I. Background ng Problema

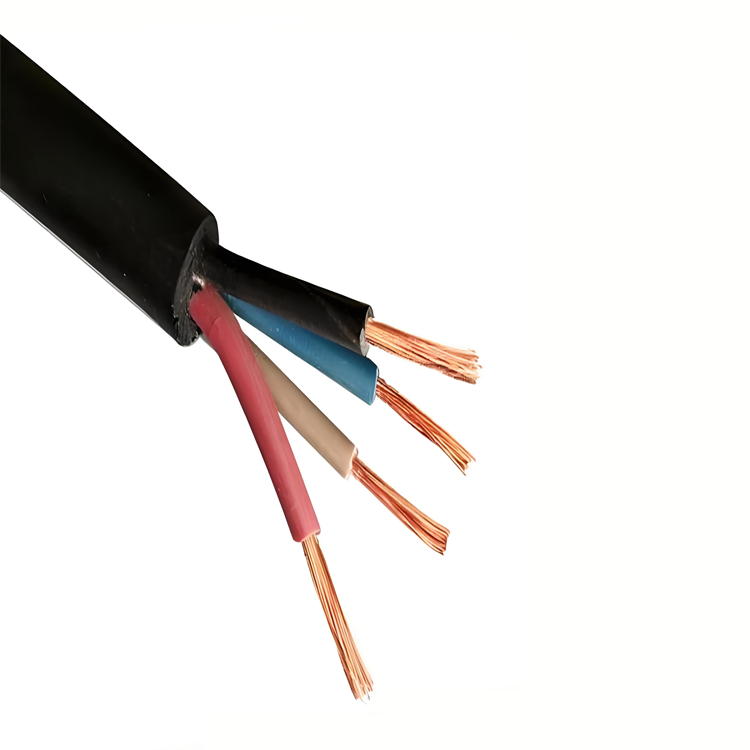

Ang mga kable ng elektrisidad ay ang pangunahing medium ng paghahatid ng sistema ng enerhiya. Ang kalidad ng kanilang pagganap ay direktang nagpapasya sa kabuuang estabilidad ng suplay ng enerhiya, seguridad ng operasyon, haba ng buhay ng mga aparato, at kakayahang maiwasan ang mga aksidente tulad ng sunog. Ang mga hindi naaangkop na kable ay nagdudulot ng serye ng malubhang problema, kabilang ang pagtaas ng resistansiya, labis na paglalason, pagkasira ng insulasyon, taas na panganib ng sunog, at paglabas ng signal interference. Kaya, mahalagang itatag ang isang siyentipiko, maigting, at komprehensibong sistema ng kontrol ng kalidad at pagsusuri na sumasaklaw mula sa materyales ng sangkap hanggang sa tapos na produkto.

II. Layunin ng Pamamaraan

- Pagtitiyak ng Pinagmulan: Siguruhing lahat ng materyales na ginagamit sa produksyon ng kable ay sumasang-ayon sa pinakamataas na pambansang at industriyal na pamantayan (hal., GB/T 3956, GB/T 12706, GB/T 19666, etc.).

- Kontrol sa Proseso: Epektibong monitorehin ang mga pangunahing parametro ng proseso at kalidad ng mga intermediate stages sa panahon ng produksyon.

- Reliabilidad ng Produkto: Siguruhing lahat ng pangunahing indikador ng pagganap ng tapos na kable - kasama ang elektrikal, pisikal & mekanikal, at pagganap sa sunog - ay sumasang-ayon o lumalampas sa mga requirement ng disenyo at kontrata.

- Pamamahala ng Panganib: Matukoy ang potensyal na kaputulan sa pamamagitan ng sistemang pagsusuri upang maiwasan ang pagpasok ng mga di naaangkop na produkto sa merkado at mapabuti ang panganib sa paggamit.

- Traceability: Itatag ang buong sistema ng tala ng pagsusuri ng kalidad upang maisakatuparan ang traceability ng mga batch ng pangunahing materyales at resulta ng pagsusuri ng produkto.

III. Pangunahing Solusyon: Kontrol at Pagsusuri ng Kalidad ng Kable ng Elektrisidad

(A) Kontrol at Pagsusuri ng Kalidad ng Materyales ng Sangkap (Kontrol ng Pinagmulan)

- 1. Pagqualify at Pagsusuri ng Supplier:

- Piliin ang mga supplier na may maigting na Sistema ng Pamamahala ng Kalidad (hal., sertipikasyon ng ISO 9001), matatag na kakayahan ng supply, at mabuting reputasyon sa industriya.

- Gumawa ng regular na random sampling inspection o verification ng third-party sa mga materyales ng supplier.

- 2. Pagsusuri ng Pangunahing Materyales ng Sangkap:

- Materyales ng Conductor (Copper/Aluminum Rod/Wire):

- Mga Item ng Pagsusuri: Analisis ng kemikal na komposisyon (content ng copper, impurity elements), mekanikal na katangian (tensile strength, elongation, repeated bending), measurement ng resistivity (sa 20°C).

- Standard Reference: GB/T 3953 (Round Copper Wire for Electrical Purposes), GB/T 3954 (Aluminum Rods for Electrical Purposes), GB/T 3956 (Conductors of Insulated Cables), etc.

- Mga Paraan ng Pagsusuri: Kemikal na analyzer (hal., spectrometer), tensile testing machine, Wheatstone bridge, o precision resistance meter.

- Insulation at Sheath Materials (PVC, XLPE, PE, LSZH, etc.):

- Mga Item ng Pagsusuri:

- Pisikal na Katangian: Itsura, density, uniformity ng thickness, tensile strength & elongation sa break, paghahambing ng performance bago/pagkatapos ng aging.

- Elektrikal na Katangian: Volume/surface resistivity.

- Thermal na Katangian: Heat deformation, hot set test (para sa XLPE), low-temperature impact/bend test.

- Pagganap sa Sunog (para sa LSZH/Flame Retardant Materials): Oxygen index, smoke density, acid gas content, halogen content (para sa halogen-free requirement).

- Standard Reference: GB/T 8815 (Unplasticized Polyvinyl Chloride Compounds), GB/T 15065 (Crosslinked Polyethylene Insulation Compounds), GB/T 18380 (Tests on Electric Cables Under Fire Conditions - Single Flame Test), GB/T 17651 (Measurement of Smoke Density), GB/T 17650 (Halogen-free, Low-smoke Materials and Products), at iba pang applicable standards.

- Mga Paraan ng Pagsusuri: Universal material testing machine, aging oven, resistivity tester, hot set test device, oxygen index analyzer, smoke density chamber, kemikal na analyzer.

- Shielding Material (Copper Tape/Wire): Thickness, resistance, coverage rate.

- Filling/Bedding Materials: Water resistance (kung applicable), mechanical strength, compatibility.

- 3. Mga Requirement ng Pagsusuri:

- Lahat ng papasok na materyales ng sangkap ay dapat kasama ang Certificate of Analysis (COA)/Certificate of Conformity (COC) ng supplier.

- Gawin ang batch sampling inspection sa pagdating batay sa inilagay na sampling plans (hal., GB/T 2828.1). Ang frequency ng sampling ay maaaring palakihin o gawin ang full batch inspection para sa mga critical materials (hal., conductor, main insulation material).

- Ang mga materyales ng sangkap na hindi umabot sa standard ay mahigpit na ipinagbabawal na gamitin sa produksyon.

(B) Kontrol ng Kalidad ng Proseso ng Produksyon (Monitoring ng Proseso)

- 1. Monitoring ng Pangunahing Parameter ng Proseso:

- Conductor Stranding: Lay ratio, outer diameter, compaction (conductor).

- Extrusion Process: Temperature settings at control per zone, extrusion pressure, line speed, cooling process (significantly impacts crystallinity).

- Cross-linking Process (for XLPE): Irradiation dose/vulcanization temperature & time (critical for degree of cross-linking), cooling conditions.

- Shielding Process: Coverage rate, overlap quality.

- Cabling: Lay length, core stability.

- Sheath Extrusion: Thickness uniformity, surface quality, printing legibility.

- 2. Process Sampling:

- Itatag ang online o offline inspection points sa mga critical stages (hal., after extrusion, cross-linking, cabling, sheathing).

- Common Sampling Items: Insulation/sheath thickness and eccentricity, outer diameter, structural dimensions, appearance (surface defects), spark test / withstand voltage test (online/offline), partial physical property sampling (e.g., tensile).

(C) Kontrol at Pagsusuri ng Kalidad ng Tapos na Kable (Final Verification)

- 1. Type Testing (for new products or first batch of important contracts): Perform all tests specified in relevant standards (e.g., GB/T 12706.1/2) to comprehensively verify design conformity.

- 2. Routine Tests (Per Batch / Per Drum / Per Reel):

- Core Items:

- Conductor DC Resistance Test: Measure the resistance of each conductor to verify compliance with nominal cross-section requirements (GB/T 3956). This is fundamental for ampacity and heating calculations.

- Partial Discharge Test (Essential for MV/HV cables): Detect minute defects within the insulation that may lead to long-term failure (GB/T 3048.8, GB/T 12706). Extremely Important!

- Voltage Test (Withstand Voltage Test):

- Power Frequency AC Withstand Voltage: Most common. Apply multiple rated voltage (e.g., 2.5U₀) for a specified duration (e.g., 5 min). Insulation must not break down.

- DC Withstand Voltage (Specific applications): Used for certain cable types or as a supplement to AC tests.

- Insulation Resistance Measurement: Measure the resistance between conductor and shield/metallic sheath/earth, reflecting the insulation material's basic insulating properties (GB/T 3048.5/6).

- 3. Sample Tests (Batch Sampling or Periodic Tests):

- Electrical Performance:

- Capacitance measurement (if applicable).

- Dielectric loss tangent (tan δ) measurement (especially for HV cables).

- Structural Dimensions and Physical Properties:

- Insulation and sheath thickness measurement: Ensure compliance with minimum design requirements.

- Outer diameter measurement: Control tolerances.

- Physical & Mechanical Performance Tests:

- Tensile Strength and Elongation at Break (insulation/sheath) before/after aging: Key indicators, reflecting material's anti-aging capability and toughness (GB/T 2951.1).

- Hot Set Test (Essential for XLPE insulation): Verify the degree of cross-linking compliance (GB/T 2951.21).

- Low Temperature Impact/Bend Test: Assess material brittleness at low temperatures.

- Flexing/Bending Test: Simulate installation and operating conditions to test cable flexibility (GB/T 12527).

- Bending Test: Verify the cable's minimum allowable bending radius (usually performed on finished cable).

- Fire Performance Tests (As per design requirements):

- Single vertical flame test (GB/T 18380.1 series).

- Bunched flame test (GB/T 18380.3 series).

- Smoke density test (GB/T 17651).

- Halogen-free, Low-smoke performance tests (Acid gas content, pH value, conductivity, light transmittance, halogen content - GB/T 17650).

- Structural Examination: Conductor structure, shield coverage rate, core arrangement, filling density, metallic armor layer (dimensions, lay length, overlap gap), etc.

- 4. Testing Process:

- Assign unique identification per finished cable batch/drum/reel.

- Select representative samples according to defined sampling plans (per GB/T 2828.1 or contract requirements).

- Conduct tests in accredited laboratories, adhering to current and valid national standards, industry standards, enterprise standards, or contract technical agreements.

- All test items must have clearly defined pass/fail criteria.

- Record test results in the finished product test report.

(D) Third-Party Verification and Inspection (Optional but Recommended)

- For major projects, high-value cables used in critical locations, or upon specific user request:

- Engage accredited independent third-party testing institutions (e.g., with CNAS/CMA accreditation) to perform sampling/re-testing of incoming materials or finished products.

- Commission professional inspection agencies to witness and conduct on-site observation (audit/surveillance) during cable production (especially key processes) and final testing.

IV. Quality Testing Agency and Equipment Assurance

- Accreditation: Laboratories performing testing tasks must possess relevant accreditation (e.g., CNAS, CMA).

- Equipment Requirements: Equipped with comprehensive, fully functional testing equipment of requisite accuracy, regularly calibrated and verified (according to JJG procedures):

- High-voltage test equipment (Power Frequency AC, DC, Impulse, Partial Discharge Systems).

- Precision Bridges, Resistance Meters.

- Universal Material Testing Machines (with high/low temperature chambers and aging ovens).

- Hot Set Test Apparatus.

- Fire Test Equipment.

- Precision Measuring Tools (Calipers, Projectors).

- Chemical Analysis Instruments (Spectrometer, Titrator, Ion Chromatograph, etc.).

- Thickness Gauges (Laser, Ultrasonic).

- Personnel Requirements: Testing personnel must be professionally trained, proficient in standards and operating procedures, and hold valid certification.

V. Non-Conforming Product Handling

- Identify and isolate any product found non-conforming during any stage (raw material, process, finished goods).

- Conduct non-conformance review to analyze the root cause.

- Based on the review conclusion, implement one of the following actions: Re-work/Repair (if feasible upon evaluation and core performance is unaffected), Downgrade/Use as Concession (only for non-critical scenarios with user approval), or Scrap.

- Strictly prohibit non-conforming products from reaching the project site in any form.

VI. Records and Traceability

- Establish complete electronic and physical backup records of all inspections, including at least:

- Raw Material Supplier Information, Batch Number, Purchase Order Number, Raw Material Test Reports.

- Production Batch Number, Operation Logs (Key Parameters), Process Inspection Records.

- Finished Product Identification (Type, Specification, Length, Manufacturing Date, Batch/Drum/Reel No.), Complete Finished Product Test Report (covering all mandatory and optional test results), Copy of Type Test Report (if applicable).

- Third-Party Test/Inspection Reports.

- Maintain archives for the defined period (typically not less than the product's expected lifecycle) to ensure product quality traceability. In case of quality issues, enable rapid tracing back to raw material batches, production conditions, and test data.