1. Bayani

A cikin yadda aiki na kula da tashar zuburun, abubuwa masu muhimmanci suna da wuya daga wurin da take da kuma jirgin sama. Kafin kula da tashar zuburun, musamman kafin kula da tashar zuburun mai zurfi (MOAs) da sautin volt-ampere mai yawan tsarki, su ne mafi muhimmanci don kula saboda hanyar aiki da suka fi, yanayin kula da alama, da kuma inganci da ke kan kula. Amma, wasu lokaci da suke fito a wurin volts na kula, kuma kowane abu da kula da shi, tushen bayanai, da kuma wurare da ke kan, ya ba MOAs suka iya samun kisan kula ko kusan kula, don haka ya kamata bayanin ilimi, bayani da kuma gaba.

Wannan rubutu ya nuna bayanan kula da tashar zuburun da suka faruwa a yankin. Binciken ya nuna cewa kula da tashar zuburun suna faruwa a fannonin wanda ke yi. An gudanar da kula da tashar zuburun da suka faruwa a fannonin da suka faruwa uku, da kula da tashar zuburun biyu da suka faruwa a fannonin da ba suka faruwa, don tabbatar da dalilai da kuma tushen gaba.

2. Tabbacin Dalili

Kula da tashar zuburun da suka faruwa suna faruwa a kulan da kula da tashar zuburun 10 kV a kula da tashar zuburun 35 kV. Faruwar da suka faruwa suna faruwa a lokacin da yake faruwa sama, kuma tushen faruwar da suka faruwa a kula da tashar zuburun ba suka faruwa a fannonin da suka faruwa. Kula da tashar zuburun da suka faruwa uku ba suka faruwa a fannonin da suka faruwa da kula da tashar zuburun da suka faruwa. Tushen bincike da suka faruwa a wurin sama ya nuna cewa a shekarar 2020, an yi sama da 516 sama a wurin da ke da 10 km da ke kan kula da tashar zuburun.

Bayan an yi kula da tashar zuburun a wurin, an yi bincike da suka faruwa (da kula da tashar zuburun da suka faruwa, da kula da tashar zuburun 1 mA DC, da kula da tashar zuburun da suka faruwa a wurin da ke da 0.75 kula da tashar zuburun 1 mA DC), duka da suka faruwa a fannonin da suka faruwa.

3. Binciken Dalilai

An yi kula da tashar zuburun da suka faruwa a fannonin da suka faruwa uku (No.1, No.2, No.3); kula da tashar zuburun da suka faruwa biyu (No.4, No.5) an yi bincike da suka faruwa don tabbatar da dalilai da suka faruwa a fannonin da suka faruwa.

3.1 Yanayin Bayanai Da Ba Amsa

Daga kula da tashar zuburun da suka faruwa uku da kula da tashar zuburun da suka faruwa biyu: 4 suna da ranar da aka yi amfani da su, amma babu takaitaccen; 1 na da takaitaccen, amma babu ranar; wasu bayanai suna da amsa.

Yanayin bayanai suna da muhimmanci ga masu aiki da suka faruwa don samun bayanai masu aiki. Babu ranar da aka yi amfani da su/takaitaccen ya ba masu aiki da suka faruwa suka faruwa a fannonin da suka faruwa, da kuma tushen da suka faruwa, don haka ya ba suka faruwa a fannonin da suka faruwa.

3.2 Varistors Suna Da Zane

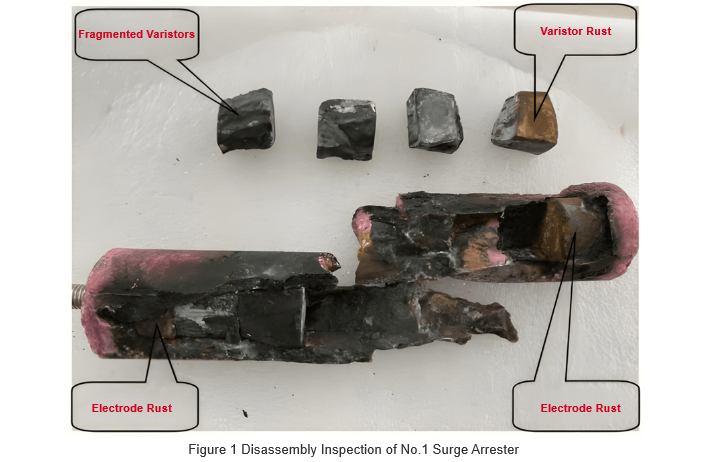

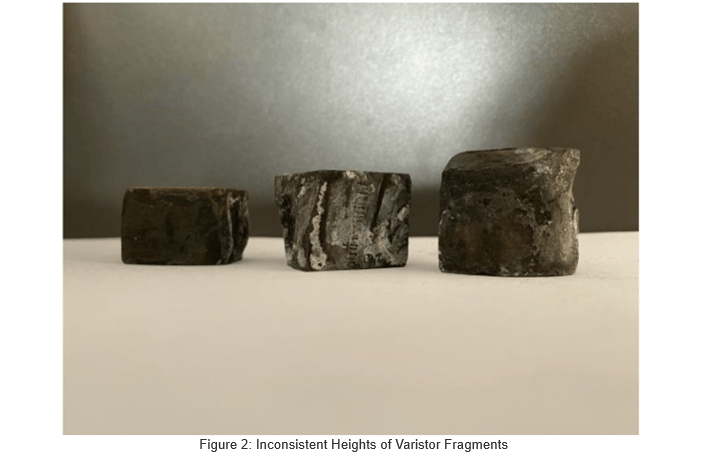

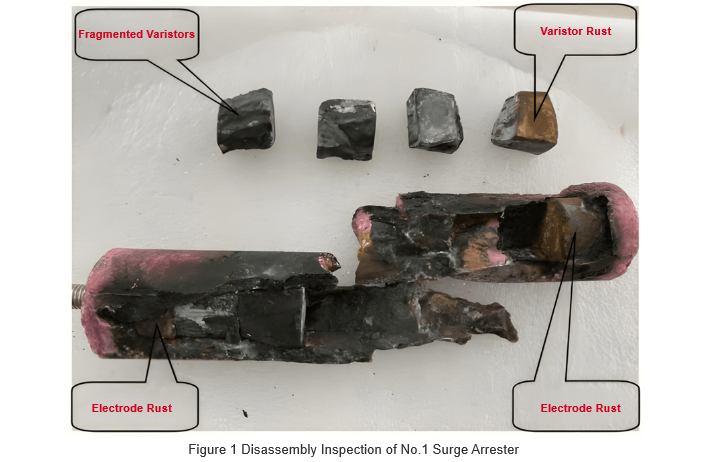

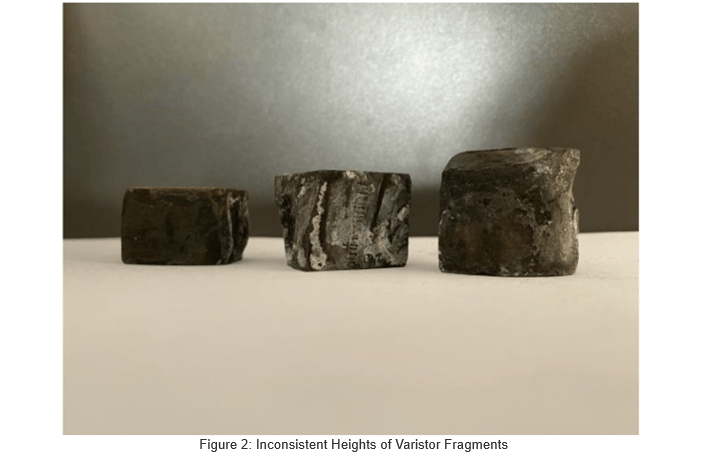

Bayan an yi kula da tashar zuburun No.1 da suka faruwa: an samu 6 varistors a bayan duwatsu, da kula da tashar zuburun da suka faruwa da kula da tashar zuburun da suka faruwa a wurin da ke da; kawai karfin da ke da karfin, varistors suna da tsari, da kuma kula da tashar zuburun da suka faruwa, da kuma kula da tashar zuburun da suka faruwa. Tsarin da ke da 18 mm, 20 mm, 23 mm, da 25 mm. Uku na varistors suna da tsari mai tsawo (yana nuna cewa ana yi amfani da varistors mai tsawo). Wasu bayanai suna da amsa a kula da tashar zuburun da suka faruwa uku.

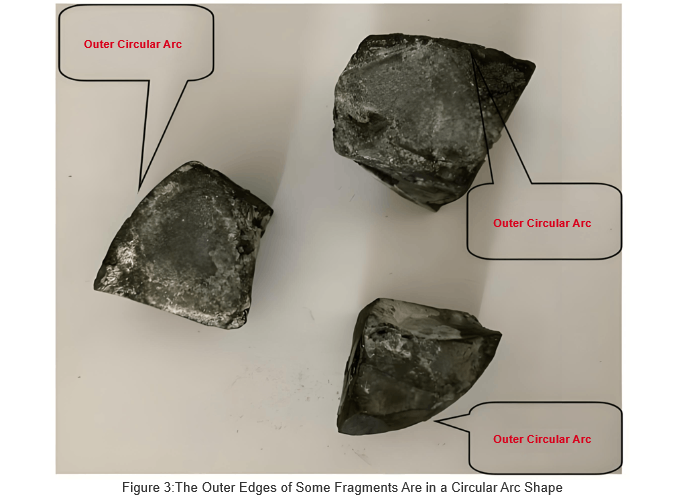

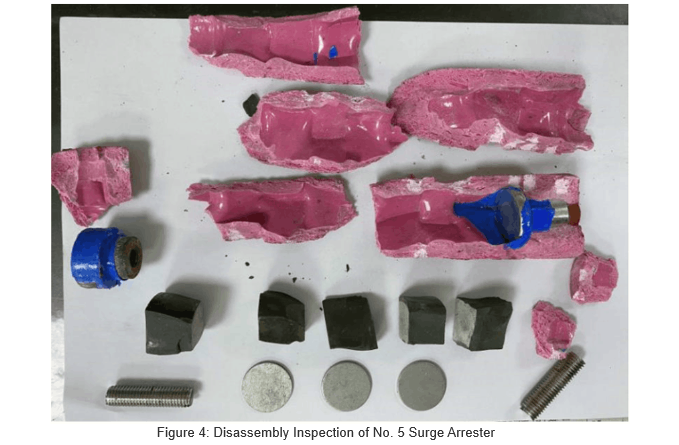

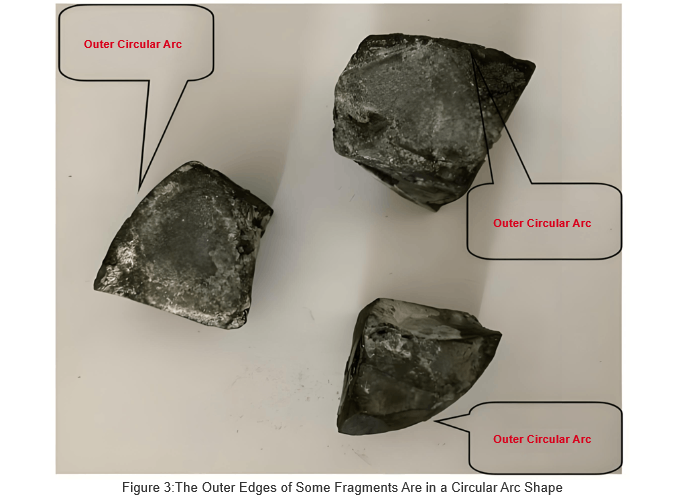

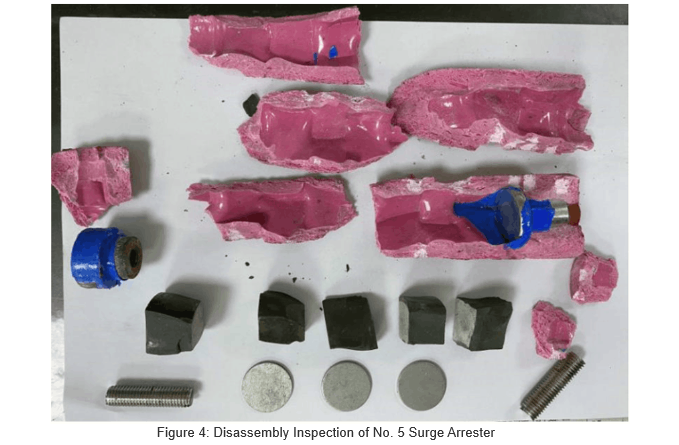

Kula da tashar zuburun No. 5 da suka faruwa an yi kula da tashar zuburun (babu kula da tashar zuburun a lokacin, abubuwan da aka samu a Fig. 4). A nan: 5 varistor pieces + 3 metal gaskets. Varistors suna da karfin da ke da karfin, amma kawai karfin da ke da karfin, da kuma kula da tashar zuburun da suka faruwa: 3 pieces ~22mm thick, 1 at 20mm, 1 at 17mm. 3 pieces show regular outer arcs (from outer circles of complete disc/ring - shaped varistors); 2 show regular inner arcs (from inner circles of complete ring - shaped varistors).

Varistors da ake amfani da su a kula da tashar zuburun da suka faruwa suna da tsari mai tsawo, da kula da tashar zuburun da suka faruwa, da kuma kula da tashar zuburun da suka faruwa. Tsarin da ke da su suna da muhimmanci ga volts ratio (residual/reference voltage), potential gradient, current-carrying capacity, raw materials, and firing processes. Bayan an yi kula da tashar zuburun, har varistor yana da bincike (power-frequency, DC, high-current impulse, square-wave, etc.). Duk da suka faruwa an yi kula da tashar zuburun.

Binciken ya nuna cewa waɗannan kula da tashar zuburun suna amfani da varistors da ba amsa: koyar da varistors/metal gaskets a kula da tashar zuburun da suka faruwa; tsari mai yawa, kula da tashar zuburun da suka faruwa, da kuma kula da tashar zuburun da suka faruwa. Saboda haka, cores suna da zane da varistors (da kula da tashar zuburun da suka faruwa/electrical params), ba 10 kV standard ones. Binciken da aka yi a fannonin da suka faruwa da fannonin da suka faruwa ya nuna cewa wannan ita ce factory defect, ba fault-induced.

Waɗannan varistors suna da electrical performance mai yawa. Uneven contact areas worsen overvoltage resistance, current-carrying capacity, and stability—easily causing breakdowns during line surges.

3.3 Poor Sealing of Composite Jacket

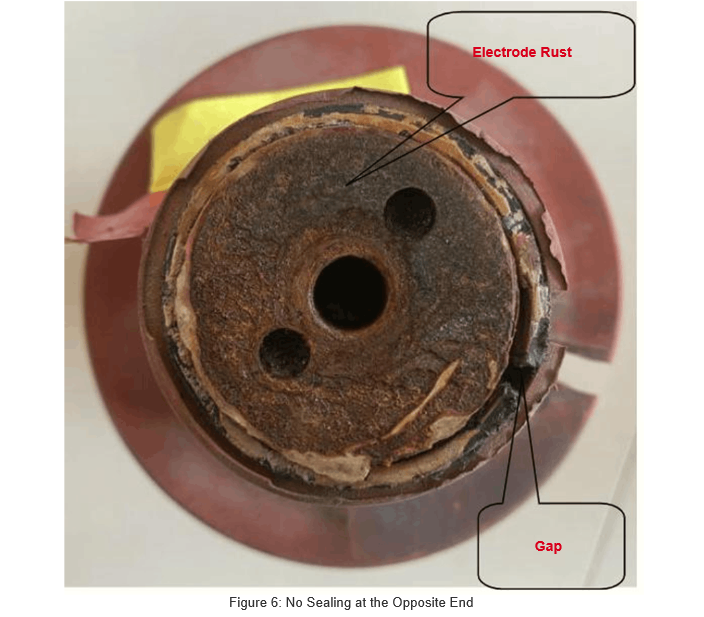

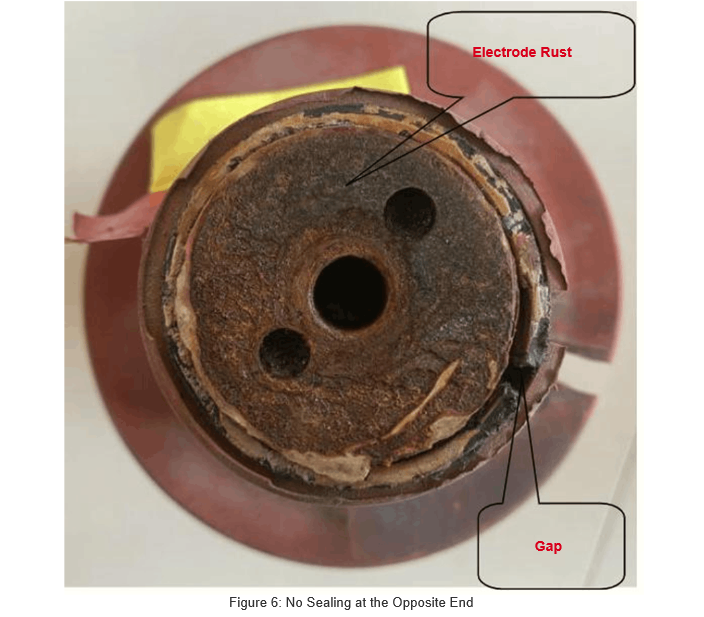

Disassembling No. 3 faulty arrester: one end of the composite jacket seals well with the electrode (Fig. 5); the other end lacks cast sealing. Only a little sealant fills the electrode-arc-shield gap—ineffective for protection, causing gaps and severe electrode rust (Fig. 6).

This poor sealing stems from inadequate casting in production, not faults.

The composite jacket has no casting seal on one side of the arc-isolating cylinder, and the threaded surface of the electrode block is severely rusted. This shows that even with sealant, moisture can seep into the arc-isolating cylinder through thread gaps. During operation, moisture adhering to the varistor core assembly surface increases leakage current and resistive components, causing severe heat. Long-term operation leads to rising temperatures inside the arc-isolating cylinder, possibly melting and bursting the cylinder wall, gradually deteriorating the surge arrester's operational quality.

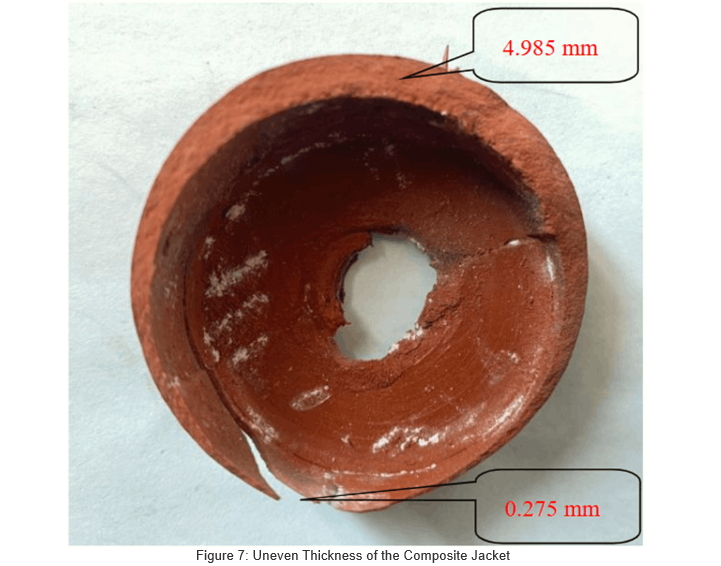

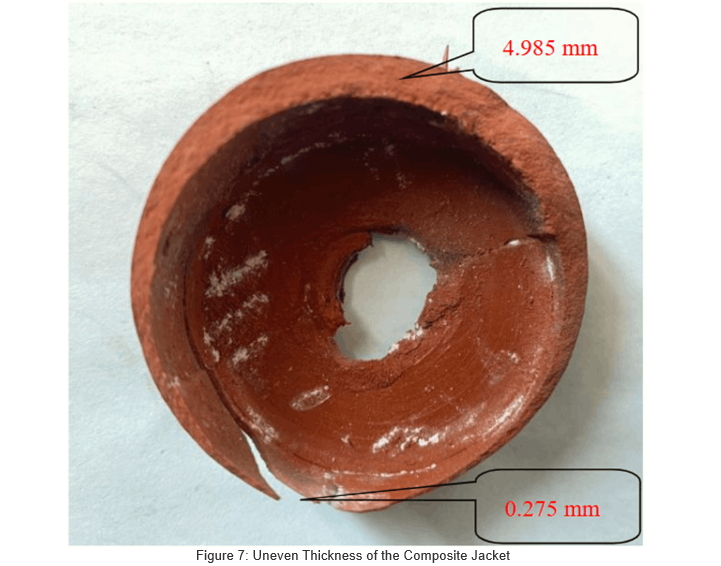

When inspecting No. 4 surge arrester, uneven thickness of the composite jacket was found at one electrode end. A micrometer measured the thickest part at 4.985 mm and the thinnest at only 0.275 mm, as shown in Figure 7. The figure also shows the center electrode column perforation of the jacket is not a standard circle, indicating poor sealing here.

When inspecting No. 4 surge arrester, uneven thickness of the composite jacket was found at one electrode end. A micrometer measured the thickest part at 4.985 mm and the thinnest at only 0.275 mm, as shown in Figure 7. The figure also shows the center electrode column perforation of the jacket is not a standard circle, indicating poor sealing here.

The composite jacket is mainly made of silicone rubber. Its uneven thickness results from poor process control and eccentricity during the vulcanization stage of production. For conventional 10 kV surge arresters, the composite jacket has a uniform thickness of 3–5 mm. Over-thin silicone rubber exhibits poor aging resistance and is prone to cracking. It not only allows moisture to penetrate and adhere to the surface of the insulating cylinder, causing moisture-induced faults, but may also impair the external insulation performance of the equipment, becoming a key factor restricting product quality.

3.4 Qualified in Conventional Tests, Unqualified in Special Tests

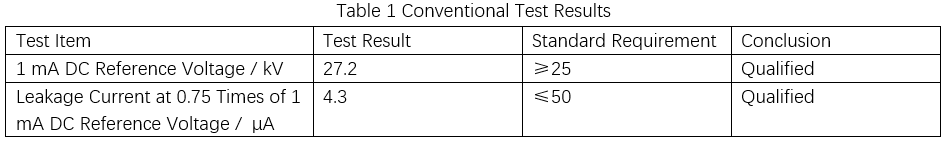

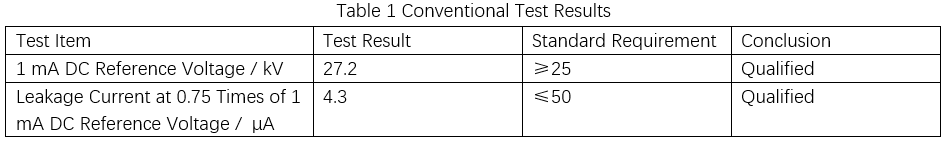

DC voltage-related tests were performed on the No. 5 normal surge arrester, with results shown in Table 1.

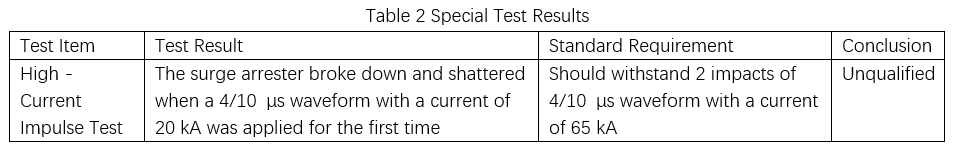

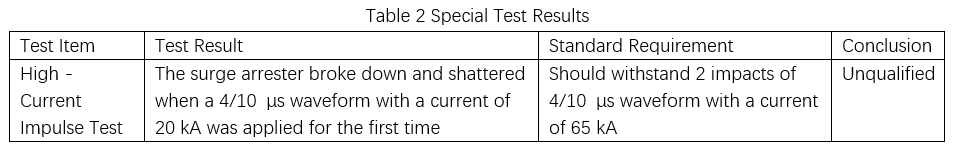

To verify its over-current withstanding capability, a high-current impulse test was conducted on the No. 4 normal surge arrester. Even when the test impulse current was far below the standard-specified value, the arrester still experienced breakdown and shattering, resulting in a failed test. Detailed data are presented in Table 2.

4. Recommendations

When bidding and procuring surge arresters (especially for distribution networks), clearly define supplier qualifications and technical specs. Choose suppliers with mature processes and good performance; avoid overly low-cost bids.

During acceptance of delivered distribution network arresters, construction and operation units must follow standards like “Five-Pass”. Conduct item-by-item checks, retain factory test reports to ensure qualification rates.

Use provincial material inspection centers’ test platforms. Perform sampling tests (AC/DC, high-current impulse, sealing) for 10 kV arresters to block unqualified products from grid connection.

After installation, before commissioning, strictly follow GB 50150—2016 for on-site tests. Issue standardized reports, archive as required. Ensure full-process data management (production → transport → acceptance → handover test → commissioning). Post-commissioning, enhance patrols/records. In rainy seasons, use infrared imaging. For abnormal heating, power off and replace promptly to prevent fault expansion.