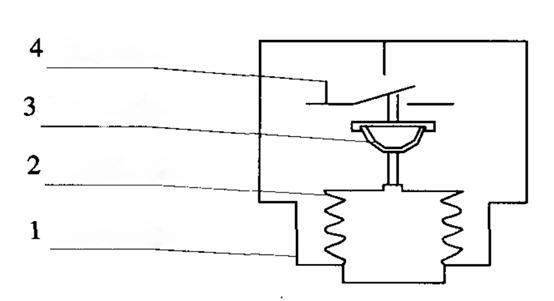

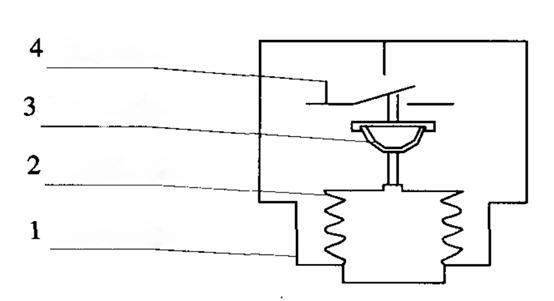

Kutumia mfano wa aiana ya bellows (angalia Ch. 1):

Chumba chenye gesi limetengeneza kwa viwango sawa na chumba chenye gesi kinachotambuliwa;

Bellows ya chuma imeunganishwa na chumba chenye gesi kinachotambuliwa;

Ikiwa kukosa gesi, viwango ndani ya bellows yanapopungua, kuanzia tofauti ya viwango inachomoa bellows. Hii inafanya mikono ya mikrosawa kwa njia ya mekaniiki, kutetea ishara ya taarifa au kuzuia matumizi.

Tangu chumba chenye gesi limetengeneza kuna katika mazingira sawa, mabadiliko ya joto yanavyofanya kila upande sawa, inafanya malipo ya joto yenyewe.

Ch. 1. Mfano wa Relay ya Ukunguaji wa Gesi la Uchumi

(Note: 4—mikrosawa; 3—strip ya bimetal; 2—bellows ya chuma; 1—chumba chenye gesi limetengeneza)

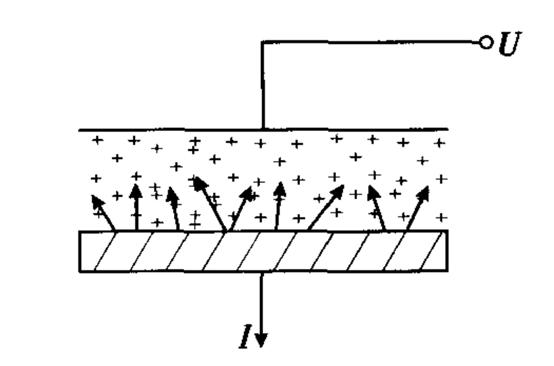

1.2 Relays za Digit

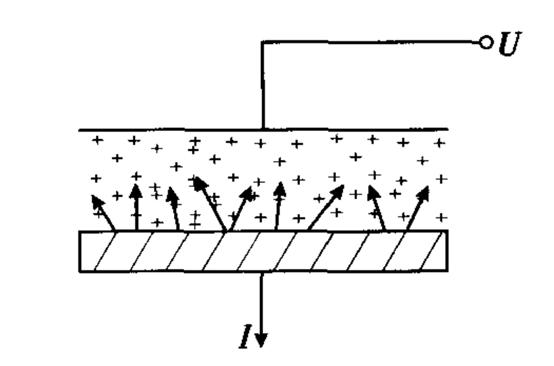

Relays hizi hujihusisha na ufanisi mkubwa wa atomi za SF6. Chombo chenye gesi chenye chanzo cha alpha particles huchomoka gesi, na kwa kutumia DC electric field, current ya ion inatumika. Hii ina uhusiano na ukunguaji wa gesi. Ikiwa ukunguaji upopungua, output current upopungua, kusaidia kutambua kwa wakati.

Faida za relays za digit ni:

Onyesha digital ya viwango, viwango sawa na 20°C, na joto la mifumo;

Uingizaji wa computer systems kwa ajili ya kutambua kwa wakati;

Uwezo wa kuchora curves za leakage, kusaidia maintenance ya hali;

Mstari mzima wa kutathmini bila kutumia rangi, na parameters zenye kurekebisha;

Output ya gas-refill alert na under-pressure lockout contact signals.

Ch. 2. Mfano wa Relay ya Ukunguaji wa Gesi la Digit

(Note: Alpha particles katika chombo chenye gesi chenye chanzo chenye chanzo cha alpha particles huchomoka gesi la SF6; electrons humtema kwenye anode, positive ions hurejea kwenye emitter, kutengeneza current ambayo hupanuliwa na kutumika)

2. Hitaji wa Kutathmini Relays za Ukunguaji kwenye Nchi

Relays za ukunguaji zinaweza kutathminwa kwenye nchi au katika lab. Ingawa kutathmini katika lab unategemea zaidi, ana hatari kadhaa:

Kurudisha kuhusu seal yoyote, kurudisha kwa wakati na kusema kwamba itakuwa rahisi;

Vifaa vinavyovimuilika kwa sababu ya safari;

Timelines za maintenance zinaweza kusababisha kutumia muda sana.

Kwa hivyo, kutathmini kwenye nchi inaweza kutumika ikiwa ni rahisi, ni rahisi na salama zaidi.

3. Vifaa Vinavyotumiwa kwa Kutathmini kwenye Nchi

Tangu mifumo ya umeme ya SF6 hayawezi kuteleka na mafuta au gesi mingine, vipimo tu vya SF6 vinaweza kutumiwa kama medium ya kutathmini. Kitu kingine ambacho kitu kipaumbele kinapaswa kuwa na:

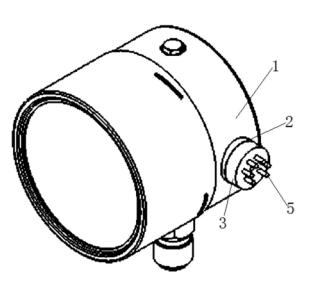

Hii article inainishia JMD-1A SF6 Gas Density Relay Calibration Unit, ambayo ina:

Cylinder ya SF6 na system ya pressure regulation;

Inafunga circuit ya gas ya mifumo wakati wa kutathmini, kutumia supply yake yenyewe;

Inaconvert measured values kwa standard pressure ya 20°C;

Inahitaji factory recalibration kila mwaka kuhakikisha accuracy;

Accuracy class 0.5, kufikia requirement ya "standard instrument error shall not exceed one-third of the tested instrument’s error" (tested relays are typically below class 1.5), fully satisfying on-site requirements.

4. Kutathmini Content for Gas Density Relays

4.1 Testing Standards and Frequency

According to GB50150-1991 and DL/T596-1996:

New equipment must undergo density relay testing before commissioning;

In-service equipment should be tested every 1–3 years, or after major maintenance or when necessary;

Action values must comply with manufacturer’s technical specifications;

Pressure gauge indication error and hysteresis must be within allowable limits for the specified accuracy class.

4.2 Test Items

Main test items include:

Alarm (gas refill) activation pressure;

Lockout activation pressure;

Lockout return pressure;

Alarm return pressure;

If equipped with a pressure gauge, its indication must also be tested.

Pressure gauge testing requirements:

At least 5 test points evenly distributed across the range;

Two full cycles of pressurization and depressurization;

Pressure applied slowly and steadily, with readings taken at each point;

The maximum indication error from the two cycles is taken as the final result.

Action value requirements:

Must comply with manufacturer’s specifications;

The difference between activation and return pressure should be less than 0.02 MPa;

All pressure values must be converted to standard values at 20°C;

Record ambient temperature, measured pressure, and converted 20°C pressure.

5. Connection Methods Between Density Relay and Equipment

There are four common connection types:

With Isolation Valve

A valve (FA) is installed between the relay and equipment. During testing, close FA, connect the test head, then open FB to begin testing.

With Check Valve

After removing the relay, the check valve automatically seals the equipment side, allowing direct connection of the test device to the external port.

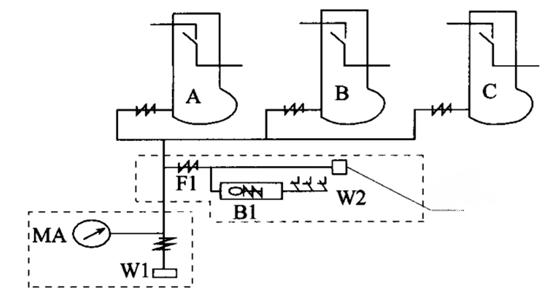

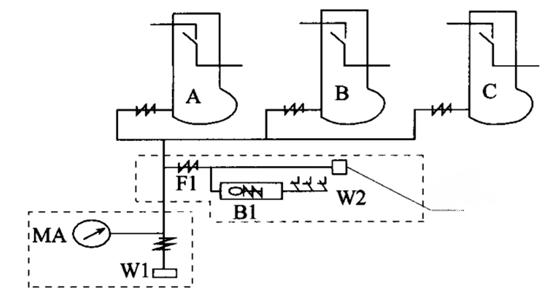

With Check Valve + Plunger Bolt (see Figure 3)

No disassembly required. Unscrew the plunger bolt at W2; the check valve F1 automatically isolates the gas path, allowing direct connection of the test head.

Figure 3. Schematic of Density Relay with Check Valve and Plunger Bolt

(Labels: B1—density relay; W1—gas charging port; W2—test port; MA—pressure gauge; F1—check valve)

Conclusion: The first three connection types allow on-site testing; the fourth does not.

6. Precautions for On-Site Calibration

Power-Off Operation: Testing must be conducted with the equipment de-energized. Disconnect control power and isolate alarm/lockout contacts at the terminal block to prevent unintended secondary circuit operation.

Confirm Connection Type: Connection structures vary among equipment. Confirm the type before disassembly to prevent misoperation and gas leakage.

Restore Isolation Valves: After testing, ensure all isolation valves are restored to their correct positions and verified.

Clean Connectors: Clean all piping connectors before and after testing. Flush with a small amount of SF6 gas if necessary to prevent contamination or moisture ingress.

Sealing Protection: Protect sealing surfaces, replace with new gaskets, and perform leak detection after reassembly.

Pressure Unit Conversion: The JMD-1A tester displays gauge pressure. If the relay uses absolute pressure (e.g., ABB LTB145D circuit breaker), convert units before comparison.

7. Conclusion

The SF6 gas density relay is a critical component ensuring the safe operation of SF6 electrical equipment. Its operational performance directly impacts system reliability. Therefore, regular on-site testing must be conducted in accordance with relevant regulations to ensure accuracy and reliability. During testing, strict adherence to prescribed test cycles, procedures, and precautions is essential to eliminate safety hazards and prevent erroneous conclusions.