Ut nucleum productionis industrialis, systemata automationis electrica directe influunt in summas costus productionis et impactum environmental. Operatio constans velocitatis saepe ad periculum energiae ducit quando variis demandatis onerum respondet et difficultatem accuratae controlis processus parit. Technologia regulationis velocitatis variabilis frequentia, ut methodus motorum controlis praestantior, solutionem promissam his quaestionibus offert. Haec studia exemplum systematis automationis electricae stationis electricitatis sumpserunt ut explorarent schemata renovationis fundata in technologia controlis velocitatis converteris et effectus eius conservativi, intendentes dare exemplum ad meliores efficiendi similibus scenariis industrialibus.

1 Status Praesens et Requirimenta Renovationis Applicationum Converterum in Automatione Electrica

1.1 Aparatus Existentes

Systema automationis electricae stationis electricitatis principiter ex tribus partibus constat: systema distributionis electricitatis, unitates motorum drive, et systema controlis. Systema distributionis electricitatis includit apparatum commutationis altae tensionis 10 kV, transformatores, et apparatum commutationis bassae tensionis 400 V, dispositum in structura arborea pro distributione electricitatis. Drives motorum sunt primarie motrices asynchronae controlatae per initiationem directam vel star-delta reductam. Onus maximus aequipamentorum in loco est pompis, quae pompas aquae circulantis, pompas refrigerationis, et pompas alimenti includunt. Haec opera constanter velocitate, cum fluxus per valvas regatur, resultante consumptione magna energiae. Structura systematis existentis est relativiter dispersa, cum administratione partiali centrali. Systema superior monitorandi communicat cum systematis controlis in agro via Ethernet industriali ad datarum display centrale et operationem remotam. Tamen systema controlis praesens algorithmos controlis praestantiores pro regulatione velocitatis variabilis frequentia desiderat, quod ad defectus in managemento energiae et optimisatione processus ducit.

1.2 Requirimenta Renovationis

Ex status aparatorum praesentium, requirimenta renovationis systematis automationis electricae principiter in melioratione efficientiae energiae et optimisatione controlis consistunt. Oportet introducere technologiam controlis velocitatis basata in converteribus ut pomparum et ventilatorum operationem efficacem per adjustmentem velocitatis motorum ad demandatas onerum permittat.

Simul, utentes stationibus pompis et facilitatibus productionis existentibus, necessitas urgens est ad platformam intelligentem monitorandi constructam, conformem requisitis protectionis cybersecurity nivellis duobus. Centrata in computatione nubis et integrata cum technologia IoT, haec platforma integrationem sine interruptione inter managementum enterprise et controlis in agro permittet. Structura systematis adoptat tricenstruturam "platforma centralis + subsystemata distributa + terminales mobilia," securitatem acquisitionis datarum real-time, processingus efficientem, et storageum securum assecurans.

Platforma centralis, constructa super cluster serverorum praestantium, deployat algorithmos analysis datarum praestantes ad supportum decisionum accuratum praebendum. Subsystemata distributa includunt modulos pro monitoring conditionis aequipamentorum, surveillance video, et collectionem parametrorum ambientalium, omnia aspecta operationum productionis comprehensive operientes. Terminales mobilia, per applicationes customizatas, remota monitoringem et notificationes instantaneas permittunt.

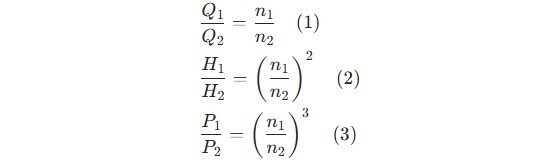

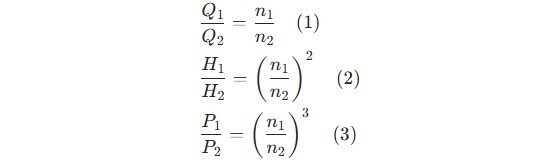

2 Basis Theoretica Effectuum Conservativorum

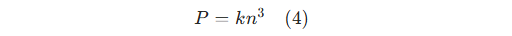

Analysis effectuum conservativorum technologiae controlis velocitatis variabilis frequentia in hac studia principaliter fundatur in legibus affinitatis pro ventilatoribus et pompis et principiis conversionis energiae regulationis velocitatis variabilis frequentia. Ex status operativo aequipamentorum stationis, magnus numerus pompis et ventilatorum operatur constanter velocitate, cum fluxus per valvas regatur, resultante perditis significantibus energiae. Contrario, controlis velocitatis variabilis frequentia adjustat velocitatem motoris ad demandatas onerum, sic conservationem energiae assequens. Leges affinitatis pro ventilatoribus et pompis constituuntur ex relationibus inter fluxum, caput, et potentiam, cum formulis calculationis relevantibus sequentibus:

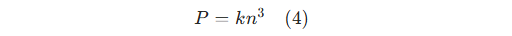

ubi QQ est fluxus (m³/h); nn est velocitas rotationis (r/min); HH est caput (m); PP est potentia (kW), cum P1P1 repraesentet potentiam nominalem et P2P2 potentiam ad velocitate reducta. Formula conversionis energiae pro regulatione velocitatis variabilis frequentia est:

Ex supradictis relationibus theoreticis, quando demanda fluxus systematis decrescit, motor automaticus reducit velocitatem per controlum frequentiae, significanter consumtionem potentiæ minuens et conservationem energiae assequens. Hoc fundamentum theoreticum pro subsequenti designo renovationis et evaluatione conservationis praebet.

3 Schemata Renovationis Technologiae Controlis Velocitatis Variabilis Frequentia

3.1 Upgrade Systematis Distributionis Electricitatis

Ad technologiam controlis velocitatis variabilis frequentia effective implementandam, hoc studium systema distributionis electricitatis existens upgradavit. Pro systemate altae tensionis, apparatum commutationis 10 kV per installationem circuit-breakers vacuum intelligentium cum corrente nominali non minus quam 1,250 A et capacitate rumpendi circuiti short-circuit nominale 31.5 kA potentiavit. Relays protectionis microprocessor-based integrata sunt, protectionem multifunctionem includentia overcurrent, short-circuit, et ground fault, cum tempore responsus sub 20 ms. Systema monitoring qualitatis electricitatis introductum est, sensorem high-precision gradus A usum ad parametras tali modo harmonicos, fluctuationes tensionis, et unbalance triphasica in real-time monitorandum, stabilitatem systematis securans.

Pro systemate bassae tensionis, systema 400 V fuit focus upgradendi. Circuits feeder converterorum dedicati ad systema existens additi sunt, usus cabinetis feeder independentibus equipped with intelligent molded-case circuit breakers. Correntia nominalis electa est inter 400 A et 630 A secundum requirementa oneris, feature electronic trip units for precise overload and short-circuit protection. Unusquisque circuitus converteris est equipatus interruptor switch matching the circuit breaker's rated current and includes a visible break feature to facilitate equipment maintenance.

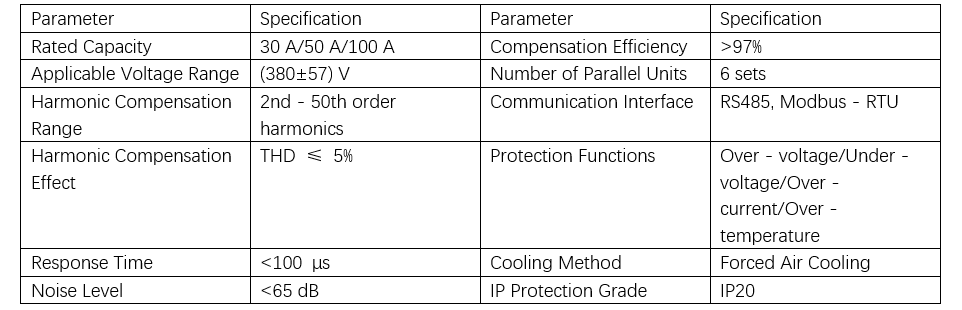

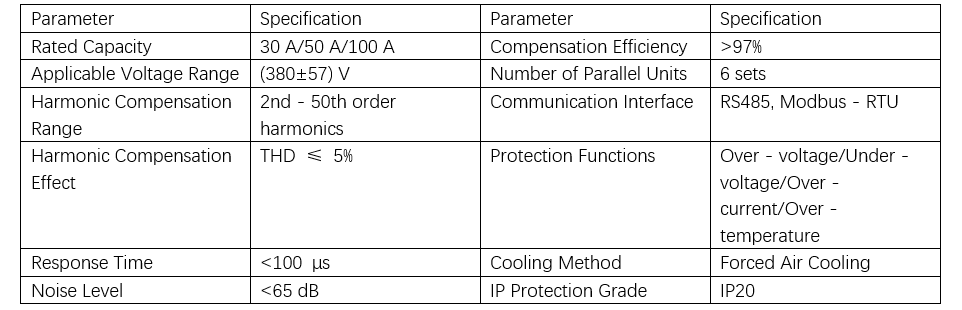

Pro mitigatione harmonicorum, active power filters (APF) installantur at input side of the inverter, with specific specifications as listed in Table 1.

Pro optimisatione systematis grounding, hoc studium methodum wiring TN-S adoptavit, separating the neutral line (N) from the protective earth line (PE) starting from the distribution cabinet. Main PE line uses copper conductors with a cross-sectional area of no less than 95 mm² to ensure a ground resistance of less than 1 Ω. Equal potential bonding bars were added at critical equipment locations such as inverters and motors, using copper conductors with a cross-sectional area greater than 16 mm². This effectively suppresses common-mode interference and enhances the system's EMC performance [21].

3.2 Selectio et Optimitatio Parametrorum Aparatorum Converterorum

Selectio converterum fundatur in accurate conformatione characteristicarum oneris et requirementorum processus. Pro oneribus pompae, vector control inverters eliguntur, cuius potentia nominalis strictim correspondit motori, et capacity overload 150%/1 min. Hoc studium series inverter ABB ACS880 elegit, qui DTC (Direct Torque Control) technology features, with a torque response time of less than 5 ms and speed control accuracy of ±0.01%. Considering the on-site environment, a sealed inverter with an IP54 protection rating was used, equipped with a forced air cooling system, ensuring a cooling airflow of no less than 1 m³/(min·kW).

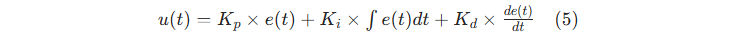

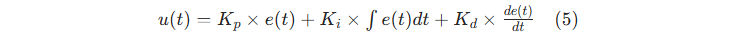

For parameter optimization, the focus is on adjusting the PID control parameters and utilizing the self-tuning algorithm built into the inverter. Through step response testing, the optimal proportional gain KpKp, integral gain KiKi, and derivative gain KdKd are automatically calculated. The calculation formula for the PID controller output u(t)u(t) is:

The built-in auto-tuning algorithm of the inverter is used to automatically calculate the optimal proportional gain KpKp (range: 0.1–100), integral time TiTi (range: 0.1–3600 s), and derivative time TdTd (range: 0–10 s) through a step response test. Acceleration time is set to 10–30 s and deceleration time to 15–45 s to effectively prevent water hammer effects. Torque limiting is enabled with a setting of 120% of the motor's rated torque to prevent overload. For fan loads, the inverter's energy-saving mode is activated: under light-load conditions (load rate < 50%), the output voltage is automatically reduced, with a maximum reduction of up to 20%. Meanwhile, the V/F curve is optimized by increasing the voltage output in the low-speed range (0–10 Hz) to ensure sufficient starting torque.

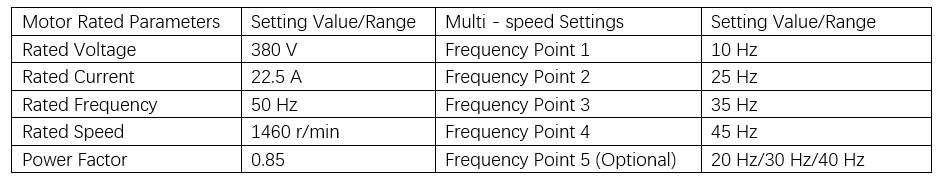

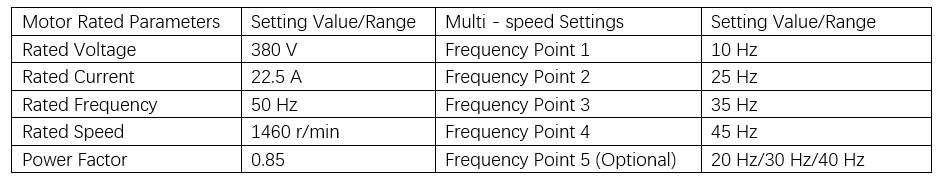

A sleep-wake function is configured: when the operating frequency remains below 10 Hz for 60 s, the inverter enters sleep mode; it automatically wakes up when the system pressure drops by 5%, further improving system efficiency. In the basic inverter settings, the carrier frequency is set to 4 kHz. Based on the actual requirements of the power plant, the overvoltage and undervoltage protection thresholds are set to 418 V and 304 V, respectively. Additionally, the motor's rated parameters and multi-speed operation settings are configured as detailed in Table 2.

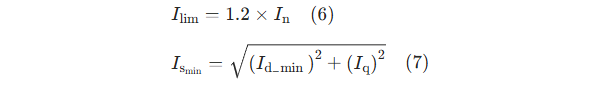

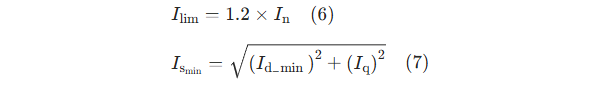

The calculation formulas for current limitation and minimum current optimization are respectively as follows:

where IlimIlim is the maximum current limit; InIn is the motor rated current; IsminIsmin is the minimum stator current; IdoptIdopt is the optimal excitation current; and IqIq is the torque current component. By incorporating current limiting and minimum current optimization strategies, fine-grained control of motor operation is achieved. Overvoltage and undervoltage protection settings ensure the motor operates within a safe range. Stall protection and current limiting measures effectively prevent overload. Additionally, this control method supports communication via the Modbus-RTU protocol, enabling remote monitoring and parameter adjustment, thereby significantly enhancing the system's intelligence level.

3.3 Upgrade et Integratio Systematis Controlis

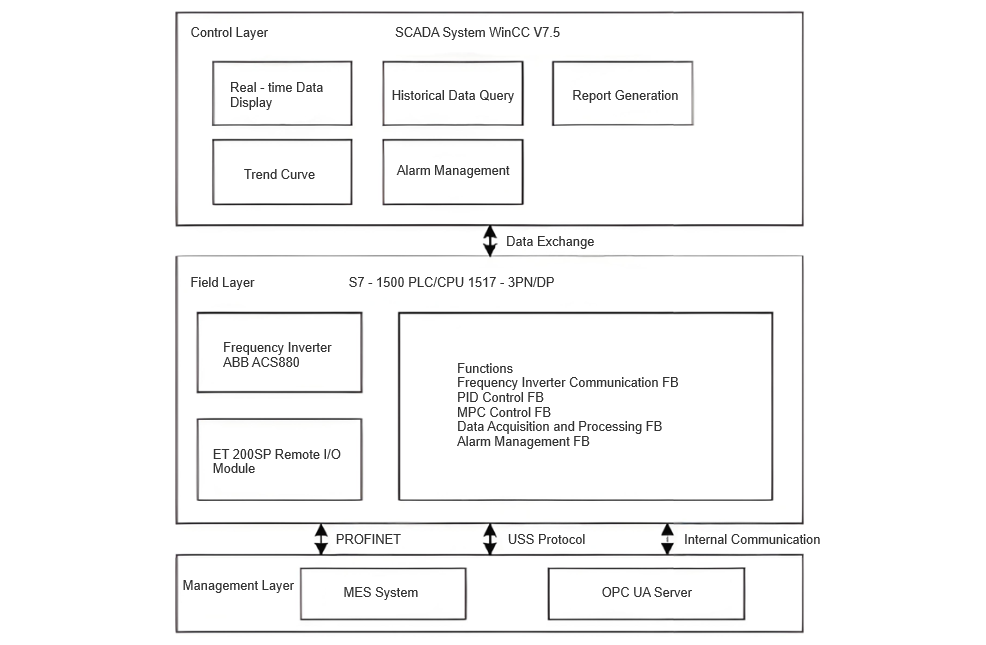

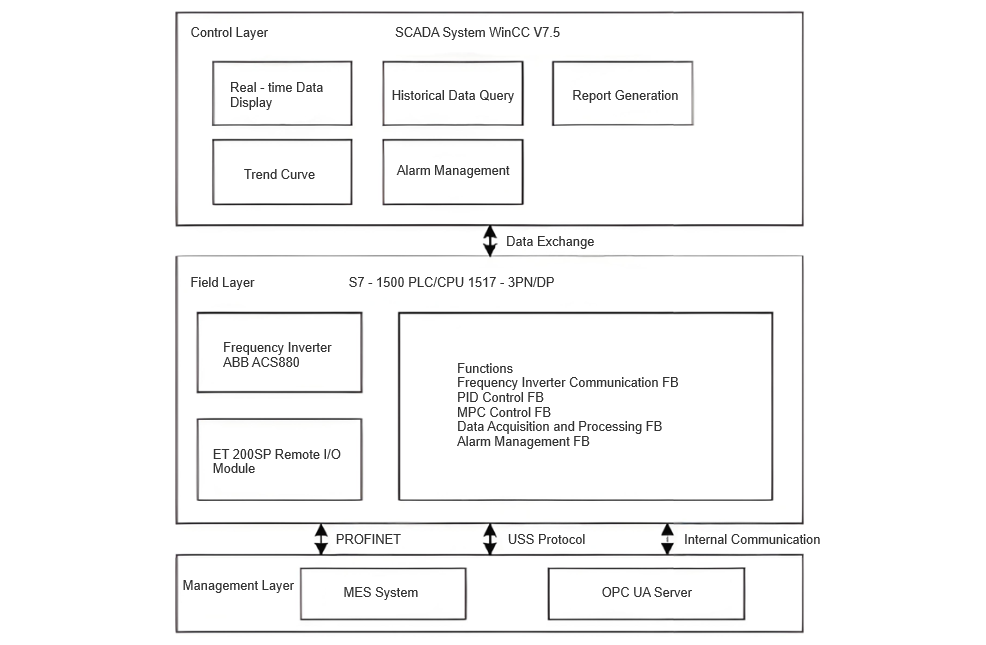

Upgrade systematis controlis employt Siemens S7-1500 series PLC, specifically the CPU 1517-3 PN/DP model, which features a 2 ns bit operation speed and a 40 ns word operation speed. The PLC is equipped with 1.6 GB of working memory and 32 MB of load memory, supporting communication protocols including PROFINET, PROFIBUS, and OPC UA. The system adopts a distributed architecture with ET 200SP series remote I/O modules, achieving a 250 μs communication cycle via PROFINET.

The software architecture is based on the TIA Portal V16 integrated development environment. The PLC program includes function blocks (FBs) for inverter communication, PID control, Model Predictive Control (MPC), data acquisition preprocessing, and alarm management. The detailed system framework is illustrated in Figure 1.

4 Analysis Effectuum Conservationis Energiae

The energy-saving benefits of inverter speed control technology are primarily reflected in reduced power consumption and improved system efficiency. By comparing energy consumption data before and after the retrofit, the energy-saving performance can be quantitatively evaluated. The post-retrofit system data in this study were collected using the following methods:

Energy Metering System: Smart meters were installed on the power supply lines of major electrical equipment to collect electricity consumption data before and after the retrofit. The meter model is Schneider PM5560, with an accuracy class of 0.2S and a sampling interval of 15 minutes.

Inverter Built-in Functions: The built-in energy monitoring function of the ABB ACS880 inverter was used to record operating time, output power, and energy consumption. Data were transmitted to the central control room via the Modbus-RTU protocol.

SCADA System: A real-time data acquisition and storage system was built using the Siemens WinCC V7.5 platform. Key parameters such as motor speed, load rate, output voltage/current, and power factor were monitored with a 1-second sampling cycle.

On-site Testing: The Fluke 435 II power quality analyzer was used to conduct spot measurements under various load conditions, capturing instantaneous power, harmonics, and power factor data.

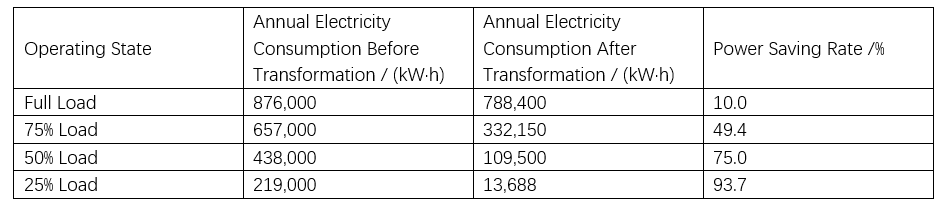

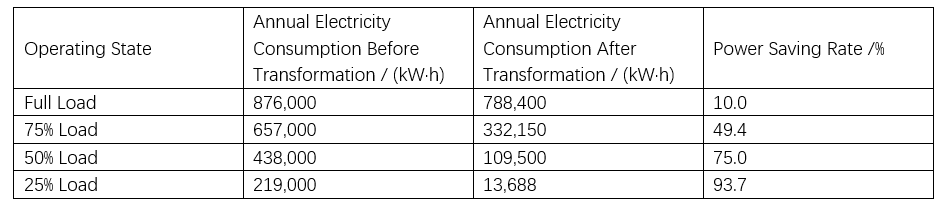

Based on the measured data, the annual average load rate was calculated. By comparing energy consumption before and after the retrofit, the power-saving rates under different load conditions were determined, as shown in Table 3.

The results show that the energy-saving effect gradually increases as the load rate decreases, which aligns with the cubic law principle of energy saving in variable frequency speed control. Under full-load operation, the power-saving rate is 10%, primarily attributed to the high efficiency and precise control capability of the inverter, indicating that even under high-load conditions, frequency control technology still offers significant energy-saving potential.

At a 75% load rate, the power-saving rate increases to 49.4%, highlighting the advantages of variable speed control under partial load. When operating at 50% load, the power-saving rate reaches 75%, demonstrating its excellent performance under medium load. At 25% load, the power-saving rate reaches as high as 93.7%, fully showcasing the substantial energy-saving potential of variable speed control under low-load conditions.

Overall, the annual average power-saving rate is 56.8%, indicating that the optimized system achieves good comprehensive energy-saving performance during actual operation cycles. Considering the time distribution across different load states, these results provide valuable guidance for energy efficiency optimization in industrial electrical automation systems.

For fan loads, the inverter’s built-in energy optimization function automatically adjusts the V/F curve under light-load conditions. Measurements using the Fluke 435 II power quality analyzer at various load rates reveal the relationship between voltage reduction and power consumption reduction.

Results show that in the load rate ranges of 20%–30%, 30%–40%, and 40%–50%, power consumption reductions are 36.7%, 25.3%, and 15.8%, respectively. This indicates that the lower the load rate, the greater the proportional reduction in power consumption achieved by the same degree of voltage adjustment. For ultra-light-load conditions below 20%, more aggressive control strategies or equipment shutdown should be considered to further improve overall system efficiency.

5 Conclusion

This study, through the retrofitting practice of an electrical automation system in a power plant, verifies the significant energy-saving effectiveness of variable frequency speed control technology. By optimizing control strategies and system integration, substantial reductions in power consumption and improvements in operational efficiency are achieved. The findings provide a technical reference for energy-saving retrofits in similar industrial scenarios. Future work will