Ujenzi wa stesheni ya vovu 110kV yetu ulianzishwa na kutumika Februari 2005. Mfumo wa 110kV unatumia ZF4-126\1250-31.5 aina ya SF6 GIS (Gas-Insulated Switchgear) kutoka Beijing Switchgear Factory, unayejumuisha saba bai na 29 magari la SF6, ikiwa ni tano magari la circuit breaker. Kila magari la circuit breaker linalikuwa na kirenga cha ukungu wa SF6. Vitengo yetu vilivyotumiwa ni aina ya MTK-1 modeli ya kirenga chenye mafuta kutoka Shanghai Xinyuan Instrument Factory. Kirenga haya yanapatikana katika viwango vya -0.1 hadi 0.5 MPa na -0.1 hadi 0.9 MPa, na seti moja au mbili za mizigo. Yanatumia Bourdon tube na strip bimetalic kama viwango. Wakati ukuaji wa gas ukaribu kiwango fulani, mizigo yasiyo ya kuonyesha au kuzuia yanatengeneza ishara za amri, kusaidia matumizi tofauti ya usalama. Tarehe 17 Oktoba 2015, wakati wa utambuzi wa kawaida, wafanyakazi wa umma waligundua ukungu wa gas tofauti katika kirenga cha magari 11, 19, na 22. Tukio hili lilionyesha hatari za kazi zinazopatikana kutokana na ukungu wa mafuta katika kirenga cha ukungu wa SF6.

1. Hatari za Ukungu wa Mafuta katika Kirenga cha Ukungu wa SF6

Ukungu wa mafuta katika kirenga cha ukungu unatengeneza hatari nyingi kwa vyombo vya umeme:

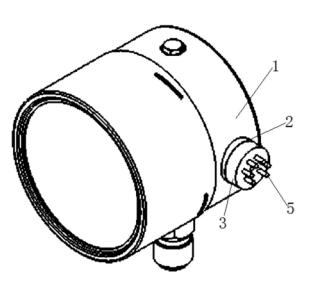

1.1 Mara tu mafuta ya kuzuia ukungu ndani ya kirenga chenye mafuta yakawa kamili, uwezo wake wa kuzuia ukungu unapungua sana. Ikiwa circuit breaker anafanya kazi (kufungwa au kufunguka) kwenye hali hiyo, inaweza kuunda matatizo kama vile kutofungwa, ukurasa mkubwa kutoka kiwango cha kimataifa, kujaza pointer, na matatizo mengine (angalia Picha 1: Kirenga chenye mafuta).

1.2 Kwa sababu ya sifa maalum za mizigo katika kirenga cha ukungu wa SF6—nguvu ndogo ya mizigo na muda mrefu wa kutumika—mizigo yanaweza kucheleka kwa muda, kusababisha mizigo yasiyo ya kuonyesha au kuzuia. Katika kirenga cha ukungu wa SF6 ambacho yametoka mafuta yake, mizigo ya mafuta ya mizigo yanaweza kupewa mafuta na kuunda mizigo yasiyo ya kuonyesha. Kwenye mchakato wa kutumika, imeonekana kuwa 3% ya mizigo ya kirenga cha ukungu wa SF6 hayawezi kufanya kazi vizuri, kwa sababu ya kukosa mafuta ya kuzuia ukungu. Ikiwa pointer wa kirenga cha ukungu wa SF6 anakosa kuonyesha, au ikiwa mizigo hayawezi kufanya kazi vizuri, usalama na uhakika wa mtandao wa umeme huathiriwa kwa moja kwa moja.

2. Sababu za Ukungu wa Mafuta katika Kirenga cha Ukungu wa SF6

Sababu muhimu ya ukungu wa mafuta katika kirenga cha ukungu wa SF6 ni kushindwa kwa seal katika eneo la mzunguko wa terminal base na pamoja, na seal kati ya glass na case. Hii kushindwa kwa seal ni kwa sababu ya uzee wa vitanga. Seal ya mafuta ya kuzuia ukungu katika kirenga cha ukungu wa SF6 mara nyingi yanajumuisha nitrile rubber (NBR). NBR ni elastomer moja ya kijamii kinachojumuisha butadiene, acrylonitrile, na emulsion, na mfumo wa molekuli unaeza kusaidia ukungu wa gas. Kiwango cha acrylonitrile kinahusu sifa za NBR: kiwango cha juu cha acrylonitrile kinongeza uzito wa mafuta, solvent, na dharura, na nguvu, ngumu, uripoti, na moto, lakini kinapunguza uripoti wa baridi, nguvu, na kongwa. Viwango vinavyohusu uzee wa vitanga vya NBR vinaweza kugundulika kwa viwango vya ndani na nje.

2.1 Viwango vya Ndani

2.1.1 Mfumo wa Molekuli wa Nitrile Rubber

NBR si mifupa ya hydrocarbon yenye uzito kamili; mitengo yake miwili yana bondi zisizozingati. Kwenye viwango vya nje, oxygen hunyanyanyuka kwenye bondi hizo, kusababisha ufunguo. Ufunguo huu unabadilika kwa rubbere peroxides, kusababisha kuvunjika kwa mitengo miwili. Mara nyingi, viwango vidogo vya kuonyesha kunagunduliwa, kusaidia kujenga mitengo miwili. Hii kinongeza ukungu wa mitengo miwili, kusababisha rubbere kuwa ngumu na ngumu. Idadi ya bondi zisizozingati huingilia kasi ya uzee.

2.1.2 Vitenganishi vya Rubber

Chaguo la vulcanizing agents wakati wa kutengeneza rubbere ni muhimu. Ongezeko la kiwango cha sulfur cross-linking kinongeza mchakato wa uzee wa rubbere.

2.2 Viwango vya Nje

2.2.1 Oxygen ni sababu muhimu ya uzee wa rubbere. Molekuli za oxygen huchanganya na kurejeshiwa. Sababu nyingine ni ozone, ambayo ni reaktive sana. Ozone hujitokeza kwenye bondi zisizozingati katika mitengo miwili, kusababisha ozonides zinazobadilika na kuvunjika mitengo miwili. Kwa sababu ya seal ya mafuta ya kuzuia ukungu kuwa na maji, na oxygen/ozone kunaweza kuleta maji, wanaweza kushiriki katika mchakato wa uzee wa maji.

2.2.2 Nyuzi huchonge mchakato wa oxidation. Mara nyingi, ongezeko la 10°C la moto linongeza mchakato wa oxidation. Pia, moto huchonge mchakato wa mitengo miwili na vitenganishi, kusababisha viwango vidogo vya rubbere kuhisi, kusababisha upunguaji wa nguvu ya rubbere na kurejelea muda wake wa kutumika.

2.2.3 Ulezi wa Mchakato. Kwenye mchakato wa muda, rubbere hupata stress, kusababisha mchakato wa mechanical-oxidative. Pamoja na moto, hii huchonge mchakato wa oxidation. Kwenye muda wa kutumika, rubbere hupungua nguvu, kusababisha uzee wa mchakato. Rubbere iliyopungua seal hazitawezi kuzuia ukungu, kusababisha ukungu wa mafuta.

2.2.4 Kukosa Compression ya Awali ya Seal. Seal za rubbere hutumia deformation wakati wa kutengeneza ili kutengeneza fit sahihi kati ya seal na surface ya sealing, kusababisha ukungu. Kukosa compression ya awali ni sababu muhimu ya ukungu. Matatizo ya ubuni—kama kutumia seal na cross-section ndogo, kutumia groove ya kutengeneza inayotaka, au kutengeneza kitufe cha case kwa kutumia akili—yanaweza kutoa compression ya awali. Kwenye ustawi, kutengeneza kitufe cha relay case kwa kutumia akili ni vigumu, kusababisha kukosa compression ya sahihi. Pia, rubbere ana cold-shrink coefficient zaidi ya asili ya metal. Kwenye baridi, cross-section ya seal ya rubbere hupungua na material huwa ngumu, hupunguza compression.

2.2.5 Compression Rate ya Juu. Kusaidia performance ya sealing, O-rings za rubbere yanahitaji compression rate fulani. Lakini, hii haiwezi kongezwa kwa busara. Compression ya juu inaweza kuchanganya permanent wakati wa kutengeneza, kusababisha stress equivalent kwa seal, kusababisha failure ya material, kurejelea muda wake wa kutumika, na kumwisho ukungu wa mafuta. Ten tena, kutengeneza kitufe cha relay cover kwa kutumia akili mara nyingi huchanganya compression kwa sababu ya kukosa position sahihi.

3. Aina ya ZDM-Type Oil-Free, Anti-Seismic Density Relay

3.1 Shock Absorption na Operating Principle ya ZDM-Type Relay

Aina ya ZDM-type oil-free, anti-seismic density relay (angalia Picha 2) huchukua shock absorption kwa kutumia pad ya kuzuia ukungu kati ya connector na case. Pad hii huchukua vibrations zinazotengenezwa wakati wa kutumia circuit breaker. Impact na vibrations kutoka kwenye switch operation huchukua kwa connector hadi pad ya kuzuia ukungu, ambayo huchukua energy hii kabla ya kuchukua kwenye case ya relay. Kwa sababu ya buffering effect, vibrational na impact energy inayowasili kwenye case ya relay inapungua sana, kusababisha performance nzuri ya kuzuia ukungu.

Pia, operating principle ya ZDM-type relay hutumia spring tube kama elastic element, na temperature compensation strip inayosaidia pressure na temperature variations ili kurejelea changes za ukungu wa SF6 gas. Output contacts hutumia micro-switch mechanism. Control ya micro-switch signal hutengenezwa kwa temperature compensation strip na spring tube, pamoja na buffering effect ya pad ya kuzuia ukungu. Design hii huchukua false signals kutokana na vibrations, kusaidia system kufanya kazi vizuri na vizuri. Inongeza performance nzuri ya kuzuia ukungu ya pointer-type density relay, kusababisha device ya performance nzuri.

3.2 Sifa za Aina ya ZDM-Type Oil-Free, Anti-Seismic Density Relay

3.2.1 Enclosure kamili ya stainless steel na sifa nzuri za water-proof na corrosion-resistant, na aina ya kuvutia;

3.2.2 Accuracy: 1.0 class (katika 20°C), 2.5 class (katika -30°C hadi 60°C);

3.2.3 Operating ambient temperature: -30°C hadi +60°C; operating ambient humidity: ≤95% RH;

3.2.4 Anti-seismic performance: 20 m/s²; anti-impact performance: 50g, 11ms; sealing performance: ≤10⁻⁸ mbar·L/s;

3.2.5 Contact rating: AC/DC 250V, 1000VA/500W;

3.2.6 Enclosure protection rating: IP65;

3.2.7 Oil-free design, resistant to vibration and impact, and permanently leak-proof;

3.2.8 Stable and highly consistent performance of the temperature-sensing element.

Sifa hizi zinashiriki kuwa aina ya ZDM-type oil-free, anti-seismic density relay imeondoka tatizo la ukungu wa mafuta. Kwa kutumia ubuni mzuri na pads za kuzuia ukungu badala ya mafuta ya kuzuia ukungu, inachukua ukungu wa mafuta kwenye mchakato.

4. Mwisho

Sababu muhimu za ukungu wa mafuta katika kirenga cha ukungu zinatokana na matatizo ya kutengeneza, kutumia, na kutunza. Wakati ukungu wa vyombo vya umeme upungue, sio tu insulation strength ipungue, lakini interrupting capacity ya circuit breaker pia ipungue. Kwa hivyo, kutumia mara kwa mara kirenga cha ukungu cha mafuta kunaweza kuwa muhimu. Kusaidia kazi salama na vizuri, inaweza kutumia aina ya ZDM-type oil-free, anti-seismic density relay au devices sawa kwenye matumizi ya baadaye.