Kama mtaalamu ambaye amejikita katika uhusiano wa ufundi wa mifumo ya umeme kwa miaka mingi, nimekuwa na maoni yangu kwa mara kwa mara kuhusu ukuaji wa teknolojia na utaratibu wa matumizi ya vifaa vya utambuzi wa mzunguko wa umeme. Kama kifaa cha umeme chenye muhimu katika hatua ya pili ya utambuzi wa mifumo ya umeme, ukubwa na ufanisi wa vifaa hivi huwasiliana moja kwa moja na uendeshaji wa kiwango cha ustawi na usalama wa mtandao wa umeme. Hapa ni tathmini kamili ya mipangilio muhimu ya unda wa vifaa vya utambuzi wa mzunguko, ikipunguza viwango vya sekta na mapendekezo ya uhandisi.

1. Mbinu ya Unda Kamili na Mpango wa Mfumo

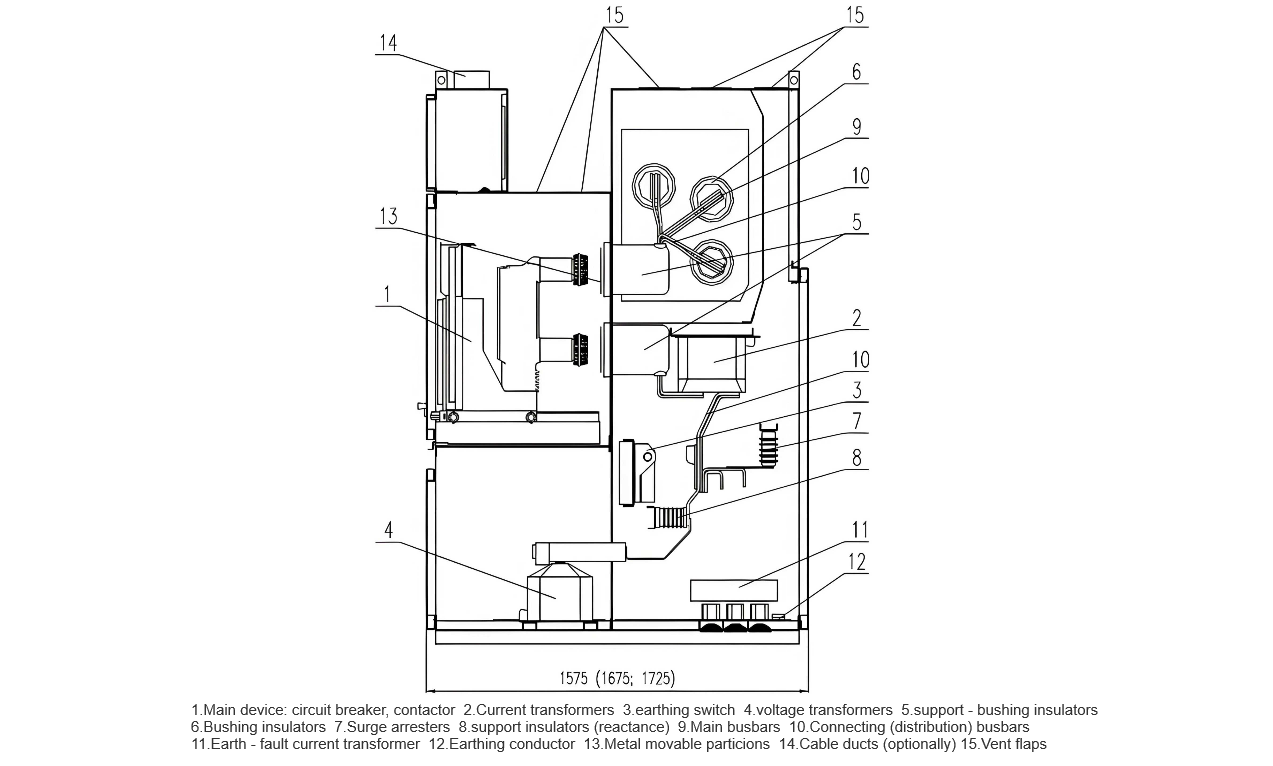

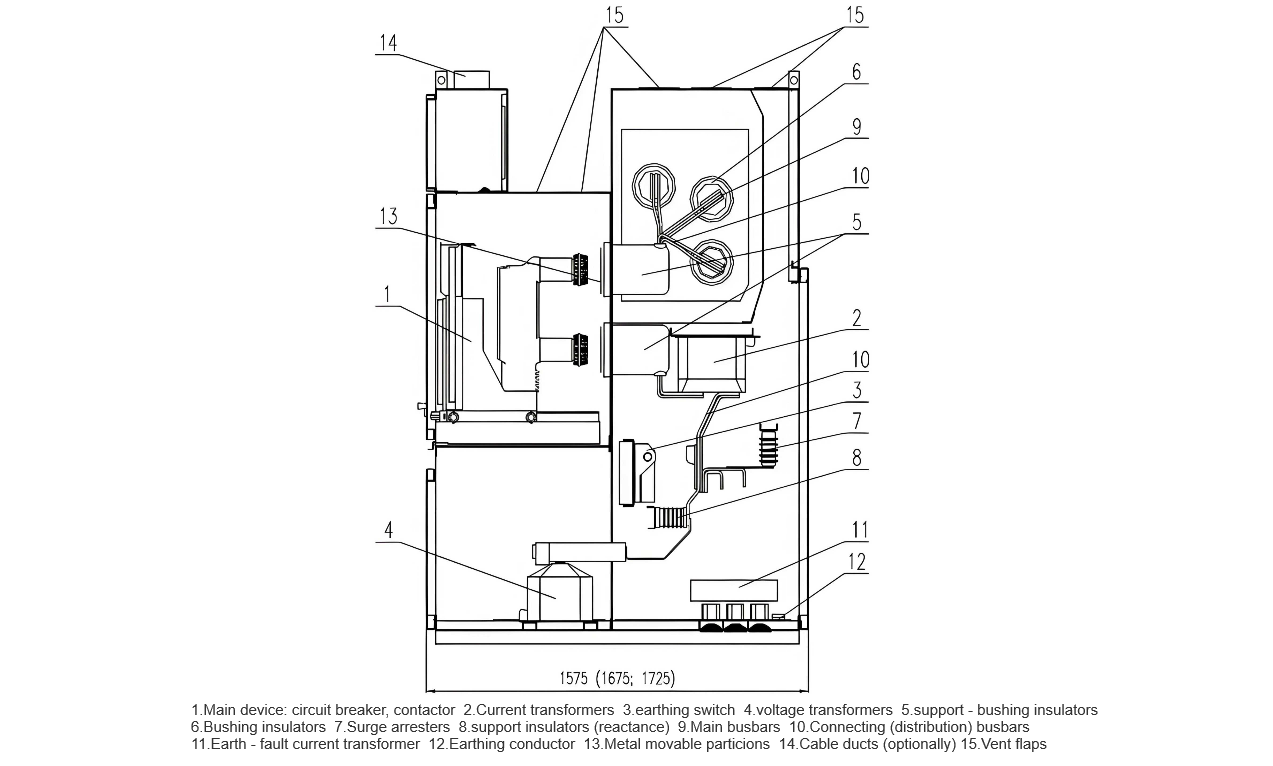

Unda wa switchgear za utambuzi wa mzunguko lazima ufanyike kwa kutosha kufanana na mahitaji ya uendeshaji wa mifumo ya umeme na viwango vya taifa. Inapaswa kuweka wazo zaidi kwenye mazingira ya kutumia, vigezo vinavyotumika, na sifa za vifaa vya umeme vya msingi ili kukusanya mfumo wa vipengele vya faida. Vipengele vya msingi vilivyotumika ni circuit breakers na load switches, na vifaa vingine vya kuzuia kidogo vina tumia vifaa vya umeme vilivyokumbuka. Wakati wa kunda, unaweza kupanga awali “load switch + fuse” circuit imara—mfumo huu una muundo mgumu na unaweza kutumika kama chanzo cha uhakiki wa muundo, mpangilio, na uzito wa nje wa vifaa. Miundombinu mingine, kama vile circuits zenye tu load switch, yanapaswa kutumia unda wake uliyofanikiwa kwa kutosha ili kufikia kimataifa na kwa kila mtu.

Kulingana na misingi hayo, vyumba vingine vingine vyanaweza kupatikana: vyumba vya load switch, vyumba vya vifaa vya umeme vilivyokumbuka, vyumba vya circuit breaker, vyumba vya mikabilio mingi, na kadhalika. Unda wa primary conductive circuit unahitaji kujadili kwa kutosha tatu ya vipengele muhimu: uwezo wa kutumia current, uwezo wa kutegemea na nguvu ya umeme, na ufanisi wa kutengeneza moto:

Ukubwa wa Vipengele: Tumia nguvu ya umeme kwa ufanisi ili kutahidi kwamba contacts zinazozotea hazitoshi kwenye majaribio ya thermal na dynamic stability, kufanya kazi ya mekaniko na ya umeme.

Chaguo la Busbar: Chagua busbar za duara au busbar za mche kwa kutosha kulingana na uwezo wa kutumia current, kudhibiti vizuri density ya current, na kuafanulia balansia kati ya kutumia current na kutengeneza moto.

Imara ya Uhusiano wa Umeme: Contacts zinazozotea na zinazopimika, connections zinazozotea na zinazopimika lazima ziwe na resistance ya chini. Wakati wa kununganisha conductors tofauti za metal, tumia utaratibu wa tinning na silver plating ili kupiga vita dhidi ya corrosion ya electrochemical na kuingiza hasara ya contact.

Unda wa compartments unafuata sera ya “safety first, process adaptation, and convenient operation and maintenance”: protection level si chini ya IP3X, chaguo la material (metal/non-metal) linachaguliwa kulingana na hitaji, na devices za pressure relief na measures za limiting fault arc zimeganishwa—kwenye faults za internal arc, gas ya pressure inayokuwa juu inaweza kutoka kwenye chanel ya relief ili kuhakikisha safety ya vifaa na watu.

2. Matumizi Ya Nguvu Kubwa Kwa Unda Wa Mfano Wa Insulation

Switchgear inahitaji kutegemea na maximum operating voltage na overvoltage ya fupi (atmospheric and internal overvoltage) kwa muda mrefu. Unda wa insulation unahitaji kujadili kwa kutosha masuala kama environmental adaptability, chaguo la materials, structure optimization, na process control:

(1) Electric Field Optimization and Insulation Coordination

Muundo wa conductors unawezekana kubadilisha electric field distribution ndani ya cabinet. Katika unda, itumie rounded copper bars, round bar busbars, na iweze kuboresha shapes ya dynamic and static contact seats, internal conductors, na support electrodes ili kugawa points na edges, kufanya electric field iwe uniform zaidi. Kwa kutumia software ya finite element analysis (kama ANSYS Maxwell), weak insulation links zinaweza kupewa maeneo safi. Kwa kutumia layout adjustment na structure optimization (kama application of shielding technology), electric field inaweza kuwa uniform na kureduce maximum field strength, kuboresha reliability ya insulation.

(2) Application Logic of Multiple Insulation Media

Air Insulation: Kwa composite insulation ambayo air ni muundo mkuu, electrical clearance na creepage distance iliyotakikana kwa viwango vinapaswa kutumika kwa kutosha katika unda ili kubalansia performance ya insulation na compactness ya vifaa.

Gas Insulation: Gas-insulated cabinets zinatumia SF₆, N₂, dry compressed air, au mixed gases kama media za insulation (katika low-pressure range). Ingawa pressure ya gas si kubwa, sealing design ni muhimu—nitumaini kwa component changes za gas kwa sababu ya permeation wakati wa operation mrefu (kama air infiltration na exudation ya insulation gas). Kwa compartments za gas-filled ambazo hazina arc decomposition products, moisture content inapaswa ikubalishwa kwa kutosha: wakati rated pressure ≤ 0.05MPa, itakuwa ≤ 2000μL/L; wakati > 0.05MPa, allowable value ya moisture content inapatikana kwa kutumia saturated water vapor pressure kwenye -10°C.

Interface and Solid Insulation: Waktu solid insulation parts zinapunguza, elastic materials kama silicone rubber zinatumika kugawa air gaps na kuboresha interface insulation level (related to surface pressure, finish, na contact length). Kutumia materials kama epoxy resin na silicone rubber kutengeneza na vulcanize na kupack high-voltage components, na kuyajaza na grounding/semiconductive layer, inaweza kuboresha safety level, reduce equipment volume, na kurahisisha layout.

3. Precise Design of Mechanical Transmission and Interlocking System

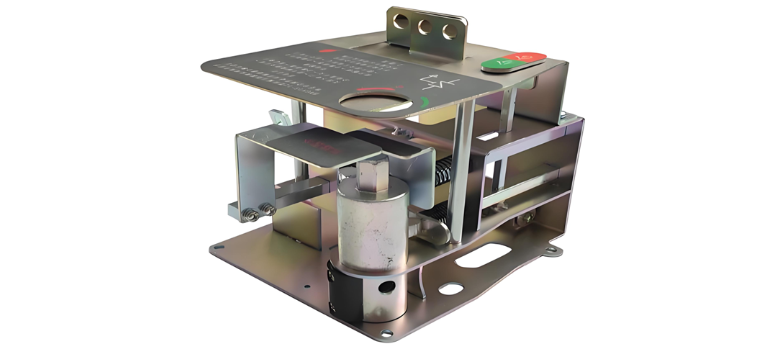

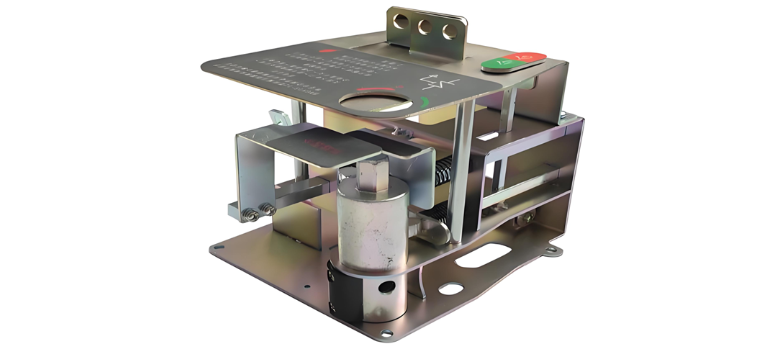

Mechanical transmission hukusanya vitendo kama circuit breaker operating mechanisms, disconnectors, earthing switches, na door interlocks. Unda unahitaji kutengeneza kwa kutosha dimensions kama principle, layout, force mode (pressure/tension), span, transmission ratio, stroke angle, na mechanical efficiency: simplify structure, reduce number of parts, na lower the operating force, kupata “reasonable force bearing, reliable transmission, stable operation, and convenient operation and maintenance”.

“Five-prevention” interlocking ni muhimu wa kuhakikisha safety ya operation—mechanical interlocking ni preffered (composed of levers, connecting rods, baffles, etc. to form a lock, with clear procedures, intuitive and reliable); if the components are far apart or mechanical interlocking is difficult to implement, electrical interlocking is supplemented; intelligent cabinets can be superimposed with microcomputer software programming interlocking (used in conjunction with mechanical interlocking) to build a multi-level safety protection system.

4. Construction of a Reliable Earthing System

Earthing design huna hitaji kufanana na dual requirements za “operation safety” na “fault withstand”:

Wakati wa kuhakikisha, earthing switch inaweza kuhakikisha earthing ya main circuit kwa kutumia regulations.

Frame cha chini cha shell chenye earthing conductors na terminals zinazofaa kwa conditions za fault, na cabinets zinazohusiana kwa conductors, na circuit special kati ya earthing switch na earthing conductor.

Earthing conductors, connection circuits, na connections kati ya cabinets zinapaswa kutegemea na rated short-time/peak withstand current.

Frame, cover plate, door, partition, na components zingine zinapaswa kuwa electrically continuous ili kuhakikisha earthing connection ya functional units.

DC voltage drop kutoka chochote point ya shell metal parts hadi earthing conductor kupitia 30A ni ≤ 3V, kuhakikisha effectiveness ya earthing.

5. Technological Evolution and Development Direction

Kwa mchakato wa power grid transformation na cable undergrounding, multi-circuit distribution units zinajitengeneza haraka kuelekea “miniaturization, modularization, and automation”, ambayo huchukua innovative development ya SF₆ na composite insulation technologies na high-performance components. Siku za baadaye, ni lazima kusikitisha upgrades za manufacturing processes (kama precision processing na integrated packaging), optimization ya cable connectors, iteration ya current-limiting fuses, research and development ya small operating mechanisms, na innovation ya auxiliary components, ili kuboresha design na manufacturing level ya domestic ring main distribution equipment. Kuanzisha generation mpya ya ring main cabinets na “full working condition adaptation, maintenance-free, high reliability, and miniaturization” ili kusaidia distribution automation itakuwa direction muhimu kwa industry breakthroughs.