I. مسئله په پسوند کې

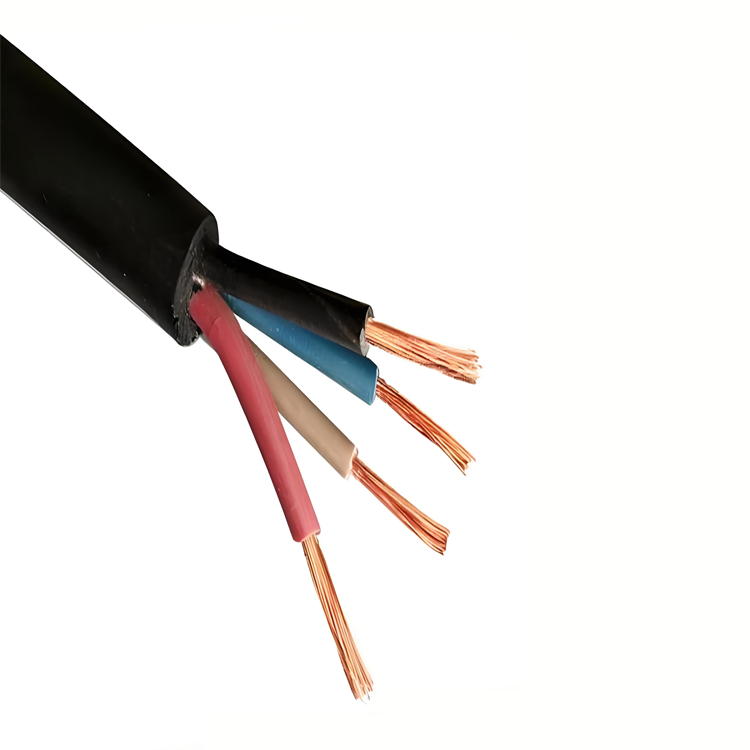

کابل د اوږدوي توان نظام کې د ټولنې د انتقال وسیله دی. دا د کیفیت لارښوونه په مستقیم توګه د سیستم د توان د وړاندې لپاره، د عملې د امنیت، د تجهیزات عمر، او د جلا ورکو ډولونو د جلوگړي د فایر کې چیرته کولو لپاره د ځانګړتیا تعیین کوي. د استاندارد نه لنډ کابلونه د یو سلسله د غوره مسائلو ترمنځ شامل دي، د هڅه افزایش، زیاده ګرمۍ تولید، د عایقه شکست، د فایر خطر بیا راځي، او د سیګنال تداخل د افزایش. په له دې روښانه کې، د علمي، د قانوني، او د ټولنې د کیفیت کنټرول او د ازمونه نظام تاسیس کول مهم دی، چې د موادو څخه تر پایېنې برخې پورې په ګام کې.

II. طرح اهداف

- سرچینه ګارانتی: د کابل تولید کې د کارولو ټول مواد په بلندترین ملي او صنعتي استانداردونو سره (مثال: GB/T 3956, GB/T 12706, GB/T 19666, او غیره) مطابقت لري.

- پروسه کنټرول: د تولید کې د کلیدي پروسه پارامتر او د وسطي مرحلې کیفیت په موثر ډول مراقبت کول.

- محصول موثقیت: د تمام شوی کابلونو د کلیدي عملکرد اشارې - د الکترونيک، فيزيکي & مکانيکي، او د فایر عملکرد - د ډیزاین او د قرارداد ضرورتونو سره مطابقت لري يا د دې په څو څخه لوړ وي.

- خطره مدیریت: د منظم ازمونو په موجب د محتمل دیکتکشنونو په تشخیص کول، د نامناسب محصولاتو د بازار ته ورودو د منع او د استعمال خطراتو د کم کول.

- پیگیری: د کامل کیفیت ازمونه ریکارډ سیستم تاسیس کول، د کلیدي موادو د ټولنې او د محصول ازمونه نتیجې په پیگیری کول.

III. کور حلول: الکترونيکي کابل کیفیت کنټرول او ازمونه

(A) موادو کیفیت کنټرول او ازمونه (سرچینه کنټرول)

- 1. فروشنده کوالیفیکیشن او ارزیابی:

- د سلامت کیفیت مدیریت سیستم (مثال: ISO 9001 سرتیفیکیټ)، ثابت ترین فراهم کولو قدرت، او د صنعت د خوب نومې د فروشندو انتخاب کول.

- د فروشنده موادو په منظم ډول ناشناخته سمپل ګرفتن او یا ټریډ پارتی ورکولو په واسطه د ارزیابی کول.

- 2. کلیدي موادو ازمونه:

- کنډکټر مواد (کپر/المونیم ډنډ/سلب):

- ازمونه موارد: کیمیائي چمتو کول (کپر مقدار، غیرصاف عناصر)، مکانيکي خصوصیتونه (تیره کولو قوت، طول، تکراره انحناء)، مقاومتی مقدار (د 20°C).

- استاندارد مرجع: GB/T 3953 (د الکترونيک کارولو لپاره ګول کپر سلب)، GB/T 3954 (د الکترونيک کارولو لپاره المونیم ډنډونه)، GB/T 3956 (عایقه کابلونو د کنډکټرون)، او غیره.

- ازمونه روشونه: کیمیائي آناليزر (مثال: سپکتروميټر)، تیره کولو ماشين، ویټسټون بریج، یا دقیق مقاومت میټر.

- عایقه او پوسته مواد (PVC, XLPE, PE, LSZH، او غیره):

- ازمونه موارد:

- فيزيکي خصوصیتونه: د څرګندن، چپې، د چپې یکسانیت، تیره کولو قوت & په شکست کې طول، د چیرې او د ګرمۍ په مخ کې د عملکرد په موازنه.

- الکترونيکي خصوصیتونه: حجم/سطح مقاومت.

- حرارتي خصوصیتونه: حرارتی دگرگونی، د ګرمۍ ستل شوې ازمون (XLPE لپاره)، کم ګرمۍ د چپې/انحناء ازمون.

- د فایر عملکرد (LSZH/د فایر دیکتکشن مواد): اکسیجن اینډیکس، د دود چپې، د اسید ګاز مقدار، د هالوژن مقدار (د هالوژن نه ګرځونو لپاره).

- استاندارد مرجع: GB/T 8815 (د پلاستیک نه ګرځونو پولي وینیل کلوروئيد)، GB/T 15065 (د کراس لنک پولي ایتیلن عایقه مواد)، GB/T 18380 (د الکترونيک کابلونو د فایر شرایطو ته د ازمون - د یو شمع ازمون)، GB/T 17651 (د دود چپې په مخ کې د چپې ازمون)، GB/T 17650 (د هالوژن نه ګرځونو، کم دود مواد او محصولاتو)، او غیره.

- ازمونه روشونه: عمومي مواد ازمون ماشین، ګرمۍ اوون، مقاومت آناليزر، د ګرمۍ ستل شوې ازمون ډیوایس، اکسیجن اینډیکس آناليزر، د دود چپې چمبر، کیمیائي آناليزر.

- Shielding Material (Copper Tape/Wire): Thickness, resistance, coverage rate.

- Filling/Bedding Materials: Water resistance (if applicable), mechanical strength, compatibility.

- 3. Testing Requirements:

- All incoming raw materials must be accompanied by the supplier's Certificate of Analysis (COA)/Certificate of Conformity (COC).

- Perform batch sampling inspection upon receipt based on defined sampling plans (e.g., GB/T 2828.1). Sampling frequency may be increased or full batch inspection implemented for critical materials (e.g., conductor, main insulation material).

- Raw materials failing inspection are strictly prohibited from use in production.

(B) Production Process Quality Control (Process Monitoring)

- 1. Key Process Parameter Monitoring:

- Conductor Stranding: Lay ratio, outer diameter, compaction (conductor).

- Extrusion Process: Temperature settings and control per zone, extrusion pressure, line speed, cooling process (significantly impacts crystallinity).

- Cross-linking Process (for XLPE): Irradiation dose/vulcanization temperature & time (critical for degree of cross-linking), cooling conditions.

- Shielding Process: Coverage rate, overlap quality.

- Cabling: Lay length, core stability.

- Sheath Extrusion: Thickness uniformity, surface quality, printing legibility.

- 2. Process Sampling:

- Establish online or offline inspection points at critical stages (e.g., after extrusion, cross-linking, cabling, sheathing).

- Common Sampling Items: Insulation/sheath thickness and eccentricity, outer diameter, structural dimensions, appearance (surface defects), spark test / withstand voltage test (online/offline), partial physical property sampling (e.g., tensile).

(C) Finished Cable Quality Control and Testing (Final Verification)

- 1. Type Testing (for new products or first batch of important contracts): Perform all tests specified in relevant standards (e.g., GB/T 12706.1/2) to comprehensively verify design conformity.

- 2. Routine Tests (Per Batch / Per Drum / Per Reel):

- Core Items:

- Conductor DC Resistance Test: Measure the resistance of each conductor to verify compliance with nominal cross-section requirements (GB/T 3956). This is fundamental for ampacity and heating calculations.

- Partial Discharge Test (Essential for MV/HV cables): Detect minute defects within the insulation that may lead to long-term failure (GB/T 3048.8, GB/T 12706). Extremely Important!

- Voltage Test (Withstand Voltage Test):

- Power Frequency AC Withstand Voltage: Most common. Apply multiple rated voltage (e.g., 2.5U₀) for a specified duration (e.g., 5 min). Insulation must not break down.

- DC Withstand Voltage (Specific applications): Used for certain cable types or as a supplement to AC tests.

- Insulation Resistance Measurement: Measure the resistance between conductor and shield/metallic sheath/earth, reflecting the insulation material's basic insulating properties (GB/T 3048.5/6).

- 3. Sample Tests (Batch Sampling or Periodic Tests):

- Electrical Performance:

- Capacitance measurement (if applicable).

- Dielectric loss tangent (tan δ) measurement (especially for HV cables).

- Structural Dimensions and Physical Properties:

- Insulation and sheath thickness measurement: Ensure compliance with minimum design requirements.

- Outer diameter measurement: Control tolerances.

- Physical & Mechanical Performance Tests:

- Tensile Strength and Elongation at Break (insulation/sheath) before/after aging: Key indicators, reflecting material's anti-aging capability and toughness (GB/T 2951.1).

- Hot Set Test (Essential for XLPE insulation): Verify the degree of cross-linking compliance (GB/T 2951.21).

- Low Temperature Impact/Bend Test: Assess material brittleness at low temperatures.

- Flexing/Bending Test: Simulate installation and operating conditions to test cable flexibility (GB/T 12527).

- Bending Test: Verify the cable's minimum allowable bending radius (usually performed on finished cable).

- Fire Performance Tests (As per design requirements):

- Single vertical flame test (GB/T 18380.1 series).

- Bunched flame test (GB/T 18380.3 series).

- Smoke density test (GB/T 17651).

- Halogen-free, Low-smoke performance tests (Acid gas content, pH value, conductivity, light transmittance, halogen content - GB/T 17650).

- Structural Examination: Conductor structure, shield coverage rate, core arrangement, filling density, metallic armor layer (dimensions, lay length, overlap gap), etc.

- 4. Testing Process:

- Assign unique identification per finished cable batch/drum/reel.

- Select representative samples according to defined sampling plans (per GB/T 2828.1 or contract requirements).

- Conduct tests in accredited laboratories, adhering to current and valid national standards, industry standards, enterprise standards, or contract technical agreements.

- All test items must have clearly defined pass/fail criteria.

- Record test results in the finished product test report.

(D) Third-Party Verification and Inspection (Optional but Recommended)

- For major projects, high-value cables used in critical locations, or upon specific user request:

- Engage accredited independent third-party testing institutions (e.g., with CNAS/CMA accreditation) to perform sampling/re-testing of incoming materials or finished products.

- Commission professional inspection agencies to witness and conduct on-site observation (audit/surveillance) during cable production (especially key processes) and final testing.

IV. Quality Testing Agency and Equipment Assurance

- Accreditation: Laboratories performing testing tasks must possess relevant accreditation (e.g., CNAS, CMA).

- Equipment Requirements: Equipped with comprehensive, fully functional testing equipment of requisite accuracy, regularly calibrated and verified (according to JJG procedures):

- High-voltage test equipment (Power Frequency AC, DC, Impulse, Partial Discharge Systems).

- Precision Bridges, Resistance Meters.

- Universal Material Testing Machines (with high/low temperature chambers and aging ovens).

- Hot Set Test Apparatus.

- Fire Test Equipment.

- Precision Measuring Tools (Calipers, Projectors).

- Chemical Analysis Instruments (Spectrometer, Titrator, Ion Chromatograph, etc.).

- Thickness Gauges (Laser, Ultrasonic).

- Personnel Requirements: Testing personnel must be professionally trained, proficient in standards and operating procedures, and hold valid certification.

V. Non-Conforming Product Handling

- Identify and isolate any product found non-conforming during any stage (raw material, process, finished goods).

- Conduct non-conformance review to analyze the root cause.

- Based on the review conclusion, implement one of the following actions: Re-work/Repair (if feasible upon evaluation and core performance is unaffected), Downgrade/Use as Concession (only for non-critical scenarios with user approval), or Scrap.

- Strictly prohibit non-conforming products from reaching the project site in any form.

VI. Records and Traceability

- Establish complete electronic and physical backup records of all inspections, including at least:

- Raw Material Supplier Information, Batch Number, Purchase Order Number, Raw Material Test Reports.

- Production Batch Number, Operation Logs (Key Parameters), Process Inspection Records.

- Finished Product Identification (Type, Specification, Length, Manufacturing Date, Batch/Drum/Reel No.), Complete Finished Product Test Report (covering all mandatory and optional test results), Copy of Type Test Report (if applicable).

- Third-Party Test/Inspection Reports.

- Maintain archives for the defined period (typically not less than the product's expected lifecycle) to ensure product quality traceability. In case of quality issues, enable rapid tracing back to raw material batches, production conditions, and test data.