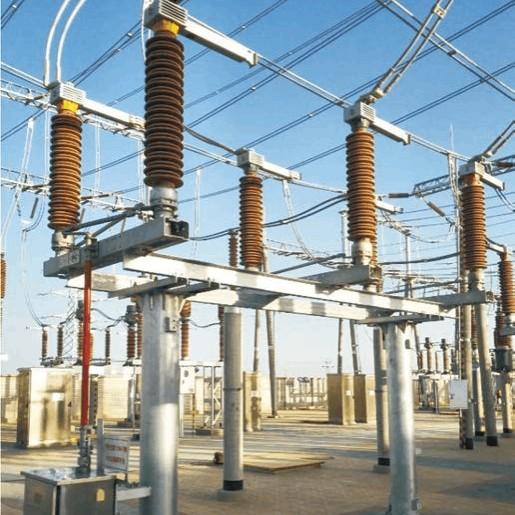

High-voltage disconnectors are critical protective devices in industrial electrical systems. Typically installed both indoors and outdoors at worksites, these disconnectors are prone to corrosion from multiple factors during long-term operation. This paper analyzes corrosion protection technologies for high-voltage disconnectors based on natural environmental conditions, internal structural design, and protective coating strategies, aiming to support the stable and reliable operation of relevant enterprises.

1. Research Background

High-voltage disconnectors serve as essential safeguarding components in enterprise electrical systems. Due to their typical deployment in both indoor and outdoor environments, they are continuously exposed to various corrosive agents over time. This paper investigates corrosion protection techniques by examining three key aspects: natural environment, internal construction, and protective coatings—providing practical guidance for enhancing equipment reliability and supporting sustainable industrial operations.

Corrosion Factors Affecting High-Voltage Disconnectors

(1) Natural Environmental Factors

Given their critical role in ensuring stable power system operation, high-voltage disconnectors have stringent environmental requirements. They are generally installed in locations with:

In many industrial settings with high ambient temperatures, disconnectors are often placed outdoors. Since most disconnector components are metallic, prolonged exposure to high humidity and temperature accelerates oxidation reactions between metal surfaces and atmospheric moisture. This leads to performance degradation over time. In regions with large diurnal temperature swings, condensation on metal surfaces significantly exacerbates corrosion.

Moreover, in industrial areas where coal combustion or chemical processing releases pollutants (e.g., SO₂, NOₓ, chlorides), atmospheric contamination intensifies the corrosion of metallic structures. Enterprises should select appropriate anti-corrosion coatings or schedule timely component replacements based on local environmental conditions.

(2) Component Structural Factors

A high-voltage disconnector typically consists of a base assembly, conductive parts, insulating components, and operating/transmission mechanisms. Poor structural design or improper installation can create gaps or dead zones where dust, moisture, and corrosive particles accumulate—eventually causing rust in critical areas.

During operation, contact plates—key interfaces connecting different conductive elements—are especially vulnerable. When dissimilar metals such as copper, aluminum, and steel come into contact under load, galvanic (electrochemical) corrosion occurs. This increases contact resistance, generates localized heating, and accelerates deterioration of transmission and operating mechanisms.

Therefore, during procurement and maintenance, personnel must accurately verify dimensional and electrical parameters, conduct trial runs to assess structural integrity, and prioritize disconnectors with robust, corrosion-resistant designs.

2. Corrosion Protection Strategies for High-Voltage Disconnectors

2.1 Insulator Fracture Detection

Insulator failure poses severe risks to electrical systems. Porcelain insulators, subjected to long-term environmental stress, may suffer corrosion and aging. As they provide critical mechanical support and electrical isolation between conductive and transmission parts, any fracture can trigger short circuits, power outages, or even safety hazards.

Ultrasonic testing is a widely adopted method for detecting insulator defects. For example, in post-type porcelain insulators, fractures commonly occur 10–20 mm beneath the cast-iron flange. Inspectors should use ultrasonic probes (≤5 mm diameter) on the flange and adjacent cylindrical surfaces, matching the probe curvature to the insulator profile. By combining K-values of angled probes with measurements of flange-to-cylinder spacing and analyzing creep-wave propagation data, micro-cracks can be precisely identified. Early detection enables timely replacement via aerial work platforms, ensuring uninterrupted disconnector operation.

2.2 Replacement of Aluminum-Based Main Components

Common materials for disconnector bodies include aluminum, steel, and copper, each with distinct corrosion resistance properties (see Table 1). Aluminum exhibits superior oxidation resistance and thermal stability. At ambient temperatures, it forms a dense, self-passivating oxide layer via the reaction:

4Al + 3O₂ → 2Al₂O₃

This Al₂O₃ film (typically 0.010–0.015 μm thick) effectively shields the underlying metal from atmospheric and thermal corrosion. Any residual moisture sensitivity can be mitigated with hydrophobic surface coatings.

Where electrical performance permits, main structural components should be replaced upon early signs of rust. In environments with high sulfur/chloride emissions (e.g., power plants), multi-factor corrosion from moisture and flue gases necessitates the use of advanced alloys—such as aluminum-copper or aluminum-zinc—as optimal material choices for critical parts.

2.3 Galvanizing Steel Components

Conventional paint coatings offer inadequate protection against aggressive industrial pollutants like SO₂ and chlorine. Hot-dip or electro-galvanizing is therefore a primary corrosion mitigation technique for steel parts in disconnectors.

Zinc is cost-effective, provides excellent cathodic (sacrificial) protection, and forms a durable corrosion-resistant layer. The galvanizing process involves:

Surface preparation: Grinding or polishing to remove burrs and rust.

Degreasing: Alkaline cleaning using NaOH and Na₂CO₃, followed by thorough hot-water rinsing.

Pickling: Immersion in acidic solution for strong etching, then water rinsing and drying.

Electroplating: Using a neutral potassium chloride-based zinc bath (with brighteners and softeners) at 25–35 °C, assisted by compressed air agitation; plating duration ≤ 30 minutes.

Passivation: Immersing the plated part in a room-temperature solution of ~8–10 g/L sulfuric acid and 200 g/L potassium dichromate to form a dense chromate conversion coating.

Final cleaning & drying: Ultrasonic-assisted rinse followed by hot-air drying.

For ongoing maintenance, technicians should use pre-fabricated spare kits, apply molybdenum disulfide (MoS₂)-based lubricants to transmission and operating mechanisms, lubricate base bearings, and seal contact gaps in conductive assemblies—thereby enhancing overall corrosion resilience through routine inspection and care.

3. Conclusion

High-voltage disconnectors are indispensable in power enterprise electrical systems, ensuring the reliable operation of insulators and other critical components. However, long-term exposure to harsh natural environments and suboptimal structural designs makes them susceptible to corrosion. To address this, this paper presents a comprehensive analysis of corrosion protection measures—including insulator fracture detection, strategic material substitution (e.g., aluminum alloys), and advanced metal protection techniques like galvanizing. These strategies collectively enhance the durability, safety, and operational lifespan of high-voltage disconnectors in demanding industrial applications.