Skiza tal-Introduzzjoni għal Unitajiet ta' Ġenerazzjoni Termal

Il-ġenerazzjoni tal-elettricità tintla fuq risorsi ta' enerġija rinnovabbli u mhux rinnovabbli. L-unitajiet ta' ġenerazzjoni tormali jirrapreżentaw l-aċċess konvenzjonali ta' produzzjoni tal-enerġija. F'dawn l-unitajiet, miniera kif il-ġilf, l-enerġija nukleare, il-gas naturali, il-bioġwel, u l-biogas jiġu murta fil-kamra tal-fuq.

Il-kamra tal-fuq tal-unita ta' ġenerazzjoni hija sistema estremament komplikata. Fl-konċett tagħha l-iqsar, tista' tiġi vistbilizzata bħala kamra li s-siddux tagħha huma miżju bl-pippi, fejn il-lanġas tista' tirkodul fl-mod kontinwu. L-enerġija termika libberrata mill-murt tal-fuq fi l-kamra tal-fuq tittrasferixxx huwa l-lanġas. Fl-proċess, dan il-lanġas jiġi mutat f'stīm saturat drijjien karatterizzat bi pressjoni għoli (ta' 150 ksc sal-380 ksc, skont it-tkabbir) u temperaturi għoli (bejn 530°C u 732°C, subjetti tas-speċifikazzjonijiet tal-tkabbir).

Dan is-stīm saturat ssir wara ftur, fejn jisferi u t-temperatur tiegħu tidher. Fl-proċess tas-sferi, is-stīm jittrasferixxx l-enerġija termika f'l-enerġija rotazjonali tal-ftur. Il-flus tas-stīm ftur jikkontrollah b'mezzan tal-kontroll, li jikkontrollah mis-sistema tal-kontroll tal-ftur. B'hekk, l-output attiv tal-enerġija tal-ftur jikkontrollah mill-governor. Il-ftur huwa miktub ma' generator sinkronu.

Il-generator sinkronu jiekol l-enerġija mekanika tal-ftur f'elettrika. Il-generatori sinkroni jipproduċu elettricità b'voltaggi relativament bass, tipikament bejn 11 kV u 26 kV, fid-frekwenza nominali. Dan il-voltagg ssir wara transformator tal-ġenerazzjoni li j żidi l-voltagg għal 220 kV/400 kV/765 kV għall-trasport fl-grażz ta' potenza. Fl-studji tas-sistema tal-enerġija, dawn il-sistema integrati kollha jintużaw bħala unita ta' ġenerazzjoni.

Kontroll tal-Governor tal-Ftur (TGC)

Bħal imsemmiet qabel, il-governor jikkontrolla l-flus attiv tal-enerġija fit-ftur b'ttalja tal-valvola tal-kontroll. Governor idroliku jista' jiġi modellat bħala kontroler integrali li jieħu feedback mid-daqqa reale tal-ftur. Il-Figura 1 turi l-operazzjoni tal-governor fil-mod ta' kontrol tad-daqq.

Id-daqq reale tal-ftur jinkiteb mal-daqq referenz (korrispondenti mal-frekwenza nominali tal-grażz). Is-segnal ta' errur tad-daqq (∆ωᵣ) ssir wara governor. Skond din l-errur, il-governor jmodifika l-pożizzjoni tal-valvola tal-kontroll: jekk sejnjal pożittiv tal-errur jiġi detektat (indika li l-frekwenza reale toqgħod il-frekwenza nominali), il-governor jiserra lill-valvola; inkontroversament, jiġi mitluba meta sejnjal negattiv tal-errur jiġi ricevut.

"R" tirrappreżenta l-impostazzjoni tal-droop tal-governor, tipikament bejn 3% u 8%. Matematikament, hija definita bħala:

R = (biddel per unit fit-frekwenza) / (biddel per unit fit-potenza)

L-impostazzjonijiet tal-droop huma importanti għal l-operazzjoni stabil parallel tal-unitajiet multipli ta' ġenerazzjoni, għax jiddeterminaw kif il-cariga tkun compartuta f'dawn l-areas tal-kontroll. L-unitajiet bl-valur droop inqas jassumaw automatikament parti akbar tal-cariga.

Area tal-Kontroll

Fl-sistema tal-enerġija, l-unitajiet ta' ġenerazzjoni u l-carigi huma distributi fuq regjunijiet geografici vasti. Biex tmassnu l-stabilità, il-grażz kollu jikkoppja f'areas tal-kontroll iżgħar (primarjament bażati għal-ġeografi). Din id-dikuzzjoni tiftaħ:

F'area tal-kontroll, huma preżenti multipli unitajiet ta' ġenerazzjoni u carigi. Id-dikuzzjoni tas-sistema tal-enerġija f'areas tal-kontroll serva diversi obbjettwi ewlenin:

1. Kontroll tal-Frekwenza tal-Cariga

Din is-skelet tiftaħ l-appaż ta' metodi tal-kontroll tal-frekwenza tal-cariga biex tmassnu l-frekwenza tal-grażz - konċett li ser jiġi esplorat aktar tard.

2. Determinal tal-Interchanges Schedulated

Jekk l-ġenerazzjoni f'area tal-kontroll toqgħod inqas mill-domanda tal-cariga, il-potenza ssir wara l-area mil-areas tal-kontroll avventini permezz ta' linji tal-iktar (u vice versa).

3. Compartiment Effiċient tal-Cariga

Id-domanda tal-cariga tivvarja waqt id-dinja (pereżempju, inqas fil-lejl, peak fil-għada u safla). L-areas tal-kontroll jsimplifikaw il-proċess ta':

Equilibbru tal-Potenza

L-enerġija elettrika tuża ftit real (mhux possibli tkun storjata fuq skała kbira). Għalhekk, l-equilibbru tal-potenza huwa riquirement fundamentali:

Potenza Mġarrba (P₉) = Domanda tal-Cariga (Pd) + Perditijiet tal-Trasport (Pₗ)

Il-perditijiet tal-trasport solitament jagħmlu ~2% tal-potenza mġarrba u solitament jiġu mgħafdi meta l-fokuss huwa fuq il-kontroll tal-frekwenza. Għal semplifikazzjoni, nahfasim:

Potenza Mġarrba (P₉) ≈ Domanda tal-Cariga (Pd)

Varjazzjoni tal-Frekwenza

Grid frekwenza tivvarja għal mistmatchi bejn id-domanda tal-cariga u l-ġenerazzjoni. While minor deviations are stabilized by system inertia, significant gaps (e.g., unit trips, large load changes) can cause frequency to vary by ±5%. Key scenarios include:

In most cases (e.g., unit/line trips, large load connection), demand exceeds generation, causing frequency to drop. Conversely, if a transmission line serving a large load trips, generation may exceed demand, causing frequency to rise. Though the system responds oppositely to these scenarios, understanding frequency dips suffices to grasp both behaviors.

Why Frequency Dips Occur

Two inherent system behaviors drive frequency dips:

1. Load Dampening

Induction motors (e.g., household fans, industrial drives) dominate grid loads. Their power consumption is frequency - dependent: a 1% frequency reduction typically reduces active power consumption by ~2% in large systems. When new loads connect, frequency drops, and existing induction loads automatically consume less power—partially mitigating the demand - generation gap.

2. Kinetic Energy Release from Turbine - Generator (TG) Sets

Conventional TG sets have massive rotors (often >25 tonnes) spinning at 3000 RPM (for 50Hz grids). When demand exceeds generation, these rotors temporarily supply stored kinetic energy (for 3–5 seconds, depending on inertia). As rotors slow down, grid frequency drops.

Frequency Control

Load - frequency control (LFC) restores grid frequency to its nominal value after demand - generation mismatches. Two tiers of control exist:

1. Primary Frequency Control

At the unit level, the turbine’s governing system adjusts speed (and thus frequency). As shown earlier, each unit modulates steam input based on frequency deviations. The full primary control loop for a generating station is depicted in the figure below.

2. Secondary Frequency Control

This involves coordinated control across multiple units in different control areas, ensuring long - term frequency stability and optimal load sharing.

Primary Frequency Control Limitations

Primary frequency control alone results in a steady - state frequency deviation, influenced by the governor droop characteristic and load frequency sensitivity. This occurs because individual units adjust speed without considering where new loads are connected or how much load is added. Without such contextual assessment, power balance cannot be fully restored, and frequency deviation persists. Following primary control actions, the steady - state frequency error may be either positive or negative.

Secondary Frequency Control

Restoring system frequency to its nominal value requires secondary control, which accounts for new load locations and adjusts reference setpoints for selected units. When load increases in a control area, generation within that area must rise to:

To achieve this:

Automatic Generation Control (AGC) assigns specific units in each control area for secondary control.

A frequency bias loop is added to their control systems, providing real - time corrective signals based on load flow calculations.

Once revised load setpoints are issued, units begin adjusting generation. Due to the mechanical nature of power production, it takes 25–30 minutes for units to reach their scheduled outputs. When all generating stations achieve target generation, power balance is reinstated, and frequency returns to nominal.

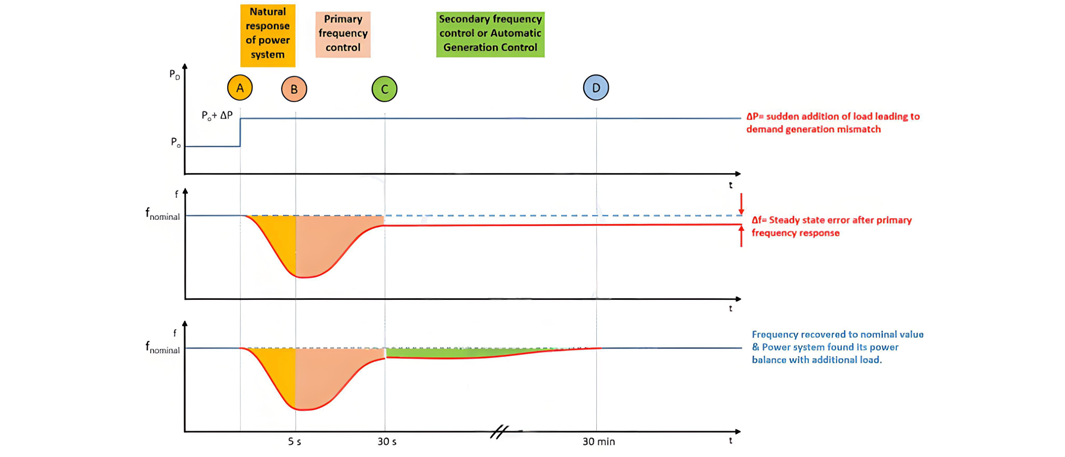

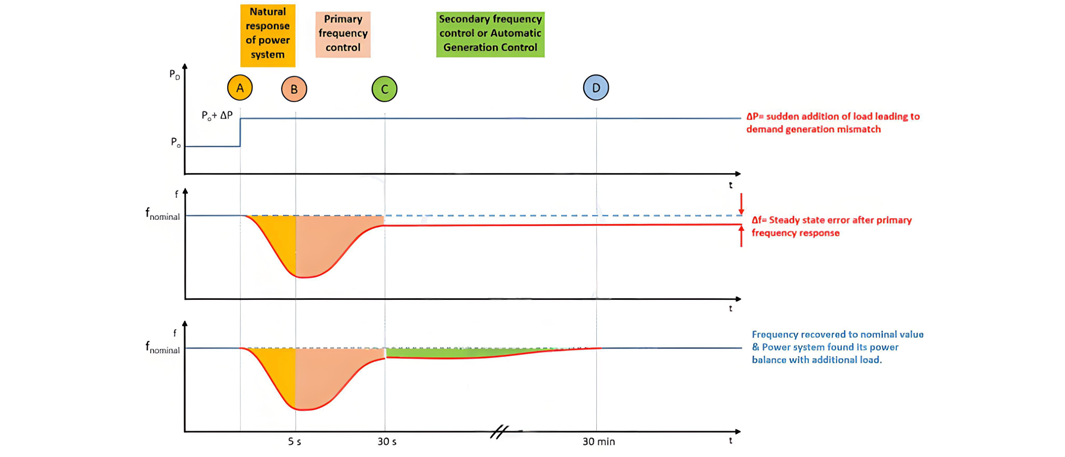

The overall response of the system with the primary and secondary frequency control can be understood by the graph below.

System Response to Load Increase (A-B-C-D)

A-B: Transient Kinetic Energy Release

Before point A, the system operates in power balance. At point A, load suddenly increases from P₀ to P₀ + ∆P. A 3–5 second delay occurs before the governor responds. During this interval, the rotor's stored kinetic energy supplies the excess load, causing rotor speed to drop and frequency to dip to a minimum value f₁.

B-C: Primary Frequency Control Action

At ~5 seconds, the governor initiates speed control, increasing steam input to restore rotor speed. This phase lasts 20–25 seconds (dependent on the frequency dip magnitude). As discussed, primary control alone leaves a steady - state frequency error ∆f due to governor droop.

C-D: Secondary Frequency Control (AGC Activation)

Once frequency stabilizes, secondary control (via AGC) adjusts generation for selected units in each control area. This process considers:

Generation adjustments are limited by the units’ design ramp rates, taking several minutes to complete. Upon finishing, scheduled interchanges return to pre - calculated values, and the system achieves a new power balance with nominal frequency.