Daga baya na gaba ta ƙarshen ɗaya, kawai insulanti mai yawa da zai iya amfani a cikin masana hanyar tashin karamin sauran kashi ne suka ce kamar kasa da kwalba. Daga baya na 1940s, saboda shiga da ma'adin polymer, kasa da kwalba ba su zama zaɓuɓɓuka a cikin zabe, wanda ya haɗa kasashe da Amurika a bincike don in samun insulanti na polymer. Sannan, an yi karatuwa masu kyau game da nuna abubuwa, kula-kula, yanayi da tsohon tsari, da kuma al'adu mai yawa na insulanti, kuma tattalin inganci ya ci gaba da ɗaya.

A cikin ma'adin polymer mai yawa da zai iya kawo kasa da kwalba, gumu rubber ta fi siffar da dabi'a tun daga 1960s kuma ta zama mafi nasara a cikin polymer. Insulanti gumu rubber suna da muhimmanci waɗanda suna da muhimmanci da insulanti kasa: kadan, su ne kifi, daidai da ke amfani, da kuma cin kanta; biyu, insulanti kasa suke magance da kusa da takalma, amma insulanti gumu rubber suna iya damar takalma masu karamin sauran kashi kamar takalma masu motoci da kuma karamin sauran kashi.

Kafin ake iya cewa ma'adin polymer mafi girman suke da muhimman waɗannan faɗa, kawai gumu rubber ne wanda ya fi siffar da dabi'a saboda babban fuskantar tattalin arziki. Insulanti polymer suna da muhimmiyar jirgin ruwa, wanda ya ci gaba da ƙarin kula-kula da kuma ƙarin kula-kula da ke faruwa saboda takalma masu ruwa. Kuma, gumu rubber suna da buƙatar daɗe da ke faruwa da muhimmanci da polymer mafi girman, wanda ya zama babban mutanen da zai iya amfani a cikin yanayi mai yawa. Wannan littafi ya bayyana muhimman gumu rubber a cikin insulanti masu karamin sauran kashi da kuma bayyana tushen da aka samu a kan zamanin.

1 Muhimman Gumu Rubber

1.1 Abubuwan Kimiyar Siloxane Bond

1.1.1 Zuba Kimiya Mai Yawa

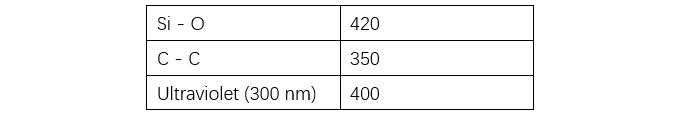

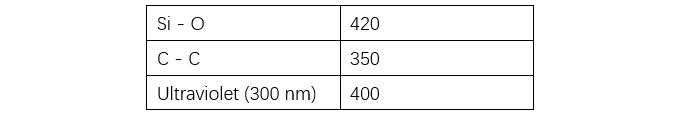

Jirgin gumu rubber ana da siloxane (Si-O) bond. Saboda farkon daɗe da ke faruwa a kan Si (1.8) da O (3.5), ana samun tsari mai yawa, kamar yadda aka bayyana a Ficil 1 (an yi kawo), wanda ya nuna muhimman tsari mai yawa. Saboda haka, energy bond Si-O ya fi karfi da C-C (za a duba Tafel 1). Kuma: (1) saboda tsari mai yawa na main chain, polarity methyl C-H groups a filiyan suke ci gaba, kuma suke da muhimmiyar daɗe da ke faruwa, wanda ya zama muhimmin kimiyar zuba; (2) saboda Si ba suke da shi a yi double ko triple bonds, main chain ba suke da muhimmiyar ci gaba, kuma Si-C bonds suna da muhimmiyar daɗe da ke faruwa, wanda ya zama muhimmin zuba gumu rubber.

1.1.2 Polymer Mai Yawa Da Kudanci

Angle bond siloxane (Si-O-Si) ya fi karfi (130°–160°), wanda ya ba su da muhimmiyar kudanci da organic polymers (C-C bond angle ~110°). Kuma, length bond Si-O (1.64 Å) ya fi karfi da C-C (1.5 Å). Wannan ya nuna cewa overall polymer molecule ya fi kudanci da kuma da yake da muhimmiyar daɗe da ke faruwa.

1.1.3 Tsari Mai Yawa

Saboda tsari mai yawa na polysiloxane, siloxane bonds a main chain suke fito da ionic attraction, amma outer side ana da methyl groups da daɗe da ke faruwa, wanda ya nuna daɗe da ke faruwa.

1.2 Muhimman Gumu Rubber

Saboda abubuwan kimiyar da aka bayyana a Section 1.1, gumu rubber suna da muhimman da suke da muhimmiyar daɗe da ke faruwa a cikin insulanti masu karamin sauran kashi.

1.2.1 Jirgin Jaɗi Da Kuli

Saboda high bond energy da kimiyar zuba mai yawa, gumu rubber suna da muhimmiyar jirgin jaɗi da kuli da organic polymers. Kuma, saboda daɗe da ke faruwa, glass transition temperature ya fi karfi, kuma suna da muhimmiyar jirgin kuli. Saboda haka, performance suke da muhimmiyar daɗe da ke faruwa musamman da yake da yake.

1.2.2 Jirgin Ruwa

Surface polysiloxane ana da methyl groups, wanda ya nuna hydrophobic properties da kuma jirgin ruwa mai yawa.

1.2.3 Abubuwan Kula-Kula

Gumu rubber suna da carbon atoms mafi girma da organic polymers, wanda ya nuna arc resistance da tracking resistance mai yawa. Kuma, idan an yi karkara, suna da insulating silica, wanda ya zama muhimmin electrical insulation performance mai yawa.

1.2.4 Jirgin Harsuna

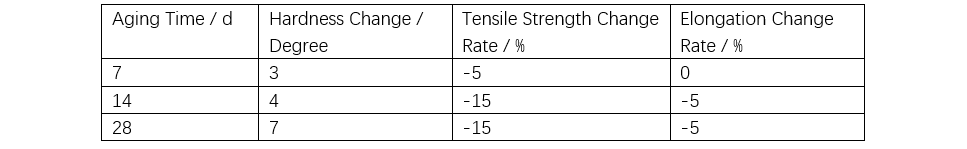

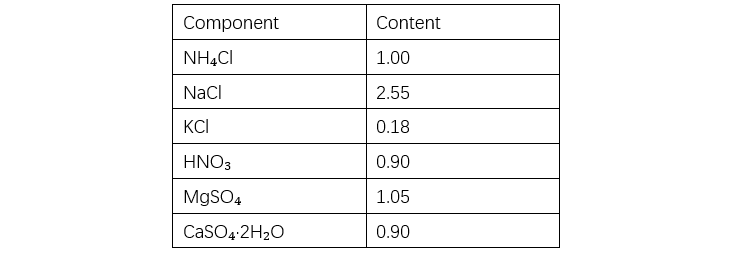

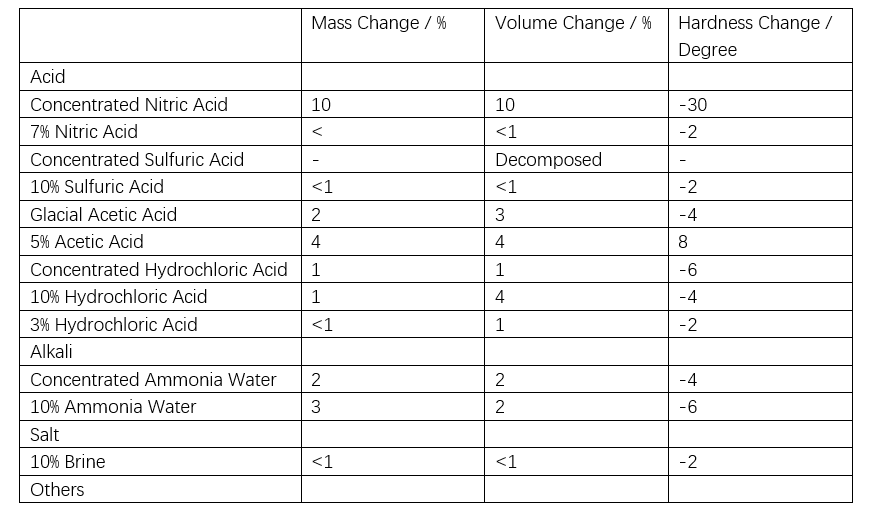

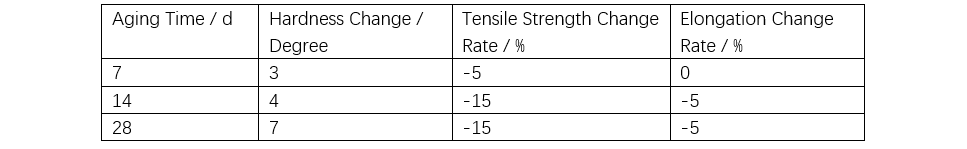

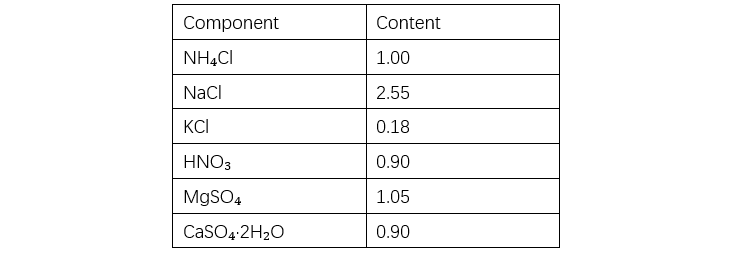

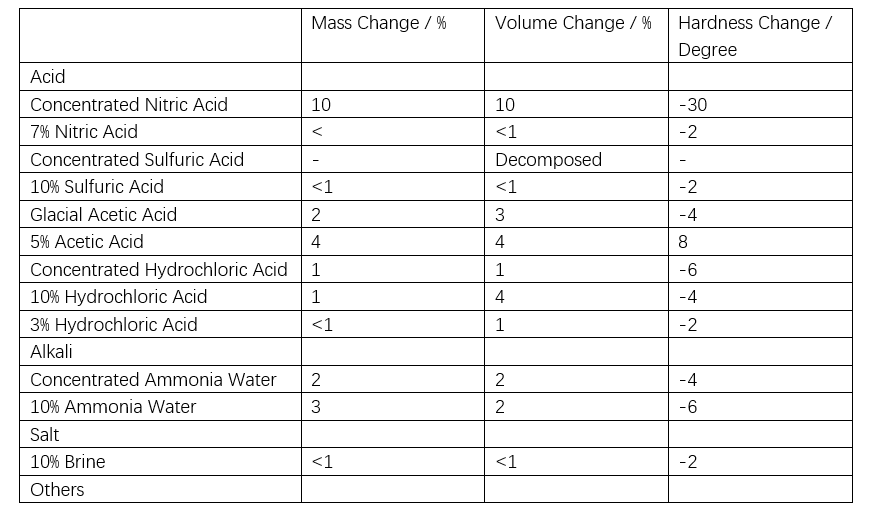

Kamar yadda aka bayyana a Tafel 1, energy bond siloxane ya fi karfi da energy ultraviolet (UV) light, wanda ya nuna jirgin UV-induced aging. A cikin accelerated ozone resistance tests, organic polymers suke magance da kusa da seconds zuwa hours, amma gumu rubber suna da ƙarin karamin daɗe da ke faruwa bayan four weeks of aging, kuma ba suke magance da kusa, wanda ya nuna jirgin ozone resistance (za a duba Tafel 2). Acid rain ita ce solution mai yawa da pH da yake 5.6. An yi artificial acid rain test da 500x concentrated solution a cikin Tafel 3. Gumu rubber suna da jirgin kimiyar zuba kamar yadda aka bayyana a Tafel 4. Idan an yi exposure to mixed solutions kamar acid rain, akwai kansa ya ƙoƙarin faruwa, amma impact ya fi karfi daɗe da ke faruwa.

Note: At room temperature, with an ozone concentration of 200 ppm and a 50% tensile strain applied to the rubber, the surface shows no cracking even after 28 days of aging.

Unit: g per 2 L of deionized water.

1.2.5 Permanent Deformation

Gumu rubber suna da muhimman permanent deformation characteristics (including permanent elongation and compression set) a cikin room temperature da elevated temperatures da organic polymers.

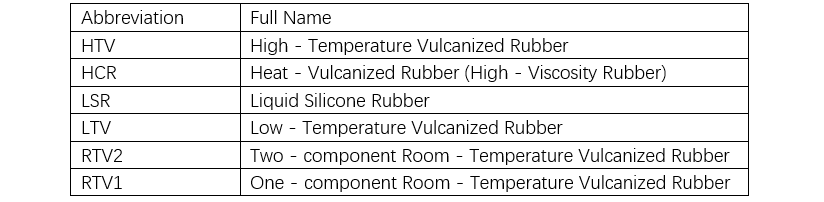

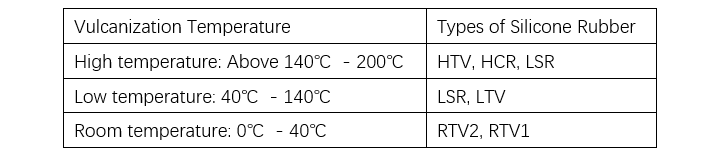

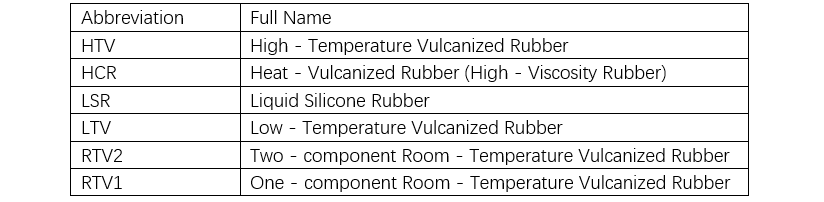

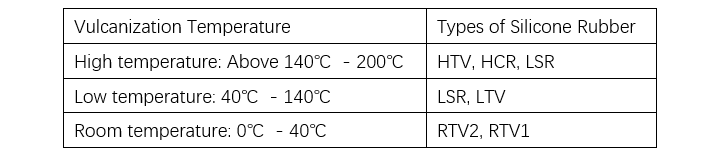

2 Classification of Silicone Rubber

Gumu rubber zan iya kawo da solid da liquid types saboda state before vulcanization, da kuma peroxide curing, addition curing, da condensation curing types saboda vulcanization mechanism. Main difference between solid and liquid silicone rubber ita ce molecular weight of the polysiloxane. Solid silicone rubber zan iya vulcanize via either peroxide curing ko addition curing, and is commonly referred to as high-temperature vulcanizing rubber (HTV) or heat-cured rubber (HCR) (see Tables 5 and 6).

Although liquid silicone rubber cured by addition reaction can also vulcanize at room temperature, it is designated as liquid silicone rubber (LSR), low-temperature vulcanizing rubber (LTV), or two-part room-temperature vulcanizing rubber (RTV), depending on the processing method and curing temperature. In the manufacturing of polymer insulators, injection molding and casting are commonly used processes.

One-component condensation-type (moisture-cure) silicone rubber can be used in construction sealants, as well as in electrical and electronic products. In electrical applications, solvent-diluted room-temperature vulcanizing (RTV) silicone rubber coatings are commonly sprayed onto ceramic insulators as protective materials.

2.1 Silicone Rubber with Aluminum Trihydroxide (ATH)

Silicone rubber with good tracking resistance and arc resistance can be obtained by incorporating a high loading of aluminum trihydroxide (ATH). Silicone rubber filled with 50 parts by mass of ATH exhibits acceptable resistance to high-voltage (4.5 kV) tracking, along with excellent arc resistance, weather resistance, salt fog resistance, and acid rain resistance, making it suitable as an insulating material in areas with severe salt fog. However, due to the high ATH loading, this material suffers from high viscosity (poor plasticity) and low mechanical strength.

2.2 Silicone Rubber without Aluminum Trihydroxide (ATH)

In inland areas of Europe and similar regions with minimal salt fog and low pollution levels, silicone rubber without ATH filler can be used. In such cases, appropriate selection of the base silicone rubber, surface treatment of fumed silica, and addition of compounding agents that enhance tracking resistance can improve hydrophobicity to meet high-voltage tracking resistance requirements. Compared to ATH-filled silicone rubber, this type has lower viscosity and superior mechanical and electrical properties.

2.3 For Outdoor Cable Accessories

As outdoor cable accessories are exposed to harsh environments, they must possess good tracking resistance. Materials with low permanent elongation can be achieved by using polymers with optimized crosslinking density, suitable for ambient-temperature shrinkable (cold-shrink) products.

2.4 For Indoor Cable Accessories

Indoor cable accessories are unlikely to be affected by salt fog, so tracking resistance is often not required. However, when used in ambient-temperature shrinkable (cold-shrink) applications, low permanent deformation characteristics are still necessary.

2.5 Coating Applications

Spraying silicone rubber coatings onto heavily polluted areas can maintain good hydrophobicity over the long term. Coatings can also be applied to already-installed insulators based on pollution levels, enabling continued service and cost savings. Recent reports indicate that coating silicone rubber insulators can further enhance the retention of hydrophobicity. Currently, two main types exist: coated insulators and rubber-type insulators.

3 Conclusion

This paper has introduced silicone rubber materials for polymer insulators. Ongoing research and testing are being conducted by various institutions and manufacturers. If high reliability can be demonstrated through durability and other performance tests, the application of silicone rubber insulators is expected to expand further.