Karamin kashi mai saka, ko kuma isolator switch ko knife switch, suna da addinin aiki da ke gaba da karfi. A wani abubuwan da ake amfani da su a cikin jihohin kashi mai saka, suke taimakawa wajen samun dalilin hanyar aiki a cikin mazauna, kuma ana bukatar darajar da dama a cikin aiki. Ingantaccen aiki na karamin kashi mai saka ta shirya yadda ake iya amfani da shi, kudin aiki da kuma darajar da dama, kuma ya ba shi nasarorin a wani abubuwan da ake amfani da shi a cikin takardun cututtuka a tattalin arziki.

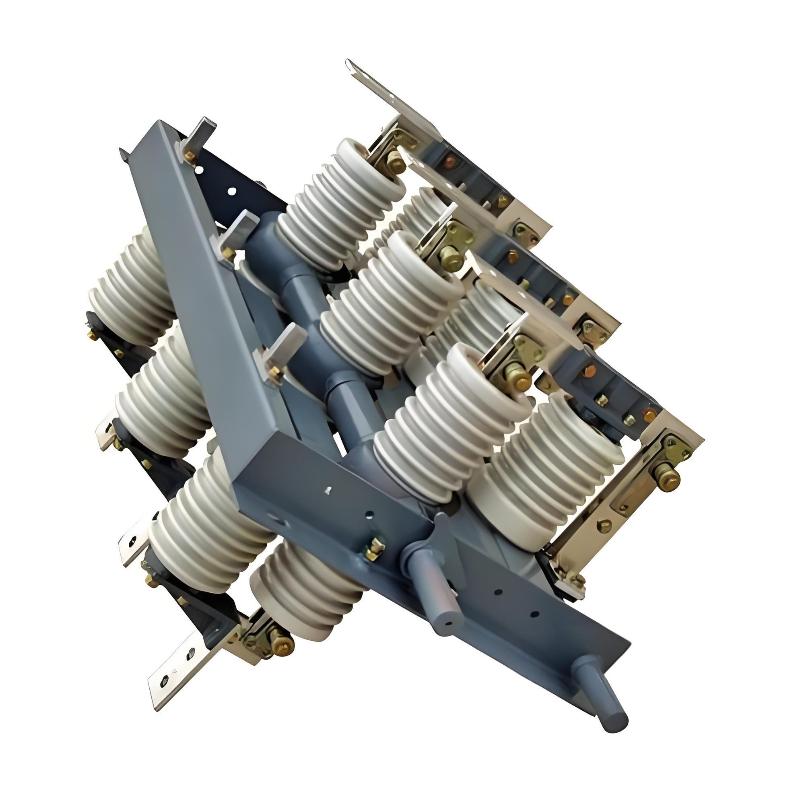

1.Gabatarwa na Karamin Kashi Mai Saka

Karamin kashi mai saka suna da amfani a cikin jihohin kashi mai saka da kuma mazauna, kuma su ne abubuwan da ke gaba da muhimmanci a cikin abubuwan da ake amfani da su a cikin kashi mai saka. Yana bukata ake amfani da su tare da karamin kashi mai saka.

Ingantaccen aiki na karamin kashi mai saka ta shirya yadda ake iya amfani da laser, ita ce cleaning gun, water chiller, optical fiber, da kuma laser source. Ana amfani da fully solid-state quasi-continuous-wave (QCW) laser don bayyana kashi mai saka da darajar da dama, da kuma aiki da ke gaba. Wannan aiki tana amfani da high-performance semiconductor side-pumped modules da reflective chips don inganta matsaloli. Darajar da dama na laser ya kamata ya fi 1,000 W, kuma fiber coupling efficiency ya kamata ya fi 96%. Abubuwan da suka da su sun hada da zero maintenance costs, compact size, da kuma suitability for integration.

Energy-transmitting optical fibers suna da amfani saboda yadda ake iya da kyau a cikin energy transmission, da lengths typically ranging from 10 to 15 meters. Precision water-cooling units don laser da optical path suna da amfani don bayyana temperature control da kuma timely ambient temperature adjustments.

Muhimmancin aiki na karamin kashi mai saka shine bayyana safe electrical isolation a lokacin da ake yi aiki a cikin jihohin kashi mai saka. Ba su da amfani don koyar da load current, fault current, ko short-circuit current, kuma ba su da amfani seba seba don koyar da small capacitive ko inductive currents. Saboda haka, ba su da arc-quenching capabilities.

A cikin yadda ake zabe, karamin kashi mai saka suna zabe da indoor ko outdoor types. Daga baya, a kan number of insulating support columns, suna zabe da single-post, double-post, ko triple-post. Voltage ratings must be selected according to specific equipment requirements.

Waɗannan karamin kashi suna bayyana visible isolation gap don bayyana safe electrical isolation a lokacin da ake yi aiki a cikin jihohin kashi mai saka, tare da bayyana safety ta mutanen. Idan suke da amfani don koyar da small currents, ba su da dedicated arc-extinguishing devices, kuma ba suke da amfani don koyar da load ko short-circuit currents.

2.Remote Online Laser-Based Defect Elimination System for Disconnector Contacts

Laser suna da high directionality and brightness, kuma suna da amfani don koyar da energy into a confined space. Laser cleaning fundamentally involves the interaction between laser radiation and contaminants, producing chemical and physical effects.

Research shows that surface contaminants adhere via capillary forces, electrostatic attraction, covalent bonding, and van der Waals forces—the latter three being particularly difficult to overcome. Laser cleaning disrupts these binding forces without damaging the underlying substrate.

Three primary laser cleaning mechanisms exist:

(1) Fragmentation and spallation: Microscopic contaminant particles absorb laser energy, expand rapidly, overcome surface adhesion forces, and fracture off the surface. The ultrashort laser pulse generates explosive shockwaves that accelerate particle detachment.

(2) Evaporation: Due to differing chemical compositions between the substrate and contaminants, their laser absorption rates vary. With appropriate laser type and pulse width selection, ~95% of laser energy reflects off the substrate, protecting it. Contaminants absorb ~90% of the energy, causing instantaneous temperature rise and vaporization, which removes them without substrate damage.

(3) Vibrational ejection: Short-pulse lasers induce ultrasonic vibrations through rapid thermal expansion. The resulting shockwaves fragment and eject particles.

The remote online defect-elimination system concentrates high energy within a precise spatial and temporal window. At the focal point, ionization causes micro-explosions that instantly strip away contaminants. The highly directional laser beam can be shaped into adjustable, non-uniform spot sizes. Laser energy intensity is precisely controlled to ensure instantaneous separation of contaminants from the substrate without damage.

3.Common Defects in High-Voltage Disconnectors During Operation

Defects often arise during operation—for example, dust accumulation due to poor contact, or formation of compound films on contact surfaces, increasing contact resistance. Analysis reveals that poor design, substandard components, and improper installation or adjustment all contribute to defects.

3.1 Component Corrosion

Prolonged exposure to rain, wind, and humidity causes corrosion of disconnector components. Some parts use galvanized coatings, but electrochemical reactions during operation can lead to severe rusting. Poor manufacturing processes further compromise quality and performance, accelerating corrosion. Severe rusting reduces mechanical transmission speed and may cause operational failure.

3.2 Incomplete Opening/Closing and Overheating

Improper opening or closing operations often result in defects. If contacts do not fully engage while the circuit remains energized, resistive heating occurs, potentially leading to burnout or safety incidents—impacting economic performance and power reliability.

Severe overheating at contact points (due to persistent current flow even when damaged) increases contact resistance, creating a vicious cycle: higher resistance → higher temperature → further resistance increase → contact damage.

3.3 Poor Sealing of Operating Mechanism Leading to Contact Damage

Most high-voltage disconnectors operate outdoors and are vulnerable to environmental factors. The operating mechanism serves as the power source; if corroded, it impairs functionality.

Don samun haka, an kula da tashar mekanisimai a cikin abubuwa masu mutanen bayan yi. Amma, hanyoyi na biyu suna iya ba wani shiga mai yankin—mafi yawa a tsawon ranar—wanda ke gina rusti a cikin. Wannan ya kawo cutar daidai ga inganci na mafi girman kontrola, wanda ke gina matsaloli. Yawan tsari na contact ta zama mai yawa, saboda hakan ya kawo karshen wannan (misali >75% na current mai yau) ya haɗa da karshen wannan da kuma cutar daidai.

3.4 Kasa na Insulator na Porcelain

Insulator na porcelain sun fiye waɗannan muhimmin abubuwan tsaro. An kasa su zama za su iya kudeta circuit na madara da kuma kafin disconnector. Dalilai sun hada da:

– Ingantaccen yanayin aiki na bude wadanda ba su iya tabbatar da ingancin porcelain;

– Yawan takardun kayan aiki a gida daga masu ilimi ba.

4.Takamarsa don Sistemin Mai Tattalin Matsaloli Da Suke Gudanar

Saboda matsalolin da dukkan suka faru ne suka faru ne saboda ilimin kasancewar ko kudancin kalmomin, yawancin amfani na korin suka bukata.

4.1 Tattalin Rusti na Abubuwa

Bincike da ingancin daidai a lokacin nan doke da kuma kudanta. Yi amfani da kiyasin daidai. A yankunan da aka da yawan jirgin sama, kawo kiyasun kiyasun daidai basu kan al'adunsu. Wasu abubuwan da aka da rusti mai yawa zai buƙaci da kawo kiyasun daidai.

4.2 Tattalin Kudanar Da Karshen Wannan

Kudanar da ba da kiyasun daidai na kudanar ke faru ne saboda kudancin kalmomin ko kudancin tsaro. Bincike da masu ilimi a gida don kudanar da kiyasun daidai da kuma kiyasun loop resistance.

Zabi materialoci na contact da kuma kiyasun kayan aiki. Amfani da boltoci na kusa. Rufe shiga masu contact daidai idan kana yi kiyasun depth. Kawo kiyasun springoci na kudanar da suka gina tension, kuma kawo kiyasun surface contaminants don in ba kiyasun daidai da kuma arcing.

4.3 Inzaman Kiyasun Mekanisimai Na Aiki

Zuba kiyasun daidai tare da kula da gaskets a cikin abubuwan mekanisimai. Zuba abubuwan da humidity sensors da dehumidifiers. Bara dehumidification kadan kadan idan kana samun yawan jirgin sama don in ba kiyasun daidai da kuma kasa inganci.

4.4 Dutsin Kasa na Insulator na Porcelain

Bara kiyasun daidai a lokacin nan doke da insulator. Bincike da masu ilimi a gida don in ba kiyasun daidai. A lokacin kiyasun daidai, bincike da cracks ko kasa, kuma kawo kiyasun daidai idan kana samun wani abu da ba da kiyasun daidai.

5.Misal: Bayanin Tattalin Matsaloli Da Suke Gudanar

Wani makarantar mai ruwa na birnin—wanda ya fiye waɗannan muhimmin aiki na kudanar da kuma gidajen ruwa, kuma kumtar aikinsu, da kuma yankin—ya zama misal don amfani da sistemin mai tattalin matsaloli da suke gudanar zuwa high-voltage disconnectors.

Amfani da kiyasun daidai:

– Zabi disconnectors na rated >126 kV, ba ka kiyasun single-arm folding designs ko kuma kiyasun spring-contact structures da ba su da kiyasun daidai; zabi models na da verified temperature-rise test reports.

– Don units ≥252 kV, yi full assembly, dimensional adjustments, da kuma marking idan kana bude da factory.

– Don units ≥72.5 kV, yi contact finger pressure tests da kuma zabe compliance certificates.

– A lokacin handover, duba silver-plating a moving da stationary contacts: thickness >20 μm, hardness >120 HV.

– Idan kana bude, ci gaba conductive loop resistance da kuma kada shi da design da kuma factory values; komisi shi idan ana cikin tolerance.

– A lokacin aiki, amfani da infrared thermography don in bincike conductive joints—mafi yawa a lokacin high-load ko kuma high-temperature conditions—and intervene promptly if anomalies are detected.

– A lokacin outage testing, bar da maintenance cycles. Test spring performance da kuma contact circuits, kawo kiyasun daidai parts. Re-verify contact pressure post-maintenance.

– Bincike inventory of spare parts da kuma laser cleaning tools don in iya bayyana online defect remediation da kiyasun daidai.

6.Kammala

Amsa, remote online laser-based defect-elimination system an yi daidai a tattalin rusti da kuma contaminants daga disconnector contacts, wanda ke gina karshen wannan da kuma burnout, kawo kiyasun wear na equipment, da kuma inzaman stability na power system. High-voltage disconnectors suna muhimmiyar nasara a modern power infrastructure—kawo kiyasun consumable use da kuma in ba da reliable, stable grid operation.