Matukio ya Kijamii na Mifano ya Maambukizi ya Mchakato wa Umeme

Takwimu ya Matukio ya Mchakato wa Umeme

Matukio ya mchakato wa umeme yanapatikana kama vya ndani na vya nje:

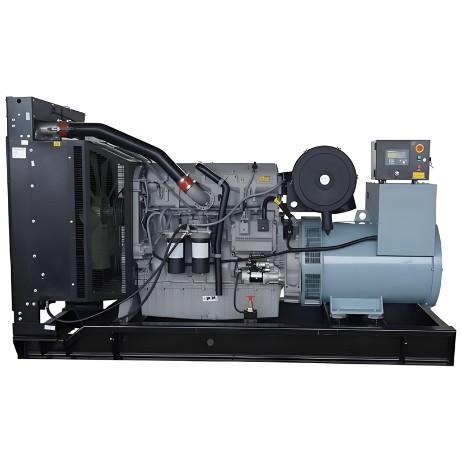

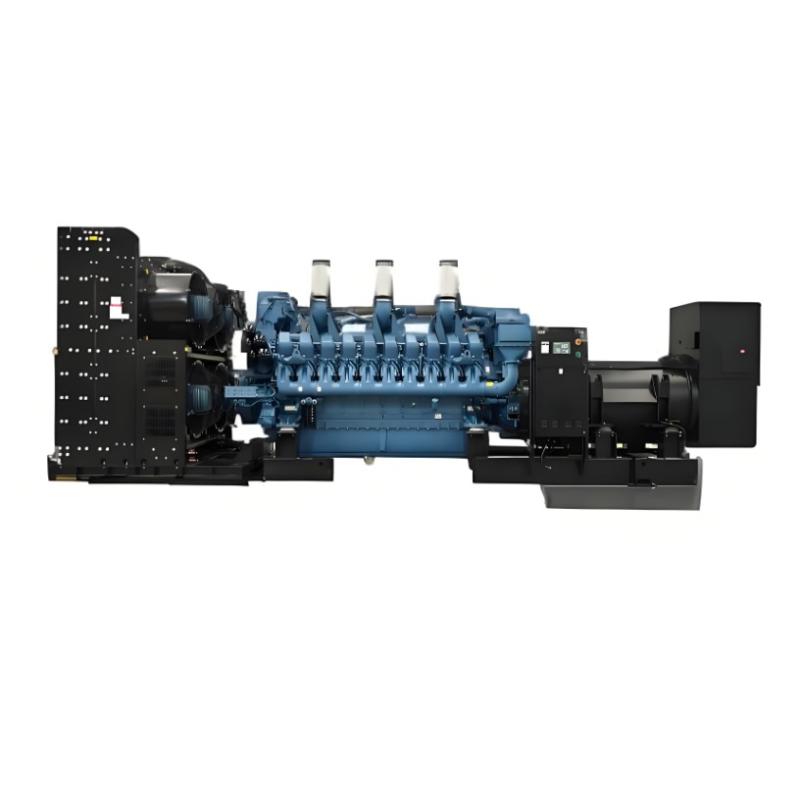

Matukio ya mifumo msingi (kama vile mbinu ya diesel, turubaini) ni vya kiuchumi na vinapatikana wakati wa kupanga zana, ingawa hazipaswi kukusanyika na maambukizi ya mchakato wa umeme kwa ajili ya kutumia.

Aina za Vitukio vya Ndani

1. Vitukio vya Stator

Kutokosea Kutoka kwa Vifaa: Inapatikana kutokana na ongezeko la mwaka au kutokosea kutoka kwa utetezi.

Tatizo kati ya Vifaa: Linapatikana kutokana na kutokosea kutoka kwa utetezi kati ya vifaa.

Tatizo kati ya Vifa na Dunia: Kutokosea kutoka kwa vifaa vya stator hadi kuwa chini.

Tatizo kati ya Miaka: Kutokosea kutoka kwa miaka inayozunguka kwenye vifaa vilivyotengeneza.

2. Vitukio vya Rotor

Tatizo kati ya Rotor na Dunia: Kutokosea kutoka kwa vifaa vya rotor hadi kuwa chini.

Kutokosea kutoka kwa Vifaa: Kinachopunguza nguvu ya kutokosea kutoka kwa vifaa na kuongeza current katika vifaa vilivyotengeneza.

Kutokosea kutoka kwa Vifaa: Inapatikana kutokana na currents zisizobalanshi kwa stator (kama vile kutokosea kutoka kwa pole moja tu, negative phase sequence).

3. Upoteze wa Nyota/Excitation

4. Kupata Kazi isiyo na Mstari

5. Utekelezaji wa Motor

6. Vitukio vya Kiuchumi

Mechanism ya Kutokosea kutoka kwa Rotor

Currents zisizobalanshi kwa stator (kama vile negative phase sequence) huunda eddy currents kwenye rotor mara mbili ya frequency ya system (100/120 Hz), kutokosea kutoka kwa vifaa. Hii huondoa rotor retaining wedges na rings.

Aina za Vitukio vya Nje

Matukio ya System ya Umeme

Vitukio vya nje: Vitukio vya grid vinavyopatikana kwa kutumia ya mchakato wa umeme.

Uhusiano usio na Mstari: Uharibifu kutokana na kutoambatana sahihi ya generators.

Overloads/Overspeed: Vinapatikana kutokana na kupunguza asilimia au kutokosea kutoka kwa mchakato wa msingi.

Phase Unbalance/Negative Sequence: Huunda eddy currents kwenye rotor na kutokosea kutoka kwa vifaa.

Frequency/Voltage Deviations: Under/over frequency au voltage kuzingatia vifaa vya mchakato wa umeme.

Zana za Maambukizi ya Mchakato wa Umeme

Mfano muhimu wa Maambukizi

1. Maambukizi ya Vitukio vya Stator

Differential Relay: Hujaribu tatizo kati ya vifaa na kati ya vifaa na dunia kwa kulingana na input/output currents.

Earth Fault Protection: Hutumia overcurrent relays (kwa resistance grounding) au voltage relays (kwa transformer grounding) kudetekta stator ground faults.

2. Maambukizi ya Vitukio vya Rotor

3. Maambukizi ya Kutokosea kutoka kwa Vifaa

4. Maambukizi ya Kutokosea kutoka kwa Vifaa

5. Maambukizi ya Kiuchumi

6. Maambukizi ya Backup na Zaidi

Reverse power relays huondoa kutokosea kutoka kwa motor, differential relays kwa stator earth faults husaidia kutokosea kutoka kwa vifaa (angalia Figure 1 kwa majengo yasiyofanikiwa).

Differential Relays: Hulingana na currents kwenye pande mbili za stator windings kudetekta vitukio vya ndani.

Principles za Maambukizi

Zero-Sequence Voltage Detection: Hujaribu inter-turn faults kwa kutazama voltage imbalances kwa kutumia voltage transformers (VT).

Grounding System Adaptation: Maambukizi yanapatikana kulingana na njia za stator grounding (resistance au transformer grounding), kutumia CTs au VTs kudetekta fault currents/voltages.

Mechanisms za Maambukizi ya Vitukio vya Winding ya Rotor

Wound rotor winding short-circuit faults zinajibabu kutokosea kutoka kwa overcurrent relays, ambazo hutrip the generator wakati wanapodetekta abnormal current surges. Earth faults zinapatikana kama hatari nyingine kwa rotor windings, ingawa maambukizi yake yanahitaji njia maalum.

Katika thermal generators makubwa, rotor au field windings zinapatikana kama ungrounded, maana tatizo moja la ground halipatikani fault current. Lakini, tatizo hili linapongeza potential ya sisi nzima na exciter system. Extra voltages induced by opening the field or main generator breaker—especially during fault conditions—can stress the field winding insulation, potentially causing a second ground fault. A second fault may lead to localized iron heating, rotor distortion, and dangerous mechanical unbalance.

Rotor earth-fault protection often employs a relay that monitors insulation by applying an auxiliary AC voltage to the rotor. Alternatively, a voltage relay is used in series with a high-resistance network (commonly a combination of linear and non-linear resistors) across the rotor circuit. The center point of this network connects to ground via a sensitive relay coil (ANSI/IEEE/IEC code 64). Modern protection schemes increasingly favor combinations of linear and non-linear resistors for improved fault detection and insulation monitoring.

Loss of Field and Overexcitation Protection Mechanisms

Loss of field protection employs a relay to detect changes in reactive power flow. A typical scheme uses an Offset Mho (impedance) relay— a single-phase device supplied by generator current transformers (CTs) and voltage transformers (VTs)—to measure load impedance. The relay triggers when the impedance falls within its operating characteristic. A timing relay initiates generator tripping if leading reactive power persists for 1 second (standard timing).

Overexcitation Protection

To prevent core saturation during startup and shutdown, overexcitation protection (ANSI/IEEE/IEC code 59) is implemented, based on the relationship:B = V/f

where:

B = magnetic flux density (tesla, T)

V = applied voltage (volts, V)

f = frequency (hertz, Hz)

Core flux must stay below the saturation point, meaning voltage can only increase proportionally with frequency (speed). Rapid excitation increases risk overexcitation, detected by Volts per Hertz relays. These relays feature linear characteristics and trip when V/f exceeds set thresholds.

Stator and Rotor Overheating Protection

Stator Windings & Bearings: Temperature monitoring via resistance temperature detectors (RTDs) and thermistors.

Stator Phase Unbalance: Time-inverse overcurrent relays set to the rotor’s maximum heat tolerance.

Negative Phase Sequence Protection: Shields the machine from rotor overheating caused by unbalanced stator currents, which induce damaging eddy currents in the rotor.

Reliable protection systems are critical to minimize damage and repair time, as generators are among the most expensive power system components.

This protection utilizes a relay that compares currents in two phases via current transformers (CTs), as illustrated in Figure 2. The protective settings are determined by the maximum time the rotor can endure overheating, defined by the equation K = I²t (derived from Joule's law), where I is the negative sequence current and t is the duration.

Manufacturer-specified typical time-current curves for this condition vary based on the prime mover type, as shown in the referenced diagram.

Reverse Power, Out-of-Step, and Frequency/Voltage Protection Systems

Reverse Power Protection (ANSI/IEEE/IEC Code 32)

This protection employs a power directional relay to monitor generator load, supplied by CTs and VTs (see Figure 3). The relay activates upon detecting negative power flow—indicating the generator is drawing power from the grid (motor operation)—and triggers tripping to prevent turbine damage.

Out-of-Step Protection

Designed to detect power system disturbances (not generator faults), this protection identifies pole slipping when the generator loses synchronism. It trips the generator breakers while keeping the turbine running, allowing re-synchronization after the disturbance clears.

Frequency and Voltage Protection

Under/Over Frequency Protection (ANSI/IEEE/IEC Code 81)

Overfrequency: Caused by sudden load shedding, risking overvoltage if not managed. Generator controls must adjust output to match demand.

Underfrequency: Results from insufficient generation for connected loads, leading to voltage drops, increased excitation, and rotor/stator overheating. Load shedding is critical to prevent system collapse.

Under/Over Voltage Relays (Codes 27/59)

Monitor and control voltage deviations to protect equipment from stress or damage.

Phase Supplementary Start Protection

Prevents starting the generator into a fault or loaded condition. Low-set overcurrent relays engage only when frequency is below 52 Hz (for 60 Hz systems) or 42 Hz (for 50 Hz systems), ensuring protection during startup transients.

External Short-Circuit Protection

Overcurrent relays (50, 50N, 51, 51N) detect and clear faults on the external network, safeguarding the generator from excessive fault currents.

These protection schemes collectively address operational anomalies—from power flow reversals to system-wide disturbances—ensuring generator integrity and grid stability.