Ag Oliver, 8 Bliain sa Tionscal Leictreach

Dia dhaoibh go léir, is mise Oliver, agus táim ag obair sa tionscal leictreach le 8 bliain anuas.

Ó mo laethanta i bhfeidhmiú uathaischóimeáil substátion go dtí anois ag riaradh cumraíochta agus meastacháin do chuid sístéimeacha díolacháin iomlána, tá an seiceálaí siombail (CT) ar cheann de na huchtáin is minicí a úsáideann mo chuid oibre.

Le déanaí, chuir cara atá ag tosú amach ceist orm:

“Conas níonn tú teistí ar shiceálaithe siombail? An bhfuil bealach simplí agus éifeachtach chun a rá an bhfuil siad ag obair go maith?”

Ceist iontach! Meastar go forleathan gur uaireannach agus modhanna stricte atá riachtanach chun CTs a thástáil, ach is é an fíric — gur féidir go leor de na fadhbanna coitianta a aithint le scileanna bunúsacha agus uchtáin.

Inniu, roinnfidh mé libh in teanga simléire — bunaithe ar mo thuairim ón gcúpla bliain anuas — conas:

Tástáil a dhéanamh ar shiceálaithe siombail, aithne a dhéanamh ar fhadhbanna coitianta, agus cad a bheidh ar eolas le linn comhairlíochta nó scrúdú.

Gan téarmaíocht, gan caighdeáin neamhfhéideartha — ach eolaíocht gníomhaíoch a bhféadfá a úsáid gach lá.

1. Cén mianach atá leis an Seiceálaí Siombail?

Sula ndéanfaimis tástáil, cuirimid aghaidh ar a ról go tapa.

D'fhéadfadh seiceálaí siombail a bheith mar aon leis an aistritheoir i gcóras fuinniúil — é a dhéanann siombail mhór príomhchónraithe a athrú i siombail níos lú seach-chónraithe a bhféadfadh a úsáid go sábháilte ag reláidí cosanta, uirlisí mearachta, agus uirlisí meastacháin.

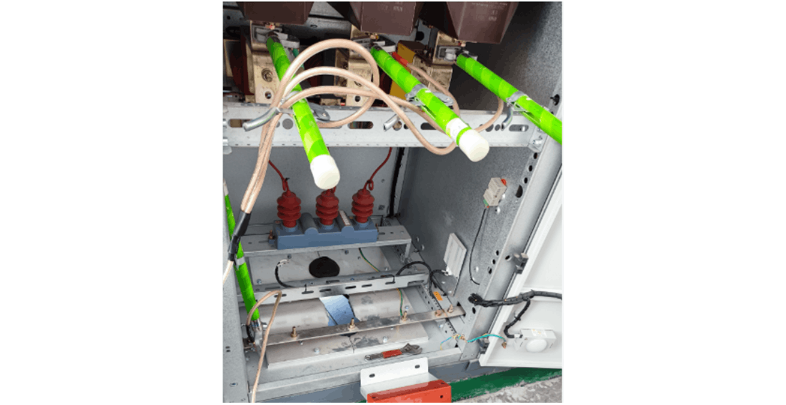

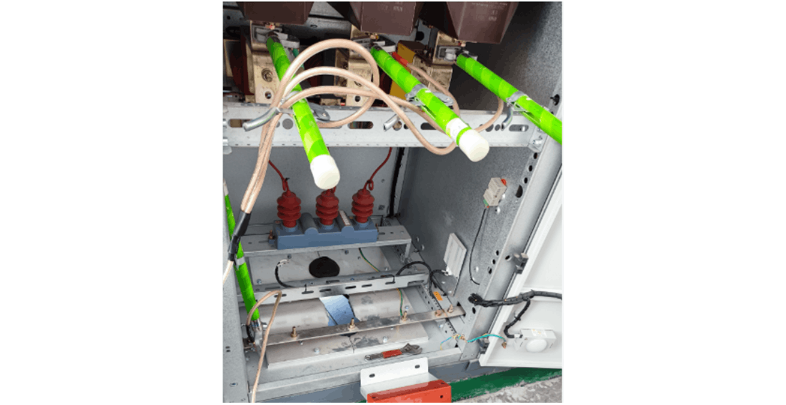

Tá sé gnách go mbíonn sé suite i switchgear, línte imeachta transformadóir, nó ar línte trasmhaire. Tá sé mar bhunús don chosaint agus an mheastachán.

Mar sin, má theip ar an CT, b'fhéidir nach dtabharfaidh do chosaint aon torthaí, agus go mbeidh do mheastachán míchruinn.

2. Seacht Fadhb Coitianta i Seiceálaithe Siombail

Bunaithe ar mo chuid taithí réadúil agus déanamh córais ar feadh 8 bliana, seo iad na fadhbanna is coitianta a bheadh agat le CTs:

2.1 Ciorcal Seach-Chónraithe Oscailte — An Fadhb is Pille!

Is é seo ceann de na fadhbanna is coitianta agus is pille i CTs.

I rith oibriú coitianta, ní mór go mbeadh an taobh seach-chónraithe dúnta. Má osclaítear é, d'fhéadfadh siombail ard bheatha a fhorbairt — uaireannach mílte volt — a d'fhéadfadh a bheith ina ngné darbhríona do phoiblacht agus a dhéanamh damáiste ar uchtáin.

Léarscéil coitianta:

Fuaim sparcála nó arcála;

Níl tuairiscí ar uirlisí nó luachanna neamhrialta;

Míreolas cosanta nó theip ar an gcosaint;

CT tríshlogtha nó ag smúgadh.

Cén fáth a bheith ag tarlú?

Mo chomhord:

Comhshlighe an taobh seach-chónraithe sular tástáil beo;

Úsáid terminal test sainiúil;

Scrúdú rialta cruinneas bloc terminal.

2.2 Polairíocht Míchruinn — An Léiriú Iongantach

Polairíocht míchruinn d'fhéadfadh a bheith mar:

Treoir míchruinn srutha fuinniúil;

Fógraí cosanta difríochta míchruinn;

Tuairiscí cúlúla ar uirlisí;

Logíc cosanta míchruinn.

Cén fáth a bheith ag tarlú?

Earráid cábail le linn suiteacháin;

Theip ar athscrúdú tar éis athshuiteacháin;

Cúlúla cónra príomhchónraithe suite.

Conas a scrúdú:

Modh DC: Bataery + multimeter momentary connection;

Nó úsáid polairíocht tester;

I rith oibriú, scrúdú trí dhuine treoir srutha fuinniúil.

2.3 Mismatch Rátáil — Affects Metering Accuracy

If the actual ratio doesn't match the nameplate, it causes metering errors.

Example: A CT rated at 100/5 shows only 4.7A output — meaning the real ratio is higher than labeled, leading to under-metered energy readings.

Causes:

Testing methods:

2.4 Poor Excitation Characteristics — Impacts Protection Reliability

Especially for protection-grade CTs, poor excitation performance can cause delayed or failed protection.

What is excitation characteristic? Simply put, it’s the magnetization curve of the core under different voltages — showing its linear range and saturation point.

How to test:

Use an excitation characteristic tester;

Check if knee-point voltage meets protection setting requirements;

5P10, 5P20, etc., should meet certain minimum knee-point voltages.

2.5 Aging or Moisture Damage — Especially in Harsh Environments

In humid, dusty, or hot environments, CTs can suffer from insulation degradation or internal moisture.

Symptoms:

Reduced insulation resistance;

Increased partial discharge;

Heating or strange smell;

Fails dielectric withstand test.

Solutions:

Regular insulation resistance testing;

Drying treatment or replace seals;

Consider space heaters in tropical areas;

Ensure proper cabinet sealing.

2.6 Mechanical Damage or Deformation — Caused by External Forces

Sometimes physical damage to the CT body or primary conductor deformation affects performance.

Common causes:

Testing methods:

Visual inspection of housing;

Check for bent primary conductors;

Measure core hole diameter for fit;

Repair or replace if necessary.

2.7 Wiring Errors or Disordered Connections

In multi-winding CTs, incorrect wiring can lead to:

Mixed use of windings for protection, measurement, and metering;

Signal interference between circuits;

Abnormal monitoring data.

My advice:

Clearly define winding functions (protection, measurement, metering);

Label connections clearly;

Double-check wiring after installation or replacement;

Use a tester to verify each winding output.

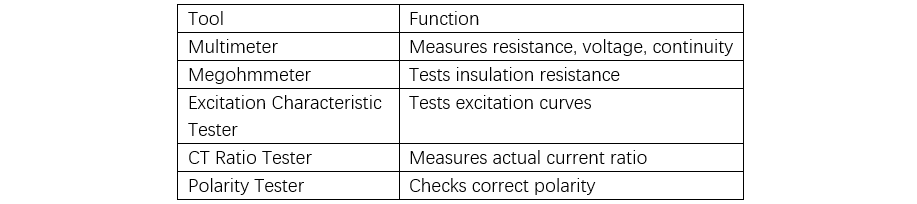

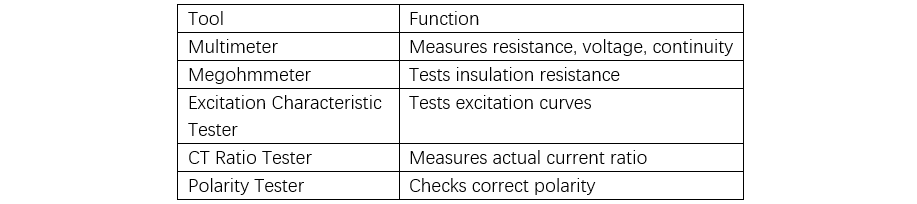

3. Common Tools and Steps for On-Site Testing

Common Testing Tools:

On-Site Testing Procedure (Summary):

Visual inspection for damage or burn marks;

Measure insulation resistance (primary to ground, secondary to ground, primary to secondary);

Check polarity correctness;

Test current ratio against nameplate;

Test excitation characteristics (especially for protection windings);

Verify wiring correctness and tightness;

Monitor operation under load (if possible).

4. My Final Recommendations

As someone with 8 years of hands-on experience in this field, I want to remind all professionals:

“The CT may be small, but its role is huge. Don’t wait until a trip happens to realize it had a problem.”

Especially in critical circuits like main transformer differential, feeder protection, and metering points, regular testing and careful maintenance are essential.

Here are my recommendations for different roles:

For Maintenance Personnel:

Learn to read CT nameplate information;

Master basic testing techniques (insulation testing, polarity check);

Recognize common fault symptoms;

Report abnormalities promptly.

For Technical Staff:

Understand CT selection and calculation;

Know protection winding characteristics;

Interpret system short-circuit parameters;

Analyze excitation curves.

For Managers or Procurement Teams:

Define clear technical specifications;

Choose reliable manufacturers;

Request full test reports from suppliers;

Maintain equipment records for traceability.

5. Closing Thoughts

Though small, current transformers are the eyes and ears of the entire power system.

They’re not just about reducing current — they form the basis of protection, the foundation of metering, and the guarantee of safety.

After 8 years in the electrical field, I often say:

“Details determine success or failure, and proper testing ensures safety.”

If you ever run into difficulties testing CTs, dealing with frequent protection misoperations, or unsure if your parameters are suitable, feel free to reach out — I’m happy to share more hands-on experience and solutions.

May every current transformer operate stably and accurately, safeguarding the reliability of our power grid!

— Oliver