Trip and Close Coils in Low-Voltage Vacuum Circuit Breakers

The trip and close coils are the core components that control the switching state of low-voltage vacuum circuit breakers. When the coil is energized, it generates a magnetic force that drives a mechanical linkage to complete the opening or closing operation. Structurally, the coil is typically made by winding enameled wire on an insulating bobbin, with an outer protective layer, and the terminals are fixed to the housing. The coil operates on either DC or AC power, with common voltage ratings including 24V, 48V, 110V, and 220V.

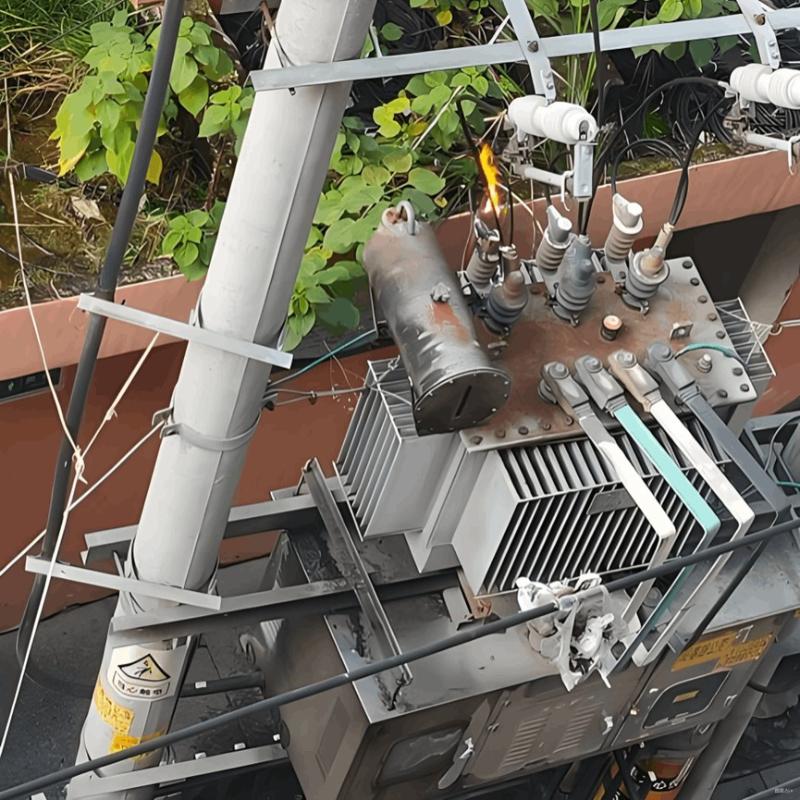

Coil burnout is a high-frequency failure. Prolonged energization causes excessive temperature rise, leading to carbonization of the insulation layer and resulting in short circuits. When the ambient temperature exceeds 40°C or more than five consecutive operations are performed, the coil’s service life can be shortened by 30%. The coil’s condition can be evaluated by measuring its resistance, with a ±10% tolerance allowed for normal values. For example, for a coil with a nominal resistance of 220Ω, a measured value below 198Ω may indicate an inter-turn short circuit, while a value above 242Ω suggests poor contact.

During installation, attention must be paid to the coil’s polarity direction, as reverse connection may cause magnetic force cancellation. During maintenance, clean the moving parts of the iron core with anhydrous alcohol, and maintain a free movement gap of 0.3–0.5mm. When replacing with a new coil, verify the voltage parameters; connecting a DC coil to an AC power source will cause immediate burnout. For models equipped with a manual trip button, perform three manual tests per month to prevent mechanical sticking.

When a circuit breaker trips frequently, first eliminate factors other than coil failure. Measure whether the control circuit voltage is stable and check if the auxiliary switch contacts are oxidized. A substation once experienced repeated coil burnouts, and the root cause was eventually traced to the trip spring pre-load being adjusted too high, resulting in excessive mechanical load.

Humid environments easily trigger coil failures. When humidity exceeds 85%, it is recommended to install a moisture-prevention heating device. In a coastal distribution room, after switching to sealed-type coils, the failure rate dropped from an average of 7 times per year to zero. For locations with strong vibrations, the coil should be potted with epoxy resin to prevent wire breakage.

When selecting a replacement part, pay attention to three parameters: rated voltage, actuation power, and response time. When replacing with a coil from a different brand, verify the mechanical fit dimensions; there have been cases where a 2mm difference in plunger length caused incomplete tripping. A transition bracket can be custom-made if necessary, but the electromagnetic pulling torque must be recalculated.

From a system strategy perspective, it is recommended to establish a coil lifecycle record. Record the ambient temperature, number of operations, and changes in resistance value for each operation. A power supply bureau found through big data analysis that when the coil resistance variation rate reaches 15%, the probability of failure within the next three months increases to 82%.

Critical thinking must run through the entire fault analysis process. When a coil burns out, do not simply replace it; instead, trace the root cause. A factory experienced repeated coil burnouts, and the final investigation revealed a design flaw in the control circuit that caused the trip signal to fail to release in time, resulting in a continuous energized state.

For emergency handling, a parallel resistor method can be temporarily used. Connect a 200W resistor in parallel across the terminals of the burnt coil to temporarily maintain operational functionality, but the coil must be replaced within 24 hours. This method is only applicable to DC coils and must not be used for AC coils. Insulated gloves must be worn during operation to prevent electric shock from residual voltage.

There are techniques for coil temperature rise testing. When using an infrared thermometer for monitoring, aim at the center of the coil. The allowable temperature rise standards are: 75°C for Class A insulation and 100°C for Class F insulation. Testing should be conducted immediately after three consecutive operations, as the temperature is closest to its peak at this point.

In terms of design improvements, new dual-winding coils are beginning to be applied. The main winding is responsible for generating magnetic force, while the auxiliary winding is used for condition monitoring. When an inter-turn short circuit occurs in the main winding, the change in inductance of the auxiliary winding triggers an early warning signal, enabling fault prediction 20 days earlier than traditional coils.

The economic viability of maintenance must be comprehensively considered. The market price of a standard coil is approximately 80–150 RMB, with a replacement labor cost of about 200 RMB. If annual failures exceed three times, upgrading to a high-temperature-resistant coil (priced at about 280 RMB) is recommended, as its lifespan is extended by three times. For critical power nodes, a redundant dual-coil configuration is more reliable.

Key points for operation training include: never plug or unplug coil connectors under power, maintain at least a 15-second interval between trip/close operations for heat dissipation, and strengthen insulation testing during the rainy season. A maintenance team failed to follow the cooling time requirement, resulting in a newly replaced coil burning out again within two days.

A technical innovation trend is emerging. Latching-type magnetic coils are beginning to replace traditional structures, using permanent magnets to hold the trip or close state, reducing power consumption by 90%. However, such coils have higher requirements for control signals and require a dedicated driver module, increasing retrofit costs by approximately 40%.

It is highly advisable to carry a digital bridge for on-site diagnosis. It can not only measure DC resistance but also detect the coil’s inductance. The normal fluctuation range of inductance should be within ±5%. If a significant drop in inductance is detected, the coil should be replaced even if the resistance value appears normal.

Protective measures must not be overlooked. In cement plants with high dust levels, installing a nanofiber filter cover on the coil effectively blocks particles larger than 0.3 microns. For chemical plants, it is recommended to use pH test paper to check the acidity or alkalinity of the coil surface quarterly, and perform anti-corrosion treatment immediately upon detecting signs of corrosion.

Lifespan prediction models are becoming more widespread. Algorithms based on the number of operations, environmental parameters, and resistance variation rates have achieved over 75% accuracy. One intelligent circuit breaker has already achieved 30-day advance warning of coil failure, preventing unplanned power outages.

Acceptance criteria after maintenance include: manual operating force not exceeding 50N, noise level below 65 dB during electric operation, and no jamming during 10 consecutive operations. During acceptance, use an oscilloscope to capture the coil current waveform. A normal waveform should be a smooth curve; a sawtooth waveform indicates the presence of mechanical resistance.