Conciliatio

Vetus rete distributionis praecipue radiale est in structura, cum plures lineae introductae et egressae sint lineae aereae. Apparatus commutationis saepe constat ex circuit breakers vacui vel circuit breakers parvo oleo. Haec rete frequenter labitur, habet sumptus operativos altos, et, si casus accidit, intermissiones longas et extensas electricitatis, quae graviter impedimenta adiungunt developmento economico.

Cum rapido crescimento economico et renovatione rete urbanum, demanda pro maiore fide acquisiti electricitatis crescit. SF₆ Ring Main Units (RMUs) plene insulata, plene sigillata, sine necessitate maintenance, et compactora rursum fiunt garantia pro fide acquisiti electricitatis.

1 Species et Structurae SF₆ RMUs

1.1 Species SF₆ RMUs

SF₆ RMUs possunt classificari in duas species principales secundum structuram: Typus Commune Reservoarium et Typus Unitatis Modularis. Primus RMUs Typus Commune Reservoarium saepe habebant unum introitum, unum circulum, et unum exitum, aptum pro minoribus oneribus. Sed cum crescente demanda onerum, emergit Typus Unitatis Modularis expansibilis, offerens capacitas distributionis usque ad 10 MVA.

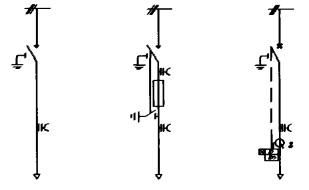

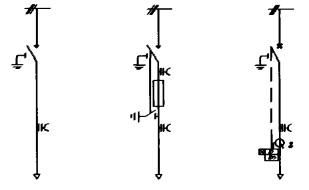

SF₆ RMUs possunt categorizari per functionem in Typus Cabello, Typus Fusoris, et Typus Circuit Breaker SF₆:

- Typus Cabello: Usus pro introitu/exitu cabilorum. Currentus nominatus est 630A.

- Typus Fusoris: Potest directe coniungi ad transformatores. Currentus nominatus est 200A. Tamen, considerando effectum caloris fusoris, unus RMU practice limitatur ad supplyendo transformatores usque ad 1600 kVA in applicationibus realibus.

- Typus Circuit Breaker SF₆: Usus ad protegendum transformatores ultra 1600 kVA. Potest etiam servire ut unitas introitus aut sectionis busbar cum protectione overcurrent et instantanea. Currentus nominatus est 630A, cum tempore totali interruptionis faulti 95ms.

Configurationes basic RMUs SF₆ ostenduntur in figura infra.

1.2 Structurae SF₆ RMUs

Typus Commune Reservoarium SF₆ RMU generaliter constat ex reservoario gas, compartimento mechanismi operationis, et compartimento connectionis cabilorum. Typus Unitatis Modularis requirit additio compartimento connectionis busbar.

SF₆ RMUs habent quattuor features majora:

- Reservoarium Gas: Hoc est pars maxime critica RMU. Reservoarium gas continet switch oneris, busbars, axis switch, et gas SF₆.

- Switch oneris est switch trilocale, includens isolating knife switch et arc chute.

- Contactus mobilis switch knive habet duos rivulos speciales de alloy Nichrome, qui serviant duobus scopis:

- Praebet lubricationem siccam durante apertura/closure switch, asserens resistencia contactus inter contactus mobiles et fixos non crescat post usu longum.

- Propter altum punctum fusionis alloy Nichrome, contactus mobilis non fundetur propter calorem generatum a currentibus short-circuit durante closure aut periodibus sustinendi.

- Arc chute continet plates deionizing quae extendunt arcum, reducunt energiam arci, et minuunt quantitatem vaporis metallici et productorum decompositionis SF₆ quando switch oneris interrupt load current.

- Partes busbar contactantes switch knive sunt contactus fixi. Praeterquam ad satisfaciendum requisitis capacitatis currentus nominati et stabilitatis dynamic/thermal, design et manufactura busbar considerant etiam effectus campi electromagnetic, minimizando impactum magnetic field.

- Axis switch penetrat reservoarium gas et connectat ad compartimento mechanismi operationis, permitens operatoribus extra compartimento controlare statum closure, apertus, et earthing switch. Structura sigilli duplicis usatur in puncto penetrationis (unicus nexus movens inter reservoarium et extra), strictim asserens airtightness reservoarium durante evacuationem vacuum et impletionem gas.

- Rata annualis leakage gas SF₆ est solum 0.0035%. Hoc ratio leakage parvum est cruciale pro longo tempore safe operation RMU.

- In addition to SF₆ gas for insulation and arc quenching, the gas tank also contains Aluminum Oxide (Al₂O₃), which accelerates SF₆ gas regeneration and acts as an excellent desiccant, maintaining SF₆ gas quality and minimizing arc faults. Should such a fault occur, an explosion-proof diaphragm below the tank protects personnel by venting hot gases directly into the cable trench beneath or behind the unit, away from operators at the front.

- Reservoarium gas constructum est ex lamina aenae inox 3mm crassitudinis, weld double-sided.

- Compartimento Mechanismi Operationis: Mechanismus interior connectat ad switch oneris et earthing switch per axis switch. Using an operating rod inserted into the operating hole, operators can easily perform closing, opening, and earthing operations with minimal effort (only 60 N·m required).

- Quia contactus switch non visibiles sunt, mechanismus operationis habet indicatorem positionis directe linkatum ad axis switch, clare ostendens statum currentem switch oneris et earthing switch.

- Interlock mechanici inter switch oneris, earthing switch, et front cover plate installati sunt, satisfacientes quinque requirementa security interlock (anti-misoperation functions).

- Both the load switch and earthing switch are equipped with quick-make/quick-break mechanisms, ensuring opening/closing speeds are independent of the operator's speed.

- Switches with fuse protection (TS Type switchgear) also have an automatic trip device, available in mechanical or electrical versions. The mechanical trip principle: During a short-circuit fault in the unit's circuit, the fuse melts within the first half-cycle (~10ms) of the fault current. The fuse's striker pin impacts the trip mechanism, causing the load switch to open. The total fault interruption time is only 35ms, effectively protecting the unit and preventing fault propagation to adjacent units. Furthermore, due to excellent mechanical performance, the transfer current of Fuse Type switchgear can reach 2300A.

- Padlocks can be added to the operating levers on the front panel of the operating mechanism compartment to prevent unauthorized operation.

- For safe operation, a gas pressure gauge, directly connected to the gas tank and sealed against moisture (preventing fogging on the dial), is installed in the compartment, allowing maintenance personnel to accurately monitor the RMU's status at any time.

- A voltage indicator is also installed in the operating mechanism compartment, allowing operators to monitor circuit energization (neon bulb indicator) and verify phasing (using test sockets).

- Compartimento Connectionis Cabilorum: Situs in fronte RMU cum altitudine 1220mm, praebens spatium ample pro terminatio cabilorum.

- Connectiones cabilorum ad bushings RMU utuntur Asbestos-free Touching Screened (AFTS) vel Asbestos-free With Kit (AWK) silicone rubber cable accessories.

- Copper or aluminum cable cross-sections range from 25–240 mm² (for Fuse Type switchgear) or 35–400 mm² (for Cable Type switchgear).

- Compartimento Connectionis Busbar (Unitatis Modularis): Positum sub reservoarium gas. Tria bushings disposita sunt in configuratione "step-up" obliqua, efficaciter minuente requisitos spatii et facilitante connectiones busbar.

- Bushings sunt conductive type hollow, permittentes tubos aenae busbar directe bolta ad busbars intra reservoarium gas.

- Silicone rubber-insulated copper tube busbars are used, effectively increasing current-carrying capacity and reducing phase spacing (only 110mm).

- Connections between busbars and bushings use silicone rubber connectors (E-type terminal connectors and T-type extension connectors) and screw-on caps for electrically seamless connections directly on the bushings. These busbars withstand harsh conditions like moisture condensation, conductive dust, and salt deposits without failure.

- Additionally, the front of the busbar compartment is shielded by a separate grounded steel plate, separating it from the cable connection compartment.

2 Parametri Technici et Applicationes SF₆ RMUs

2.1 Parametri Technici

|

Item

|

Cable-type Switchgear

|

Fuse-type Switchgear

|

Fuse-type Switch Cabinet

|

|

Rated Voltage / kV

|

12

|

12

|

12

|

|

Rated Current / A

|

630

|

200

|

630

|

|

Power-frequency Withstand Voltage / kV·min⁻¹

|

50 - 60

|

42 - 48

|

42 - 48

|

|

Impulse Withstand Voltage / kV

|

125 - 145

|

75 - 85

|

75 - 85

|

|

Rated Breaking Current / A

|

630

|

200

|

630

|

|

Rated Transfer Current / A

|

-

|

2300

|

-

|

|

Rated Short-circuit Breaking Current / kA

|

-

|

20

|

20

|

|

Breaking Capacitive Current / A

|

45

|

10

|

50

|

|

Breaking Inductive Current / A

|

16

|

16

|

-

|

|

Rated Peak Withstand Current / kA

|

50

|

-

|

50

|

|

Rated Short-time Withstand Current / kA·3s⁻¹

|

20

|

-

|

20

|

|

Rated Closing Current / kA

|

50

|

-

|

50

|

|

Number of Operations (630 A) / time

|

>100

|

>100

|

3000

|

|

Number of Closing Operations (50 kA) / time

|

5

|

5

|

5

|

|

Number of Mechanical Operations / time

|

2000

|

2000

|

4000

|

|

Ambient Temperature / °C

|

-

|

-25 - +55

|

-

|

|

Degree of Protection

|

IP65/IP4X

|

IP65/IP4X

|

IP65/IP4X

|

|

Leakage Rate / %, per year

|

-

|

0.0035

|

-

|

2.2 Applicationes SF₆ RMUs

Propter magnitudinem compactam, naturam sine necessitate maintenance, et fidem altam, SF₆ RMUs sunt praecipue apti pro distributione electricitatis in locis criticis, edificiis altis, complexibus residentialis, et retibus urbanis. Illae significanter reducunt sumptus operativos et pedem plantae.

- 3-Unit Common Tank Type: Dimensions only 980mm × 635mm × 1050mm, making it ideal for kiosk transformers and outdoor applications.

- Modular Cable Type: Can incorporate switching tap-off boxes, supporting configurations up to one incoming and three outgoing feeders (i.e., incoming via the busbar compartment, with three outgoing feeders connected in parallel via the cable connection compartment).

- Modular Fuse Type: Suitable for locations far from substations where only one transformer is operating. To achieve local transformer control without needing an additional incoming unit, the incoming cable can be directly connected to the busbar compartment of a TS Type switchgear unit, providing the same functionality.

- Circuit Breaker Type Switchgear: Equipped with overcurrent and instantaneous trip protection. It can serve as a transformer protection unit, an incoming unit, or a busbar section unit. To enable remote tripping or tripping upon transformer gas protection relay operation (for Fuse Type switchgear), simply add an electromagnetic trip coil to the operating mechanism and provide a 220V AC or 24V DC power supply to the circuit.

Motorized Operation:

- For distribution automation, an electric motor can be added to the operating mechanism compartment, along with a 350mm high control box mounted on top. Local push-button operation (open/close) remains possible.

- Adding an Automatic Transfer Switch (ATS) device enables automatic switching between two incoming supplies, with or without a defined primary/standby configuration.

- Electric motors are typically available in various voltage levels (220V AC, 220V DC, 110V DC, 48V DC, 24V DC) for user selection.

- A short-circuit fault indicator can be installed on the front panel of the operating mechanism compartment, with signals transmitted to a remote control room. This indicator can be reset automatically, manually, or remotely.

- Low-voltage through-core Current Transformers (CTs) can be added to the cable connection compartment for current measurement.

- Surge arresters can also be installed within Cable Type switchgear units for RMU protection.

Distribution automation functions primarily focus on five areas: Data Acquisition, Monitoring & Control, Fault Isolation & Service Restoration, Geographic Information System (GIS), and Data Statistics & Reporting.

- Implementing distribution automation requires primary equipment to have motorized operating mechanisms and Feeder Terminal Units (FTUs) or Remote Terminal Units (RTUs).

- Fiber optic cable is the preferred communication medium. Communication protocols should be internationally recognized standards familiar to users, such as IEC 870, DNP 3.0, or TCP/IP.

- The control room SCADA software platform should be multi-tasking and multi-user capable, such as UNIX.

- The database is recommended to be stable with sufficient processing capacity, such as Oracle.

This solution is particularly suitable for RMUs located outdoors or far from low-voltage power sources, as it guarantees simultaneous operation of two 150W motors over 50 times.

3 Lifecycle

Vita SF₆ RMUs est typice 25–30 annos, et potest convenienter retrofitti cum equipment distribution automation. Propter hoc, SF₆ RMUs debent esse electio preferenda pro projectis renovationis rete urbanum.