1. Ufani wa Matatizo ya Transformer ya Mzunguko wa Umeme

1.1 Ongezeko la Joto lisilo Sahihi

Ongezeko la joto lisilo sahihi linatumaini kwa ufanisi wa transformer na linakuwa ishara muhimu ya matatizo. Wakati wa kutumika, mabadiliko ya nishati ya umeme huchanganya namba za chuma na copper, ambayo huathiri kuwa moto. Ili kupunguza hali hii, transformers hufanya matumizi ya njia za kupunguza moto kama vile mzunguko wa mafuta na radiation ya joto ili kukabiliana na ongezeko la joto ndani yake.

Thermometers na mfumo wa utambulisho wa mtandaoni hujifunza mabadiliko ya joto ya mafuta ya juu na windings. Wakati transformer una matatizo, nyimbo za kupunguza moto husababishwa, kunyanyasa ongezeko la joto lisilo sahihi. Hii inaonyesha tatizo kama vile overload, uzee wa insulation, au upotosho wa mfumo wa kupunguza moto, ambayo hutaja matatizo mengine ya mekaniki au umeme.

1.2 Vibration na Sauti Lisilo Sahihi

Katika mchakato wa kutumika kwa kutosha, transformers hupata vibrations na sauti madogo. Umeme wa alternating current katika windings huathiri mabadiliko ya magnetic field katika core ya chuma, kunyanyasa magnetostriction katika vibao vya core. Interactions magnetic madogo kati ya laminations na adjustments electromagnetic-force ndani ya coils huundanya vibrations na sauti sahihi - kama "moyo" wa transformer, ambayo inatumaini utaratibu sahihi wa electromagnetic activities ndani yake.

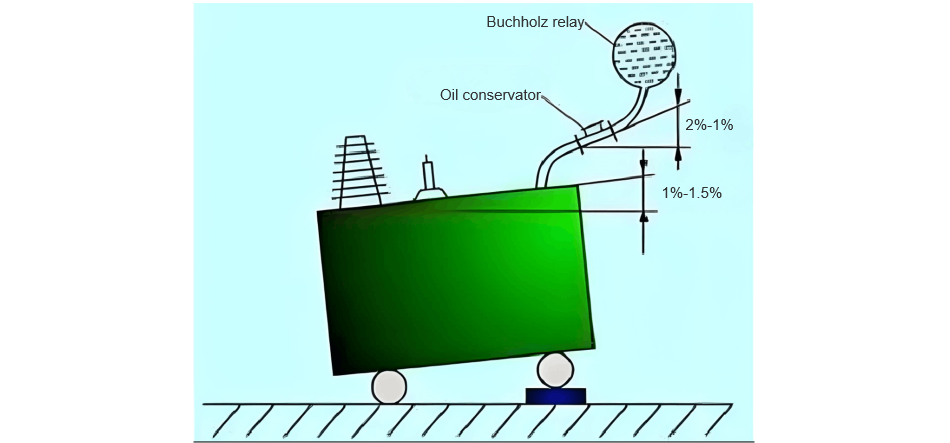

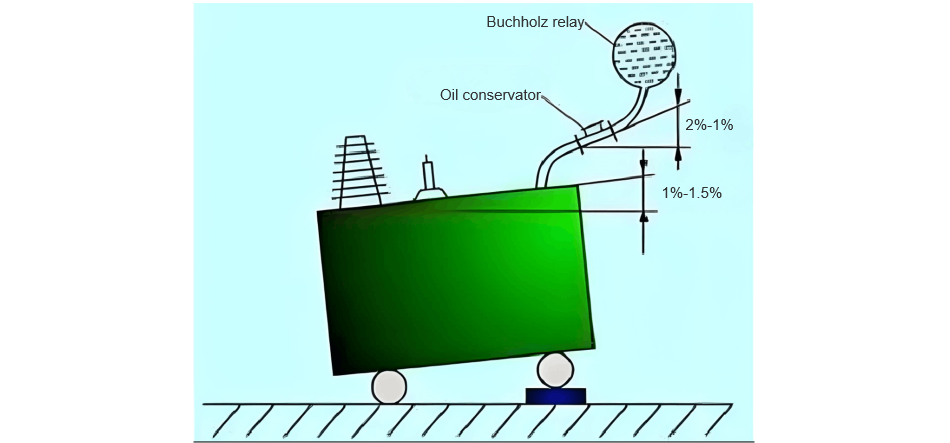

Ikiwa hii "moyo" inachanganyika (kama vile ongezeko la vibration, sauti lisilo sahihi, au sauti asili, kama inavyoonekana katika Fig. 1), inaweza kutoa taarifa kuhusu matatizo yasiyotambuliwa. Components ndani zinazokuwa hazitoshi, short-circuits ya windings, au short-circuits ya core-to-ground zinaweza kusababisha matatizo ya energy conversion, kubadilisha stress ya mekaniki na disturbances electromagnetic. Utambulisho na tathmini sahihi ya vibrations na sauti ni muhimu sana kwa ajili ya tiba na strategy ya preventive maintenance.

1.3 Kiwango cha Mafuta Kisilo Sahihi

Mafuta ya transformer, yanayoitwa "damu" ya kuhakikisha usalama wa kutumika kwa vifaa, huchukua majukumu mengi kama medium ya kupunguza moto, insulation barrier, na arc-extinguishing agent. Kutoshi kwa kiwango lake huamini kabisa kwamba transformer anaweza kudumisha ustawi na kutumika kwa ufanisi kati ya mazingira magumu.

Utambulisho wa kiwango cha mafuta unafanikiwa kwa kutumia indicator sahihi wa kiwango cha mafuta, ambaye anafanya kazi kama "liquid barometer" kwa transformer, unatumaini mabadiliko ya muda wa kiwango cha mafuta ndani yake. Mara tu indicator huu unaonyesha matatizo - hasa wakati kiwango cha mafuta kinaporuka chini ya mstari wa standard - hii si kuumiza mafuta tu, bali ni ishara ya hatari kubwa: Ruka la kiwango cha mafuta litaharibu sana ufanisi wa kupunguza moto, kunyanyasa ongezeko la joto ndani ya transformer, kubadilisha uzee wa insulation materials.

Pia, ukosefu wa mafuta utawezesha upunguzo wa protection ya insulation kwa components ndani, kunyanyasa hatari ya arc discharge, ambayo inaweza kuunda matatizo kama vile short circuits na kukushinda ustawi wa system ya umeme nzima.

2. Njia za Kutumia na Kuhifadhi Transformers za Turbine za Upepo katika Wind Farms

2.1 Tathmini Ya Kwamba Transformers

Transformers ya umeme hufanya voltage regulation ili kuleta mzunguko wa high-voltage na supply stable ya 220V kwenye user end, na kutumika na kuhifadhi yao ni muhimu sana kwa ustawi wa system ya umeme. Wind farm mkubwa, kwa kutegemea na transformers wingi vilivyodumishwa kwa urahisi, huchukua mode ghafla ya monitoring ya mbali na inspection ya mahali: Monitoring ya mbali hutumia mfumo wa mtandaoni kujifunza parameters ya kutumika, na checks ya kila siku na monitoring intense wakati wa peak periods kurekodi data kama vile load na voltage, na kutathmini matatizo mara moja; inspections ya mahali huchukua structures za nje, oil seals, line connections, na hali ya Buchholz relays, na tathmini maalum wakati wa hali za hewa magumu. Baada ya kutumika, annual average failure rate ya transformers ilipunguza kutoka 3% hadi chini ya 1%.

2.2 Kuimarisha Uendeshaji wa Intelligent System

Intelligent operation and maintenance systems huanza kuwa na capabilities za collaboration ya vifaa na processing ya data. Teknolojia za sasa hawawezi kumshikilia needs za scenarios complex kama vile supply ya power ya high-voltage, yanahitaji kuunda models mpya. Research and development hufuata process ya "theoretical conception - laboratory verification - practical application", kushiraza teknolojia kama vile cloud computing kutengeneza modular architectures, ambazo zinapatikana baada ya kutest kwenye platforms virtual. Baada ya three months of system debugging, failure rate ya transformers ilipunguza kwa 30% katika mwezi wa kwanza wa kutumika, kuboresha warning ya awali ya matatizo yanayoweza kuongezeka.

2.3 Kuimarisha Kazi ya Preventive

Preventive maintenance ni strategy msingi, inayotumaina kugundua hatari kwa kutathmini actively. Wind farm hutumia online systems kujifunza parameters kama vile oil temperature, huchukua analysis ya sample ya mafuta kila quarter ili kuevalua hali ya insulation, na kuimarisha management systems kuelimisha responsibilities za post. Maintenance ya dry-type transformers inajumuisha cleaning ya core ya chuma, kutathmini casing na windings, na kuhifadhi surfaces za busbar contact. Baada ya kutumika, unplanned downtime ilipunguza kutoka 240 hours hadi 40 hours, economic losses ilipunguza kutoka 5 million yuan hadi 800,000 yuan, na mean time between failures (MTBF) iliongezeka kutoka 2,000 hours hadi 4,500 hours.

2.4 Oil Maintenance and Management

Katika generation ya umeme wa upepo, transformers ya wind farms - vifaa muhimu vya energy conversion - huchanganya kwa ufanisi na mapato ya kiuchumi. Wakiwa wanatumia operations efficient, wind farms yanapaswa kutekeleza social responsibilities kwa kutetea green maintenance practices. Kama sehemu muhimu ya lifecycle management ya transformer, oil maintenance not only ensures long-term reliability but also underpins sustainable operations.

Transformer oil, "damu" ya transformers, ni muhimu sana kwa kupunguza moto; ubora wake huamini electrical performance na service life. Testing ya mara kwa mara ni muhimu, inaunganisha viwango vya fisadi na kimikali (dielectric strength, acid value, moisture, particle contamination); Dissolved Gas Analysis (DGA), ambayo hutathmini hydrogen, acetylene, ethylene, etc., ili kutambua matatizo ya ndani (partial discharge, overheating, arcing) na kuboresha preventive maintenance.

Oil purification na replacement ni muhimu sana kwa maintenance. Over time, oil deteriorates due to heat, oxidation, and pollutant buildup. Efficient online/offline filtration removes moisture, impurities, and free carbon, restoring insulation and heat transfer. Timely oil replacement, based on strict quality and economic analysis when aging occurs, maximizes cost-effectiveness.

Kiwango sahihi cha joto cha mafuta huimarisha performance na kuongeza uzee wa components. Checks za mara kwa mara ya cooling system - cleaning radiators, inspecting fans/pumps - prevents overheating from poor heat dissipation. All test data, maintenance records, and replacement logs should be detailed, digitized, and analyzed to form health profiles, enabling data-driven, refined maintenance planning.

3 Mwisho

Operation and maintenance ya transformers katika wind farms hujenga technical precision na intelligent management na sustainability. Integrating advanced monitoring, AI algorithms, na experience ya traditional huchanganya prediction ya matatizo, optimize cycles ya maintenance, ensures reliability ya supply ya umeme, na maximize utilization ya resources za upepo. This study, through analyzing operational characteristics, proposing maintenance optimizations, and forecasting trends, offers valuable insights for wind power engineers and decision-makers.