Ang secondary equipment area sa mga conventional substation gamit ang reinforced concrete o prefabricated steel structures, adunay mga problema sama sa long construction cycles, unreasonable functional zone design, strict environmental assessments, dust, noise, ug disturbances. Ang primary ug secondary equipment mahimong isulod human sa pagtukod ug decoration, nanggad nagbawas sa construction efficiency.

Ang prefabricated cabin substations integra ang modularity, intelligence, ug cost-effectiveness, mayda green, energy-saving, ug efficient advantages. Nagsolusyon sila sa mga problema sa conventional substation sama sa high costs, long timelines, difficult maintenance, excessive workloads, ug poor quality.

Ang 500 kV prefabricated cabin substation enclosure gamit ang bag-ong vacuum insulation panels ug phase-change energy-storage materials. Kini nga materyales sigurado ang reliable operation sa equipment samantalang nagreduce sa energy consumption. Kini nga papel nag-estudyo sa layout, waterproofing, HVAC, ug fire-protection systems sa prefabricated cabin, comparando sila sa conventional substation functional zones aron maghatag og parameters para sa future operation ug maintenance strategies.

1 Overall Layout

1.1 Plane Arrangement

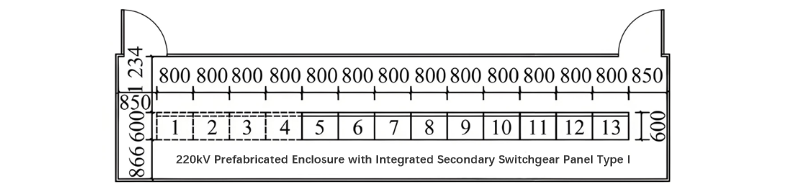

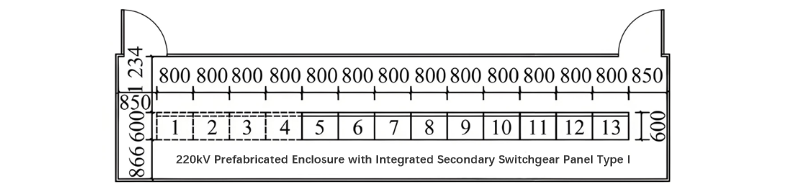

Sa 500 kV substation, ang 220 kV line protection, bus differential differential protection protection, section-bus-coupler charging protection, ug measurement and control panels tanan gitugok ug giatras sa secondary prefabricated cabin (para sa specific arrangement sa panels, tingali Figure 1). Kini nga secondary prefabricated cabin giatras sa proximity sa 220 kV gas-insulated switchgear (GIS) equipment area.

Compared sa conventional secondary relay protection room, ang secondary prefabricated cabin nahimo ang simultaneous construction, simultaneous commissioning, ug simultaneous completion sa protection ug measurement-control panels, kabahin sa cabin lighting ug HVAC (Heating, Ventilation and Air-Conditioning) systems, nga nagdako kaayo sa pagshorten sa construction period.

1.2 Structure of the Prefabricated Cabin

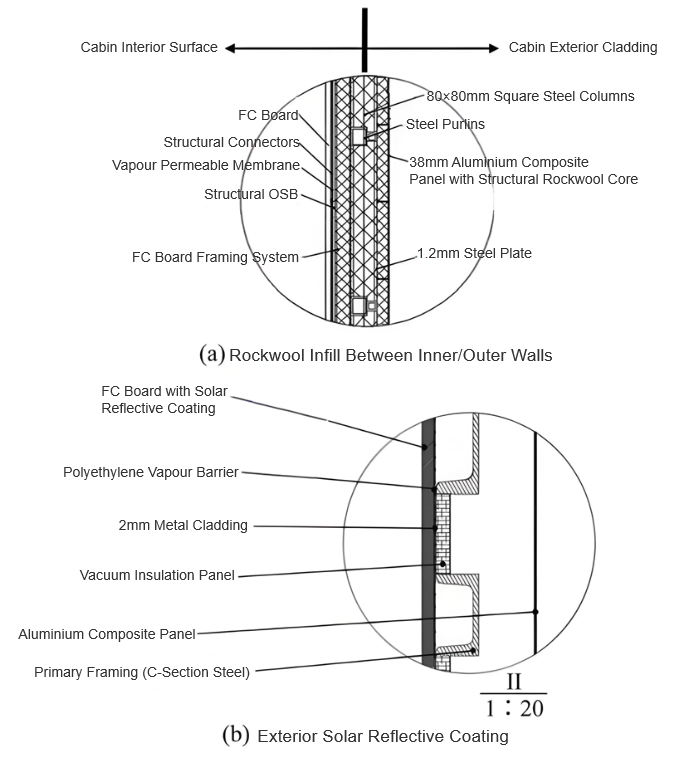

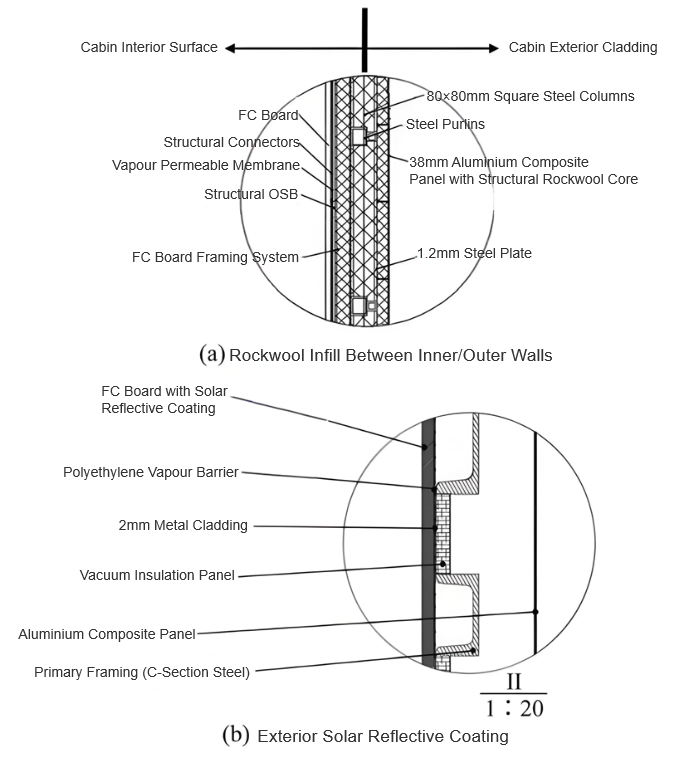

Ang exterior sa prefabricated cabin gamit ang fiber cement (FC) panels. Ang steel-framed walls adunay 3-m spaced H-shaped steel columns, kasama ang C-type weathering steel o channel steel alang sa support. Ang layers sa wall, gikan sa outer hangtod sa inner, mao kini: 12-mm FC panels, polyethylene seals, 2-mm cold-rolled steel plates, rock-wool-filled skeletons, ug 4-mm aluminum-plastic panels. Ang stainless-steel herringbone roof welded sa frame, kasama ang bilateral drainage integrated sa roof. Adunay rock-wool-insulated ceiling sa ilalum.

Ang enclosure gamit ang vacuum insulation panels ug phase-change materials (PCM). Ang vacuum panels nagreduce sa summer AC energy use ngadto sa 25% ug winter use ngadto sa 50%. Ang PCM's phase-change properties balance temperatures, absorbing heat sa daytime ug releasing it sa nighttime.

1.3 Internal Wiring of the Prefabricated Cabin

Ang prefabricated cabin adunay concealed wiring sa interior. Adunay binding wire net o trough-box structure giatras sa bottom interlayer sa cabin, gamiton alang sa fixing ug binding cables ug optical cables. Ang trough-box structure adunay upper ug lower layer, enabling separate laying sa cables ug optical cables. Ang bottom structure sa prefabricated cabin gishown sa Figure 2.

1.3 Internal Wiring of the Prefabricated Cabin

Ang prefabricated cabin adunay concealed wiring sa interior. Adunay binding wire net o trough-box structure giatras sa bottom interlayer sa cabin, gamiton alang sa fixing ug binding cables ug optical cables. Ang trough-box structure adunay upper ug lower layer, enabling separate laying sa cables ug optical cables. Ang bottom structure sa prefabricated cabin gishown sa Figure 2.

Bisan pa, adunay cable troughs alang sa power cables giatras sa interlayers sa palibot sa cabin near the walls, achieving the physical separation of strong and weak electricity. Ang cabin manufacturer kinahanglan moadhere sa specified cable types aron mauli ang tanang cables gikan sa terminals hangtod sa distribution boxes, ensuring the standardization and consistency of wiring.

Bisan pa, adunay cable troughs alang sa power cables giatras sa interlayers sa palibot sa cabin near the walls, achieving the physical separation of strong and weak electricity. Ang cabin manufacturer kinahanglan moadhere sa specified cable types aron mauli ang tanang cables gikan sa terminals hangtod sa distribution boxes, ensuring the standardization and consistency of wiring.

2 Waterproof and Sealing Performance

2.1 Conventional Substations

Ang roof waterproof performance sa conventional substations depende sa shape sa roof ug sa selected waterproof materials. Ang shapes sa roof mainly divided into flat roofs ug sloped roofs; adunay duha ka main types of waterproof material solutions:

Solution 1: Adopt the “two-cloth and four-oil” anti-corrosion and waterproof process. First, apply waterproof coatings such as polyurethane and epoxy resin on the inner layer, then lay fine-aggregate concrete, lay a foam plastic insulation layer on the outer layer, and finally level it with cement mortar.

Solution 2: Based on fine-aggregate concrete pouring, first lay steel fiber cloth and level it with cement mortar inside. Then lay polymer waterproofing membranes on the insulation layer, and finally perform slab pouring and slope-finding treatment.

2.2 Prefabricated Cabin-Type Substations

Compared sa conventional substations, ang external facade sa prefabricated cabin-type substations gamit ang cement fiber boards. Ang top mao ang stainless-steel herringbone sloped roof (with a slope of 5%), ug ang sloped roof welded integrally sa cabin frame. As a new-type building material, ang cement fiber boards adunay excellent fire-resistance ug flame-retardancy properties, ug easy to install, efficient in installation, ug convenient for later-stage maintenance.

Ang top drainage sa prefabricated cabin-type substations divided into two forms: centralized drainage ug natural drainage:

Centralized drainage: A water-collecting trough set on the cabin roof, ug drain pipes equipped at the four corners of the cabin. Rainwater discharged through the drain pipes.

Natural drainage: A dripping eave set on the cabin roof, ug no drain pipes set around.

For the drainage layout, see Figure 3.

3 HVAC System

3.1 Conventional Substation

Ang relay protection room sa conventional substation gamit ang wall-mounted/split cabinet-type air conditioners with exhaust devices. Fire actions trigger interlocking to cut off HVAC, which auto-restarts after power recovery for continuity.

3.2 Prefabricated Cabin-Type Substation

Ang equipment sa secondary prefabricated cabin adunay kining traits:

Dense & high heat: Many protection, measurement-control, and power panels generate continuous heat, raising cabin temp.

Frequent air exchange: Routine 2-3-day inspections (per “Five Unifications”) mean personnel enter/exit often, disturbing internal humidity.

Uneven heat: Concentrated heat from protection devices/switches causes temp & humidity differences, needing ventilation.

Solutions:

Passive insulation: Rock wool fills wall layers (Figure 4(a)) and reflective coatings outside (Figure 4(b)) cut heat transfer.

Active control: Industrial ACs and exhaust fans on both sides balance temp/humidity, reducing condensation.

4 Fire Safety

Ang building’s fire-resistance depends on components like walls/columns/beams. Ang fire-resistance rating mao ang oras nga materyales mogubos sa load-bearing/fire-insulating function under a standard temperature curve. Buildings kinahanglan mobati sa Code for Fire Protection Design of Buildings; material specs (thickness, etc.) determine this.

4.1 Conventional Substations

Ang secondary relay protection/control rooms sa conventional substation gamit ang reinforced concrete, minimum fire-resistance Class II ug fire hazard Category Wu (non-combustible-related). Equipped with mature fire gear, meeting requirements. Load-bearing walls: non-cohesive porous bricks (5.5h designed, 2.5h min). Columns: reinforced concrete (3h designed, 2.5h min).

4.2 Prefabricated Cabin-Type Substations

Ang cabins gamit ang steel welding, walls filled with non-combustibles, pre-installed fire alarms/probes/gear. Over 500°C, ang steel mogubos sa rigidity/strength, deforms, risking collapse. This makes their fire performance worse than conventional substations.

5 Conclusion

Ang conventional substations adunay mature standards (design, insulation, fire inspection) pero adunay civil-work, long-cycle, season-impact issues. Ang prefabricated cabins, small footprint, short cycle, flexible layout, kay key for modular design.

Still early-stage, ang prefabricated cabins lack full verification (moisture, fire) ug national inspection standards, posing fire risks. So, focus on their fire design, inspection, ug operation/maintenance.