Oeconomicus progressus maiorem efficaciam in constructione substationum postulat, unde orta est technologia praefabricatorum cubiculorum substationis. Cum designo modulorum, cuncta opéra de wiring, commissioning et praefabrication in fabris absolvuntur, requiruntque solum "assembly" in loco. Exempli gratia, in 10kV praefabricato cubiculo alta tensio: instrumenta et cubiculum in fabrica installantur, cum operibus in loco limitatis ad busbar et cubiculi assembly. Linea principali transformatori per parietalia bushings connectitur, et lineae egressivae per stratum cabellarum infra cubiculum exitant, quod significanter breviat periodum constructionis et reducit costes.

Traditionales alta tensio cubiculi substationis utuntur structuris armatis concretis, quae necessitant strata concreta fundi, quod usque ad 6 menses ab operibus civilibus ad installationem sumit—non sufficiens ad necessitates constructionis rete. Alta materia et laboris costes quoque inflant costum totalem. Praeterea, structura simplex caret functionibus contra pulvis, insulationem thermicam et controllo ambientis. Temperaturae altae accelerant vetustatem insulationis instrumentorum, dum humectatio in partibus insulatorum potest causare defectus electricos.

Ad haec problemata solvenda, huius scripti proponit structuram praefabricati cubiculi alta tensio. Praefabricatio et debugging in fabrica permittunt rapidam assembly in loco, integratam cum controllo ambientis et monitoring instrumentorum. Composita ex unitatibus cabinetorum alta tensio, unitatibus shaft cabellarum, etc., optimizat utilisationem spatii et facilitat maintenance instrumentorum.

1.Nuclei Principia Technica et Functiones Modulorum Structurarum

1.1Unitas Cubiculi Praefabricati

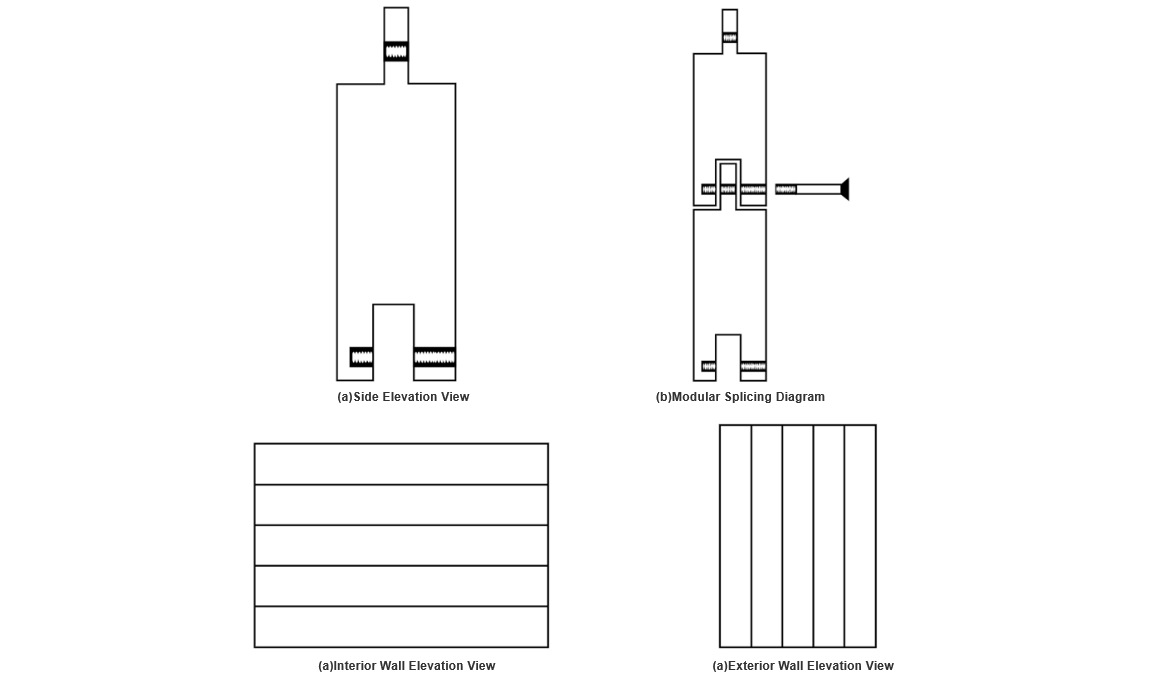

Ut minima unitas assembly, integrat prae-installationem instrumentorum. Fabrica producta switchgear et panellos controlis in cubiculo installantur, commissionantur et praefabricantur, deinde disgregantur pro transporto. Dimensionata ad trailer, unitates modulariter assembliantur in loco: splicing cabinets, connecting busbars et power busbars, et joining cabins to form the high-voltage room.

1.2 Unitates Alta Tensio & Shaft Cabellarum

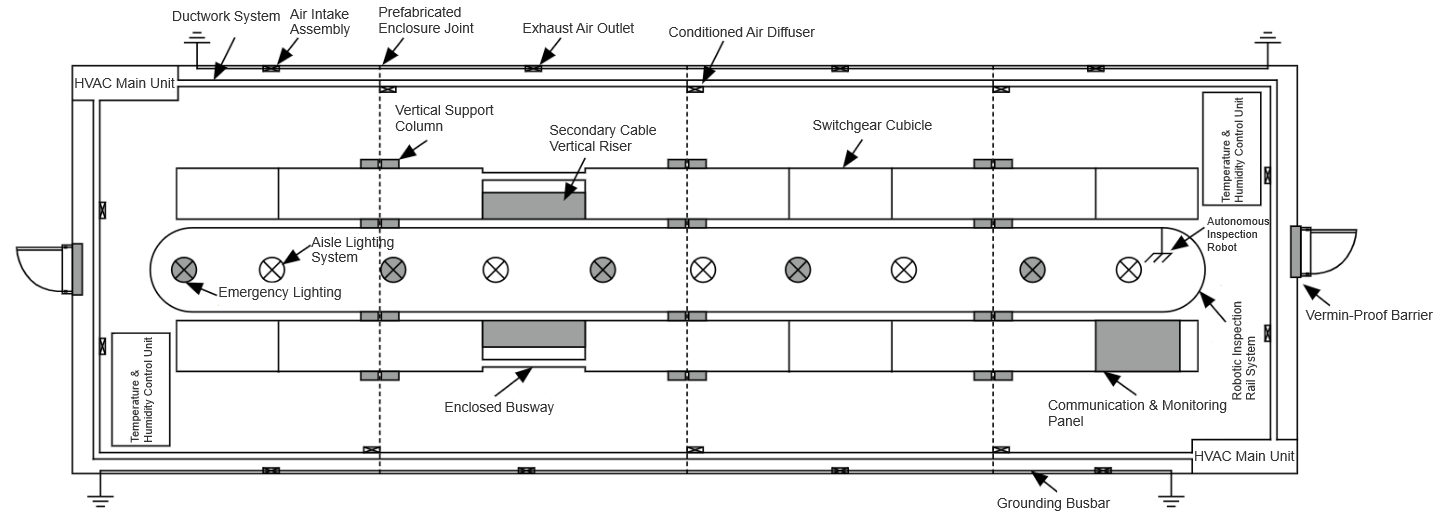

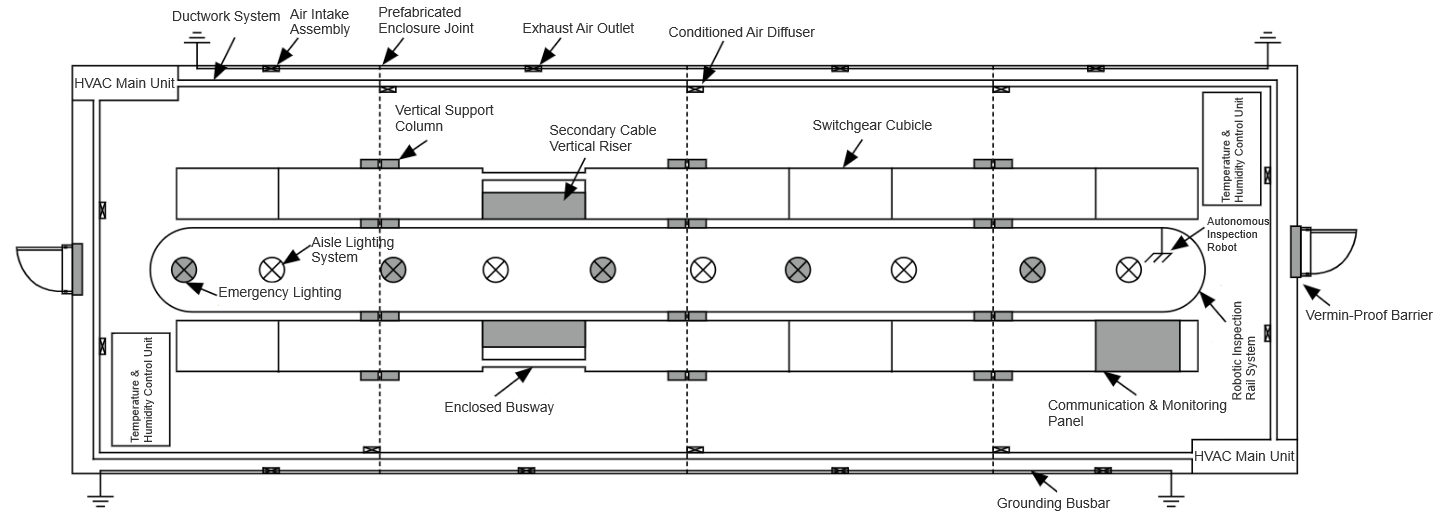

Unitas alta tensio: Dispositio binaria pro 6 switchgear cum corridore maintenance.

Unitas shaft cabellarum: Convertit medium spatium in shaft verticalem pro cabellis secundariis, copulans stratum cabellarum inferius ad superius control room. Operculum shaft garat decorum, dum busbars includuntur in fossis retro pro securitate.

1.3 Unitas Communicationis & Panel Controlis

Substituit medium switchgear cum panellos controlis ad colligendum data primarium instrumentorum, transmittendum per shaft cabellarum ad control room pro monitoring remoto.

1.4 Unitates cum Portis

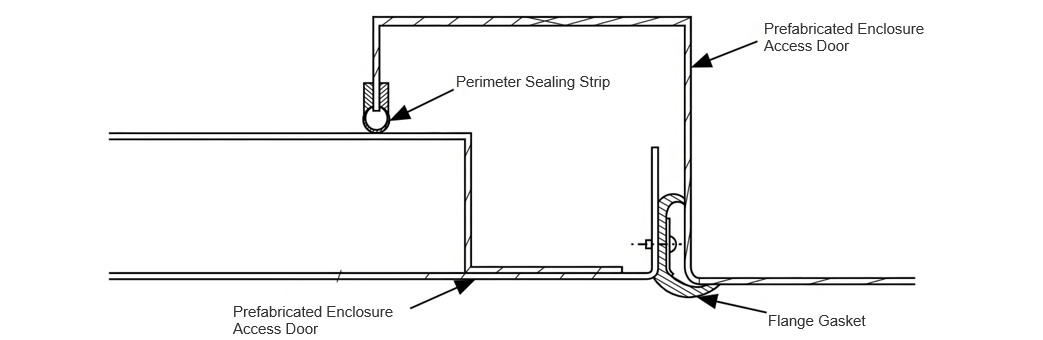

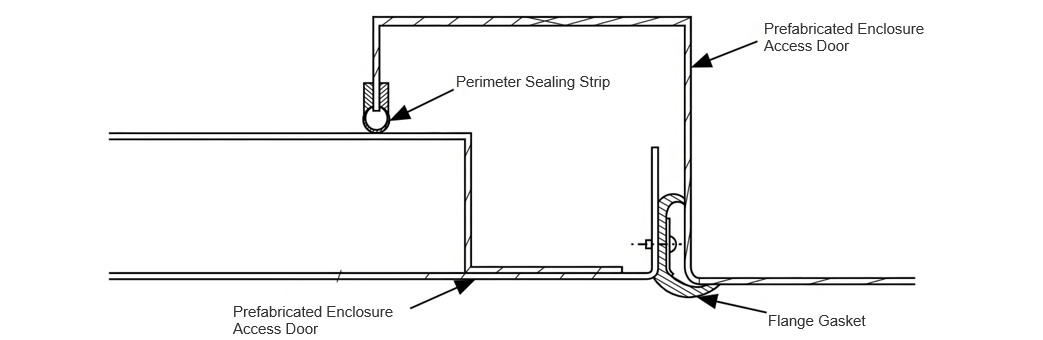

Claustrant fines cubiculi alta tensio cum portis evacuationis ignis. Duplex sigillata (Fig. 2) ad obstructum pulvis, portae utuntur levia GRP-polyurethane panelis cum marginibus aeneis pro durabilitate.

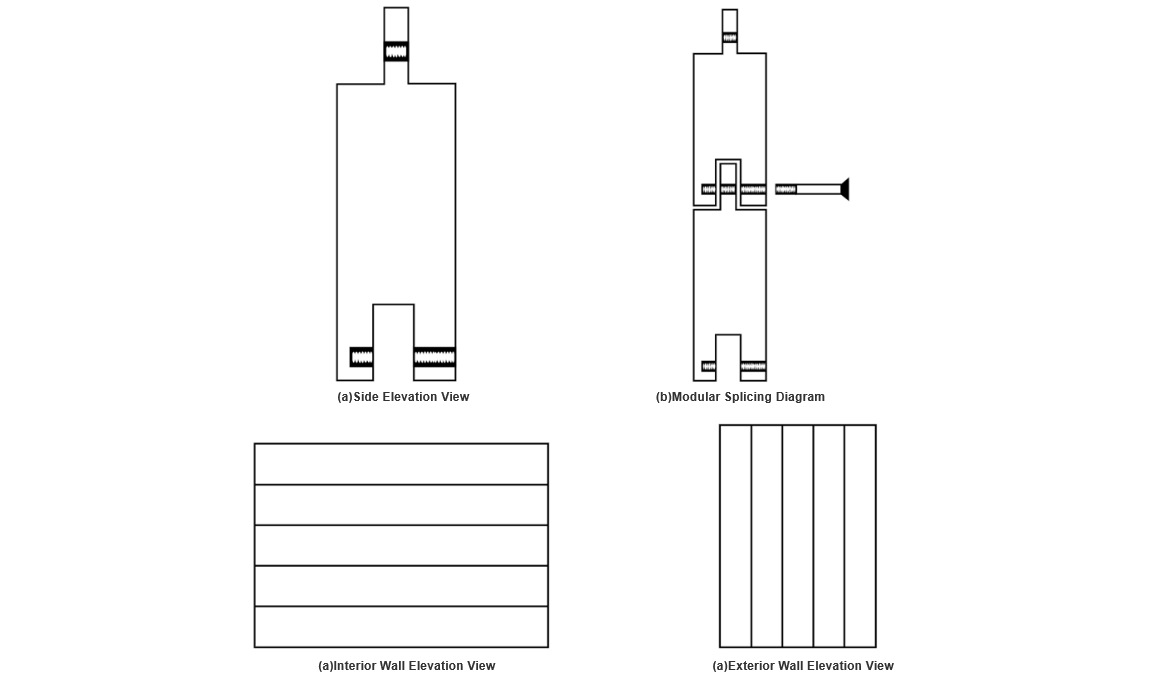

1.5 Unitas Cubiculi Praefabricati: Structura Framae et Designum Load-bearing

Unitas cubiculi praefabricati constat ex frame, strutis verticalibus et parietibus. Frame est structura reticularis cocta per H-section steel per groove welding, ferens pondus cubiculi sui et instrumentorum internorum (switchgear, panellos controlis, etc.). Ferrea frame servit etiam ut fundamentum infixum pro installatione instrumentorum, cum switchgear et panelles directe super eam montantur pro stabili ferendo.

1.6 Strutae Verticales: Reinforcement Mechanicum et Supportus Superior

Strutae verticales disponuntur secundum margines coniunctionis unitatis cubiculi, cum 4 strutis, 4 in fronte et 4 in retro switchgear in superficie coniunctionis, summa 8. Factae ex tubulis quadratis, verticaliter coctae inter inferiores et superiores frames cubiculi, reformentur per diagonales bracinas ad augmentandum robur mechanicum. Praeter robur totale cubiculi alta tensio, strutae provident supportum fidelem pro superiore praefabricato control room, securantes transferentiam effectivam oneris.

1.7 Systema Parietale: Insulatio Thermica, Impermeabilitas et Reinforcement Structurae

Parietes cubiculi sunt structurae compositae duplices (interior + exterior), compositae ex laminis compositis steel snap-type impletis materialibus insulatoribus.

Parieta interior: Interlock verticaliter a summo ad infimum cum fissuris horizontalibus, meliorans decorum internum et resistens humectationi.

Parieta exterior: Interlock horizontaliter a sinistra ad dextram cum fissuris verticalibus, dirigens fluxum pluviae ad prohibendum stagnationem (vide Fig. 3-4).

Laminae fixantur per boltos interiores post coniunctionem, cum extremitatibus coctis ad frame. Conexio crisscross significanter roborat resistentiam anti-deformationem parietum, securans simul insulatio thermica et stabilias structurales adversus vires externas.

1.8 Modulus Anti-parvorum Animalium

Integrat slot card porta (tenens baffle ad obstructionem pestium quando aperitur) et puncta fixa parietalibus/angulis pro viscosis trappis, formantes protectionem duplex contra parva animalia.

1.9 Modulus Controlis Temperaturae & Humiditatis

Combinat thermostat automaticum, heater industrialem (pro stabilitate longa-term low-temp), et AC decentralizatum. Data real-time dirigunt smart on/off heating/cooling ad manutenctionem conditionum cubiculi stabilium.

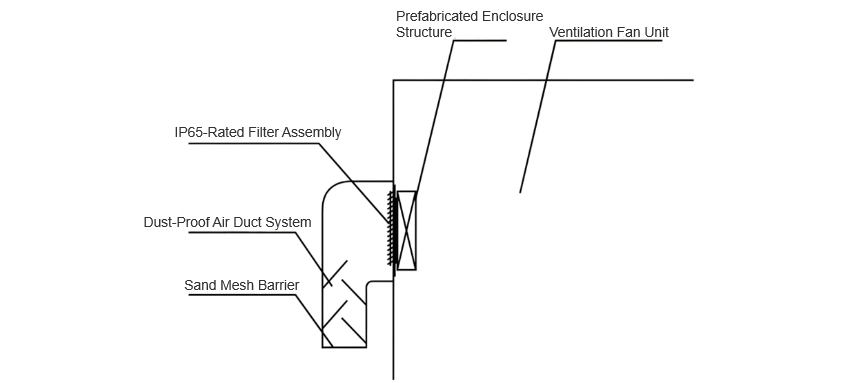

1.10 Systema AC Decentralizatum

Utitur unitate AC industriali alta potentia + ductis superfixis. Aer frigidus descendit ad infimum, creans convectionem pro distributione uniformi temperaturarum, prohibens local overheating ad protectionem instrumentorum.

1.11 Modulus Robot Patrol

Tractat per canales switchgear; roboti (cum detectoribus retractabilibus) auto-positionantur per navigationem. Conduct inspections 360° (AI recognition, IR temp, partial discharge), sending real-time data for hidden danger diagnosis—replacing manual checks.

1.12 Modulus Illuminationis

Dual-mode: LED channel lights embedded (for maintenance) + UPS-powered emergency lights (cross-installed, with warnings) for backup during outages, ensuring safe visibility.

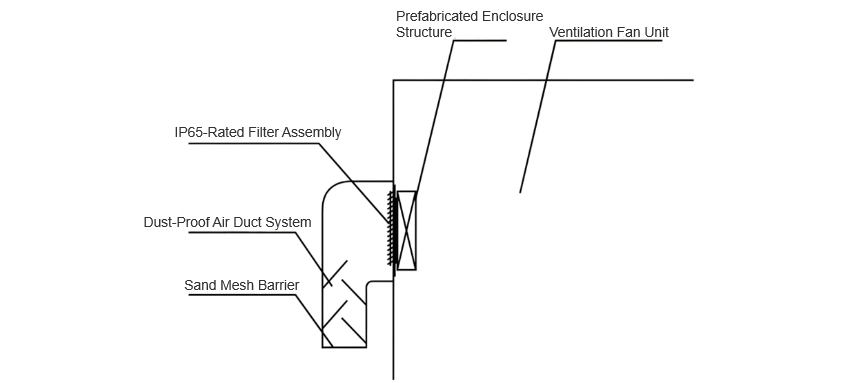

1.13 Inlets/Outlets Aerae

Inlets superiores + outlets inferiores formant convectionem. Trunk-shaped (Fig. 5) cum ventis externis versus inferius (prae-filtratis per sand nets), labyrinth ducts (to slow air, trap debris), and high-protection filters—balancing ventilation and dust control.

1.14 Design of Ring-Shaped Grounding Busbar

Ring-shaped grounding busbar, facta ex flat steel hot-dip galvanized, aperte ponitur secundum parietes cubiculi alta tensio. Connectit grounding principalium instrumentorum, protective grounding, et maintenance grounding, cum sufficientibus terminis manualis grounding ad satisfaciendum "quinque-preventionis" requirementibus et securando tuto maintenance grounding. Quattuor soft copper wires 引出 (led out) from the busbar pass through the cabin floor to form reliable connections with the main grounding grid, establishing a global grounding system.

2 Analysis of Key Technologies

Praefabricated cabin-type high-voltage rooms achieve rapid substation construction, environmental optimization, and safe operation through three core technologies, supporting stable 10kV switchgear operation:

2.1 Intensive Layout of Cable Layer

During civil construction, only the high-voltage room foundation and cable layer are built, with prefabricated cabins directly assembled above the cable layer upon arrival. Dedicated staircases (bilaterally configured with FRP rain shelters) are added, with drainage wells at the bottom connecting to sumps for stormwater discharge. This meets fire evacuation standards and facilitates operator access to the cable layer.

2.2 Factory Prefabrication and Assembly

Prefabricated cabin units are configured and pre-assembled in the factory based on electrical equipment requirements, then disassembled for on-site rapid assembly. Factory installation avoids on-site quality issues from environmental or personnel factors, enabling "cabin-cabinet integrated" delivery to reduce construction workload, adapt to complex terrains, and offer significant time and cost advantages.

2.3 Space-Optimized Double-Layer Structure

A prefabricated control room can be built above the high-voltage room. The double-layer design transforms selected switchgear positions into secondary cable shafts, allowing cables to pass through to the upper control room, improving space utilization and reducing cable length. Square steel tube vertical struts with diagonal braces enhance mechanical strength, supporting both the double layer and inspection robot tracks for space reuse.

3 Technical Advantages

3.1 Multi-Functional Module Integration

Integration of anti-small-animal, temperature-humidity control, and patrol robot modules endows the high-voltage room with dust-proofing, thermal insulation, environmental regulation, and equipment monitoring capabilities, creating an "intelligent carrier" for power equipment.

3.2 Full Lifecycle Environmental Assurance

Automatic temperature-humidity control and decentralized air conditioning maintain stable cabin conditions, improving equipment reliability and operation comfort while preventing insulation aging and short-circuit risks from high temperatures.

4 Application Case

Under China Southern Power Grid’s 2018 New Technology Pilot Application Plan, Zhongshan Power Supply Bureau applied prefabricated technology in the 110kV Tongfu Substation, completing construction (including civil works, installation, and commissioning) within 6 months—solving traditional schedule issues. Construction material costs decreased by 25%. The 10kV prefabricated high-voltage room features a reliable structure, rational equipment layout, and perfect environmental systems, achieving organic integration of electrical equipment and cabins for long-term stable operation.

Post-operation, reduced equipment hazards, optimized environment, and improved power supply reliability cut emergency repair costs, ensured 10kV feeder load supply, and delivered significant economic and social benefits.

5 Conclusion

Aiming at traditional reinforced concrete high-voltage rooms’ "long construction period, poor environment, and weak intelligent O&M", this paper proposes a prefabricated cabin-type solution: factory debugging of cabin and equipment, followed by on-site "building block" assembly after disassembly transport. The snap-fit insulated cabin, shaft cable layout, and multi-module integration enable efficient construction and environmental optimization.

This structure supports full lifecycle equipment safety, simplifies O&M, and offers broad promotion value, providing an innovative path for smart substation construction.