Di serdemên modernî yên endüstrî, inverteran rolê pîvan de di sisteman elektrik yên dîwarîn de bikin. Wan dikarin kontrolê taybetmendî yên vekirina çepê hatine ve veqetandîne û energiya xerîda bisekin, wekhevala li ser efektivîyeta herêmî û bexwaşa sistemê nûve bike. Vê nivîsê bi tevahî li ser ewaziya performansa û optimizasyona inverteran di dizayna test bench de piştgirî kirin.

Weke platformên destpêkî yên ku şertên operasyonî yên cihaneke hilbijêrin, test bench an jî demanda performansê ya bilindavên inverteran biguheztin. Nivîsa analîz ê performansa inverteran di navbera şertên operasyonî yên din de, an jî sernasên mînaka hene ke karanîn, wekî dakîna kontrolê taybetmendî, dema tepokê û xerîd bo energi. Di navbera yê din de, ji ber ku dikarin efektivîyeta inverteran bi parametrekan dizayni yên optimîz û strategiyên kontrolê bisekin, tuhafazî derbasdar û rehberî ji bo karbarkirina endüstrîyan, û piştgiriya optimizasyonê herêmî di efektivîyeta û performansa de bibin.

1 Rewşa Niha û Pirsgirêzekan û Inverteran di Test Bench de

Karberdana inverteran di test bench de wergerînî yên moderna endüstrîda wekî tendansa pîvan hatine. Wan dikarin kontrolê taybetmendî û xerîd bo energiye bi guherandina frekansa input motori veqetandin. Daneyên demînin ku di endüstrîya berbat û manufakturada de, karberdana inverteran 85% dan, ku wê dikare were parastin ku bi rêjiyekan automatekeya endüstrîya piştgirî kirin. Lê, test bench an jî demanda bilindav ê inverteran biguheztin, bêtir di taybetmendî ya kontrolê taybetmendî û dema tepokê de. Di karbarkirinan standarde endüstrî de, taybetmendî kontrolê taybetmendî ±0.5% ye, lê di test benchên taybetmendî yên berbat de, divê bi ±0.1% an jî behtar bisekin, bi dema tepokê ya milisecond, ku kompleksîyeta dizayna sistemê kontrolê zêdetir bike.

Xerîd bo energi heval dikare girîng be. Test benchan piramîn bi barên berbat yên demê digerin, ku inverterên efektivî bixwe. Li gor ku ku inverterên optimîzê dikarin bi serbestên >30% xerîd bo energi bisekin, li ser şertên teyîn bir, ku bixwe ku bi rastînî xerîd bo energi bisekin, wekhevala li ser efektivîyeta herêmî. Li ser şertên ekstrem, wekî garmîya berbat, taranîna inverteran zêdetir bike, ku dizaynê bexwaş û dayîn dibike da ku stabilitیtya و عملیاتی بلندمدت را تضمین کند.

Bi pêşkêşkirina automatekeya endüstrî, demanda inverterên intelligent û networked zêdetir bike. Inverterên intelligent dikarin statusa operasyonî yên real time monitor bikin û veguherînin, tiştên xirabkirina parêz bike, taranîna xirabkirina bisekin, û efektivîyeta nûve bike. Hejmarên test benchan bi karberdana inverterên intelligent dikarin xercbaran operasyonî yên hemîn dikarin bi serbestên 20% bisekin. Berbi, karberdana inverteran di test bench de pirsgirêzekan zêde yên din, an jî taybetmendî, tepokê çep, xerîd bo energi, bexwaş û intelligence.

2 Metodên Ewaziya Sernasên Performansê Mînaka

Di ewaziya performansa inverteran de, çend sernasên mînaka girîng ne. În sernas an jî performansa bazîcî reflektandin, an jî wekî bingeha ewaziya performansa di karbarkirinan teyîn de.

Taybetmendî kontrolê taybetmendî sernasa mînakî ye, ku devîasyona nîşan dide yên taybetmendî yên output û setpoint. Karbarkirinan amade dikarin taybetmendî yên ±0.5% bixwe, lê karbarkirinan taybetmendî yên berbat dikarin ±0.1% an jî behtar bixwe. Metodên ewaziya an jî testkirina performansa output di navbera barên û taybetmendî yên din de.

Dema tepokê sernasên mînaka din e, ku dema tepokê nîşan dide yên inverter bi komandê werdigirin. Di karbarkirinan performansê berbat de, dema tepokê divê bi milisecond kontrol bike.

Efektivîyeta energî bi ewaziya xerîd bo energi di navbera barên din de. Inverterên efektivî bixwe ku bi serbestên >30% xerîd bo energi bisekin, wekhevala li ser efektivîyeta herêmî. Ewaziya efektivîyeta an jî hesabkirina nisbata input û output power di navbera şertên operasyonî yên din de.Bexwaş û dayîn bi testkirina dirêjî di şertên mezinî yên ekstrem de nîşan dide ku stabîlî û dema xirabkirina.

Ses level, hêli navbera ku gelek ji we hej ne, girîng e di karbarkirinan kes sesê bi rastînî bixwe û an jî dikare bi rastînî bi 60 dB bisekin. Ewaziya kompîtkar în sernasên dikare ewaziya tamm ê performansa inverter bikin û bingeha ilmiyê ji bo optimizasyon di karbarkirinan teyîn de.

3 Enhancing Inverter Performance in Test Benches

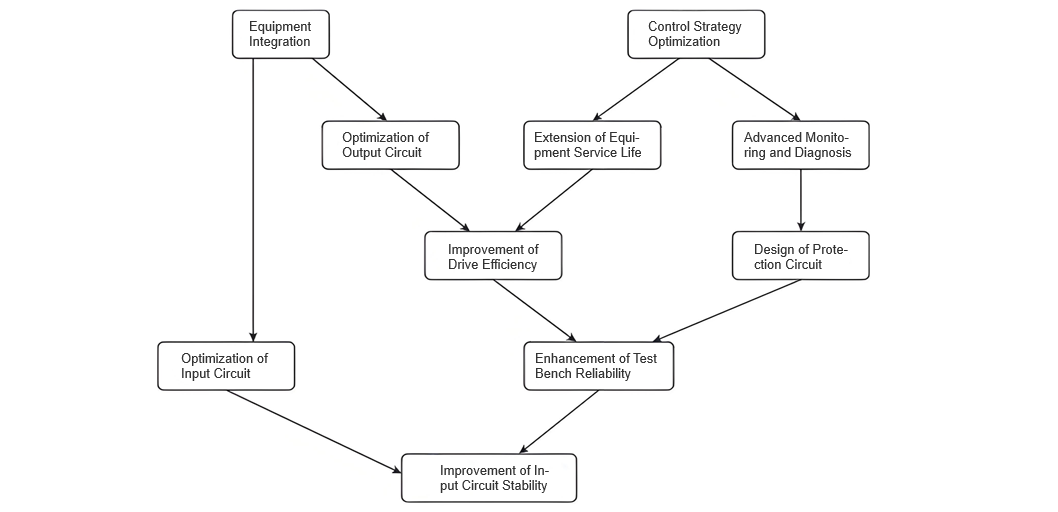

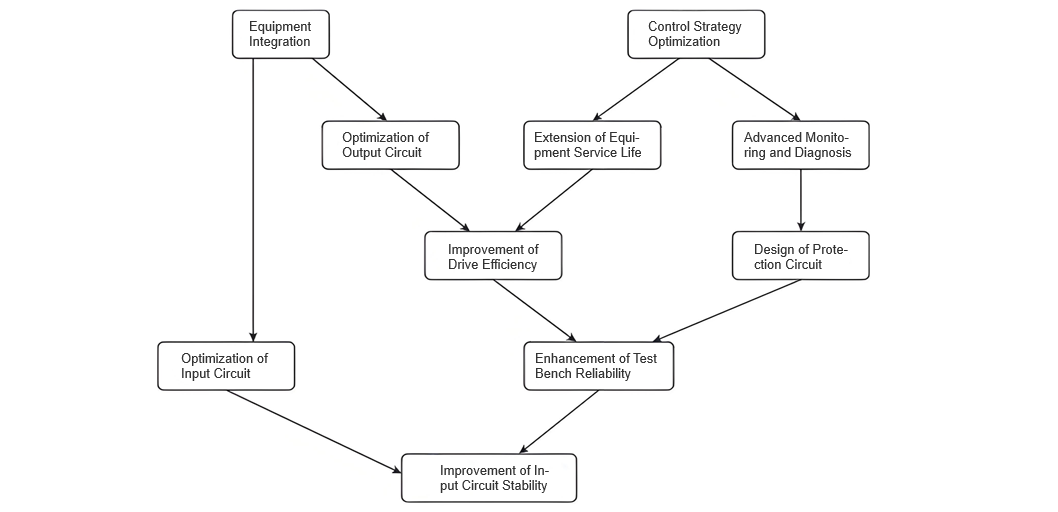

Improving inverter performance in test benches involves not only optimizing the device itself but also effectively integrating it into the test bench system and ensuring optimal performance under various operating conditions. The control schematic provides an overview of the inverter's connections and control logic, serving as the starting point for understanding and improving its performance.

In inverter applications, the design of input and output circuits is particularly critical. A stable input circuit with effective filtering reduces the impact of power supply fluctuations, enhancing system reliability. Optimizing output filters and control logic helps reduce electromagnetic interference during motor operation, improving drive efficiency.

In practical applications, optimizing control strategies is equally important. Adjusting control parameters and optimizing start/stop characteristics can reduce mechanical stress and extend equipment life. Current and voltage detection circuits in the control schematic can be used to implement advanced control algorithms (e.g., PID control), ensuring stable output during load fluctuations. Integrating advanced monitoring and diagnostic functions enables real-time monitoring of key parameters and prevention of potential failures.

Protection circuit design ensures rapid power disconnection in abnormal conditions, preventing damage to the inverter and motor. Therefore, enhancing inverter performance requires a holistic approach that considers device performance, system integration, and advanced control strategies to maximize overall performance. As shown in Figure 1.

4 Case Study

A automotive component testing facility used a 4 kW ABB ACS550 inverter for transmission performance testing. Initial evaluation showed an efficiency of only 90% under full load, significantly below the 95% required by the IE3 efficiency level in the GB 18613-2020 standard. Additionally, start/stop response time reached 200 ms, causing unstable test data.

The engineering team implemented a series of optimization measures: by tuning the inverter's PID control parameters and optimizing start/stop curves, mechanical stress was significantly reduced, cutting response time to under 50 ms and greatly improving test data stability. On the hardware side, upgrading to an efficient cooling system and low-loss capacitors increased efficiency to 92%, approaching the IE3 standard. Advanced monitoring software was introduced to enable real-time monitoring of operational data and predictive maintenance, reducing unplanned downtime. Mean time between failures (MTBF) increased from 800 hours to over 1,500 hours. Furthermore, optimizing motor-inverter matching and signal transmission paths improved control precision and enhanced test result reliability.

Through these comprehensive optimizations, the overall performance of the test bench significantly improved, with the inverter's efficiency and reliability reaching new levels. This case demonstrates the effective practice of combining technical and managerial optimization to enhance inverter performance.

5 Optimization Design of Inverter Control Systems

When discussing the optimization design of inverter control systems, the focus should be on the following aspects:

Innovation in Control Strategies: Employing advanced algorithms such as fuzzy logic or neural networks to improve system response speed and control accuracy, enabling more precise regulation of motor speed and torque, thereby enhancing overall test bench performance.

Hardware Performance Enhancement: Using high-efficiency electronic components (e.g., IGBTs or MOSFETs), optimizing circuit layout to reduce losses and improve reliability, and improving thermal design to prevent overheating and extend service life.

System Integration and Communication Technology: Utilizing industrial Ethernet or wireless communication for efficient data exchange and system compatibility, facilitating integration into smart manufacturing and Industrial Internet of Things (IIoT) platforms.

Real-time Monitoring and Adaptive Control: Leveraging sensors and data analytics tools to monitor equipment status in real time, combined with adaptive algorithms to automatically adjust operating parameters in response to load variations and environmental changes, maintaining optimal performance.

6 Conclusion and Future Development Directions

When evaluating and optimizing inverter performance in test bench design, it is essential to recognize their role as core components of electrical drive systems, directly impacting overall test bench performance. Key performance indicators include speed control accuracy, response time, energy efficiency, and reliability. In high-precision test benches, improving speed control accuracy is central to optimization. Response time is critical for tests requiring frequent speed changes; optimizing it can significantly enhance efficiency. Design improvements such as advanced cooling systems and low-loss components can effectively boost energy efficiency and reduce consumption.

Looking ahead, with the advancement of industrial automation and smart manufacturing, inverter applications in test benches will become even more widespread. Intelligent inverters will offer enhanced real-time monitoring, state adjustment, and predictive maintenance capabilities, further reducing failure rates and improving efficiency. Networked inverters will integrate more deeply into the Industrial Internet, enabling advanced monitoring and remote control. The application of new semiconductor materials (e.g., SiC, GaN) will enhance performance, reduce size and weight, and improve efficiency and reliability. Advanced control algorithms (e.g., enhanced PID or fuzzy logic control) will enable superior performance under complex operating conditions.

7 Conclusion

This paper systematically outlines the key aspects of performance evaluation and optimization of inverters in test bench design, emphasizing their importance in improving speed control accuracy, response time, energy efficiency, and reliability. Significant performance gains can be achieved through optimized design and control strategies, while highlighting the critical role of intelligence and networking in future development, as well as the central role of technological innovation in enhancing efficiency and reliability. Continuous technological advancement and application optimization will enable inverters to better meet the high standards of test benches and align with the trends of intelligence and networking.