In order to actively respond to the development requirements of the power industry, our company has intensified its investigation into grid construction faults in a certain area and provided operation and maintenance support for DC UHV transmission and transformation projects in high-altitude regions by installing and optimizing UHV transmission equipment design schemes. The total land area of the construction site is 2,541.22 m², with a net land area of 2,539.22 m². The geological strata at the construction site, listed from top to bottom, consist of loess-like soil, loess, paleosol, and silty clay—four layers of foundation soil. The geology is complex and has been subjected to long-term high-altitude effects, which can easily lead to transmission line failures.

In this context, our company conducted project calculations and determined that the building coefficient of the project is 61.48%, and the groundwater table depth ranges from 8.8 to 8.9 m, which exhibits a certain degree of corrosiveness to the concrete structures in the project. Our company primarily focuses on a 110 kV transmission and transformation project, and the construction scale is shown in Table 1.

Table 1: Construction Scale of the UHV Gas-Insulated Transmission Project

| Item |

Current Phase |

Long - term

|

| Main Transformer Equipment |

2 × 31.5MkV |

3 × 50kV |

| 110kV Outgoing Lines |

2 Circuits |

6 Circuits |

| 35kV Outgoing Lines |

0

|

0

|

| 10kV Outgoing Lines |

20 Circuits |

36 Circuits |

| Reactive Power Compensation Device |

Each main transformer is 2 × 4.8Mar |

Each main transformer is 2 × (4.8 + 4.8) Mar |

| Arc Suppression Coil |

≥869.49kVA |

≥1100VA |

In addition, our company also needs to further strengthen consideration of the pressure withstand range of UHV gas-insulated transmission equipment and reasonably apply post insulators and basin-type insulators to ensure the long-term stable operation of transformers.

1. Development of a Contact Resistance Model

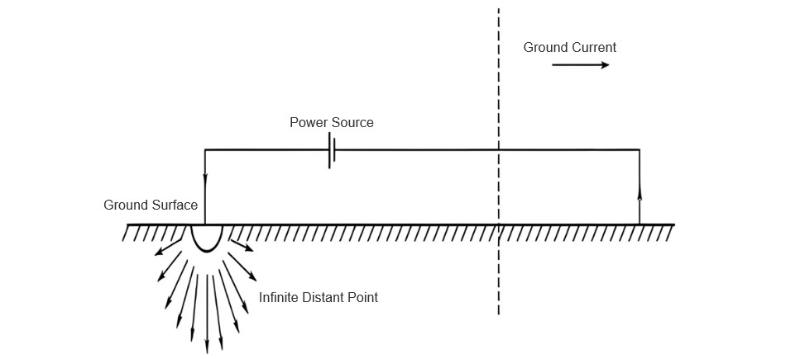

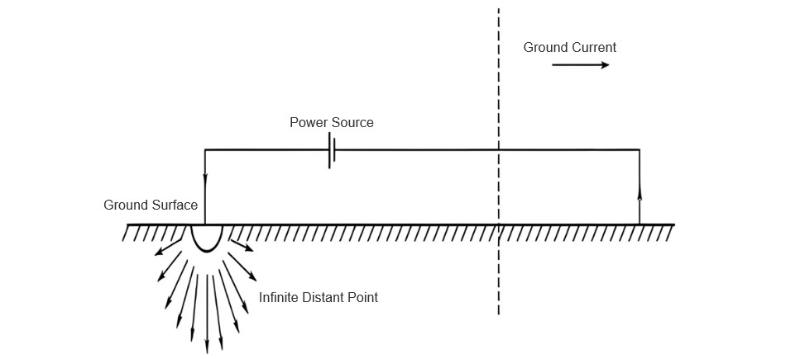

Since overloading current through current-carrying conductors is prone to occur during the operation of this project, it is necessary to avoid the formation of conducting spots. This can be achieved by enhancing the understanding of spot area and grasping the constriction behavior of current paths [1]. Thus, by intensifying on-site observation to understand changes in surrounding current lines, the distribution of ground surface, grounding current, power source, and remote wireless points can be analyzed at a microscopic level, enabling a thorough understanding of the unevenness issues occurring at contact surfaces, as shown in Figure 1.

By establishing a contact model, this paper, in combination with the application of UHV gas-insulated transmission equipment, defines the actual constriction resistance of a single contact spot as:

Re = (ρ₁ + ρ₂) / 4α,

where: Re represents the constriction resistance of a single contact spot; ρ₁ and ρ₂ are the resistivities of the contacting materials; and α denotes the radius of the contact spot.

Thus, the magnitude of contact resistance can be accurately analyzed through a correction method based on the contour of strap-type contact fingers. Furthermore, by examining material parameters of the insulation transmission equipment in the contact area, it becomes possible to determine which material should be used for the connection, as shown in Table 2.

| Component Name |

Material Name |

Elastic Modulus |

Allowable Material Stress |

| Pipe Busbar |

Aluminum / Cast Aluminum |

70GPa |

110MPa |

| Three - phase Support Insulator |

Epoxy Resin |

25GPa |

45MPa |

| Conductor |

Aluminum / Cast Aluminum |

70GPa |

110MPa |

| Bracket |

Steel |

210GPa |

235MPa |

The pressure withstand range of UHV gas-insulated transmission equipment is 1,000 kV, with a maximum withstand voltage of 1,683 kV, ensuring the safety of power transmission. Its transmission capacity can reach 2.4 to 5 times that of 500 kV EHV transmission. Pure SF₆ gas is used as the insulating medium, with a filling pressure of 0.3–0.4 MPa. With second-generation GIL (Gas-Insulated Line), a mixture of 20% SF₆ and 80% N₂ by volume fraction is employed as the insulating medium, with a filling pressure of 0.7–0.8 MPa. Alternatively, dry and clean compressed air can be used as the medium, with a filling pressure of 1–1.5 MPa. Therefore, the choice of insulating gas should be determined according to on-site conditions to ensure stable operation of UHV gas-insulated transmission equipment in the project. Operating gas pressure may also be appropriately increased, and overhead installation methods can be adopted to ensure the equipment is suitable for the current UHV voltage level.

Personnel should also pay close attention to the connection status of main material joints in UHV gas-insulated transmission equipment to enhance their load-bearing capacity. The slenderness ratio of the main structural members must also be calculated:

λ₀ = kL₀ / r,

where: λ₀ denotes the slenderness ratio of the connected main member; k is the correction coefficient; L₀ is the length of the main member of the UHV gas-insulated transmission equipment; and r is the radius of gyration of the main member.

2.Application Measures for UHV Gas-Insulated Transmission Equipment

2.1 Verification of Bus Duct and Conductor Stress

During the application of UHV gas-insulated transmission equipment, the stress condition of the pipe-type bus duct must also be considered. The internal pressure is 0.6 MPa, and the center elevation of the bus duct is 7.7 m. In the existing outdoor transmission system, the maximum span between two supports is 12 m. The external force acting on the conductor is also 0.6 MPa, and the allowable stress for both components is 110 MPa. Additionally, the transmission system is fixed via three-way support insulators and conductors.

First, the outer diameter of the bus duct is 500 mm, and the conductor’s outer diameter is 160 mm. If internal pressure is present, the outer diameter must remain unchanged, and wall thickness should be appropriately increased—from 5 mm to 20 mm. Based on the stress-thickness variation curve of the primary stress, the initial stress of the bus duct is found to be 18.45 MPa, accounting for 16.71% of the material’s allowable stress; the conductor’s initial stress is 3.45 MPa, representing 3.71% of its allowable stress. This indicates that, when the outer diameter remains constant, wall thickness significantly affects pressure response, particularly influencing the first principal stress of the pipe. Internal pressure alters the stress values of the pipeline structure—especially for thin-walled pipes—and GIL evaluation methods can be used to determine whether pressure impacts the bus duct and conductor.

Second, pressure-bearing pipelines in UHV gas-insulated transmission equipment—such as pressure pipelines and high-voltage risers—affect operational performance. Stress analysis of thin-walled pressure-bearing pipeline structures should be conducted using the following formula to calculate the circumferential normal stress σₜ on the longitudinal cross-section of the pipe:

σₜ = ρD / (2δ),

where: ρ is the internal pressure of the pipe; D is the inner diameter of the pipe; and δ is the wall thickness of the pipe. As the voltage level changes, larger-diameter bushings are preferred for higher voltage levels, while smaller-diameter bushings suffice for lower voltage levels.

2.2 Clarification of Gas Electrical Contact Characteristics

For UHV gas-insulated transmission equipment, the primary gases used include SF₆, nitrogen-oxygen mixtures, and N₂. Research into these gases should be strengthened to understand their differences in electrical contact characteristics. For strap-type contact fingers, SF₆ can be used as the insulating medium to fully leverage its excellent arc-quenching and insulation properties. Total contact resistance (Rₜ) is used to describe the electrical behavior of current-carrying structures:

Rₜ = Rₚ + R꜀₁ + R꜀₂,

where: Rₚ is the bulk resistance; R꜀₁ is the contact resistance of the upper electrode; and R꜀₂ is the contact resistance of the lower electrode. It is thus understood that the dielectric strength of SF₆ depends on gas pressure—the higher the pressure, the greater the dielectric strength.

2.3 Optimization of Electric Field Gap Design

In this project, the internal electric field is slightly non-uniform, with a non-uniformity coefficient of approximately 1.7. If lightning impulse withstand voltage conditions exist in the area, they will increase stress on the transmission lines, with an impulse coefficient of 1.25. First, based on power frequency and lightning impulse withstand voltage conditions in the region, the peak value should be confirmed within the range of 1.6–1.7 to ensure trouble-free operation of UHV gas-insulated transmission equipment.

Understanding the coaxial cylindrical structure, the electric field strength E(x) in the region can be calculated to identify scenarios requiring optimization:

E(x) = U / [x · ln(R/r)],

where: x is the distance between the conductor and the enclosure; U is the voltage applied to the electrode; R is the inner radius of the enclosure; and r is the outer radius of the central conductor. This allows assessment of whether the surface of the central conductor might be damaged under maximum field strength. Electric field safety must be controlled, and mechanical performance enhanced.

During the setup of electric field infrastructure, the actual load-bearing capacity of UHV gas-insulated transmission equipment should be verified at the foundation level, and stress calculations completed:

P = A × F,

where: P is the load-bearing capacity of the equipment; A is the cross-sectional area of the transmission tower; and F is the material strength. Additionally, if the foundation consists of silty clay, the subgrade must be compacted before overhead line installation proceeds.

Through optimized design considering product structure and manufacturing capabilities, high insulation performance under lightning impulse conditions can be ensured. Second, if the gas compartment is long, installation of UHV gas-insulated transmission equipment becomes challenging. In such cases, the local operating gas pressure can be set to 0.4–0.5 MPa through field strength design, allowing conductive particles to operate normally under electric field influence without inducing partial discharge or gas gap breakdown.

Finally, based on the specific conditions of the UHV gas-insulated equipment, the outer diameter of the conductor rod should be designed as 130 mm, and the inner diameter of the enclosure as 480 mm. Attention must also be paid to the plug-in section: wall thickness should be set to 30–40 mm, and the clearance must be <1 mm. If the outer chamfer radius of the plug-in area is set to 5 mm, the variation in electric field strength can be better understood—higher field strength near the chamfer corresponds to a larger radius, while lower field strength corresponds to a smaller radius. Under the premise of controlling local electric field concentration, excessive field strength in the gap must be prevented, enabling preliminary electrical connection design for UHV gas-insulated equipment and satisfying electric field signal distribution requirements.

2.4 Rational Insulator Design

Since insulators in UHV gas-insulated equipment operate along the ground, their flashover voltage is lower than the gap breakdown voltage, making them a weak point in electrical insulation. Therefore, gap considerations must be strengthened, and the field strength under lightning impulse conditions must be understood to properly design insulating components.

2.4.1 Enhanced Control of Insulator Field Strength

Based on project construction conditions, our company has studied flashover phenomena along insulator surfaces, including the effects of insulator material, structure, and surface charge. Metal particle contamination must also be avoided. A rational structure for UHV gas-insulated equipment is ensured by combining SF₆ gas, insulating materials, and embedded components. Drawing on past insulator design experience, field strength during operation can be limited to half that of the normal operating electric field gap. For pure SF₆-insulated equipment, the operating gas pressure can be maintained at 0.4–0.5 MPa.

The vertical electric field strength (Eₛ) can be calculated using:

Eₛ = 45.5p + 1.7,

where p is the gas pressure. Thus, depending on the equipment’s withstand voltage, the design field strength at the central conductor surface can be controlled within 19.9–24.5 kV/mm, while the insulator surface field strength must not exceed 10 kV/mm. Ensuring insulators are internally embedded within the electric field prevents abrupt field increases under UHV influence, reducing the risk of insulation failure and enabling long-term application of UHV gas-insulated transmission equipment in the project.

2.4.2 Optimized Basin-Type Insulator Design

Given the complex terrain of the project and the need for electric field simulation, basin-type insulator design must be enhanced—specifically by omitting shielding electrodes. This structure allows observation of electric field intensity near the high-voltage conductor side of the insulator. If field strength is high, the maximum value on the convex surface is found to be 12.7 kV/mm and 13 kV/mm on the concave surface; exceeding these thresholds indicates abnormal operation. When the electric field intensity near the insulator is high, the maximum power frequency operating voltage should be kept below 3.4 kV/mm. Installing shielding electrodes on basin-type insulators further optimizes and simulates the electric field.

Following previous electrical connection methods, the size of the shielding electrode should be carefully controlled, and the electrical plug-in connector should be positioned at the chamfer of the basin-type insulator to emphasize its electrode shielding effect, thereby improving the electric field distribution of UHV gas-insulated transmission equipment.

3. Conclusion

To meet the comprehensive development requirements of power enterprises, our company must further strengthen research on UHV gas-insulated transmission equipment. Based on specific operating conditions, problems should be analyzed and addressed through methods such as establishing a contact resistance model, verifying bus duct and conductor stress, clarifying gas electrical contact characteristics, optimizing electric field gap design, and rationally designing insulators—thereby extending the service life of the equipment.