Inverter ad alta tensione sunt dispositiva critica pro regula celeritatis motorum AC et usitate late in industria tali ut levatio, metallurgia, petrolei, et generatio electricitatis. Tamen, inverter ad alta tensione de 6kV saepe experientur abnormes saltus driver durante operationem propter factores sicut fluctuationes rete et impingentes oneris, significative affectantes securitatem et fidabilitatem systematum regula celeritatis motorum.

Pro securando stabilitate operationis systematum VFD ad alta tensione, meliorando efficaciam industrialem, et reducendo consumtionem energiae, gubernium introduxit seriem politicas hortantes studium et applicationem technologiae inverter ad alta tensione. Itaque, analysis profunda causarum abnormium saltuum inverter ad alta tensione de 6kV et developmentum effectorum preventivorum sunt magna significantia pro promotione technologiae VFD ad alta tensione et sustentatione crescendi economici industrialis.

1 Summa de Inverter ad Alta Tensione de 6kV

Inverter ad alta tensione de 6kV est dispositivum potens electronica potestatis quod utitur IGBTs ut elementa commutationis et adoptat topologiam multilevel pro achievemento regula celeritatis variabilis ad 6kV et supra. Suas unitates potentiae saepe adoptant circuitos neutral-point-clamped (3L-NPC) tri-level vel active-neutral-point-clamped (5L-ANPC) quinque-level, constructos per cascading multiplices submodulos. Unusquisque submodulo continet 6-24 IGBTs et diodos freewheeling, generans waveform gradatim cum 9-17 level, quae approximat sinus wave post filtrandum.

Capacitas typica range ab 3000 ad 14,000 kVA, cum level voltage covering 6kV, 10kV, et 35kV. Pro majoribus capacitatibus et requisitis voltai, topologia modular multilevel converter (MMC) potest uti, ubi submoduli employ half-bridge vel full-bridge structuras, cum centenas submodulorum stackato per phase, permitting level voltage usque ad 220kV et capacitas singulorum unitatum usque ad 400 MVA, apta pro applicationibus sicut integratio rete energiarum renovabilium, venti marini, et transmission DC flexibilis. Strategia controlis inverter ad alta tensione est complexa, involvens technologias claves sicut modulatio carrier phase-shifted, current balancing, sensorless detection, et field-weakening optimization.

2 Abnormes Saltus Driver in Inverter ad Alta Tensione de 6kV

Durante operationem, inverter ad alta tensione de 6kV frequenter saltant propter abnormalitates sicut overcurrent, overvoltage, et overheating. Faults overcurrent saepe occurrunt durante startup vel mutationes oneris repentinas, ubi current instantaneus potest excedere 2-3 times valor nominale. Si current excedit 1600A ultra 100ms vel 2000A ultra 10ms, inverter immediate blockat IGBTs et disjungit contactor output, triggerando hardware protection saltu.

Faults overvoltage sunt usualiter causati a fluctuationibus rete vel mutationibus oneris abruptis. Quando DC bus voltage excedit 1.2 times valor nominale (1368V), software overvoltage protection activatur; si excedit 1.35 times (1026V), hardware protection directe saltat. Faults overheating communiter occurrunt in ambientibus altotemporalibus vel durante operationem overload prolongata. Quando temperatura IGBT excedit 90°C vel heatsink temperature excedit 70°C ultra 5 minutas, systema emittit warning high-temperature; saltus occurrunt directe si temperatures attingunt 100°C vel 80°C, respective. Characteristicum commune trium typorum faultorum est activationem mechanismi self-protection inverter, qui rapiditer cuttat output per blocking IGBTs et disjungendo contactors, resultante in phenomena sicut stoppage emergency motor et flashing fault alarms.

3 Preventive Measures

3.1 Current-Limiting Resistor

Pro addressando faults overcurrent, resistor current-limiting potest connectari in series inter output inverter et motor. Measurementes in campo demonstrant quod quando inverter 6kV/1500kVA initiat motor de 380kW vel maior, current instantaneus initiativus potest attingere 5-8 times valor nominale, longe excedens setting overcurrent protection.

Pro suppressione currentis initiativi, resistor wire-wound vel varistor non-linear zinc-oxide cum resistencia de 1-3Ω et potencia nominale de 200-500W potest uti. Hic latter habet resistencia cold-state supra 100Ω et rapidissime diminuit cum increase current, limitando peak current initiativus intra 2-3 times valor nominale. Post initiationem motor, quando frequency output inverter ascendit supra 40Hz et current descendit infra valor nominale, drop voltage trans resistor est minor quam 50V.

In hoc puncto, contactor bypass short-circuitat resistor pro avoidance continuationis power loss. Si current surge durante initiationem, quando current transformer detectat valorem excedentem 1200A, systema controlis emittit warning; si attingit 1500A, inverter immediate blockat IGBTs et aperit contactor bypass, reinserting resistor current-limiting pro rapid reductione current. Contactor bypass tunc reclosed pro restituendo operationem normal. Totus processus switching completatur infra 0.5s, effectivamente suppressans spikes current, securans smooth initiationem motor, et significative augmentans fidabilitatem inverter.

3.2 Voltage Clamping Circuit

Pro suppressione faults overvoltage, circuitus voltage clamping potest connectari in parallel ad DC bus. Hic circuitus principaliter constat ex metal oxide varistor (MOV), fast thyristor (GTO), et detection circuit. Data in campo demonstrant quod software overvoltage protection activatur quando fluctuationes rete excedunt 15% vel quando reductio oneris causa DC bus voltage excedere 1300V ultra 20ms.

Pro preventione talium faultorum, MOV TYN-20/141 potest uti, cum voltage triggering de 1420V, maximo discharge current de 20kA, et capacity absorptionis energiae de 8800J per unit. Quando bus voltage excedit 1350V, MOV coepit conductare et absorbere excessum energiae; si voltage ascendet ad 1400V, GTO triggerat, rapidissime divertendo energiam overvoltage in resistor pro restoratione voltage ad level securum. Detection circuit continuat monitorando bus voltage.

Quando voltage descendit infra 1250V et permanet ibi ultra 50ms, signal release mittitur, turn-off faciens GTO et restituens operationem systematis normal. Si bus voltage permanet supra 1400V ultra 100ms, severe fault overvoltage identificatur, et inverter intrat in status software lockout, requirens reset manual ante restart. Practica demonstrat quod cum hoc circuitus clamping, inverter 6kV potest tolerare 35% overvoltage instantaneum et suppressere overvoltage infra 1.05 times valor nominale infra 100ms. Responsum est rapidum et fidele, effectivamente preveniens frequentes saltus overvoltage et significative augmentans continuity et fidabilitatem systematis.

3.3 Current-Sharing Design

Pro addressando faults overheating, technologia current-sharing potest uti pro reductione generationis caloris in componentibus criticis sicut IGBTs et heatsinks, preveniendo thermal saltus.

Mensi specifici includunt connectionem 1-2 condensatores electrolytic in parallel inter terminales positivos et negativos DC bus uniuscuiusque unitatis potentiae. Condensatores debent habere capacitance de 1000-2200μF, rating voltage ≥1600V, et continuous ripple current ≥100A. Quando current output inverter excedit 1.2 times valor nominale (e.g., 900A), hi condensatores parallel potest providere 10%-20% current sharing capability, reducendo current actual per IGBTs ad 720-810A. Dato quod conduction losses IGBT sunt proportionales quadrato currentis, hic approach effective reducit rise temperature.

In formula: PCPC est conduction loss IGBT (W); VCEVCE est saturation voltage IGBT (V), quae habet relationem linearem cum currente ICIC (A); UηUη est turn-on voltage IGBT (V); KK est current amplification factor IGBT.

Potest videre quod post taking shunt measures, conduction loss IGBT potest reduceri 19% ad 36%, et chip junction temperature potest descensere 10°C ad 25°C, sic greatly alleviating heating problem inverter.

In addition, install 1 to 2 electric fans in parallel at the inlet and outlet of the inverter heat sink, with a rated air volume of ≥ 3000 m³/h, which can effectively enhance the cooling effect of the heat sink. Set up 6 to 8 temperature sensors inside the control cabinet to monitor the temperatures of various power units, Mother board, IGBT drive board, etc., in real time. When any point's temperature exceeds 65°C, the control system immediately starts the electric fan at full speed and sends a "load reduction warning" signal to the inverter control unit.

If the temperature continues to rise to 75°C and lasts for more than 10 minutes, the system issues an "over-temperature alarm" signal, limiting the maximum output current of the inverter to below 50% of the rated value until the temperature drops below 60°C, at which point the "over-temperature alarm" is lifted.

If any measurement point's temperature exceeds 85°C and the motor current does not drop below 30% of the rated value, the inverter immediately locks out hardware and stops output. To further improve the cooling effect, apply nanomaterials such as graphene or carbon nanotubes on the IGBT heat sinks of each power unit, utilizing their ultra-high thermal conductivity to accelerate the heat dissipation of the IGBT chips, thereby reducing the junction temperature.

4 Effectiveness of Preventive Measures

4.1 Experimental Design

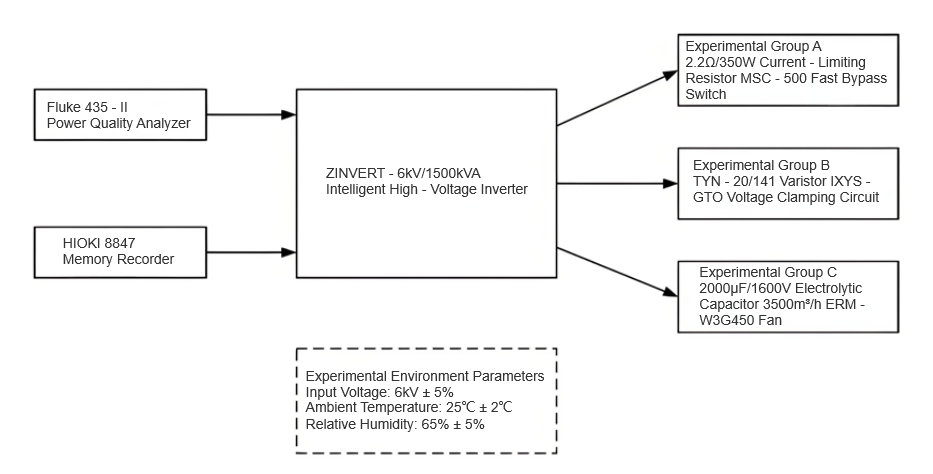

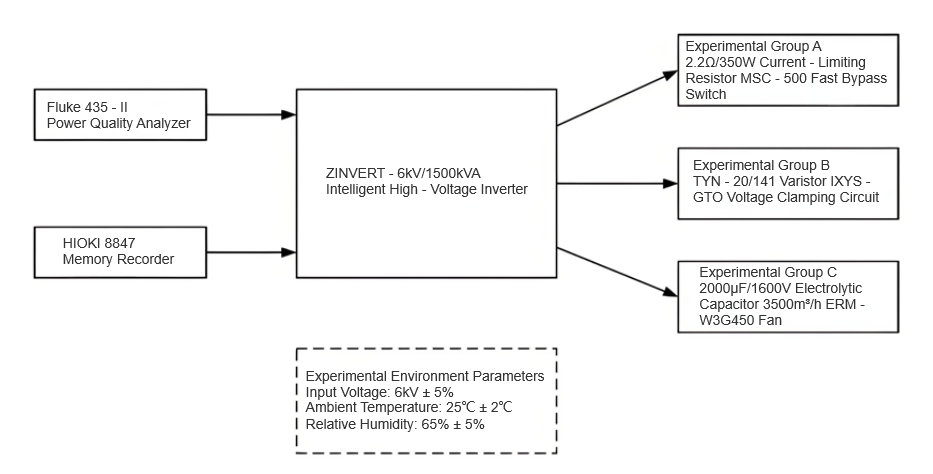

The ZINVERT-6kV/1500kVA intelligent high-voltage inverter was used as the test object, and a grouped control experiment was conducted to verify the effectiveness of the three proposed preventive measures. The experiments were carried out under rated operating conditions (input voltage: 6kV±5%; ambient temperature: 25°C±2°C; relative humidity: 65%±5%). The experiment was divided into four groups: the control group adopted no preventive measures; Group A employed a 2.2Ω/350W current-limiting resistor with an MSC-500 fast bypass switch; Group B used a voltage clamping circuit formed by a TYN-20/141 varistor and an IXYS-GTO connected in parallel, with the clamping voltage set at 1420V; Group C utilized a 2000μF/1600V electrolytic capacitor (Hitachi HCG series) connected in parallel for current sharing, combined with a 3500 m³/h variable-speed fan (EBM-W3G450) for forced cooling.

Each group operated continuously for 72 hours, with key parameters—such as inverter output current, DC bus voltage, and IGBT junction temperature—recorded every 6 hours. Data were collected using a Fluke 435-II power quality analyzer and an HIOKI 8847 data logger. During the experiment, three typical fault scenarios were simulated: inrush overcurrent (8 times rated current / 0.5s), grid voltage fluctuation (+20% / 1s), and full-load operation (ambient temperature 35°C / 2h). The experimental setup is shown in Figure 1.

4.2 Result Analysis

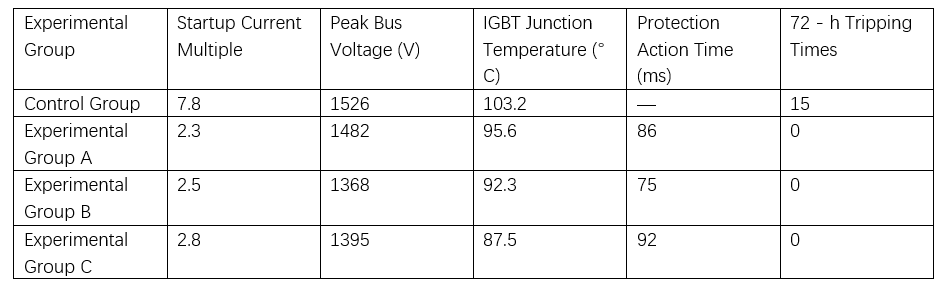

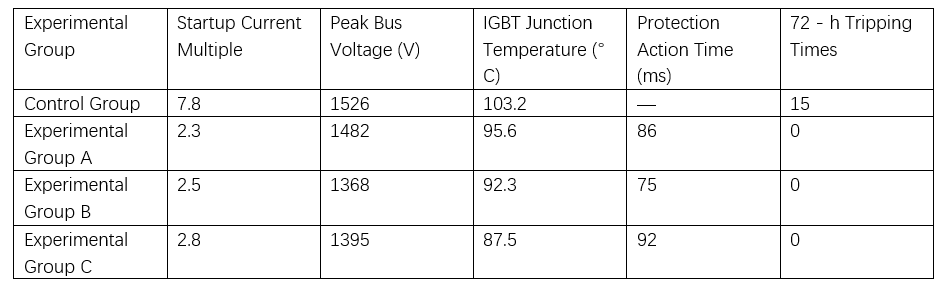

After 72 hours of continuous operation, data from the four groups were collected and analyzed, with results presented in Table 1. The control group experienced tripping under all three fault conditions, whereas the experimental groups with preventive measures demonstrated effective fault suppression. In Group A, the peak starting current was reduced from 7.8 to 2.2 times the rated value, effectively preventing overcurrent tripping.

In Group B, the voltage clamping circuit limited the maximum DC bus voltage fluctuation to 1368V, well below the 1420V protection threshold. In Group C, the combination of current sharing and forced cooling maintained the maximum IGBT junction temperature below 87.5°C, significantly lower than the 100°C tripping threshold. Furthermore, the response time of all three preventive measures was within 100ms, meeting the requirement for fast protection. No false triggering occurred during the experiment, indicating stable and reliable system performance.

5 Conclusion

This study systematically analyzed the causes of abnormal tripping in 6kV high-voltage inverters and proposed targeted preventive measures. Experimental results confirm that the current-limiting resistor effectively controls inrush current, the voltage clamping circuit significantly suppresses DC bus overvoltage, and the combination of current sharing with forced cooling greatly reduces the risk of IGBT overheating, thereby enhancing the overall reliability of the system.