1 Mafiyaunuka na Kudin Kudin Fasahar Capacitor

Capacitor fasahar kusa da karkashin kafin, capacitor core, mafi yawan cuta, da kuma tashar terminal. Karkashin kafin yana da kyau a kan harsuna da kuma stainless steel, tare da bushings mai girma a cikin takalma. Capacitor core yana da polypropylene film da aluminum foil (electrodes), kuma tushen karkashin kafin yana da liquid dielectric don yawan cuta da kuma kawo jiki.

A nan da ita ce babban device mai sarrafa, mafiyaunuka masu gaba-gaban capacitor fasahar sun haɗa:

Mafiyaunuka na elementi na capacitor;

Fuse blowing;

Mafiyaunuka na internal short-circuit;

Mafiyaunuka na external discharge.

Mafiyaunukan daga fagenan yana da darasi ga jikin capacitor, kuma idan ya faru, ba zan iya lada a matsayin, wanda ke taimaka wajen ci nasara a tattalin arziki.

1.1 Mafiyaunuka na Elementi na Capacitor

Mafiyaunuka na elementi na capacitor yana da sababbin da suka hada da yawan cuta, gaske, kudin kudin, da kuma harshen aiki. Idan elementin ba ta da fuse na baya, mafiyaunuka na elementi kawai zai shiga elementi na biyu, kuma zai kula shiga shugaban voltage. Wannan zai sa shi a yi tasiri a kan shugaban voltage a kan elementi na biyu. Idan ba a yi isolation a lokacin, wannan zai ba da abin da ke tsakanin aiki da kuma kula shi a yi tasiri a kan cin kala.Amfani da fuse na baya yana taimaka a yi isolation na elementi na fasahar, kuma yana taimaka a yi nasara a cikin aiki.

Mafiyaunuka na capacitor yana da tsohon rukuni uku: electrical breakdown, thermal breakdown, da partial discharge breakdown.

Electrical Breakdown: Yana faru saboda overvoltage ko harmonics, wanda ke taimaka a yi electric field strength mai yawa a kan dielectric, wanda ke taimaka a yi yawan cuta a kan wuraren fasahar. Ana sanya a lokacin da take faru da shugaban field intensity mai yawa. Breakdown strength yana da alaka da field uniformity amma ba ta da alaka da temperature ko duration da voltage.

Thermal Breakdown: Yana faru idan heat generation ya kasa heat dissipation, wanda ke taimaka a yi continuous temperature rise a kan dielectric, wanda ke taimaka a yi material degradation da kuma yawan cuta a kan wuraren fasahar. Wannan yana faru a lokacin da take faru a kan steady-state operation, tare da shugaban voltage mai yawa da kuma duration mai yawa saboda electrical breakdown.

Partial Discharge Breakdown: Yana faru saboda localized high electric fields a kan dielectric, wanda ke taimaka a yi partial discharges, wanda ke taimaka a yi yawan cuta a kan insulation performance, kuma a yi yawan cuta a kan wuraren fasahar. Wannan yana faru a lokacin da take faru a kan non-penetrating discharges, kuma a yi yawan cuta a kan insulation failure.

1.2 Fuse Blowing

Fuse protection yana da muhimmanci a kan power capacitors, kuma yana taimaka a yi nasara a cikin aiki. Yana da duwan rukuni: external da internal fuse protection.

External Fuse Protection: Idan elementi na capacitor yana faru, fault current a kan capacitor da external fuse yana zama. Idan current ya kasa rated melting threshold, fuse yana hota, kuma yana melt, kuma yana disconnect faulty capacitor, kuma yana taimaka a yi prevention da fault escalation.

Internal Fuse Protection: Idan elementi yana faru, parallel elements yana discharge a kan elementi na fasahar, kuma yana taimaka a yi high-amplitude, rapidly decaying transient current. Energy a kan current yana taimaka a yi melting da series-connected internal fuse, kuma yana taimaka a yi isolation da elementi na fasahar, kuma yana taimaka a yi continuation da aiki.

A nan da ita ce, selection da poor terminal contact yana iya ba da fuse blowing a lokacin aiki, kuma yana iya ba da removal da capacitors masu nasara, kuma yana iya kula shi a yi reactive power output.

Idan internal fuses ba su da size daidai, kuma ba su da isolation da faults, fault yana iya zama, kuma yana iya ba da capacitor explosion ko fire.

1.3 Internal Short-Circuit Faults

Mafiyaunuka na internal short-circuit faults a kan power capacitors yana da live electrode-to-housing shorts da inter-electrode shorts. Wannan yana faru saboda yawan cuta, gaske, overvoltage stress, ko inherent insulation defects, kuma yana taimaka a yi puncture-type insulation breakdown da internal short circuits.

1.4 External Discharge Faults

Mafiyaunuka na external discharge faults yana faru saboda factors na baya, tare da bushing surface flashover, bushing puncture, phase-to-phase ko phase-to-ground short circuits, ko cracks a kan porcelain bushings. Wannan yana faru a kan external circuitry, kuma yana taimaka a yi detection da mitigation a lokacin relay protection actions, routine inspections, ko offline testing. Probability da severity yana zama, amma yana da muhimmanci a kan attention.

2 Mafiyaunuka da Sababbin Da Suke Faru a Kan Power Capacitors

2.1 Oil Leakage from Capacitor Body

A nan da ita ce babban device mai sarrafa, oil leakage a kan power capacitor yana taimaka a yi reduction da insulation level, kuma yana taimaka a yi moisture ingress. Wannan yana taimaka a yi insulation dampness, reduced insulation resistance, da kuma yawan cuta a kan elementi na baya, ko kuma capacitor explosion.

Sababbin da suke faru oil leakage sun haɗa: poor welding, aging gaskets, mechanical damage, inadequate maintenance, da kuma mechanical stress damaging bushing seals.

2.2 Capacitor Housing Deformation

A nan da ita ce aiki, minor expansion ko contraction a kan capacitor housing yana da kyau. Amma, idan electric field strength yana zama, wanda ke taimaka a yi partial discharge ko short circuits, dielectric yana decompose, kuma yana taimaka a yi large amounts of gas, kuma yana taimaka a yi increase internal pressure, kuma yana taimaka a yi housing bulging ko deformation.

Idan severe deformation yana faru, repair a matsayin ba zan iya, kuma replacement yana da kyau. Housing deformation yana taimaka a yi deterioration da internal insulation, kuma yana taimaka a yi damage da electrical structure, kuma yana taimaka a yi change original insulation clearances. A nan da ita ce, yana iya ba da bushing fracture, kuma yana iya ba da capacitor explosion ko fire.

Housing deformation yana faru saboda product quality issues, tare da: poor electrode ko dielectric material quality, use of non-gas-absorbing insulating oil, substandard manufacturing environment ko processes, residual impurities, excessive pursuit of specific performance metrics, ko housing material being too thin.

2.3 Abnormal Temperature Rise in Capacitors

Abnormal temperature rise a kan power capacitors yana taimaka a yi excessive body temperature, kuma yana taimaka a yi thermal aging da internal dielectric, kuma yana taimaka a yi reduction da insulation strength, kuma yana iya ba da partial discharge. Service life a kan power capacitors yana da "8°C rule": saboda 8°C increase above the design-allowed operating temperature, expected lifespan yana zama approximately half.

Abnormal temperature rise yana faru saboda poor ventilation ko prolonged overcurrent conditions. Misali: unreasonable spatial layout a kan capacitor room, improper placement a kan ventilation equipment, overvoltage operation, harmonic currents, dielectric aging, moisture ingress, ko internal component faults, kuma yana taimaka a yi power losses, kuma yana taimaka a yi temperature rise.

2.4 Surface Flashover Discharge on Capacitor Bushings

Components a kan power capacitor installations yana da arrangement compact. A lokacin aiki, surrounding environment yana da high temperature da electric field intensity, kuma yana taimaka a yi airborne charged particles to be adsorbed, kuma yana taimaka a yi contamination buildup on bushing surfaces, kuma yana taimaka a yi surface leakage current. Under the combined influence of system harmonics and voltage, localized surface arcing may occur on the bushing porcelain. When contamination accumulates to a critical level, it can result in surface flashover discharge, accompanied by abnormal noise. In severe cases, this may lead to external phase-to-ground short circuits.

2.5 Abnormal Noise from Capacitors

Power capacitors yana da static reactive compensation devices without moving parts or electromagnetic excitation components. A lokacin aiki, ba zan iya faɗiwa. Idan abnormal noise yana faru, yana nufin high-energy partial discharge, kuma yana bukatar de-energizing for inspection.

2.6 Capacitor Rupture

Capacitor rupture yana da severe consequences. Yana faru idan internal capacitor element yana faru inter-electrode ko electrode-to-housing insulation breakdown, kuma yana taimaka a yi through-fault short circuit. Other capacitors operating in parallel yana taimaka a yi rapid charge da discharge a kan faulty unit. Idan injected energy yana kasa mechanical strength a kan housing, capacitor yana iya rupture, kuma yana iya eject oil, kuma yana iya ba da fire, endangering the safety of the entire substation, da kuma yana iya ba da personnel injuries or fatalities.

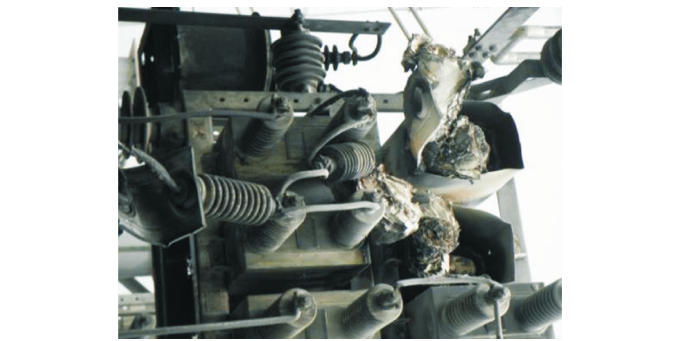

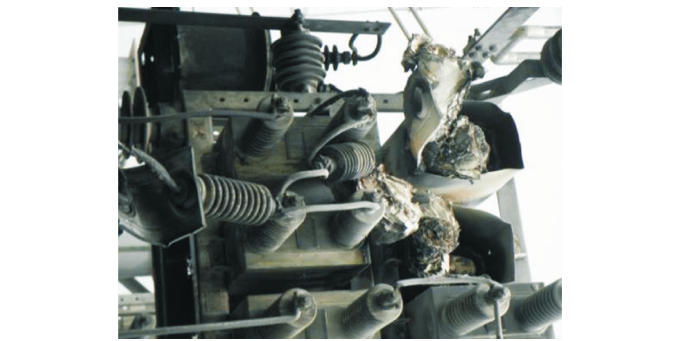

Cascading rupture incident involving an entire capacitor bank is shown in Figure 2, triggered by internal capacitor element breakdown; the detailed condition of the failed element is illustrated in Figure 3.

2.7 Overheating of Capacitor Bank Connection Terminals

Once energized, power capacitor banks operate under full load with high circuit currents. If internal connections exhibit poor contact, inadequate design or installation practices, or insufficient maintenance, localized overheating at the connection points may occur. Prolonged overheating can lead to excessive thermal energy accumulation, potentially causing the connecting conductors to melt. Overheating faults at capacitor bank terminals are relatively common; the condition of a melted connection is shown in Figure 4.

3 Preventive Measures Against Accidents

3.1 Ensuring Quality in Equipment Manufacturing and Installation Commissioning

Safe operation of power capacitors hinges on the quality of equipment manufacturing and installation commissioning. During production, it is essential to strictly follow process flows, use qualified raw materials and production equipment, and enhance quality supervision throughout the process. Rigorous factory inspections ensure product quality. On-site installations should be reasonably "phased and grouped" to ensure balanced capacitance matching between phases and sections. Additionally, emphasis should be placed on site handover and acceptance after installation to guarantee installation quality and minimize faults during operation.

3.2 Improving Operation and Running Methods

When performing power-on and power-off operations for line loads, capacitor banks must adhere to the principle of "disconnect first, then connect," while load lines should follow the sequence of "connect first, then disconnect." This order cannot be arbitrarily changed.

Before restoring capacitor bank operations, sufficient discharge time must be ensured. Frequent switching of capacitor banks should be minimized; only after complete discharge can re-closing occur. If a fault causes protective devices to trip the capacitor bank, it cannot be reconnected before identifying the cause to prevent an accident from escalating.

To avoid high-order harmonics affecting capacitor banks, select appropriate reactor rates based on specific application scenarios. This effectively suppresses high-order harmonics, reduces inrush currents and overvoltage upon closing, ensuring safe operation of the entire system.

3.3 Controlling Operating Environment Temperature

The operational temperature of capacitors directly impacts their performance and lifespan. High temperatures accelerate insulation aging, shortening service life. Therefore, controlling the operating environment temperature is crucial. Indoor-installed capacitor banks should maintain good ventilation and, where necessary, install automatic temperature control systems. Outdoor units should avoid direct sunlight exposure and ensure proper ventilation and heat dissipation. Regularly perform live infrared thermography on capacitor banks and associated equipment to take timely measures, ensuring internal medium temperatures and environmental temperatures comply with regulations.

3.4 Implementing Online Monitoring of Equipment Operational Status

Installing online monitoring devices on capacitor banks facilitates real-time monitoring of operational status, aiding in the prompt detection and handling of potential faults. This includes monitoring actual operating voltage, partial discharges, dielectric loss, capacitance, leakage current, and other characteristic signals. Not only does this help in diagnosing and isolating faults, but it also enables analysis of potential defects, achieving predictive fault warnings.

3.5 Enhancing Routine Inspection of Equipment

Strengthening routine inspection is vital for ensuring normal operation of capacitor banks. Focus should be placed on checking for deformations in casing, oil leaks, contamination levels of porcelain insulators, signs of discharge, electrical distances, and environmental temperatures. Auxiliary methods such as infrared thermography can detect overheating at connections, enabling timely maintenance and ensuring safe operation of power capacitor assemblies.

Conclusion

By analyzing the failure mechanisms, characteristics, and causes of power capacitors, this article proposes preventive measures from five aspects: equipment and installation commissioning quality, operation methods, control of operating environment temperature, online monitoring of running conditions, and routine inspections. These recommendations provide practical guidance for the effective application of power capacitors.