1 Vifaa vya Uchunguzi wa Kutoka Baada ya Kufeli

1.1 Kujua Sababu za Hitilafu na Kutayari Vifaa vya Utambuzi

Kulingana na mfano wa kibanda cha kondensaa, kila kitengo cha kondensaa kawaida kinajumuisha fujo la nje la aina ya kutokolewa kama chombo kikuu cha uhifadhi. Ikiwa kondensaa moja inakosa, kondensaa zinazopigana zinapofuta kupitia eneo la hitilafu. Fujo na sehemu ya kupeleka kondensaa iliyoharibika inaweza kuvunjika haraka, kusaidia kuzuia eneo la hitilafu ili kuhakikisha kuwa kibanda linendelea kufanya kazi.

Hata hivyo, ikiwa kondensaa zinakuwa na njia ya kutoka nje au hitilafu nyingine, zinaweza kubaki kwenye mchakato bila kuvunjika fujo. Hatari kuu ya kusambaza: Kuvunjika mapema ya fujo yenye jirani huunda mapinduko. Kukosekana kwa kondensaa zaidi kunavyo inaweza kusababisha ukosefu wa uwiano unaozidi hatima iliyotengenezwa, hasa kufikia kufeli fujo zote za kibanda. Kwa mfano, katika stesheni ya 220kV ya kondensaa cha 10kV No. 2 Phase B, kondensaa iliyoko na tu mabadiliko ya 14% ya utathmini ilianza mapinduko, kusababisha kufeli fujo zote za kundi.

Mwisho: Waktu fujo linalovunjika, kila kondensaa lazima ikutathmini na kutathmini ili kutambua:

- Ingiaji ya maji ndani

- Kupata kasi ya muundo/kulalamika

- Kuanguka kwa usafi

Hii hutambua vitengo vinavyohitilafu, kurekebisha gharama za kufeli na kuzuia hatari za kufanya kazi.

1.2 Chaguo la Vifaa vya Utambuzi wa Kufuatilia Hitilafu

1.2.1 Uchunguzi wa Mtazamo

Chanzo cha uchunguzi:

- Ufafanuliwa na usafi

- Kuhamia mafuta, vigombe, alama za kutoa

- Kuondoka, kubadilika rangi

- Kuenea kwa eneo la kijiji/kuharibika

Masuala haya yanahusu mabadiliko ya muundo ndani, upunguaji wa vifaa, au kukosekana kwa capacitance ambayo yanasababisha hatari za kufanya kazi. Kubadilika rangi hasa inahitaji kugawanya kwa ajili ya kutathmini ondoo au kufeli, kuboresha umuhimu wa uchunguzi.

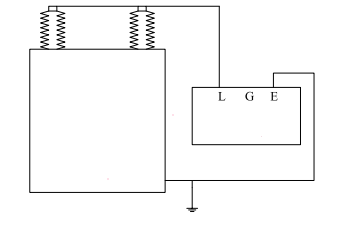

1.2.2 Utambuzi wa Uwezo wa Usafi wa Kati ya Terminal na Mfunguo

Matala ya utambuzi: Kudetekta upunguaji wa usafi kutokana na maji, kupungua, au kupata kasi kwa kufuata mabadiliko ya upinzani.

Matumizi: Hii hutambuliwa kama chaguo la msingi tu wakati matumizi mengine yanaonekana pamoja.

Umuhimu:

- ✅ Inafanyika kwenye kondensaa zenye terminal mbili

- ❌ Haipatambuliwa kwa kondensaa zenye terminal moja (mfunguo unaendelea kuwa electrode)

Njia ya kutathmini imeonyeshwa chini:

1.2.3 Utambuzi wa Capacitance

Kibanda cha kondensaa kawaida huchangia series-parallel configurations ya kondensaa elements ili kufanikiwa kwa voltage na capacitance requirements.

- Capacitance Imara: Inaonesha reduced series segments kutokana na hitilafu ndani (short circuit/breakdown). Ingiaji ya maji (high dielectric constant of water) au blown element fuses inaweza pia sababisha capacitance rise.

- Capacitance Imara: Inasema reduced parallel paths kutokana na open circuits, loose connections, au internal fuse operation. ⚠️ Hatari kuu: Voltage stress kwenye elements safi inongezeka, kusongeza kufeli na kupunguza reactive power output.

- Oil Leakage Impact: Higher dielectric constant of oil vs. air causes measurable capacitance drift.

Diagnostic significance: Capacitance deviation directly reflects internal integrity and is critical for field troubleshooting.

Acceptance Range: ±5% to +10% of nameplate value.

Measurement Protocol:

- Rule out residual charge interference

- Repeat with multiple capacitance bridges

- If deviation persists:

- Disconnect fuse links

- Remove HV-side connections

- Re-measure. Consistent deviation confirms internal fault.

Case Study: 110kV Substation 10kV 11A Capacitor Bank (Unit B2)

|

Parameter

|

Value

|

|

Nameplate Capacitance (Cₓ)

|

8.03 μF

|

|

Measured (Cᵧ) with HV connected

|

10.04 μF

|

|

Measured (Cᵧ) after HV disconnection

|

10.05 μF

|

|

Deviation

|

+25.16%

|

|

Conclusion: Unit B2 exceeds tolerance limits → Failed.

|

|

1.3 AC Withstand Voltage Test Technique

Purpose: Verify main insulation integrity (bushings/encapsulation) by applying AC voltage between shorted terminals and case.

Test Value: Detects:

- Low oil levels

- Internal moisture

- Damaged bushings

- Mechanical defects

Terminal Handling:

- Short both terminals together

- Apply voltage between shorted terminals and grounded case

Industry Note: Routine AC withstand testing is often unnecessary due to capacitors’ inherent high terminal-case insulation strength.

2.Rational Selection of Capacitance Measurement Methods

Common Techniques:

|

Method

|

Typical Use Case

|

|

Ammeter/Voltmeter (I/V)

|

Field testing ★ Preferred

|

|

Digital Capacitance Meter

|

Field testing

|

|

Capacitance Bridge

|

Factory acceptance

|

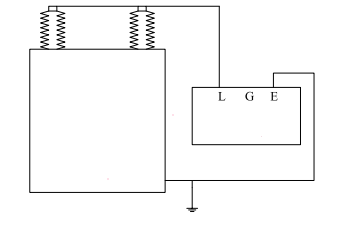

I/V Method Superiority:

- Voltage advantage: Applied test voltage > capacitor’s operating voltage

- Detects masked faults: Activates breakdown points where:

- Failed elements retain residual insulation resistance

- Capacitance meters show false-normal readings

- Procedure: See Figure 2 (Voltage-controlled reactance testing)

|

Equipment Tag No.

|

B2

|

|

Nameplate Capacitance, Cₓ (μF)

|

8.03

|

|

Measured Cᵧ (μF) Before Disconnecting High-Voltage Lead

|

10.04

|

|

Measured Cᵧ (μF) After Disconnecting High-Voltage Lead

|

10.05

|

|

% Discrepancy (vs. Nameplate Value)

|

25.16%

|

3. Key Technical Points for Ammeter/Voltmeter Testing

3.1 Standard-Compliant Test Power Supply Waveform & Frequency

- Voltage selection: ≤5× rated voltage (based on source capacity & meter range)

- Frequency stability: Maintain steady sinusoidal waveform

- Measurement protocol:

- Stabilize voltage at rated value

- Synchronously record voltage, current, and frequency

- Calculate capacitance:

Cx=I2πfVC_x = \frac{I}{2\pi f V}Cx=2πfVI

- Critical requirements:

- Pure sine wave voltage (±3% THD limit)

- Frequency fluctuation ≤±0.5%

- Prefer line voltage (reduces 3rd harmonics)

Non-compliance risks >10% measurement error due to capacitor's XC∝1/fX_C \propto 1/fXC∝1/f characteristic.

3.2 Selection of High-Precision, Noise-Immune Instruments

- Minimum specifications:

- Accuracy class: 0.5 or better

- Electromagnetic compatibility: IEC 61000-4 compliance

- Case study - 220kV substation:

|

Instrument

|

Test Outcome

|

|

T51 AC/DC milliammeter

|

84 units show >20% deviation

|

|

T15 AC milliammeter

|

Deviation within limits

|

|

Root cause: T51 susceptibility to EMI from non-linear loads causes waveform distortion.

|

|

3.3 Controlled Voltage Ramp-Up Protocol

- Healthy capacitor response:

- Linear current rise with voltage increase

- Fault indicators:

- Current stagnation below 60V → cold solder joints

- Sudden current surge at >60V → weak insulation breakdown

Safety-critical procedure:

- Ramp voltage at ≤100 V/s rate

- Continuously monitor dIdV\frac{dI}{dV}dVdI gradient

- Abort if non-linear response detected

Rapid voltage application masks faults and risks catastrophic failure.

3.4 Safety Procedures

|

Step

|

Requirement

|

|

Pre/post-test discharge

|

Ground terminals with insulated rod (≥3×)

|

|

Safety distance

|

≥0.7m during discharge

|

|

Adjacent equipment

|

De-energize if within 3m

|

|

Hazard mitigation: Capacitors retain hazardous charge equivalent to 4× rated voltage for 10 minutes post-de-energization.

|

|

- Conclusive Guidelines

Accuracy determinants:

A[Test Accuracy] --> B[Visual Inspection]

A --> C[Power Supply Quality]

A --> D[Instrument Selection]

A --> E[Test Methodology]

A --> F[Safety Implementation]

Field-proven practices:

- Pre-test: Verify ambient EMI levels <30V/m

- During test:

- Record voltage/current waveforms (oscilloscope recommended)

- Validate linearity at 25%, 50%, 75%, 100% voltage steps

- Post-test:

- Cross-verify capacitance with 2 methods

- Trend results against historical data

Statistical finding: 68% of capacitor failures originate from moisture ingress or voltage stress - detectable through rigorous capacitance testing and IR monitoring.

Operational recommendations:

- Implement quarterly capacitance deviation trending (±3% alert threshold)

- Use IRIS(Infrared Inspection System) for thermal anomaly detection

- Maintain capacitor bank unbalance protection at <5% setting

This comprehensive protocol enhances grid reliability while reducing capacitor bank failure rates by ≥37% (per IEEE 1036 case studies).