1. Overload

First, with the improvement of people's living standards, electricity consumption has generally increased rapidly. The original H59 distribution transformers have small capacity—“a small horse pulling a big cart”—and cannot meet user demands, causing the transformers to operate under overload conditions. Second, seasonal variations and extreme weather conditions lead to peak electricity demand, further causing H59 distribution transformers to run overloaded.

Due to long-term overload operation, internal components, windings, and oil insulation age prematurely. Transformer loads are largely seasonal and time-dependent—especially in rural areas during busy farming seasons, when transformers operate at full or overload capacity, while at night they run under light load. This results in a large load curve variation, with operating temperatures reaching above 80 °C at peak and dropping as low as 10 °C at minimum.

Moreover, inspections of rural transformers show that each transformer accumulates more than 100 grams of moisture at the bottom on average. This moisture enters through the breathing action of transformer oil during thermal expansion and contraction and then precipitates out of the oil. Additionally, insufficient oil levels lower the oil surface, increasing the contact area between insulating oil and air, which accelerates moisture absorption from the atmosphere. This reduces internal insulation strength, and once insulation degrades below a critical threshold, internal breakdown and short-circuit faults occur.

2. Unauthorized Oil Top-Up on H59 Distribution Transformers

An electrician added oil to an H59 distribution transformer while it was energized. One hour later, the high-voltage drop-out fuse blew on two phases, accompanied by slight oil spraying. On-site inspection confirmed the need for major repair. The main causes of transformer burnout were:

The newly added transformer oil was incompatible with the existing oil inside the tank. Transformer oils have different base formulations, and mixing different types is generally prohibited.

Oil was added without de-energizing the transformer. Mixing hot and cold oil accelerated internal circulation, stirring up moisture from the bottom and distributing it into the high- and low-voltage windings, reducing insulation and causing breakdown.

Substandard transformer oil was used.

3. Improper Reactive Power Compensation Causing Resonant Overvoltage

To reduce line losses and improve equipment utilization, regulations recommend installing reactive power compensation devices on H59 distribution transformers rated above 100 kVA. However, if compensation is improperly configured—such that total capacitive reactance equals total inductive reactance in the circuit—ferroresonance can occur in the line and connected equipment, leading to overvoltage and overcurrent that may burn out the H59 transformer and other electrical devices.

4. System Ferroresonance Overvoltage

In rural 10 kV distribution networks, lines vary in length, ground clearance, and conductor size. Combined with frequent switching of H59 transformers, welding machines, capacitors, and large loads, system parameters change significantly. Additionally, intermittent single-phase grounding in a 10 kV ungrounded neutral system can trigger resonant overvoltage. When this occurs, minor cases result in blown high-voltage fuses; severe cases cause transformer burnout, and in rare instances, bushing flashover or explosion.

5. Lightning Overvoltage

H59 distribution transformers must, per regulations, be equipped with qualified surge arresters on both high- and low-voltage sides to mitigate damage from lightning and ferroresonant overvoltages to windings and bushings. Common causes of overvoltage-related damage include:

Improper installation or testing of arresters. Typically, three arresters share a single grounding point. Over time, corrosion from weather exposure or poor maintenance can break or degrade this ground connection. During lightning or resonant overvoltage events, inadequate grounding prevents effective discharge to earth, leading to transformer breakdown.

Overreliance on insurance coverage. Many users assume that since the transformer is insured, arrester installation and testing are unnecessary—believing insurers will cover failures. This mindset has contributed significantly to widespread transformer damage over the years.

Emphasis only on high-voltage side arresters while neglecting the low-voltage side. Without low-voltage arresters, a lightning strike on the LV side can induce inverse voltage surges that stress the HV winding and potentially damage the LV winding as well.

6. Secondary Short Circuit

When a secondary short circuit occurs, short-circuit currents several to dozens of times the rated current flow on the secondary side. A correspondingly large current also flows on the primary side to counteract the demagnetizing effect of the secondary fault current. Such massive currents:

Generate enormous mechanical stress within windings, compressing coils, loosening main and interlayer insulation, and causing deformation;

Cause rapid temperature rise in both windings. If fuses are improperly sized or replaced with copper/aluminum wire, windings can burn out quickly.

7.Poor Contact at Tap Changer

Low-quality tap changers with poor design, insufficient spring pressure, or incomplete contact between moving and stationary contacts can reduce insulation distance between misaligned contacts, leading to arcing, short circuits, and rapid burnout of tap windings or entire coils.

Human error: Some electricians misunderstand no-load tap-changing principles. After adjustment, contacts may only partially engage. Alternatively, long-term operation causes contamination on stationary contacts, resulting in poor contact, arcing, and eventual transformer failure.

8. Blocked Breather Port

Transformers rated above 50 kVA typically have a “breather” installed on the conservator tank. The breather housing is usually a transparent glass cylinder filled with desiccant. It is fragile during transport, so manufacturers often ship units with a small square metal plate bolted over the breather port instead of installing the actual breather, to prevent moisture ingress.

Upon commissioning, this metal plate must be promptly removed and replaced with the functional breather. If not, heat generated during operation causes oil expansion and increased internal pressure. Without a functioning breather, oil cannot circulate properly, heat cannot dissipate, and temperatures of the core and windings keep rising. Insulation degrades continuously until the transformer ultimately burns out.

9. Other Issues

Common problems in daily operation and maintenance of H59 distribution transformers include:

During maintenance or installation, tightening or loosening the conductive rod nut may cause the rod to rotate, leading to contact between secondary soft copper leads—causing phase-to-phase short circuits or breaking primary winding leads.

Accidentally dropping tools or objects during work on the transformer can damage bushings, causing minor flashover-to-ground or severe short circuits.

After maintenance, testing, or cable replacement on paralleled transformers, failure to perform phase sequence verification and random reconnection can result in incorrect phasing. When energized, large circulating currents flow, burning out the transformer.

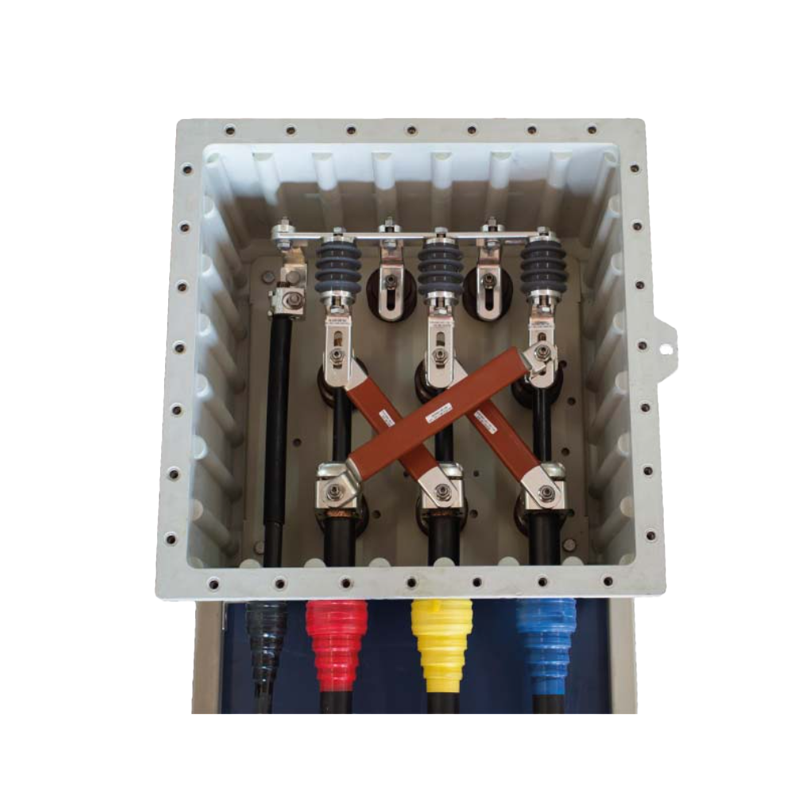

Anti-theft metering boxes installed on the low-voltage side often suffer from space constraints and poor workmanship—some connections are simply wrapped with wire. This creates high contact resistance at LV terminals, leading to overheating and arcing under heavy load, eventually burning out the conductive rods.