Pagpahilom

Ang gas nga SF6 gikuhaan og dako sa paggamit isip insulating ug arc-quenching medium sa high-voltage ug extra-high-voltage electrical equipment tungod sa iyang excellent insulation, arc-extinguishing properties, ug chemical stability. Ang insulation strength ug arc-quenching capability sa electrical equipment depende sa density sa gas nga SF6. Ang pagbaba sa density sa gas nga SF6 mahimong magresulta sa duha ka pangunahon nga mga panganib:

Bis-an pa, ang pag-leakage sa gas kasagaran nagresulta sa pag-ingreso sa moisture, na nagsayop sa moisture content sa gas nga SF6 ug nagdugay pa sa pagpangababa sa insulation performance. Tungod niini, ang pag-monitor sa density sa gas nga SF6 importante para sa pag-ensure sa safe operation sa equipment.

Ang SF6 gas density relay (o mas nailhan isip density monitor, controller, o density gauge) gitukod sa SF6 electrical equipment aron mapakita ang mga pag-usab sa internal gas density. Gitukod kini aron mokonsider ang mga pag-usab sa pressure aron mapakita ang mga pag-usab sa density, mag-issue og alarm signal kon ang density mobaba ngadto sa pre-set alarm level, ug mog-lockout sa switching operations kon mobaba pa kini ngadto sa lockout level. Tungod kay ang iyang performance direkta makakaapekto sa safety sa equipment, importanti ang regular testing sa iyang reliability ug accuracy.

1. Mga Tipo ug Operating Principles sa SF6 Gas Density Relays

1.1 Mechanical Gas Density Relays

Ang mechanical relays makaklasihi batas sa structure isip bellows-type ug bourdon-tube-type, ug batas sa function isip yana naa'y pressure display ug wala. Ang tanang klase mitumong temperature compensation aron maponitor ang gas density.

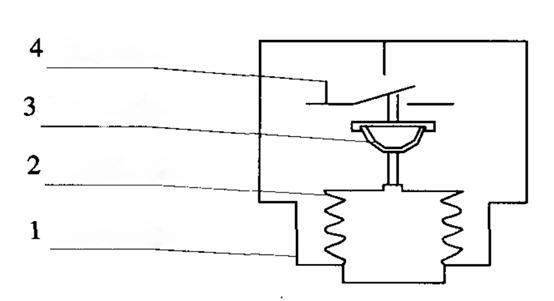

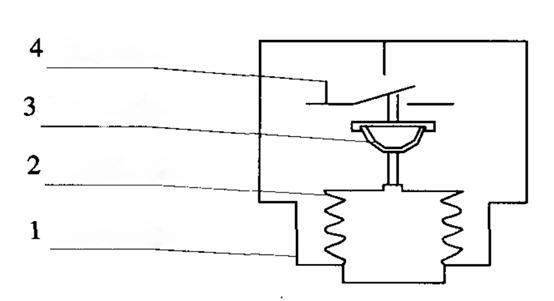

Tungod sa typical bellows-type isip ehempiyo (tan-awon ang Figure 1):

Ang pre-charged chamber gibuno sa gas nga SF6 sa parehas nga pressure sa monitored chamber;

Ang metal bellows gigikot sa monitored chamber;

Kon may leak, ang internal pressure sa bellows mobaba, na mosiguro og pressure differential nga mocompres ang bellows. Kini nga movement mogtrigger og microswitch pinaagi sa mechanical linkage, triggering an alarm or lockout signal.

Tungod kay ang pre-charged chamber nasa parehas nga environment, ang mga pag-usab sa temperature sama-sama nga makaapekto sa duha ka panig, naghimo og automatic temperature compensation.

Figure 1. Principle of Mechanical Gas Density Relay

(Note: 4—microswitch; 3—bimetal strip; 2—metal bellows; 1—pre-charged chamber)

1.2 Digital Gas Density Relays

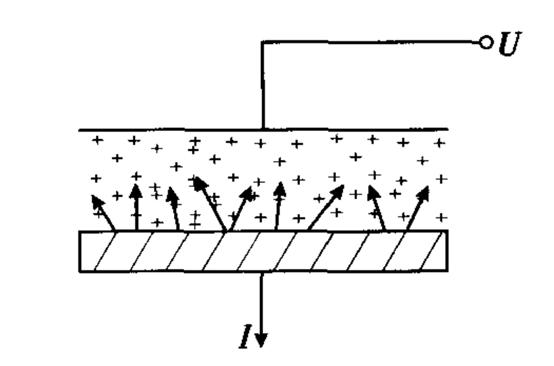

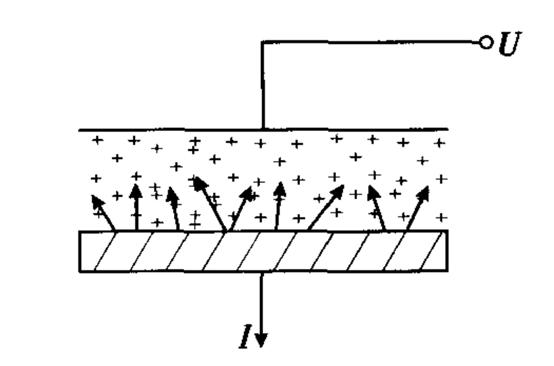

Kini nga mga relays gigamit ang strong electronegativity sa molecules sa SF6. Ang alpha particle source sa ionization chamber mo-ionize ang gas, ug sa applied DC electric field, maform ang ion current. Kini nga current proportional sa gas density. Kon mobaba ang density, ang output current mobaba, naghatag og real-time monitoring.

Mga Advantages sa digital density relays kinahanglan:

Direct digital display sa pressure, equivalent pressure sa 20°C, ug equipment temperature;

Compatibility sa computer systems para sa online monitoring;

Ability sa pagplot og leakage trend curves, supporting condition-based maintenance;

Full-scale measurement wala man sa range switching, na field-adjustable parameters;

Output sa gas-refill alarm ug under-pressure lockout contact signals.

Figure 2. Principle of Digital Gas Density Relay

(Note: Alpha particles in the ionization chamber ionize SF6 gas; electrons migrate to the anode, positive ions return to the emitter, generating a current that is amplified and output)

2. Necessity of On-Site Testing of Density Relays

Ang density relays mahimo mogtest on-site o sa laboratory. Bis-an pa, ang laboratory testing offer higher precision, pero adunay daghang drawbacks:

Ang dismantling mogbreak sa original seal, making reassembly ug sealing difficult to guarantee;

Ang precision instruments mahimo moglose calibration tungod sa transportation shocks;

Tight maintenance schedules mahimo mogmake ang disassembly ug reassembly time-consuming.

Tungod niini, ang on-site testing recommended kon feasible, tungod kay mas efficient ug safer.

3. Instruments Used for On-Site Testing

Tungod kay ang SF6 electrical equipment dili mogamo sa oil o uban pang mga gases, only SF6 gas can be used as the test medium. Ang ideal nga calibration device kinahanglan adunay:

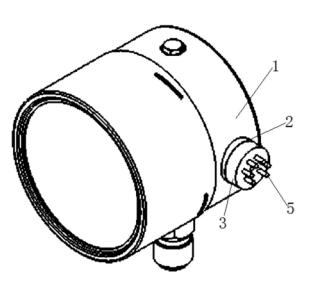

Kini nga artikulo introduce ang JMD-1A SF6 Gas Density Relay Calibration Unit, nga adunay features:

Built-in SF6 cylinder ug pressure regulation system;

Isolates ang equipment’s gas circuit sa testing, using its own gas supply;

Automatically converts measured values to standard pressure sa 20°C;

Requires annual factory recalibration aron ensure accuracy;

Accuracy class 0.5, meeting the requirement that “standard instrument error shall not exceed one-third of the tested instrument’s error” (tested relays are typically below class 1.5), fully satisfying on-site requirements.

4. Testing Content for Gas Density Relays

4.1 Testing Standards and Frequency

Sumala sa GB50150-1991 ug DL/T596-1996:

Ang bag-o nga equipment kinahanglan mogdensity relay testing bago imong commissioning;

Ang in-service equipment kinahanglan mogtest every 1–3 years, o human sa major maintenance o kon necessary;

Action values must comply with manufacturer’s technical specifications;

Pressure gauge indication error ug hysteresis must be within allowable limits for the specified accuracy class.

4.2 Test Items

Main test items include:

Alarm (gas refill) activation pressure;

Lockout activation pressure;

Lockout return pressure;

Alarm return pressure;

If equipped with a pressure gauge, its indication must also be tested.

Pressure gauge testing requirements:

At least 5 test points evenly distributed across the range;

Two full cycles of pressurization and depressurization;

Pressure applied slowly and steadily, with readings taken at each point;

The maximum indication error from the two cycles is taken as the final result.

Action value requirements:

Must comply with manufacturer’s specifications;

The difference between activation and return pressure should be less than 0.02 MPa;

All pressure values must be converted to standard values at 20°C;

Record ambient temperature, measured pressure, and converted 20°C pressure.

5. Connection Methods Between Density Relay and Equipment

Adunay apat ka common connection types:

With Isolation Valve

A valve (FA) is installed between the relay and equipment. During testing, close FA, connect the test head, then open FB to begin testing.

With Check Valve

After removing the relay, the check valve automatically seals the equipment side, allowing direct connection of the test device to the external port.

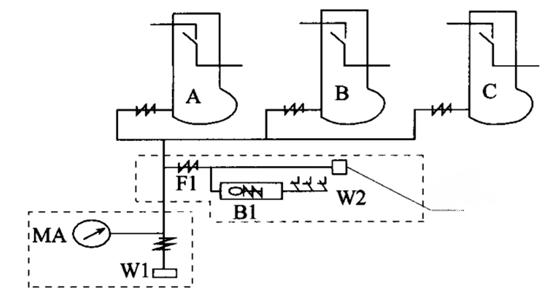

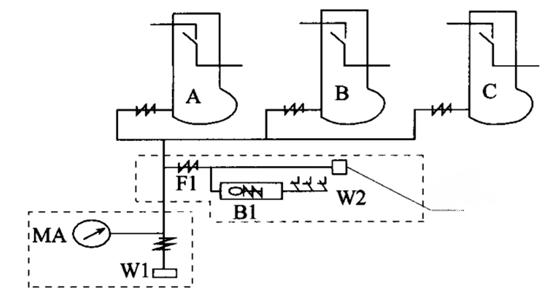

With Check Valve + Plunger Bolt (see Figure 3)

No disassembly required. Unscrew the plunger bolt at W2; the check valve F1 automatically isolates the gas path, allowing direct connection of the test head.

Figure 3. Schematic of Density Relay with Check Valve and Plunger Bolt

(Labels: B1—density relay; W1—gas charging port; W2—test port; MA—pressure gauge; F1—check valve)

Conclusion: The first three connection types allow on-site testing; the fourth does not.

6. Precautions for On-Site Calibration

Power-Off Operation: Testing must be conducted with the equipment de-energized. Disconnect control power and isolate alarm/lockout contacts at the terminal block to prevent unintended secondary circuit operation.

Confirm Connection Type: Connection structures vary among equipment. Confirm the type before disassembly to prevent misoperation and gas leakage.

Restore Isolation Valves: After testing, ensure all isolation valves are restored to their correct positions and verified.

Clean Connectors: Clean all piping connectors before and after testing. Flush with a small amount of SF6 gas if necessary to prevent contamination or moisture ingress.

Sealing Protection: Protect sealing surfaces, replace with new gaskets, and perform leak detection after reassembly.

Pressure Unit Conversion: The JMD-1A tester displays gauge pressure. If the relay uses absolute pressure (e.g., ABB LTB145D circuit breaker), convert units before comparison.

7. Conclusion

The SF6 gas density relay is a critical component ensuring the safe operation of SF6 electrical equipment. Its operational performance directly impacts system reliability. Therefore, regular on-site testing must be conducted in accordance with relevant regulations to ensure accuracy and reliability. During testing, strict adherence to prescribed test cycles, procedures, and precautions is essential to eliminate safety hazards and prevent erroneous conclusions.