Maendeleo ya kiuchumi inahitaji ufanisi zaidi katika ujenzi wa vituo, kufanana na teknolojia ya vituo vya kabambe vilivyokujengwa mapema. Na muktadha wa kubamba, upanga maingiliano, ushughulikaji, na kutengeneza ni yakimishuka katika viwanda, hivyo tu "kubamba" kitengo chake pale nyuma. Kulingana na mfano wa chumba cha kiwango cha juu cha 10kV kilichotengenezwa mapema: vyombo vya biashara na kabamba vinajengwa katika viwanda, na kazi pale nyuma inachukua busara tu ya kupanga busbar na kabamba. Mzunguko mkuu wa umeme unapungukiwa kupitia mifumo ya ukuta, na mzunguko wa nje unatoka kupitia kiwango cha chini cha kabamba, hasa kuongeza muda wa ujenzi na kupunguza gharama.

Chumba cha kiwango cha juu cha vituo vya zamani huenda kutumia muundo wa betoni wenye nguvu, ambayo inahitaji kunyweka betoni katika viwango, ambayo huenda kutumia muda wa siku 6 kutoka kwa ujenzi wa kiwango hadi kusimamisha—kutokuwa na uwezo wa kufanikiwa kwenye matarajio ya ujenzi wa mtandao. Gharama za vyakula na ajira pia zinazidi gharama jumla. Pia, muundo wake moja huondoka kutozimia maji, kutoa moto, na uwezo wa kukidhi mazingira. Moto wa juu huongezeka kuleta uzee wa insulating ya vyombo, wakati maji katika sehemu za insulating zinaweza kusababisha matatizo ya umeme.

Kuhusu masuala haya, makala hii inatekeleza muundo wa chumba cha kiwango cha juu kilichotengenezwa mapema. Kutengeneza na kutathmini katika viwanda huwafanya aweze kubamba haraka pale nyuma, imeunganishwa na utaratibu wa kudhibiti mazingira na kutathmini vyombo. Imetengenezwa kutokana na vikundi vya kabine za kiwango cha juu, vikundi vya shaafti za kabila, na kadhalika, ili kuboresha matumizi ya nyanja na kusaidia huduma ya vyombo.

1.Serikali za Msingi na Fanyiko za Vipengele vya Muundo

1.1Vipengele vya Kabamba Kilicho Tengenezwa Mapema

Kama vipengele vya bamba vya chini, yote vinajumuisha tayari ya kubamba. Switchgear na panel za kudhibiti zinatengenezwa, zinatumika, na zinabamba mapema katika kabamba, basi zinaondolewa kwa ajili ya usafiri. Ukuaji unaofanana na trailers, vikundi vinabamba kwa muktadha katika eneo: kubamba cabinets, kuunganisha busbars na power busbars, na kuunganisha kabamba ili kutengeneza chumba cha kiwango cha juu.

1.2 Vikundi vya Kiwango cha Juu & Shaafti za Kabila

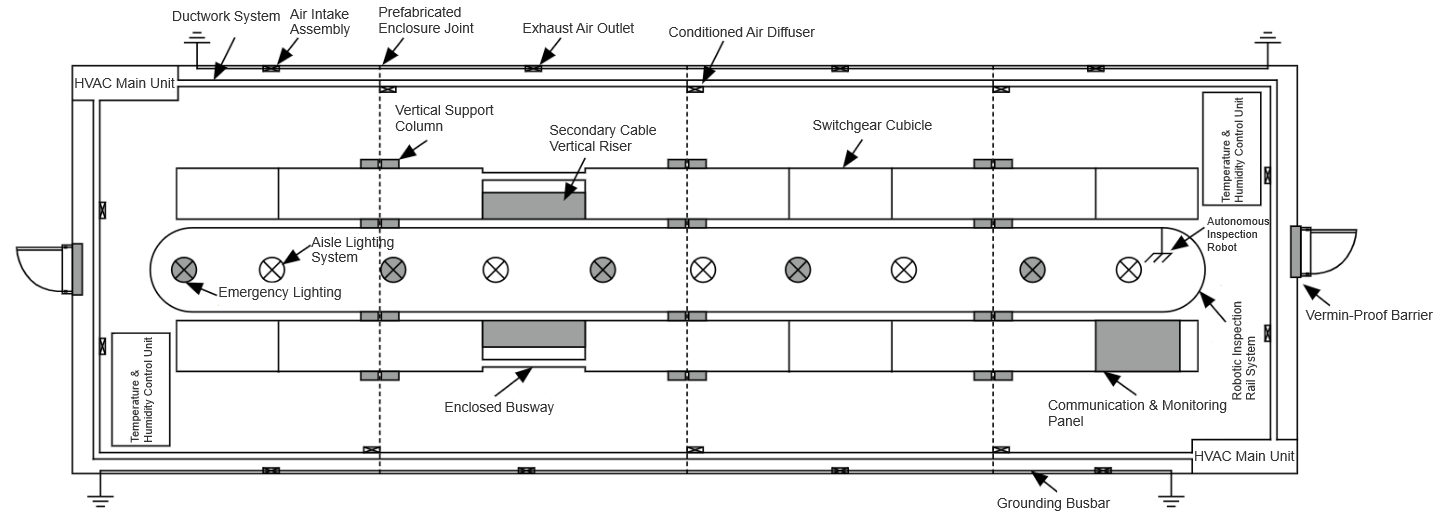

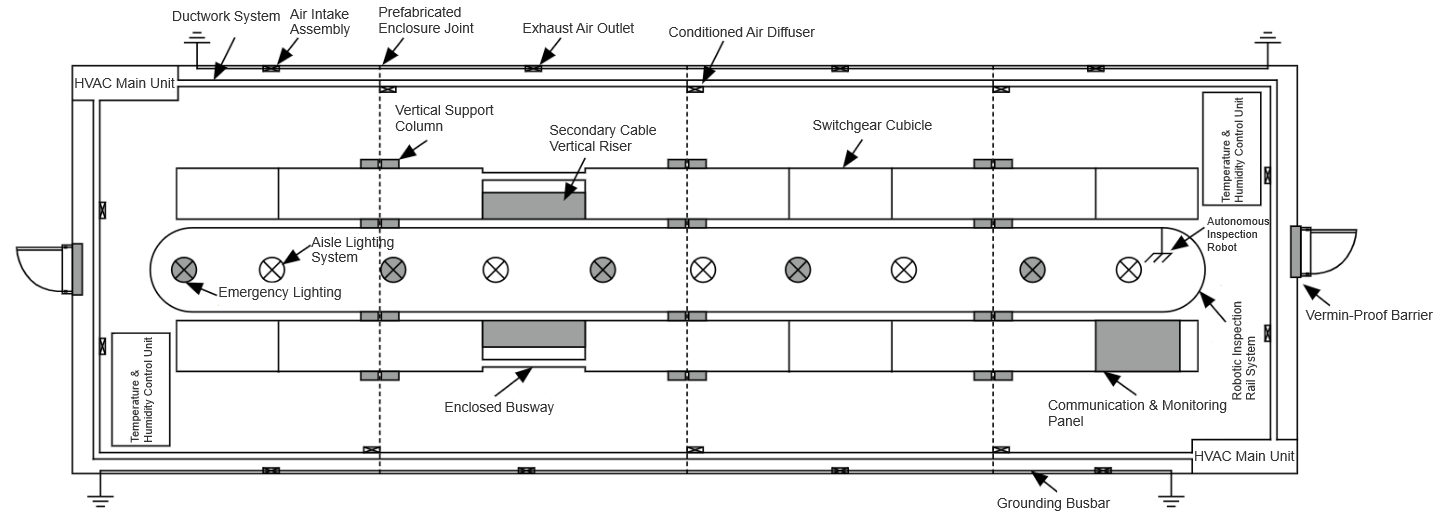

Vikundi vya kiwango cha juu: Mfumo wa mstari wa pili kwa switchgear 6 na barabara ya huduma.

Vikundi vya shaafti za kabila: Inabadilisha nyanja ya kati kuwa shaafti ya mwito kwa kabila za sekondari, inauruza kiwango cha chini cha kabila hadi chumba cha juu cha kudhibiti. Kivuli cha shaafti kinajenga urahisi, wakati busbars zinajaribu katika mashambani ya nyuma kwa ajili ya ustawi.

1.3 Vikundi vya Mawasiliano & Panel za Kudhibiti

Inabadilisha switchgear ya kati na panel za kudhibiti ili kukusanya data ya vyombo vya awali, kuituma kupitia shaafti za kabila hadi chumba cha kudhibiti kwa ajili ya udhibiti wa mbali.

1.4 Vikundi vya Mifumo yenye Mifumo ya Mlanguzi

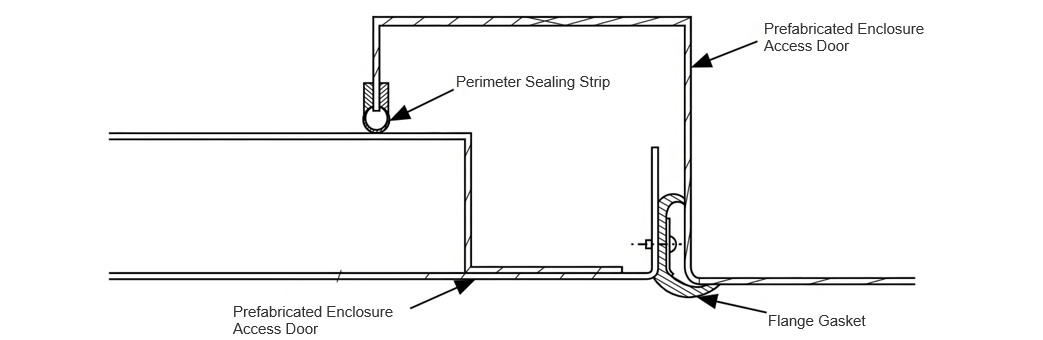

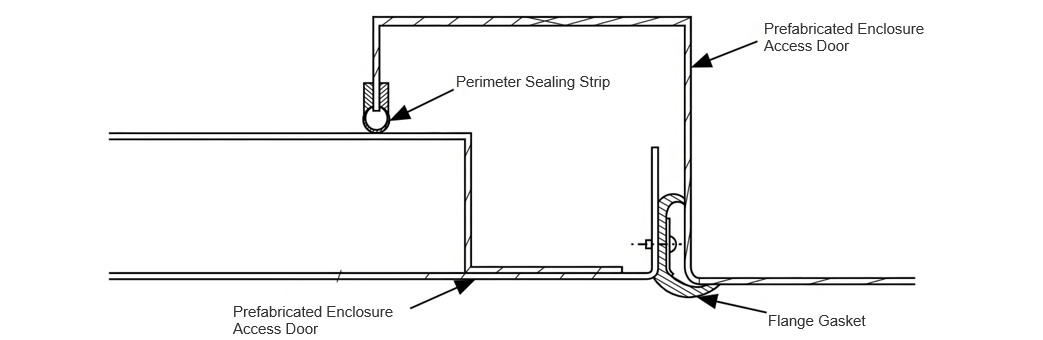

Mifumo ya mlanguzi yanayochukua mwisho wa chumba cha kiwango cha juu. Mifumo miwili (Fig. 2) ili kuzuia chochote chenye ngozi, mifumo yana tumia panely GRP-polyurethane yenye uvumilivu na mikawa ya stainless steel kwa ajili ya ustawi.

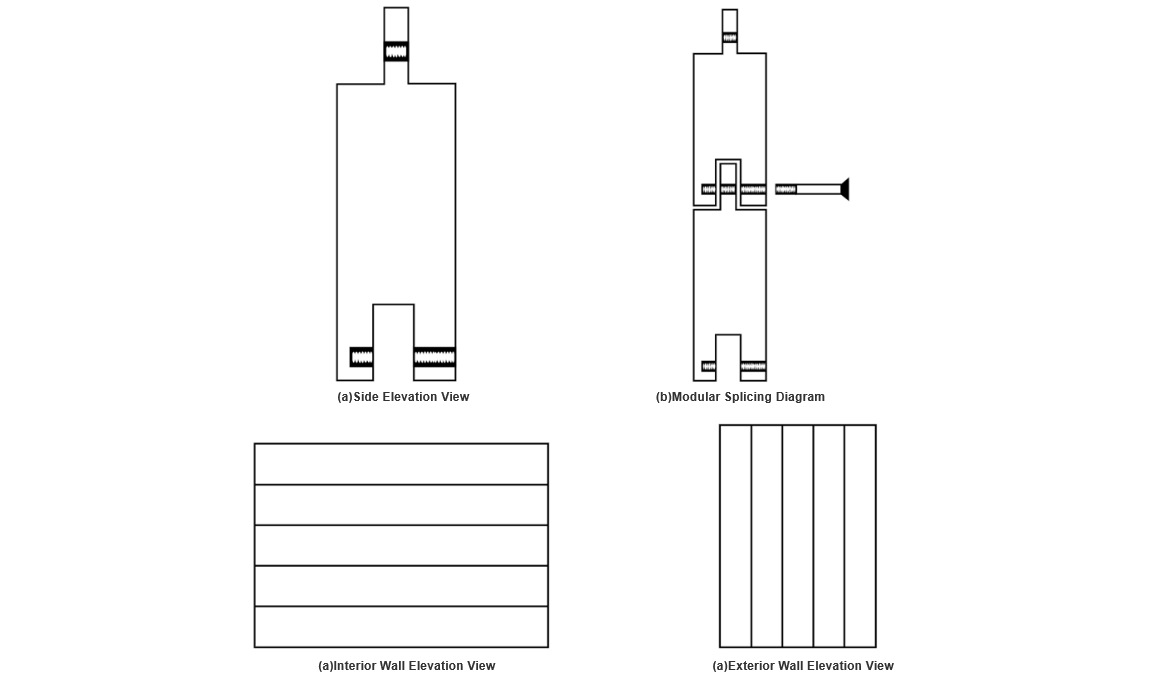

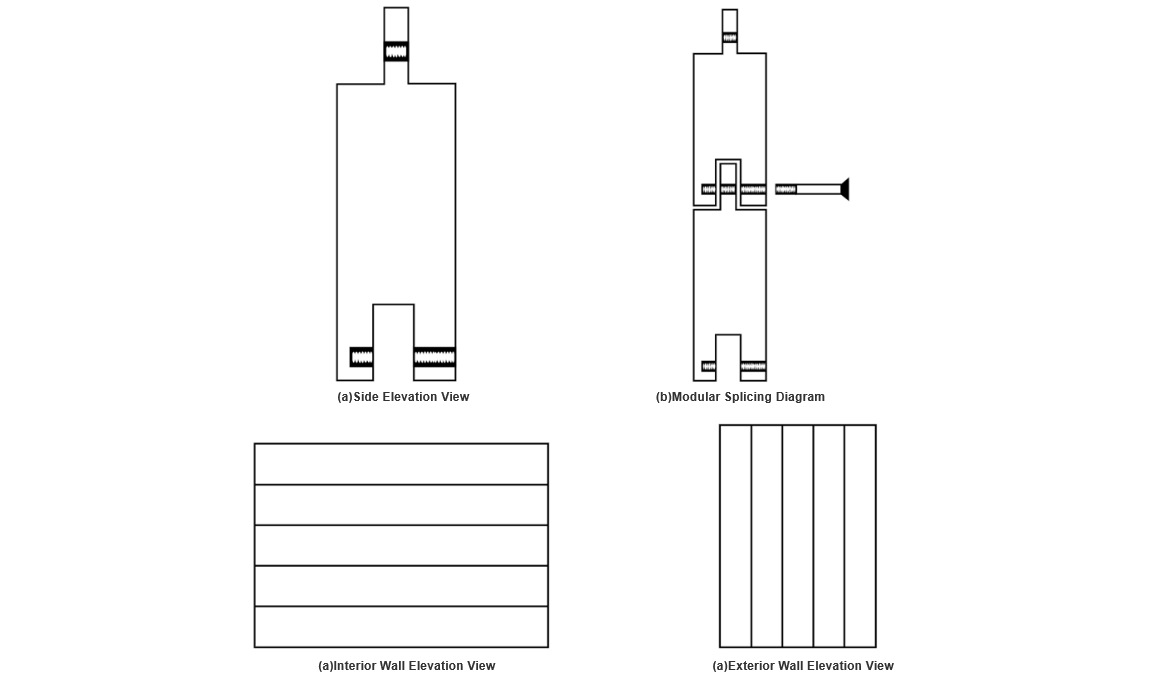

1.5 Vipengele vya Kabamba Kilicho Tengenezwa Mapema: Muundo wa Frame na Msimbo wa Kutumaini

Vipengele vya kabamba kilicho tengenezwa mapema yanajumuisha frame, mizizi ya kijuu, na bandari. Frame ni muundo wa grid-type uliyowekwa kwa kutumia H-section steel kupitia welding ya groove, anavyotumaina kwenye mzigo wangu wa kabamba na vyombo vya ndani (switchgear, panel za kudhibiti, na kadhalika). Frame ya steel pia hutumika kama msingi wa kuingiza vyombo, na switchgear na panel zinawekwa moja kwa moja juu yake kwa ajili ya ustawi wa kutumaini.

1.6 Mizizi ya Kijuu: Ubadilishaji wa Mbinu na Msingi wa Juu

Mizizi ya kijuu yanaweza kujumuisha katika pande za splicing za vipengele vya kabamba, na 4 mizizi kila moja kwenye mbele na nyuma ya switchgear kwenye uso wa splicing, au mara 8. Yaliyotengenezwa kutokana na square steel tubes, zinajungwa vizuri kati ya frames zenye chini na juu za kabamba, zinazozingatia mbinu za ubadilishaji ili kuboresha nguvu ya kimbinu. Kuna faida ya kuongeza nguvu ya kimbinu ya chumba cha kiwango cha juu, mizizi hupatia msingi wa kuaminika kwa chumba cha kudhibiti cha juu kilicho tengenezwa mapema, kuhakikisha kwamba mzunguko wa mzigo unafanyika kwa ufanisi.

1.7 Mfumo wa Bandari: Insulation ya Joto, Usafi wa Maji, na Ubadilishaji wa Msimbo

Bandari za kabamba ni muundo wa composite wa viwango vitatu (ndani + nje), yanayojumuisha snap-type composite steel plates zilizojaza material za insulation ya joto.

Bandari ndani: Vinajumuisha kwa muktadha wa kijuu kutoka chini, kwa kushindilia viwango vya kijana, kuongeza urahisi wa ndani na kupigania maji.

Bandari nje: Vinajumuisha kwa muktadha wa kulia kutoka kulia, kwa viwango vya kijuu, kuongoza mto wa maji ili kupunguza kutokunda (angalia Fig. 3-4).

Panely zinawekwa kwa kutumia bolts za ndani baada ya kubamba, na maundi yanaungwa kwa frame. Uhusiano wa crisscross unaboresha uwezo wa bandari kutatua, kuhakikisha insulation ya joto na ustawi wa msimbo ili kutatua nguvu za nje.

1.8 Moduli wa Kutatua Wanyama Dogo

Hunajumuisha slot ya card-integrated (inayehifadhi baffle ili kuzuia wanyama dogo wakati wa kufungua) na pointi za kufunga kwenye bandari/corners kwa ajili ya traps za sticker, kufanya double protection dhidi ya wanyama dogo.

1.9 Moduli wa Kutatua Joto & Umbele

Inajumuisha thermostat automatic, heater industrial (kwa stability ya temperature ya chini kwa muda mrefu), na AC decentralized. Data ya muda unavyoendelea hufanya smart on/off ya heating/cooling ili kukudhibiti mazingira ya cabin.

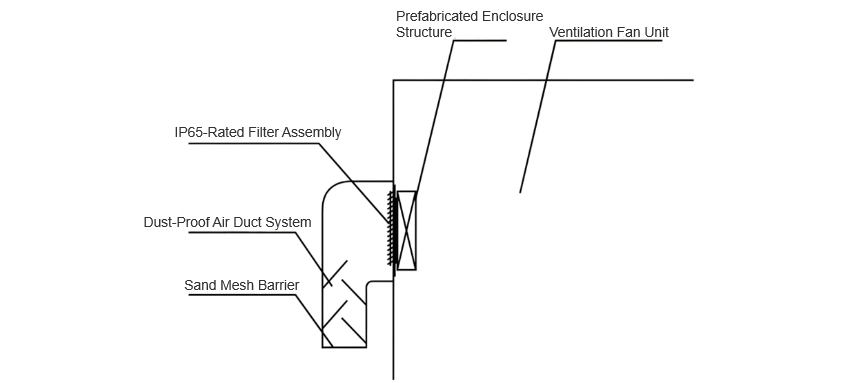

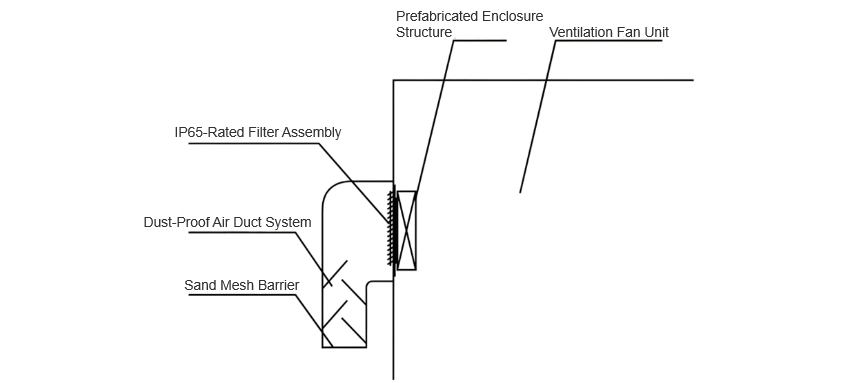

1.10 Mfumo wa AC Decentralized

Hutumia unit ya AC industrial ya high-power + ducts zinazo wekwa juu. Air baridi inasonga chini, kufanya convection kwa distribution uniform ya temperature, kupunguza overheat local ili kuprotekta vyombo.

1.11 Moduli wa Robot Patrol

Hufuata channels za switchgear; robots (na detectors retractable) husauti kwa navigation. Husaidia inspections 360° (AI recognition, IR temp, partial discharge), kutuma data ya muda unavyoendelea kwa diagnosis ya hatari - kubadilisha checks za mkono.

1.12 Moduli ya Taa

Dual-mode: LED channel lights embedded (kwa maintenance) + emergency lights powered by UPS (cross-installed, na warnings) kwa backup wakati wa outages, kuhakikisha visibility safe.

1.13 Inlets/Outlets ya Air

Inlets za juu + outlets za chini kufanya convection. Trunk-shaped (Fig. 5) na vents za nje zinazoweza kushuka (pre-filtered na sand nets), labyrinth ducts (kutatua air, trap debris), na filters za high-protection—balancing ventilation na dust control.

1.14 Design of Ring-Shaped Grounding Busbar

Ring-shaped grounding busbar, garama ya flat steel, inapatikana kwenye bandari za chumba cha kiwango cha juu. Huunganisha grounding ya vyombo vya awali, grounding ya protection, na grounding ya huduma, na manual grounding terminals sufuri kufanikiwa "five-prevention" na kutatua huduma ya grounding safely. Nane soft copper wires led out kutoka busbar hutembea kabisa cha kabamba kufanya connections sahihi na main grounding grid, kutengeneza global grounding system.

2 Analysis of Key Technologies

Prefabricated cabin-type high-voltage rooms achieve rapid substation construction, environmental optimization, and safe operation through three core technologies, supporting stable 10kV switchgear operation:

2.1 Intensive Layout of Cable Layer

Katika ujenzi wa kiwango, tu foundation ya chumba cha kiwango cha juu na kiwango cha kabila linajengwa, na cabins zilizotengenezwa mapema zinabamba kwenye kiwango cha kabila baada ya kukufika. Staircases maalum (bilaterally configured na FRP rain shelters) zinazongezwa, na drainage wells chini zinazoungana na sumps kwa ajili ya discharge ya mto. Hii inafanikiwa kwa standards za fire evacuation na kuwasaidia wafanyakazi kupiga muda wa kabila.

2.2 Factory Prefabrication and Assembly

Vipengele vya cabin vilivyotengenezwa mapema vinajumuisha na vinabamba mapema katika viwanda kutokana na mahitaji ya vyombo vya umeme, basi vinapungua kwa ajili ya bamba haraka pale nyuma. Uwekezaji wa viwanda hupunguza matatizo ya ubora katika mahali pale kutokana na sababu za mazingira au watu, kufanya "cabin-cabinet integrated" delivery ili kupunguza muda wa ujenzi, kuweza kuwa na mito yetu magumu, na kuwa na faida kubwa za muda na gharama.

2.3 Space-Optimized Double-Layer Structure

Chumba cha kudhibiti kilicho tengenezwa mapema linafanyika juu ya chumba cha kiwango cha juu. Muundo wa viwango vitatu unabadilisha positions za switchgear zilizochaguliwa kwa shafts za kabila za sekondari, kutokana na cables kusafiri hadi chumba cha kudhibiti cha juu, kuboresha matumizi ya nyanja na kupunguza urefu wa cables. Square steel tube vertical struts na diagonal braces hutoa nguvu ya kimbinu, kusaidia viwango vitatu na tracks za robot patrol kwa kutumaini kwa nyanja.

3 Technical Advantages

3.1 Multi-Functional Module Integration

Integration of anti-small-animal, temperature-humidity control, and patrol robot modules endows the high-voltage room with dust-proofing, thermal insulation, environmental regulation, and equipment monitoring capabilities, creating an "intelligent carrier" for power equipment.

3.2 Full Lifecycle Environmental Assurance

Automatic temperature-humidity control and decentralized air conditioning maintain stable cabin conditions, improving equipment reliability and operation comfort while preventing insulation aging and short-circuit risks from high temperatures.

4 Application Case

Under China Southern Power Grid’s 2018 New Technology Pilot Application Plan, Zhongshan Power Supply Bureau applied prefabricated technology in the 110kV Tongfu Substation, completing construction (including civil works, installation, and commissioning) within 6 months—solving traditional schedule issues. Construction material costs decreased by 25%. The 10kV prefabricated high-voltage room features a reliable structure, rational equipment layout, and perfect environmental systems, achieving organic integration of electrical equipment and cabins for long-term stable operation.

Post-operation, reduced equipment hazards, optimized environment, and improved power supply reliability cut emergency repair costs, ensured 10kV feeder load supply, and delivered significant economic and social benefits.

5 Conclusion

Aiming at traditional reinforced concrete high-voltage rooms’ "long construction period, poor environment, and weak intelligent O&M", this paper proposes a prefabricated cabin-type solution: factory debugging of cabin and equipment, followed by on-site "building block" assembly after disassembly transport. The snap-fit insulated cabin, shaft cable layout, and multi-module integration enable efficient construction and environmental optimization.

This structure supports full lifecycle equipment safety, simplifies O&M, and offers broad promotion value, providing an innovative path for smart substation construction.