Bê hemî salên di navçeyê de ji bo xebitina cihazên taybetî yên daxuyaniya nîvendî, hêman bêtir li ser çavkaniya teknolojî û zanînên amûrkarî ya cihazên dastrîna rastînî yên pargînî. Cihazê wê ye ku ji bo anjîma elektrîkî ya yekemîn daxuyaniya nîvendîyê ya sisteman ên parzûndiyê ve tiştîne û performansa wê ya direkta li ser berdest û stabîl bikekirina rêzanîna şarafê. Jiyan derve heye nirxandina taybetî yên sereke yên cihazên dastrîna rastînî, bi destpêka standartên çarza û amûrkarên inženîrî.

1. Logika Girîng û Plankirina Arkitektur

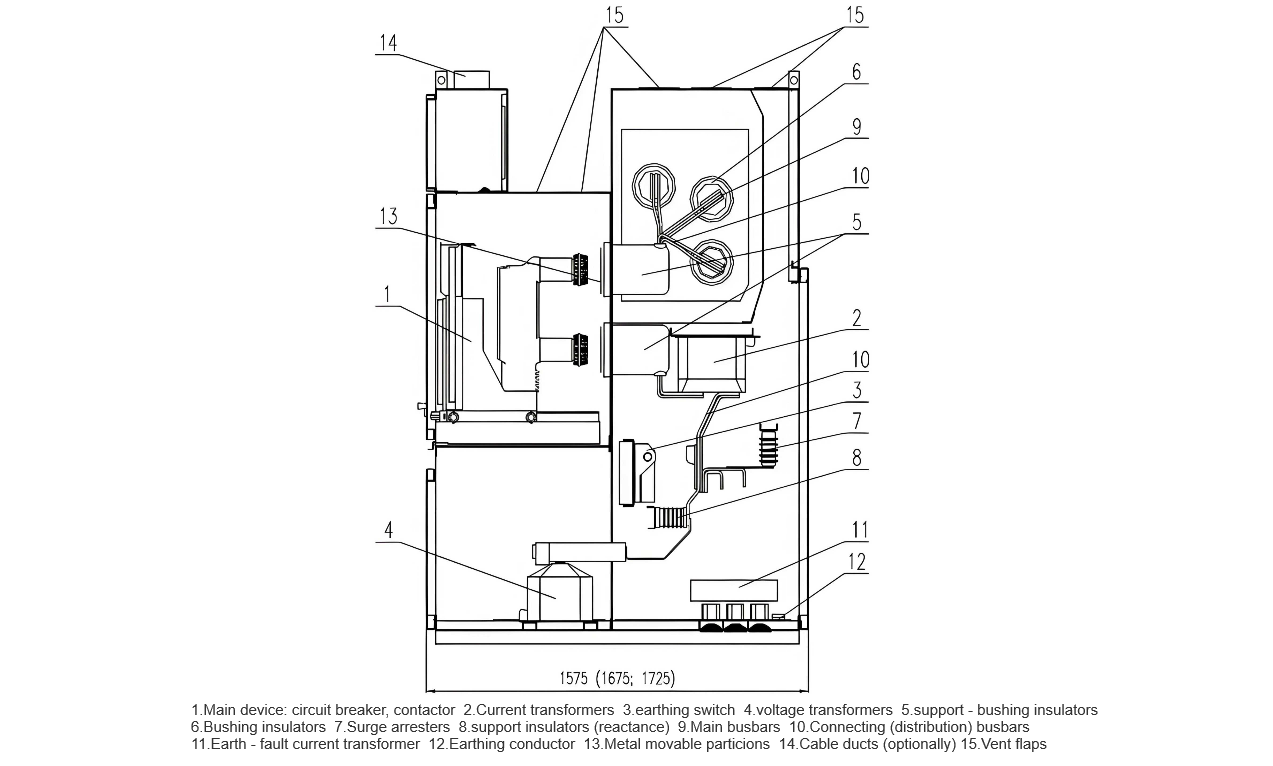

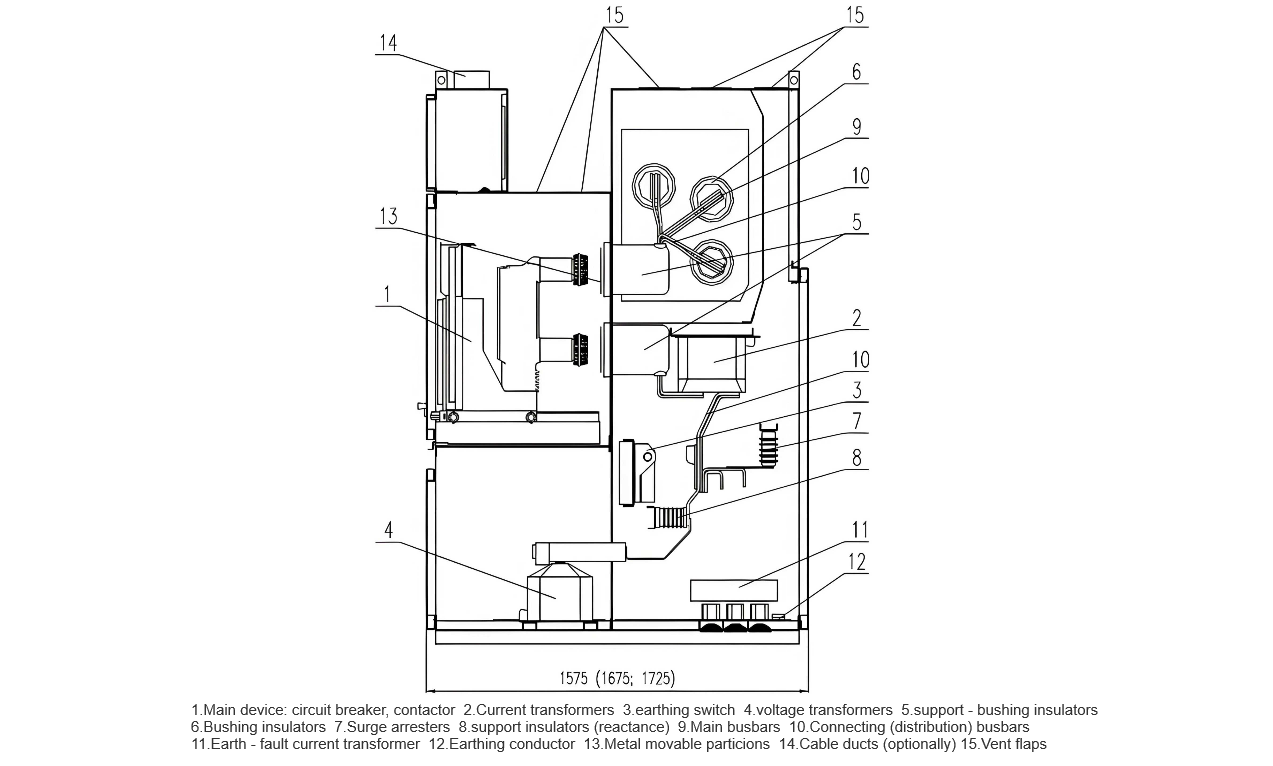

Xebitina cihazên dastrîna rastînî yên daxuyaniya nîvendî divê be girtin bi vêşangên operasyonê ya sisteman ên parzûndiyê û standartên nasional. Divê li ser senaryoyên bikaranîn, objektên kontrol û taybetî yên komponentên elektrîkîya nîvendî bixebite birîkarî û sistemên unit. Serbîçavan switchên serekan bi circuit breakers û load switches hatine tayin kirin, û qesetek bi combined electrical appliances. Li ser xebitina, priority di hate jî "load switch + fuse" combined circuit - ev cihaz struktûra rastînî ye û divê wek model bi kar bibe ji bo bêtirîna strukturê, layout, û dimensiyonên derveya cihazan. Heke circuits din, wekî pure load switch circuits, divê designê ya paşîn bi kar bibe ji bo bêtirîna standardizasyon û universalizm.

Li ser binaveya vê, çend tipda cabinet hatine çêkirin: load switch cabinets, combined electrical appliance cabinets, circuit breaker cabinets, multi-circuit cabinets, etc. Xebitina primary conductive circuit hewce ye systematic bi tekmil bi tîn elemendant sereke: current-carrying capacity, electric force withstand capability, û heat dissipation efficiency:

Arrangement of Components: Skillfully utilize the closing electric force to ensure that the moving contacts do not withdraw during the dynamic and thermal stability tests, achieving the coordination of mechanical and electrical performance.

Selection of Busbars: Precisely match circular or flat busbars according to the current-carrying capacity, reasonably control the current density, and balance current-carrying and heat dissipation.

Optimization of Electrical Connections: The dynamic and static contacts, sliding/fixed connections must ensure low contact resistance. When connecting different metal conductors, processes such as tinning and silver plating are used to suppress electrochemical corrosion and eliminate the hidden danger of contact failure.

Xebitina compartments li ser principle ya "safety first, process adaptation, and convenient operation and maintenance": protection level is not lower than IP3X, the partition material (metal/non-metal) is selected as needed, and pressure relief devices and fault arc limiting measures are configured—during internal arc faults, high-pressure gas can be discharged through the relief channel to ensure the safety of equipment and personnel.

2. Multi-dimensional Considerations for Insulation Structure Design

Switchgear needs to withstand the maximum operating voltage and short-term overvoltage (atmospheric and internal overvoltage) for a long time. The insulation design needs to comprehensively consider factors such as environmental adaptability, material selection, structure optimization, and process control:

(1) Electric Field Optimization and Insulation Coordination

The shape of conductors directly affects the electric field distribution inside the cabinet. In the design, rounded copper bars, round bar busbars should be used, and the shapes of dynamic and static contact seats, internal conductors, and support electrodes should be optimized to eliminate sharp points and edges, making the electric field more uniform. With the help of finite element analysis software (such as ANSYS Maxwell), the weak insulation links can be accurately located. Through layout adjustment and structure optimization (such as the application of shielding technology), the electric field can be uniformized and the maximum field strength can be reduced, improving insulation reliability.

(2) Application Logic of Multiple Insulation Media

Air Insulation: For composite insulation with air as the main body, the electrical clearance and creepage distance specified by the standards must be strictly followed in the design to balance insulation performance and equipment compactness.

Gas Insulation: Gas-insulated cabinets mostly use SF₆, N₂, dry compressed air, or mixed gases as insulation media (in the low-pressure range). Although the gas pressure is not high, the sealing design is crucial—attention must be paid to the component changes of the gas due to permeation during long-term operation (such as air infiltration and insulation gas exudation). For gas-filled compartments without arc decomposition products, the moisture content must be precisely controlled: when the rated pressure ≤ 0.05MPa, it should be ≤ 2000μL/L; when > 0.05MPa, the allowable value of moisture content is calculated according to the saturated water vapor pressure at -10°C.

Interface and Solid Insulation: When solid insulation parts are butted, elastic materials such as silicone rubber are used to eliminate air gaps and improve the interface insulation level (related to surface pressure, finish, and contact length). Using materials such as epoxy resin and silicone rubber to cast and vulcanize and package high-voltage components, and covering them with a grounding/semiconductive layer, can significantly improve the safety level, reduce the equipment volume, and simplify the layout.

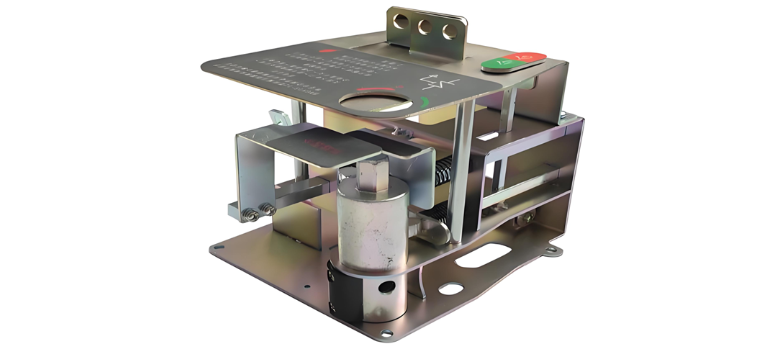

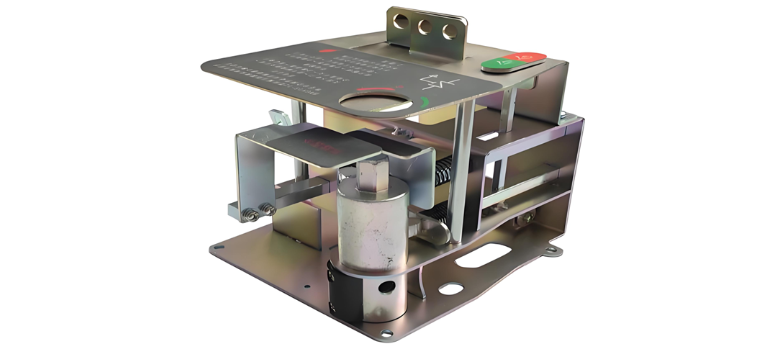

3. Precise Design of Mechanical Transmission and Interlocking System

Mechanical transmission covers links such as circuit breaker operating mechanisms, disconnectors, earthing switches, and door interlocks. The design needs to be optimized from dimensions such as principle, layout, force mode (pressure/tension), span, transmission ratio, stroke angle, and mechanical efficiency: simplify the structure, reduce the number of parts, and lower the operating force, achieving “reasonable force bearing, reliable transmission, stable operation, and convenient operation and maintenance”.

The “five-prevention” interlocking is the core of ensuring operation safety—mechanical interlocking is preferred (composed of levers, connecting rods, baffles, etc. to form a lock, with clear procedures, intuitive and reliable); if the components are far apart or mechanical interlocking is difficult to implement, electrical interlocking is supplemented; intelligent cabinets can be superimposed with microcomputer software programming interlocking (used in conjunction with mechanical interlocking) to build a multi-level safety protection system.

4. Construction of a Reliable Earthing System

The earthing design needs to cover the dual requirements of “operation safety” and “fault withstand”:

During maintenance, the earthing switch can reliably earth the main circuit according to regulations.

The bottom frame of the shell is equipped with earthing conductors and terminals suitable for fault conditions, and the cabinets are interconnected by conductors, with a dedicated circuit between the earthing switch and the earthing conductor.

The earthing conductors, connection circuits, and connections between cabinets must withstand the rated short-time/peak withstand current.

The frame, cover plate, door, partition, and other components are electrically continuous to ensure the earthing connection of functional units.

The DC voltage drop from any point of the shell metal parts to the earthing conductor through 30A is ≤ 3V, ensuring the effectiveness of earthing.

5. Technological Evolution and Development Direction

With the process of power grid transformation and cable undergrounding, multi-circuit distribution units are rapidly iterating towards “miniaturization, modularization, and automation”, which drives the innovative development of SF₆ and composite insulation technologies and high-performance components. In the future, it is necessary to focus on manufacturing process upgrades (such as precision processing and integrated packaging), optimization of cable connectors, iteration of current-limiting fuses, research and development of small operating mechanisms, and innovation of auxiliary components, so as to improve the design and manufacturing level of domestic ring main distribution equipment. Developing a new generation of ring main cabinets with “full working condition adaptation, maintenance-free, high reliability, and miniaturization” to enable distribution automation will become a key direction for industry breakthroughs.