1 Mga Mechanismo sa Pagkabigo sa Power Capacitors

Ang power capacitor naglalaman ng bahay, capacitor core, insulating medium, ug terminal structure. Ang bahay kasagaran gihimo sa hinay-hinay nga bakal o stainless steel, uban ang mga bushings giweld sa cover. Ang capacitor core gigulang gikan sa polypropylene film ug aluminum foil (electrodes), ug ang interior sa bahay gipuno sa liquid dielectric alang sa insulation ug heat dissipation.

Isip usa ka fully sealed device, ang mga karong tipo sa pagkabigo sa power capacitors mao ang:

Pagkabigo sa internal capacitor element;

Pagputok sa fuse;

Internal short-circuit faults;

External discharge faults.

Ang mga internal failures mas destructive sa capacitor body, ug kapag nahitabo, dili na mahimong i-repair on-site, sigurado nga maghatag og dako nga epekto sa equipment utilization efficiency.

1.1 Pagkabigo sa Internal Capacitor Element

Ang pagkabigo sa capacitor element kasagaran gisulayan pinaagi sa mga factor sama sa dielectric aging, moisture ingress, manufacturing defects, ug harsh operating conditions. Kon ang element wala adunay internal fuse, ang usa ka element breakdown mag-short-circuit sa iyang parallel-connected counterparts, nagsilbi isip pagtanggol sa voltage sharing. Kini mosiguro sa pagtaas sa operating voltage sa remaining series-connected elements. Walay timely fault isolation, kini naghatag og serious safety risks ug mao ang makadaghan sa catastrophic failures.Ang paggamit sa internal fuses nag-enable sa effective ug prompt isolation sa faulty elements, nag-improve sa operational safety.

Ang capacitor breakdown mahimong ikategoryahan isip tulo ka klase: electrical breakdown, thermal breakdown, ug partial discharge breakdown.

Electrical Breakdown: Gisulayan pinaagi sa overvoltage o harmonics, resulta sa kaayo taas nga electric field strength sa dihang mag-abot sa dielectric, nagresulta sa insulation failure sa defective points. Ikaugalingon niini ang maoy short duration ug high field intensity. Ang breakdown strength estrengtiha related sa field uniformity apan less sensitive sa temperature ug voltage duration.

Thermal Breakdown: Nag-oksyon kon ang heat generation gibati sa dissipation, nagresulta sa continuous temperature rise sa dielectric, nagresulta sa material degradation ug eventual insulation failure. Kini kasagaran mogahin sa steady-state operation, kasagaran lower breakdown voltage ug longer voltage application time kumpara sa electrical breakdown.

Partial Discharge Breakdown: Resulta gikan sa localized high electric fields sa dihang mag-abot sa dielectric, gibati sa breakdown strength sa low-permittivity regions sama sa liquids, gases, o impurities. Kini nagsugyot sa partial discharges nga gradual degrade sa insulation performance, eventual evolving into a complete through-electrode breakdown. Ang proseso progressive, developing gikan sa non-penetrating discharges hangtod sa full insulation failure.

1.2 Pagputok sa Fuse

Ang fuse protection usa ka sa labi common protective measures para sa power capacitors ug nagplay og vital role sa safe ug stable operation sa compensation systems. Ikaugalingon niini ang external ug internal fuse protection.

External Fuse Protection: Kon ang internal capacitor element mogahin, ang fault current sa capacitor ug external fuse mag-increase. Kapag ang current nabati sa fuse’s rated melting threshold, ang fuse mag-init, mag-break thermal equilibrium, ug mag-melt, disconnecting ang faulty capacitor aron maprevent ang fault escalation.

Internal Fuse Protection: Kon ang element mogahin, ang parallel elements mag-discharge sa faulted element, generating a high-amplitude, rapidly decaying transient current. Ang energy gikan sa kini nga current mag-melt sa series-connected internal fuse, isolating ang faulty element ug allowing the rest of the capacitor to continue operating.

Sa praktikal, improper fuse selection o poor terminal contact mao ang makadaghan sa abnormal fuse blowing sa normal operation, mistakenly removing healthy capacitors ug reducing reactive power output.

Kon ang internal fuses wala maapil ug fail to isolate faults promptly, ang fault mao ang mogahin, potentially leading to capacitor explosion or fire.

1.3 Internal Short-Circuit Faults

Ang internal short-circuit faults sa power capacitors kasagaran gikatakd-an sa live electrode-to-housing shorts ug inter-electrode shorts. Kini kasagaran gisulayan pinaagi sa long-term dielectric aging, internal moisture ingress, overvoltage stress, o inherent insulation defects gikan sa design o manufacturing processes, tanan niini mao ang makadaghan sa puncture-type insulation breakdown ug internal short circuits.

1.4 External Discharge Faults

Ang external discharge faults refer to failures occurring outside the capacitor body, gisulayan pinaagi sa external factors sama sa bushing surface flashover, bushing puncture, phase-to-phase or phase-to-ground short circuits, o cracks in porcelain bushings gikan sa mechanical stress. Kini nga mga faults adunay diverse causes apan mogahin sa external circuitry. Kasagaran maoy detectable ug mitigated in time pinaagi sa relay protection actions, routine inspections, o offline testing. Ang occurrence probability ug severity lower than internal faults, apan mao gihapon ang importante nga atensyon.

2 Common Fault Characteristics and Causes of Power Capacitors

2.1 Oil Leakage from Capacitor Body

Isip usa ka fully sealed, high-field-strength, high-current device, ang oil leakage sa power capacitor dili lamang molabay sa insulation level tungod sa lowered oil level apan usab nagallow sa moisture ingress tungod sa decreased internal pressure. Kini nagresulta sa insulation dampness, reduced insulation resistance, ug ultimately internal element breakdown o even explosion.

Main causes sa oil leakage kasagaran poor welding resulting sa inadequate sealing; aging o unevenly stressed gaskets; mechanical damage during transportation o installation; inadequate maintenance causing housing corrosion; ug mechanical stress damaging bushing seals.

2.2 Capacitor Housing Deformation

Sa normal operating conditions, minor expansion o contraction sa capacitor housing tungod sa temperature ug voltage variations acceptable. Apan, kon ang internal electric field strength kaayo taas, causing partial discharge o short circuits, ang dielectric decomposes ug generates large amounts of gas. Kini nag-increase sa internal pressure sa sealed chamber, nagresulta sa housing bulging o deformation.

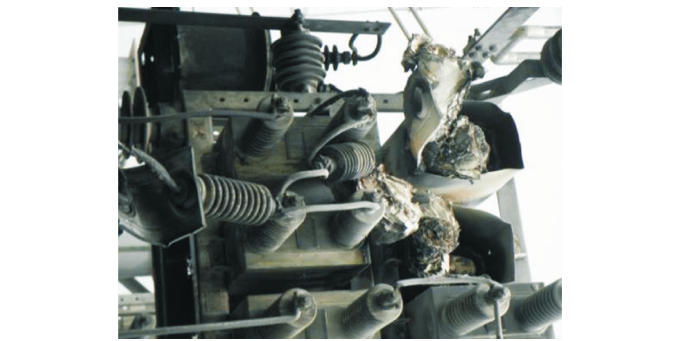

Kapag severe deformation mogahin, on-site repair dili na possible, ug replacement required. Ang housing deformation dili lamang exacerbates internal insulation deterioration apan usab makadaghan sa electrical structure, altering original insulation clearances. Sa severe cases, mao ang makadaghan sa bushing fracture (see Fig. 1), potentially leading to explosion or fire.

Housing deformation kasagaran gisulayan pinaagi sa product quality issues, sama sa: poor electrode o dielectric material quality; use of non-gas-absorbing insulating oil; substandard manufacturing environment o processes; residual impurities during production; excessive pursuit of specific performance metrics; o housing material being too thin.

2.3 Abnormal Temperature Rise in Capacitors

An abnormal temperature rise in power capacitors leads to excessive body temperature, which accelerates thermal aging of the internal dielectric, reduces its insulation strength, and may even trigger partial discharge. The service life of power capacitors generally follows the "8°C rule": for every 8°C increase above the design-allowed operating temperature, the expected lifespan is approximately halved.

Abnormal temperature rise kasagaran gisulayan pinaagi sa poor ventilation o prolonged overcurrent conditions. Examples include: unreasonable spatial layout sa capacitor room o improper placement sa ventilation equipment leading sa inadequate heat dissipation; increased heating tungod sa overvoltage operation causing overcurrent; ug harmonic currents generated sa rectifier units that also contribute sa capacitor overheating. Additionally, dielectric aging, moisture ingress, o internal component faults can increase power losses, further exacerbating temperature rise.

2.4 Surface Flashover Discharge on Capacitor Bushings

Components sa power capacitor installations kasagaran arranged compactly. Sa operation, ang surrounding environment features high temperature ug electric field intensity, easy sa airborne charged particles to be adsorbed. Kini nagresulta sa contamination buildup sa bushing surfaces, increasing surface leakage current. Sa combined influence sa system harmonics ug voltage, localized surface arcing mogahin sa bushing porcelain. Kon ang contamination accumulates to a critical level, mao ang resulta sa surface flashover discharge, accompanied sa abnormal noise. Sa severe cases, kini mao ang makadaghan sa external phase-to-ground short circuits.

2.5 Abnormal Noise from Capacitors

Power capacitors static reactive compensation devices without moving parts o electromagnetic excitation components. Sa normal operation, sila dili dapat mag-produce sa audible sound. Kon abnormal noise mogahin sa operation, kini mao ang indication sa high-energy partial discharge sa capacitor, ug ang equipment should be immediately de-energized for inspection.

2.6 Capacitor Rupture

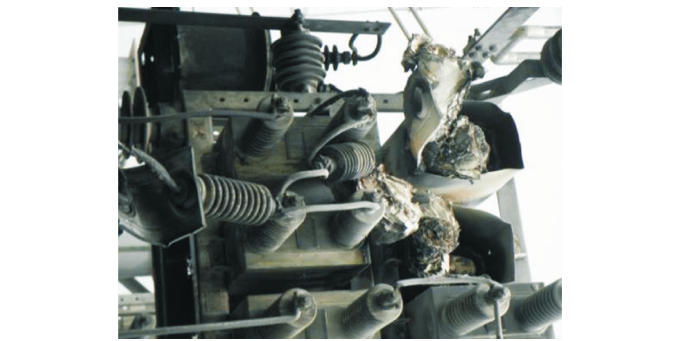

Capacitor rupture severe failure with significant consequences. Kasagaran mogahin kon ang internal capacitor element suffers inter-electrode o electrode-to-housing insulation breakdown, resulting sa through-fault short circuit. Other capacitors operating in parallel will then rapidly charge ug discharge sa faulty unit. Kon ang injected energy exceeds the mechanical strength sa housing, ang capacitor may rupture ug eject oil, potentially causing fire, endangering the safety sa entire substation, ug even leading sa personnel injuries or fatalities.

A cascading rupture incident involving an entire capacitor bank is shown in Figure 2, triggered by internal capacitor element breakdown; the detailed condition of the failed element is illustrated in Figure 3.

2.7 Overheating of Capacitor Bank Connection Terminals

Once energized, power capacitor banks operate under full load with high circuit currents. Kon ang internal connections exhibit poor contact, inadequate design o installation practices, o insufficient maintenance, localized overheating sa connection points mogahin. Prolonged overheating can lead sa excessive thermal energy accumulation, potentially causing the connecting conductors to melt. Overheating faults sa capacitor bank terminals kasagaran common; the condition of a melted connection is shown in Figure 4.

3 Preventive Measures Against Accidents

3.1 Ensuring Quality in Equipment Manufacturing and Installation Commissioning

The safe operation sa power capacitors hinges sa quality sa equipment manufacturing ug installation commissioning. Sa production, essential to strictly follow process flows, use qualified raw materials ug production equipment, ug enhance quality supervision throughout the process. Rigorous factory inspections ensure product quality. On-site installations should be reasonably "phased and grouped" to ensure balanced capacitance matching between phases ug sections. Additionally, emphasis should be placed sa site handover ug acceptance after installation to guarantee installation quality ug minimize faults during operation.

3.2 Improving Operation and Running Methods

When performing power-on ug power-off operations for line loads, capacitor banks must adhere sa principle sa "disconnect first, then connect," while load lines should follow the sequence sa "connect first, then disconnect." This order cannot be arbitrarily changed.

Before restoring capacitor bank operations, sufficient discharge time must be ensured. Frequent switching sa capacitor banks should be minimized; only after complete discharge can re-closing occur. Kon ang fault causes protective devices to trip the capacitor bank, it cannot be reconnected before identifying the cause to prevent an accident from escalating.

To avoid high-order harmonics affecting capacitor banks, select appropriate reactor rates based sa specific application scenarios. This effectively suppresses high-order harmonics, reduces inrush currents ug overvoltage upon closing, ensuring safe operation sa entire system.

3.3 Controlling Operating Environment Temperature

The operational temperature sa capacitors directly impacts their performance ug lifespan. High temperatures accelerate insulation aging, shortening service life. Therefore, controlling the operating environment temperature crucial. Indoor-installed capacitor banks should maintain good ventilation ug, where necessary, install automatic temperature control systems. Outdoor units should avoid direct sunlight exposure ug ensure proper ventilation ug heat dissipation. Regularly perform live infrared thermography sa capacitor banks ug associated equipment to take timely measures, ensuring internal medium temperatures ug environmental temperatures comply sa regulations.

3.4 Implementing Online Monitoring of Equipment Operational Status

Installing online monitoring devices sa capacitor banks facilitates real-time monitoring sa operational status, aiding sa prompt detection ug handling sa potential faults. This includes monitoring actual operating voltage, partial discharges, dielectric loss, capacitance, leakage current, ug other characteristic signals. Not only does this help sa diagnosing ug isolating faults, but it also enables analysis sa potential defects, achieving predictive fault warnings.

3.5 Enhancing Routine Inspection of Equipment

Strengthening routine inspection vital sa ensuring normal operation sa capacitor banks. Focus should be placed sa checking for deformations sa casing, oil leaks, contamination levels sa porcelain insulators, signs sa discharge, electrical distances, ug environmental temperatures. Auxiliary methods such as infrared thermography can detect overheating sa connections, enabling timely maintenance ug ensuring safe operation sa power capacitor assemblies.

Conclusion

By analyzing the failure mechanisms, characteristics, ug causes sa power capacitors, this article proposes preventive measures from five aspects: equipment ug installation commissioning quality, operation methods, control sa operating environment temperature, online monitoring sa running conditions, ug routine inspections. These recommendations provide practical guidance for the effective application sa power capacitors.