1. Manifestations of Generator Set Transformer Failures

1.1 Abnormal Temperature Rise

Abnormal temperature rise directly reflects a transformer’s health and serves as a key fault - warning indicator. During operation, electromagnetic energy conversion causes iron and copper losses, which turn into heat. To ensure normal operation, transformers use heat - dissipation mechanisms like oil circulation and heat radiation to maintain internal temperature balance.

Thermometers and online detection systems monitor upper - layer oil and winding temperature changes. When a transformer malfunctions, heat - dissipation rhythms are disrupted, causing abnormal temperature spikes. This signals potential issues like overload, insulation aging, or cooling system failure, hinting at deeper mechanical or electrical faults.

1.2 Abnormal Vibration and Noise

In normal operation, transformers produce weak vibrations and audible noises. Alternating current in windings causes periodic magnetic field changes in the iron core, inducing magnetostriction in core sheets. Subtle magnetic interactions between laminations and dynamic electromagnetic - force adjustments inside coils generate regular vibrations and sounds—akin to the transformer’s “vital pulse,” reflecting harmonious internal electromagnetic activity.

If this “pulse” deviates (e.g., increased vibration, abnormal audio, or atypical noises, as in Figure 1), it may reveal hidden faults. Loose internal components, winding short - circuits, or core - to - ground short - circuits can disrupt energy conversion, causing extra mechanical stress and electromagnetic disturbances. Precise monitoring and analysis of vibration and noise are critical for diagnosis and preventive maintenance strategy - making.

1.3 Abnormal Oil Level

Transformer oil, hailed as the "lifeblood" for ensuring safe operation of equipment, plays multiple core roles as a heat dissipation medium, insulation barrier, and arc-extinguishing agent. The adequacy of its volume directly determines whether the transformer can maintain stable and efficient operation under complex working conditions.

Oil level monitoring is achieved through a precisely designed oil level indicator, which acts like a "liquid barometer" for the transformer, reflecting real-time changes in internal oil volume. Once the oil level indicator shows abnormalities—especially when the oil level drops below the standard line—it is by no means a simple reduction in oil quantity, but a warning signal indicating potential serious risks: A drop in oil level will drastically reduce cooling efficiency, causing heat accumulation and intensified temperature rise inside the transformer, accelerating the aging of insulation materials.

Meanwhile, insufficient oil will weaken the insulation protection for internal components, significantly increasing the risk of arc discharge, which may further trigger catastrophic faults such as short circuits and threaten the safe operation of the entire power system.

2. Operation and Maintenance Strategies for Transformers of Wind Turbines in Wind Farms

2.1 General Inspection of Transformers

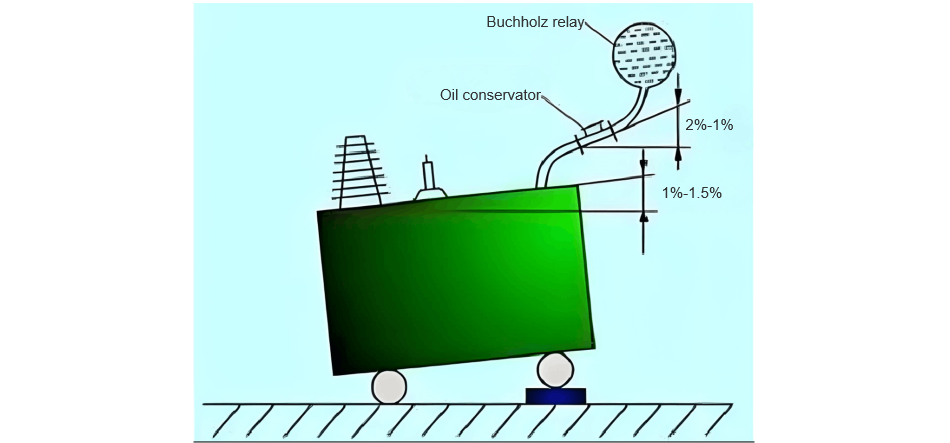

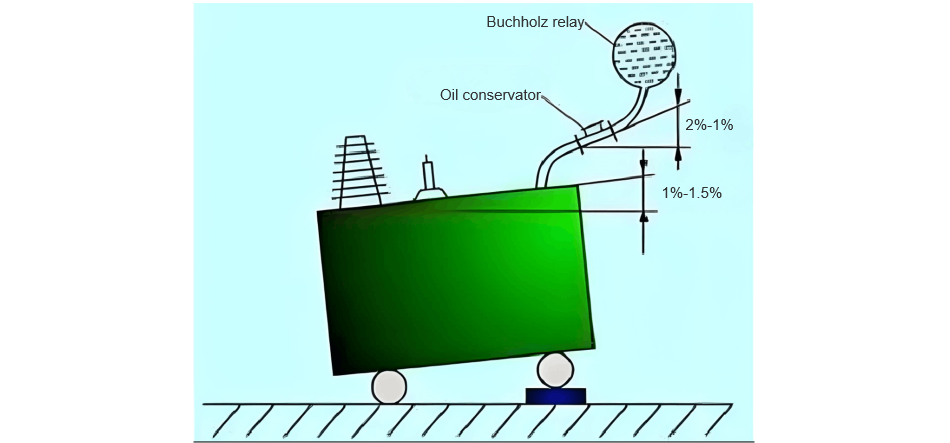

Power transformers achieve high-voltage transmission and stable 220V power supply at the user end through voltage regulation, and their operation and maintenance are crucial to the stability of the power system. A large wind farm, faced with a large number of widely distributed transformers, adopts a combined mode of remote monitoring and on-site inspection: Remote monitoring uses online systems to monitor operating parameters, with daily routine checks and intensified monitoring during peak periods to record data such as load and voltage, with timely disposal of abnormalities; on-site inspections cover external structures, oil seals, line connections, and the status of Buchholz relays, with targeted inspections in special weather conditions. After implementation, the annual average failure rate of transformers dropped from 3% to below 1%.

2.2 Improving Intelligent System Operation

Intelligent operation and maintenance systems need both equipment collaboration and data processing capabilities. Existing technologies can hardly meet the needs of complex scenarios such as high-voltage side power supply, requiring the construction of new models. The research and development follow the process of "theoretical conception - laboratory verification - practical application", combining technologies such as cloud computing to develop modular architectures, which are deployed after testing on virtual platforms. After three months of system debugging, the failure rate of transformers dropped by 30% in the first month of operation, enabling early warning of potential faults.

2.3 Strengthening Preventive Work

Preventive maintenance is a core strategy, aiming to eliminate hidden dangers through active inspections. The wind farm uses online systems to monitor parameters such as oil temperature, conducts quarterly oil sample analysis to evaluate insulation status, and optimizes management systems to clarify post responsibilities. Maintenance of dry-type transformers includes cleaning the iron core, inspecting the casing and windings, and maintaining busbar contact surfaces. After implementation, unplanned downtime reduced from 240 hours to 40 hours, economic losses dropped from 5 million yuan to 800,000 yuan, and the mean time between failures (MTBF) increased from 2,000 hours to 4,500 hours.

2.4 Oil Maintenance and Management

In wind power generation, wind farm transformers—core energy conversion equipment—directly impact overall efficiency and economic returns. While pursuing efficient operations, wind farms must fulfill social responsibilities by advancing green maintenance practices. As a core part of transformer lifecycle management, oil maintenance not only ensures long-term reliability but also underpins sustainable operations.

Transformer oil, the "lifeblood" of transformers, is critical for heat dissipation; its quality determines electrical performance and service life. Regular testing is thus vital, focusing on two aspects: 1) physical and chemical properties (dielectric strength, acid value, moisture, particle contamination); 2) Dissolved Gas Analysis (DGA), which detects hydrogen, acetylene, ethylene, etc., to early-warning internal faults (partial discharge, overheating, arcing) and support preventive maintenance.

Oil purification and replacement are key to maintenance. Over time, oil deteriorates due to heat, oxidation, and pollutant buildup. Efficient online/offline filtration removes moisture, impurities, and free carbon, restoring insulation and heat transfer. Timely oil replacement, based on strict quality and economic analysis when aging occurs, maximizes cost-effectiveness.

Proper oil temperature optimizes performance and extends component life. Regular cooling system checks—cleaning radiators, inspecting fans/pumps—prevent overheating from poor heat dissipation. All test data, maintenance records, and replacement logs should be detailed, digitized, and analyzed to form health profiles, enabling data-driven, refined maintenance planning.

3 Conclusion

Transformer operation and maintenance in wind farms blend technical precision with intelligent management and sustainability. Integrating advanced monitoring, AI algorithms, and traditional experience improves fault prediction, optimizes maintenance cycles, ensures power supply reliability, and maximizes wind resource utilization. This study, through analyzing operational characteristics, proposing maintenance optimizations, and forecasting trends, offers valuable insights for wind power engineers and decision-makers.