Substatio 110kV in nostra fabrica fuit constructa et in operationem tradita Februarii 2005. Systema 110kV utitur ZF4-126\1250-31.5 typus SF6 GIS (Gas-Insulated Switchgear) ex Beijing Switchgear Factory, constans septem bayis et 29 SF6 gas compartmentibus, inter quos quinque sunt circuit breaker compartmenta. Unumquodque circuit breaker compartmentum est instructum SF6 gas density relais. In nostra fabrica MTK-1 modello oleo impleta density relais a Shanghai Xinyuan Instrument Factory usitata est. Haec relais disponuntur duobus pressionis ambitibus: -0.1 ad 0.5 MPa et -0.1 ad 0.9 MPa, cum uno aut duobus contactorum setibus. Utilizant tubum Bourdon et bimetallic strip ut sensibilia elementa. Cum gas effluat ad certum gradum, electrica contacta alarum vel lockout signa trigger, permittentes varias functiones protectionis. Die 17 Octobris 2015, in inspectione ordinaria, electrici de officio varia gradus effluxus gas in density relais pro compartmentis 11, 19, et 22 detegerunt. Hoc incidentium operativum periculum a oleo effluxu in SF6 density relais ostendit.

1. Pericula Olei Effluxus in SF6 Density Relais

Olei effluxus in density relais significat damnum ad apparatum electricum:

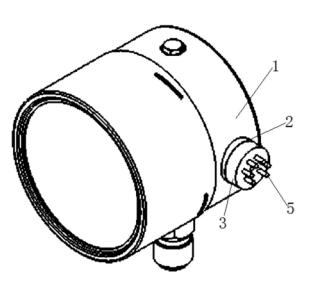

1.1 Dum anti-seismicum oleum in density relais totaliter amittitur, eius capabilitas absorptiva tremoris valde diminuitur. Si circuitus interruptor operatur (aperit vel claudit) sub talibus conditionibus, potest ad contactum defectum, excessivam deviationem a standardibus valoribus, pointer obstructionem, et alia mala ducere (vide Figura 1: Oleo impleta density relais).

1.2 Propter characteristica specifica contactorum in SF6 density relais—parvam vim contactus et longam operationem temporis—contactus oxidari possunt tempore, ad malum vel interrupsum contactus ducens. In SF6 density relais quae oleum totaliter amiserunt, magnetica assistentia electrica contacta aeris exponebantur, promovendo oxidationem et pulvis accumulationem, quae facile ad malum contactus in punctis contactus ducit. In operatione observatum est 3% SF6 density relais contactorum non efficaciter conducta, principaliter propter insufficiens anti-seismicum oleum. Si pointer SF6 density relais obstructus est, vel si contactus deficiunt vel non posse recte conducere, directe tuta et fiducia rete electricum minantur.

2. Causae Olei Effluxus in SF6 Density Relais

Principale causa olei effluxus in SF6 density relais est fallacia sigillorum in duobus locis: iunctura inter terminalem basim et superficiem, et sigillum inter vitrum et casum. Haec sigillorum fallacia principaliter est propter senectutem anularum sigillatorum. Anti-seismicum oleum sigilla in SF6 density relais saepius ex nitrilo gummi (NBR) facta sunt. NBR est copolymer synteticus elastomer compositus ex butadieno, acrylonitrilo, et emulsione, cum structura moleculari habente catenam carbonii insaturam. Contentus acrylonitrili directe affectat proprietates NBR: maior contentus acrylonitrili augeat olei, solventis, et chemicae resistentiam, simul cum fortitudine, duretate, wear resistance, et calori resistencia, sed minuit flexibilitatem frigidi, elasticitatem, et augeat impermeabilitatem gas. Factores afficientes senectutem NBR sigillorum categorizari possunt in internos et externos factores.

2.1 Factores Interni

2.1.1 Molecular Structure of Nitrile Rubber

NBR non est saturatum hydrocarbonum rubber; suas polymer catenas continet insaturatos duplex vincula. Sub variis externis influentiis, oxygenium reagat in his duplex vinculis, formando oxides. Haec oxides ulterius decomponuntur in rubber peroxides, ad molecular chain scission ducens. Simul, parva quantitas activorum grouporum generatur, promotionem cross-linking rubber molecule faciens. Hoc significanter augeat cross-linking densitatem, faciens rubber fragilis et durus. Numerus duplex vinculorum directe influet in velocitatem senectutis.

2.1.2 Rubber Compounding Agents

Selectio vulcanizing agentum in rubber manufactura critica est. Aumentum sulfur cross-linking concentration accelerat processum senectutis rubber.

2.2 Factores Externi

2.2.1 Oxygenium est prima causa rubber senectutis. Oxygenium moleculae causant chain scission et re-cross-linking. Alius factor est ozon, qui est valde reactivus. Ozon attacat duplex vincula in rubber moleculis, formando ozonides quae decomponuntur et rumpunt polymer catenas. Quia anti-seismicum oleum sigillum est in directo contactu cum aere, et oxygenium/ozon potest dissolveri in oleo, participent in senectutis reactionibus intra oleum.

2.2.2 Thermal Energy accelerationem oxidationis rate. Usualiter, 10°C incrementum temperature duplicat oxidationis rate. Praeterea, calor accelerationem reactionum inter rubber catenas et compounding agentes facit, causans volatiles componentes in rubber evanescere, significanter degradantes rubber performance et breviando eius servitium vitae.

2.2.3 Mechanical Fatigue. Sub sustinata stress, rubber subit strain, ad mechanical-oxidative effectus ducens. Combinatus cum thermal energy, hanc accelerationem oxidationis. Super servitium vitae, rubber paulatim amittit elasticitatem, ad mechanical senectutem ducens. Aged rubber sigilla amittunt suam sigillandi capability, resultante olei effluxu.

2.2.4 Insufficient Initial Compression of the Seal. Rubber sigilla reliantur super deformationem in installatione ad creandum strictum fit inter sigillum et sigillandi superficiem, praeventum effluxum. Insufficient initial compression est maxime effluxum causare. Design issues—sicut selectio sigilli cum parvo sectione transversa, usus oversized installation groove, vel improper tightening case cover in installatione—omnes possunt resultare in insufficient initial compression. In praxi, tightening relay case cover saepius fit per sensum, faciens difficile optimam positionem assequi, sic ad insufficient compression ducens. Praeterea, rubber habet cold-shrink coefficient plus decies maiorem quam metal. Ad frigido, rubber sigillum section transversa contracta et material induratus, amplius reducens compressionem.

2.2.5 Excessive Compression Rate. Ut sigillandi performance assequatur, rubber O-rings requirent certum compressionem rate. Sed hoc non potest cæcare augeat. Excessiva compressio potest permanentem deformationem in installatione causare, generans altam equivalentem stress in sigillo, ad material failure ducens, breviando servitium vitae, et ultime ad olei effluxum. Iterum, praxis tightening relay cover per sensum saepius ad excessivam compressionem ducit propter difficultatem in correctam positionem assequendi.

3. ZDM-Type Oil-Free, Anti-Seismic Density Relay

3.1 Shock Absorption and Operating Principle of the ZDM-Type Relay

ZDM-type oil-free, anti-seismic density relay (vide Figura 2) shock absorption assequit incorporando shock-absorbing pad inter connector et casum. Hoc pad buffer vibrations generatas durante circuitus interruptor operatione. Impactus et vibration ab switch operatione transmittuntur per connector ad shock-absorbing pad, quod tum dampens energiam ante eam transmittendo ad relay casum. Propter hanc buffering effect, vibrational et impactus energy ad relay casum valde minuitur, resultante in excellenti anti-seismic performance.

Praeterea, operating principle ZDM-type relay dependet a spring tube ut elastic element, cum temperature compensation strip corrigens pro pressure et temperature variationes ad reflectendum changes in SF6 gas density. Output contacts utuntur micro-switch mechanism. Control micro-switch signal perficitur per temperature compensation strip et spring tube, combinata cum buffering effect shock-absorbing pad. Hoc design falsa signa propter vibrationem prohibet, assecurans reliable et effective system operation. Significanter augeat anti-seismic performance pointer-type density relay, faciens eum high-performance device.

3.2 Features of the ZDM-Type Oil-Free, Anti-Seismic Density Relay

3.2.1 Totus stainless steel enclosure cum excellentibus waterproof et corrosion-resistant proprietatibus, et ornato aspectu;

3.2.2 Accurate: 1.0 class (ad 20°C), 2.5 class (ad -30°C to 60°C);

3.2.3 Operating ambient temperature: -30°C to +60°C; operating ambient humidity: ≤95% RH;

3.2.4 Anti-seismic performance: 20 m/s²; anti-impact performance: 50g, 11ms; sealing performance: ≤10⁻⁸ mbar·L/s;

3.2.5 Contact rating: AC/DC 250V, 1000VA/500W;

3.2.6 Enclosure protection rating: IP65;

3.2.7 Oil-free design, resistant to vibration and impact, and permanently leak-proof;

3.2.8 Stable and highly consistent performance of the temperature-sensing element.

Haec features demonstrant ZDM-type oil-free, anti-seismic density relay problem olei effluxus totaliter eliminat. Utilizando unicum structural design et shock-absorbing pads vice anti-seismic oil, fundamentaliter olei effluxum in operatione prohibet.

4. Conclusion

Principales causae olei effluxus in density relais originantur ex manufactura, operatione, et maintenance issue. Quando equipment density diminuit, non solum dielectric insulation strength minuitur, sed etiam circuitus interruptor interrupting capacity compromittitur. Itaque, opportuna replacement olei effluxus density relais essenti est. Ut assequatur safe et reliable operation, recommendatur uti ZDM-type oil-free, anti-seismic density relais vel similares devices in futuris applicationibus.