With the advancement of smart grid technologies, sequential control (SCADA-based automated switching) in substations has become a core technique for ensuring stable power system operation. Although existing sequential control technologies have been widely deployed, challenges related to system stability under complex operating conditions and equipment interoperability remain significant. Unmanned Aerial Vehicle (UAV) technology—characterized by its agility, mobility, and non-contact inspection capabilities—offers an innovative solution for optimizing sequential control operations.

By deeply integrating UAV-based functions such as aerial patrol and real-time condition monitoring into traditional sequential control systems, the limitations of manual operations can be effectively overcome, enabling precise, real-time perception of equipment status and significantly enhancing both the reliability and intelligence level of sequential control. Research into UAV applications in substation sequential control holds substantial practical significance for advancing smart grid development.

1.Overview of Sequential Control Operations in Substations

1.1 Definition

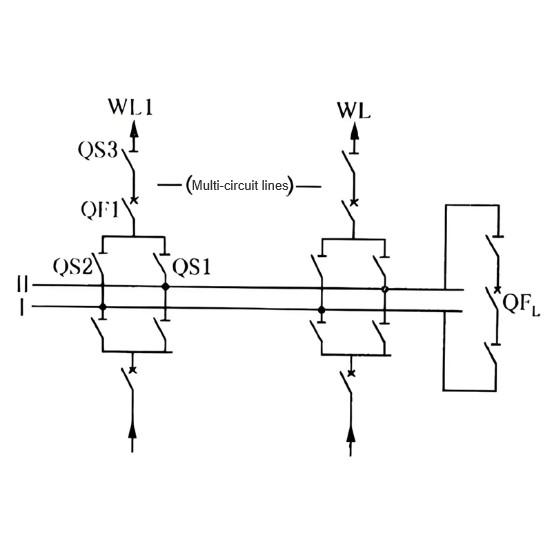

Sequential control in substations refers to the automated, step-by-step execution of a series of electrical equipment operations according to pre-defined procedures and logical rules via an automation control system. Taking bus transfer (switching) operations as an example: traditionally, operators must manually operate circuit breakers, disconnectors, and other devices one by one. In contrast, with sequential control, operators only need to issue a single comprehensive command from the monitoring workstation; the system then automatically and accurately executes the entire sequence—such as tripping a line circuit breaker followed by opening associated disconnectors—greatly simplifying the operational workflow.

1.2 Technical Principles

Substation sequential control relies on an integrated automation system composed of key components including a supervisory host, measurement and control units, and intelligent terminals. The supervisory host serves as the human-machine interface, receiving operator commands and converting them into executable control signals. Measurement and control units continuously collect real-time operational data—such as current, voltage, and equipment position—providing both situational awareness for operators and critical inputs for sequential logic decisions. Intelligent terminals interface directly with primary equipment to perform switching operations and communicate with measurement/control units and other devices via fiber optics or cables, ensuring fast and accurate data transmission to support safe and efficient sequential control execution.

1.3 Advantages

1.3.1 Improved Operational Efficiency

In conventional substation operations, switching procedures suffer from notable inefficiencies. For instance, during a 220 kV bus transfer operation, personnel must repeatedly move between bays to verify equipment IDs, confirm statuses, and manually operate breakers and disconnectors. Due to human limitations, a single complete operation typically takes 2–3 hours, consuming considerable manpower and carrying inherent risks of error that impact grid efficiency.

With the evolution of smart grid technologies, sequential control systems offer a transformative approach. Upon receiving a command from the monitoring backend, the system automatically executes the full sequence—including device status verification, operation ticket validation, and switching commands—at millisecond-level speed based on pre-programmed logic. Field data show that using sequential control reduces the 220 kV bus transfer time to under 20 minutes—a more than 80% improvement over traditional methods. This breakthrough enhances grid operational flexibility, enabling rapid reconfiguration during load fluctuations and significantly shortening outage durations during faults, thereby improving overall power supply reliability and quality.

1.3.2 Enhanced Operational Safety

Manual substation operations are vulnerable to numerous unpredictable human factors that pose hidden safety risks. Operator alertness is critical; fatigue from overnight shifts, for example, can lead to misreading labels or executing steps out of sequence. Additionally, skill levels vary among personnel—new hires are far less familiar with complex procedures than seasoned staff—increasing the likelihood of mistakes. Incomplete statistics indicate that hundreds of substation equipment failures and grid incidents annually stem from human error.

Sequential control establishes a robust safety barrier. Before execution, built-in logic validation rigorously checks each step against predefined safety and electrical interlock rules. Only when all conditions are satisfied will the system proceed. For example, during line energization, the system automatically verifies the status of breakers and disconnectors; if any anomaly is detected, the operation halts immediately and triggers an alarm. This prevents severe errors such as opening a disconnector under load or closing a grounding switch while energized, fundamentally reducing the risk of equipment damage and grid accidents, and ensuring safer, more stable substation operations.

1.4 Current Application Status

As China continues to advance its smart grid initiative, sequential control has become a cornerstone of modern substation operations. In newly constructed substations, intelligent design principles are now standard, with sequential control integrated as a core functional module. For example, in East China, the adoption rate of sequential control in new substations over the past five years has reached 95%. In economically developed cities like Shenzhen and Shanghai, coverage exceeds 80% for 220 kV and higher voltage substations, significantly boosting regional grid efficiency and safety.

Meanwhile, retrofitting older substations with intelligent capabilities is also progressing steadily. In North China, a 20-year-old 110 kV substation was successfully upgraded with sequential control functionality through replacement of intelligent I/O units and modernization of the supervisory system, markedly improving operational efficiency and reliability.

However, as sequential control scales up, technical bottlenecks in complex scenarios are becoming evident. Under extreme weather, multi-line faults, or sudden load swings, the system must process massive real-time data and execute intricate logic, which can lead to response delays, logic stalls, or even erroneous actions. Moreover, interoperability issues among equipment from different vendors—due to inconsistencies in communication protocols, data formats, and interface standards—often cause abnormal data transmission or delayed command responses, undermining the smoothness and accuracy of sequential operations.

To address these challenges, the power industry is pursuing dual-track solutions: technological innovation and standardization. Technically, algorithms are being optimized to enhance data processing and decision-making under complex conditions. On the standards front, efforts focus on unifying communication interfaces and protocols to improve cross-vendor interoperability.

In this context, UAV technology—offering flexible maneuverability, diverse viewing angles, and non-contact sensing—presents an innovative pathway for enhancing sequential control. During sequential operations, UAVs can perform real-time dynamic monitoring of equipment status using multispectral imaging, infrared thermography, and other advanced techniques, enabling precise parameter acquisition and rapid anomaly detection. This real-time feedback effectively supports smarter decision-making in sequential control systems, elevating the intelligence and reliability of power grid operations.

2. Application of UAV Technology in Substation Sequential Control

2.1 Building a 3D Realistic Model of the Substation Using UAV Technology

Integrating UAV technology to construct a high-fidelity 3D digital twin of a substation represents a highly innovative and practical advancement in sequential control. Equipped with high-precision survey-grade cameras, UAVs can conduct comprehensive aerial surveys from multiple altitudes and angles, capturing both the overall layout and fine details of critical equipment. This generates a rich dataset of high-resolution images essential for accurate 3D modeling. To ensure data consistency and geometric accuracy, flight missions must strictly adhere to specified UAV operational parameters, as detailed in Table 1.

| Serial Number |

Item |

Parameter |

| 1 |

Flight Height / m |

120 |

| 2 |

Flight Speed / (m/s) |

2 ~ 5 |

| 3 |

Exposure Time Interval / s |

2 ~ 3 |

| 4 |

Longitudinal Overlap / % |

85

|

| 5 |

Lateral Overlap / % |

75 |

| 6 |

Camera Focal Length / mm |

35 ~ 50 |

| 7 |

Camera Sensor Size / mm |

6 048 × 4 032 |

| 8 |

Ground Resolution / (cm/pixel) |

1.5 |

Among these parameters, the flight altitude is set at 120 m—a height that ensures the UAV captures imagery covering the entire substation while maintaining sufficient detail clarity. The flight speed is controlled between 2–5 m/s to keep the UAV stable during flight and prevent motion blur caused by excessive speed. The exposure interval is set to 2–3 seconds, enabling consistent image brightness and reliable quality under varying lighting conditions.

A forward overlap of 85% and a side overlap of 75% guarantee ample overlapping areas between adjacent images, providing the necessary redundancy for subsequent image stitching and 3D modeling. The camera lens focal length ranges from 35 to 50 mm, paired with a high-resolution sensor of 6,048 × 4,032 pixels, effectively capturing fine details of various substation equipment. Additionally, a ground sampling distance (GSD) of 1.5 cm/pixel ensures each pixel corresponds precisely to a real-world dimension on the ground, significantly enhancing spatial accuracy.

By strictly adhering to these flight parameters, the UAV acquires high-quality imagery that—after processing through professional photogrammetry software involving stitching, fusion, and 3D reconstruction—yields a highly realistic and detailed 3D digital twin of the substation. This model provides intuitive and accurate spatial reference information for sequential control operations, enabling operators to clearly understand equipment layout and status, thereby laying a solid foundation for precise execution of automated switching sequences.

2.2 Implementation of “Dual Confirmation” for Disconnector Position in Substations

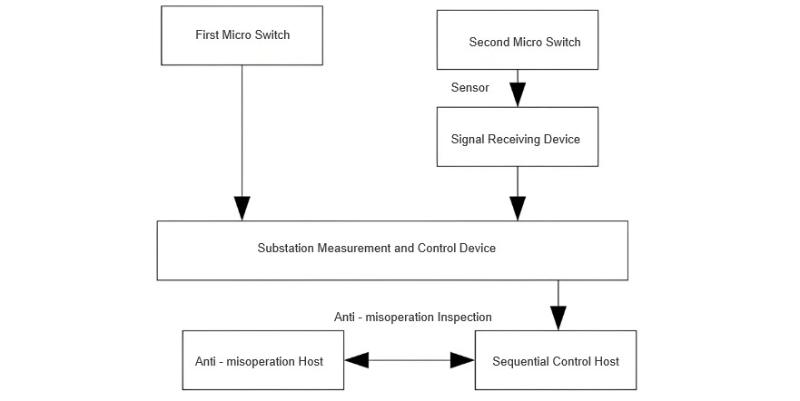

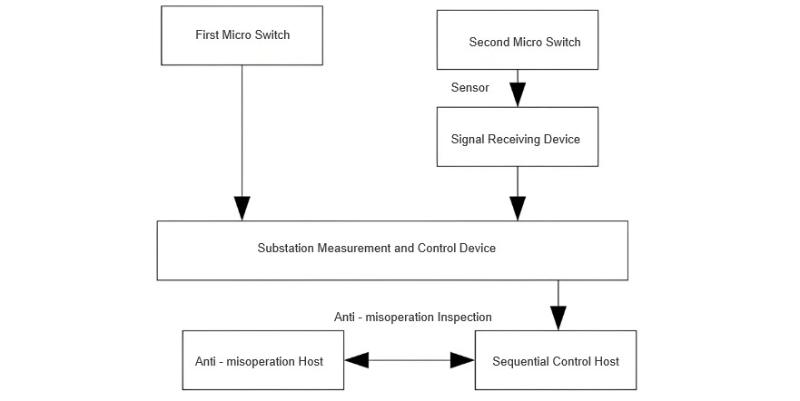

The “dual confirmation” device for disconnectors serves as a critical component for verifying switch position. It employs sensors mounted directly onto the primary mechanical operating mechanism to monitor actual disconnector status. The system features two micro-switches: the second micro-switch is directly linked to the sensor and responsible for capturing the true physical position of the disconnector blade. The collected signal is transmitted via the sensor to a signal receiver, which then forwards the data to the substation’s measurement and control system. This closed-loop transmission mechanism enables real-time, high-fidelity detection of disconnector positions, offering reliable positional validation for sequential control operations.

As the central hub, the substation’s measurement and control unit receives signals from both the first micro-switch (mechanical feedback) and the processed signal from the second micro-switch (sensor-based feedback). After integrating and validating these dual inputs, the unit sends the consolidated status data to the sequential control host. Simultaneously, an anti-misoperation host cross-checks all operation commands issued by the sequential control host. Only after passing this anti-error verification can the sequential operation proceed.

This “dual confirmation” mechanism technically eliminates risks associated with single-point signal failure or misjudgment, drastically improving the reliability of disconnector position detection. In real-world scenarios—whether during routine switching operations or emergency responses—the dual-confirmation disconnector ensures operators always receive accurate position information, effectively preventing misoperations and reinforcing the safety and stability of sequential control systems.

2.3 Practical Application

In an expansion project at a 110 kV substation, integrating new equipment into the existing sequential control system posed significant challenges—challenges effectively addressed through UAV technology. Operators deployed UAVs following strict flight parameters: a flight altitude of 120 m ensured comprehensive coverage of the substation while preserving equipment-level detail; a flight speed of 2–5 m/s maintained platform stability for sharp imagery; and an exposure interval of 2–3 seconds adapted to changing light conditions to secure high-quality photos. With 85% forward overlap and 75% side overlap, the dataset provided ample redundancy for robust photogrammetric processing.

Using advanced photogrammetry and 3D modeling techniques, the high-resolution UAV imagery was transformed into an accurate 3D digital twin of the substation. This immersive spatial model allowed the operations team to precisely analyze the spatial relationships between legacy and newly installed equipment. During simulation of sequential control procedures, operators leveraged the model to pre-plan optimal operational paths and accurately identify target devices using precise geospatial coordinates—dramatically reducing commissioning time for new equipment integration.

In practice, this approach enabled the project team to complete integration and commissioning of the sequential control system three days ahead of schedule. This not only shortened the overall project timeline but also accelerated the substation’s transition toward intelligent operation, establishing a solid foundation for its safe and reliable long-term performance.

In the daily sequential control operation and maintenance scenarios of this 110 kV substation, the disconnector “dual confirmation” mechanism serves as the core safeguard for operational safety and efficiency, while UAV technology provides strong auxiliary support. Taking a nighttime emergency sequential control operation as an example: after operators issue a disconnector opening command from the sequential control host, the “dual confirmation” device immediately activates its precise signal transmission and verification mechanism. The two micro-switches inside the device transmit the disconnector blade position signals in real time to the substation’s measurement and control unit. This unit integrates and pre-processes the signals before forwarding them to the sequential control host. Simultaneously, the anti-misoperation host performs logic-based verification of the operation command; only after the anti-misoperation host confirms the command as valid can the opening operation be executed.

During this process, the UAV also plays a significant role. Leveraging its agile flight capabilities, the UAV conducts real-time, all-around monitoring of substation equipment—particularly focusing on the disconnector area. While the “dual confirmation” device is operating, the UAV transmits live on-site video feeds back to the control room, providing operators with an additional visual reference to further ensure operational accuracy.

Compared with traditional manual on-site verification, this integrated approach reduces operation time from the original 10 minutes to just 3 minutes, significantly improving efficiency. More importantly, it effectively eliminates the risk of misjudgment caused by poor lighting and operator fatigue during nighttime manual checks.

3.Conclusion

UAV technology has brought innovative breakthroughs to substation sequential control operations. By constructing 3D realistic models, it effectively enhances the efficiency of integrating new equipment into sequential control systems and accelerates project implementation. When working in synergy with the disconnector “dual confirmation” devices, UAVs significantly improve the safety and precision of equipment operations. As UAV technology continues to evolve and becomes more deeply integrated with sequential control systems, it holds promise for further addressing challenges such as adaptability under complex operating conditions and equipment interoperability, continuously advancing substation operations toward greater intelligence and reliability, and providing robust technical support for the stable and efficient operation of power systems.