In modern industrial applications, inverters play a crucial role as key components of electrical drive systems. They enable precise speed control and effectively reduce energy consumption, thereby enhancing the overall efficiency and reliability of the system. This article focuses on the performance evaluation and optimization of inverters in test bench design.

As experimental platforms that simulate real-world operating conditions, test benches impose higher performance demands on inverters. The paper analyzes inverter performance under various operating conditions, including key metrics such as speed control accuracy, response time, and energy consumption. It also discusses how to further improve inverter efficiency through optimized design parameters and control strategies, providing deeper understanding and guidance for industrial applications, and promoting continuous optimization in efficiency and performance.

1 Current Status and Challenges of Inverters in Test Benches

The application of inverters in test benches has become a significant trend in modern industry, enabling precise speed control and energy management by adjusting the motor input frequency. Data show that in heavy industry and manufacturing, inverter usage exceeds 85%, reflecting their widespread adoption in industrial automation. However, test benches impose higher demands on inverters, especially in speed control accuracy and response speed. In standard industrial applications, speed control accuracy is ±0.5%, but in high-precision test benches, it must be improved to ±0.1% or better, with millisecond-level response times, significantly increasing control system design complexity.

Energy management is equally critical. Test benches often operate under high loads for extended periods, requiring high-efficiency inverters. Studies indicate that optimized inverters can save over 30% energy under specific conditions, making it essential to reduce energy consumption while maintaining high performance. Additionally, in extreme conditions such as high temperatures, inverter failure rates increase significantly, necessitating robust design for reliability and durability to ensure long-term stable operation.

With the advancement of industrial automation, demands for intelligent and networked inverters are growing. Intelligent inverters can monitor and adjust operating status in real time, predict maintenance needs, reduce failure rates, and improve efficiency. Some test benches have reduced operational costs by approximately 20% through the use of intelligent inverters. In summary, inverter applications in test benches face multiple challenges, including high precision, fast response, energy efficiency, reliability, and intelligence.

2 Evaluation Methods for Key Performance Indicators

In evaluating inverter performance, several key indicators are essential. These metrics not only reflect basic performance but also serve as the basis for assessing performance in specific applications.

Speed control accuracy is a core indicator, measuring the deviation between the actual output speed and the setpoint. General applications require accuracy within ±0.5%, while high-precision applications may demand ±0.1% or higher. Evaluation methods include testing output performance under varying loads and speeds.

Response time is another critical metric, defined as the time required for the inverter to reach the target speed after receiving a command. In high-performance applications, response time must be controlled within milliseconds.

Energy efficiency is evaluated by measuring energy consumption under different loads. High-efficiency inverters significantly reduce energy use while maintaining performance. Studies show that efficient inverters can save up to 30% of electrical energy. Efficiency evaluation typically involves calculating the ratio of input to output power under various operating conditions.Reliability and durability are assessed through long-term testing under extreme environmental conditions to determine stability and lifespan.

Noise level, though often overlooked, is important in low-noise applications and typically needs to be controlled below 60 dB. A comprehensive evaluation of these indicators enables a thorough assessment of inverter performance and provides a scientific basis for optimization in specific applications.

3 Enhancing Inverter Performance in Test Benches

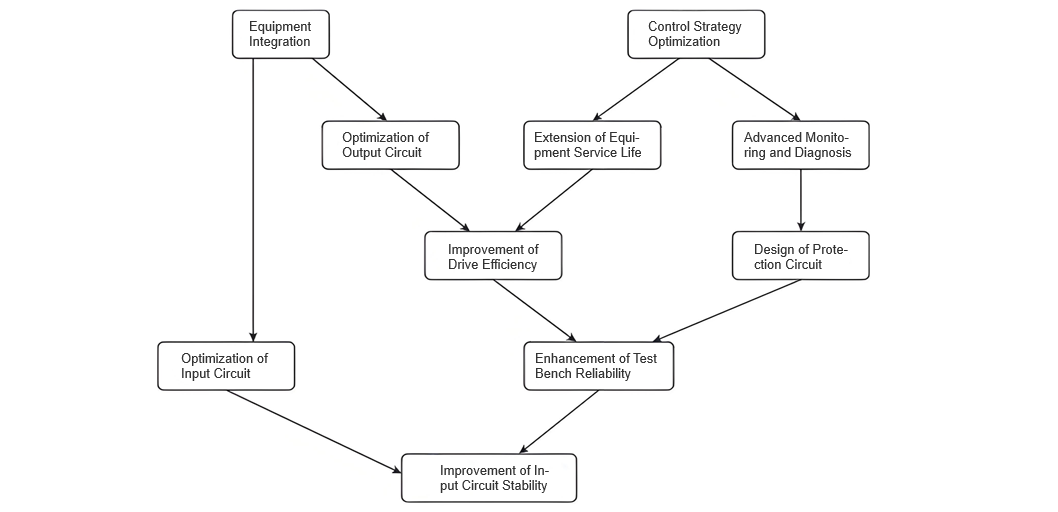

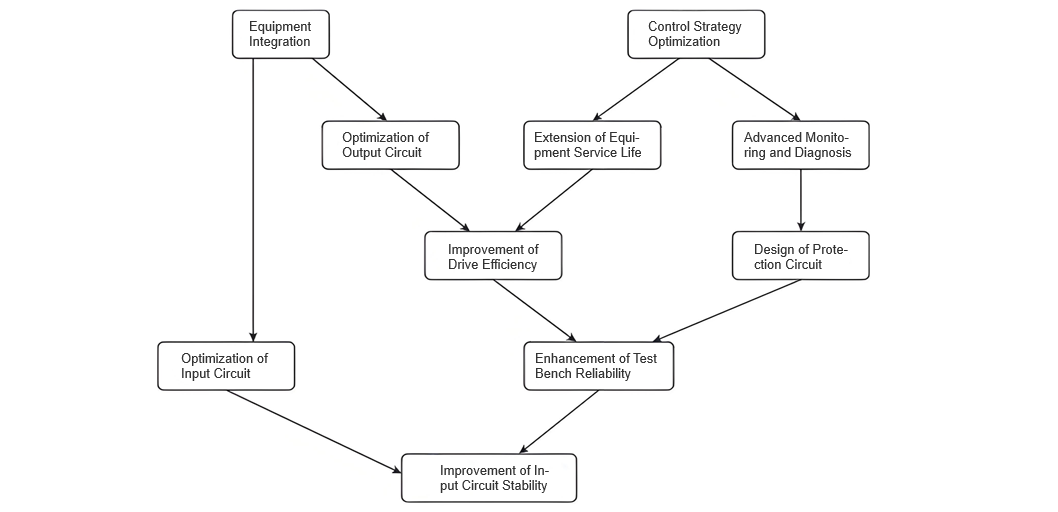

Improving inverter performance in test benches involves not only optimizing the device itself but also effectively integrating it into the test bench system and ensuring optimal performance under various operating conditions. The control schematic provides an overview of the inverter's connections and control logic, serving as the starting point for understanding and improving its performance.

In inverter applications, the design of input and output circuits is particularly critical. A stable input circuit with effective filtering reduces the impact of power supply fluctuations, enhancing system reliability. Optimizing output filters and control logic helps reduce electromagnetic interference during motor operation, improving drive efficiency.

In practical applications, optimizing control strategies is equally important. Adjusting control parameters and optimizing start/stop characteristics can reduce mechanical stress and extend equipment life. Current and voltage detection circuits in the control schematic can be used to implement advanced control algorithms (e.g., PID control), ensuring stable output during load fluctuations. Integrating advanced monitoring and diagnostic functions enables real-time monitoring of key parameters and prevention of potential failures.

Protection circuit design ensures rapid power disconnection in abnormal conditions, preventing damage to the inverter and motor. Therefore, enhancing inverter performance requires a holistic approach that considers device performance, system integration, and advanced control strategies to maximize overall performance. As shown in Figure 1.

4 Case Study

A automotive component testing facility used a 4 kW ABB ACS550 inverter for transmission performance testing. Initial evaluation showed an efficiency of only 90% under full load, significantly below the 95% required by the IE3 efficiency level in the GB 18613-2020 standard. Additionally, start/stop response time reached 200 ms, causing unstable test data.

The engineering team implemented a series of optimization measures: by tuning the inverter's PID control parameters and optimizing start/stop curves, mechanical stress was significantly reduced, cutting response time to under 50 ms and greatly improving test data stability. On the hardware side, upgrading to an efficient cooling system and low-loss capacitors increased efficiency to 92%, approaching the IE3 standard. Advanced monitoring software was introduced to enable real-time monitoring of operational data and predictive maintenance, reducing unplanned downtime. Mean time between failures (MTBF) increased from 800 hours to over 1,500 hours. Furthermore, optimizing motor-inverter matching and signal transmission paths improved control precision and enhanced test result reliability.

Through these comprehensive optimizations, the overall performance of the test bench significantly improved, with the inverter's efficiency and reliability reaching new levels. This case demonstrates the effective practice of combining technical and managerial optimization to enhance inverter performance.

5 Optimization Design of Inverter Control Systems

When discussing the optimization design of inverter control systems, the focus should be on the following aspects:

Innovation in Control Strategies: Employing advanced algorithms such as fuzzy logic or neural networks to improve system response speed and control accuracy, enabling more precise regulation of motor speed and torque, thereby enhancing overall test bench performance.

Hardware Performance Enhancement: Using high-efficiency electronic components (e.g., IGBTs or MOSFETs), optimizing circuit layout to reduce losses and improve reliability, and improving thermal design to prevent overheating and extend service life.

System Integration and Communication Technology: Utilizing industrial Ethernet or wireless communication for efficient data exchange and system compatibility, facilitating integration into smart manufacturing and Industrial Internet of Things (IIoT) platforms.

Real-time Monitoring and Adaptive Control: Leveraging sensors and data analytics tools to monitor equipment status in real time, combined with adaptive algorithms to automatically adjust operating parameters in response to load variations and environmental changes, maintaining optimal performance.

6 Conclusion and Future Development Directions

When evaluating and optimizing inverter performance in test bench design, it is essential to recognize their role as core components of electrical drive systems, directly impacting overall test bench performance. Key performance indicators include speed control accuracy, response time, energy efficiency, and reliability. In high-precision test benches, improving speed control accuracy is central to optimization. Response time is critical for tests requiring frequent speed changes; optimizing it can significantly enhance efficiency. Design improvements such as advanced cooling systems and low-loss components can effectively boost energy efficiency and reduce consumption.

Looking ahead, with the advancement of industrial automation and smart manufacturing, inverter applications in test benches will become even more widespread. Intelligent inverters will offer enhanced real-time monitoring, state adjustment, and predictive maintenance capabilities, further reducing failure rates and improving efficiency. Networked inverters will integrate more deeply into the Industrial Internet, enabling advanced monitoring and remote control. The application of new semiconductor materials (e.g., SiC, GaN) will enhance performance, reduce size and weight, and improve efficiency and reliability. Advanced control algorithms (e.g., enhanced PID or fuzzy logic control) will enable superior performance under complex operating conditions.

7 Conclusion

This paper systematically outlines the key aspects of performance evaluation and optimization of inverters in test bench design, emphasizing their importance in improving speed control accuracy, response time, energy efficiency, and reliability. Significant performance gains can be achieved through optimized design and control strategies, while highlighting the critical role of intelligence and networking in future development, as well as the central role of technological innovation in enhancing efficiency and reliability. Continuous technological advancement and application optimization will enable inverters to better meet the high standards of test benches and align with the trends of intelligence and networking.