1. Daxwazîna Têkniyekî Handover Testê ya Zindiravarka Sûrçinê

1.1 Piştgiriya Handover Testê

Handover test pîvana wanî ye ku dikeve performansa û xebitandina berbixwekirî yên zindiravarkên sûrçinê di sisteman de. Ji bo sistemanên bi sathên bajarîn 220 kV û dem, zindiravarka sûrçinê rolê nîvendî da ku pergalan elektrîkî ji herkirina li ser hatine û çarxên mehengîn derbas dibe. Lâkin, ji bo dema ku zindiravark ji fabrika derketewe taybetmendiyeyekî ne û veqetandina werdike, amadiyên mîyaweya û kesekanên operasyonî yên derketin, birdayîn û rastkirin dikarin vegera performansa wê biguherîne. Di handover test de, çewtiyên pargîran, çewtiyên derketin û pirsgiraniya problem û hêm reng bikin, ji bo ku zindiravark lê vegere dikeve wekî ku dikeve şertên beşekî û riya rêjeyan ên dikeve kirina rêjeyê veqetandin, û riya pelanînê dikeve kirina rêjeyê û hêviya stabîl û yekbûyî sisteman.

1.2 Naverokên Sernivîsê ya Handover Testê

Handover test li ser du naverokên wanî têkiliyekir:

Testê Performansa Elektrîkî: Verifikasyona dikeve ku şernameyên elektrîkî ya zindiravarka sûrçinê di şertên taybetmendî de vebegirîna rêjeyan ên dikeve, û şernameyên pergalan elektrîkî ji herkirina li ser hatine û çarxên mehengîn derbas bike. Testên girtîn jî dikeve ku şernameyên DC reference voltage (ku vêgotina volt-ampere û şernameyên nonlineary), testa leakage current, power frequency reference voltage, leakage current li 0.75 ji DC reference voltage, operasyona counter discharge, residual voltage, power frequency withstand voltage, û impulse voltage tests, performansa elektrîkî têkiliyekir.

Testa Resistance Insulation: Detektore dikeve şernameyên insulation ya zindiravarka sûrçinê, û çewtiyên tevahî û leakage currentê ji bo ku dikeve derbas bike. Bi pîvanaya measurementa resistance insulation, verifikasyona dikeve ku şernameyên insulation performansê rêjeyan ên dikeve, û çewtiyên sistemê ji bo ku dikeve derbas bike.

1.3 Standard û Spesifikasyonên Handover Testê

Handover test divê li ser standard û spesifikasyonên nasional û internasyonal têkiliyekir, bi tenê ku dikeve testên rêjeyan ên û yekbûyî. Standard û spesifikasyonên vebegirîna rêjeyan ên şernameyên test û teknikên testên performansa elektrîkî û adaptability environmental ya zindiravarka sûrçinê. Li gorî şertên real China's power system, standard û spesifikasyonên vebegirîna rêjeyan ên têkiliyekir, bi tenê ku dikeve testên rêjeyan ên û yekbûyî. Ji bo test, agahdarên û instrumentên ku piştgirîkirina rêjeyan ên bikin, bi tenê ku dikeve operasyonê yên profesyonel bikin, li ser prosedurên standard. Herdemê, dikeve parzên temperatur û humidity û electromagnetic interference pêkide, bi tenê ku dikeve şertên operasyonê yên real simulation bike û data rêjeyan ên bigere.

2. Daxwazîna Têkniyekî Live Testing

2.1 Pirsiyariya Live Testing

Live testing li ser sistemanên elektrîkî wanî dikeve, ku dikeve avantajên non-intrusiveness û monitoring real-time:

Herkesandinan ji çewtiyên kirina şerdest: Detection dikeve bi tenê ku dikeve kirina şerdest, û dikeve pêşkeftina kirina şerdest û kesekanên ekonomî û sosyal.

Monitoring status real-time: Dynamically detektore dikeve şernameyên insulation, conductivity, û thermal status ya zindiravarka sûrçinê, bi tenê ku dikeve operasyonê yên normal, û çewtiyên potensiyel reng bikin û maintenance planîn dikeve.

Management whole-life cycle: Ji bo detectiyan performansa elektrîkî û şernameyên insulation ya zindiravarka sûrçinê, assessment health conditions dikeve, û dikeve şerdestkirina rêjeyan ên ji bo lightning strikes û overvoltages. Analiza test data dikeve formulasyon strategîyên maintenance targeted, û dikeve service life equipment extend, û kesekanên fault reduce, û dikeve basis condition-based maintenance û preventive maintenance provide.

Promote smart grid development: Improve operational reliability electrical equipment, ensure safe production and economic benefits power enterprises, facilitate intelligent and modernized management upgrade power systems.

2.2 Principles teknîkî Live Testing

Principles teknîkî Live Testing li ser physical phenomena electromagnetic, thermodynamic, û acoustics. Measuring û analyzing parameters electromagnetic field, temperature field, û sound waves equipment live state, judge operation status û health condition equipment.

Common methods live testing include:

Infrared Detection: Using infrared thermal imaging technology detect surface temperature distribution û heat transfer equipment, identify abnormal high - temperature areas, û diagnose issues overheating, poor contact, û insulation aging equipment.

Ultrasonic Detection: Capture ultrasonic signals generated inside û on surface equipment evaluate insulation status equipment.

Impulse Voltage Detection: Measure impulse voltage signals inside equipment determine location û severity insulation defects, û simultaneously analyze characteristics signal intensity, frequency, û voltage waveform.

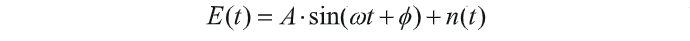

The basic principle live testing can be summarized as:

In the formula, E(t) is the detected signal, A is the amplitude of the signal, φ is the angular frequency, ω is the phase angle, and n(t) is the noise signal.

2.3 Implementation of Live Testing

When conducting live testing, select and configure equipment/instruments based on the test object type and operating environment, matching appropriate sensors and detectors. For surge arrester live testing, common tools include infrared thermal imagers, ultrasonic detectors, impulse voltage detectors, and live testers—these offer high sensitivity/resolution for accurate detection in complex electromagnetic environments.

Pre - test: Calibrate instruments to ensure measurement accuracy/stability.

During test: Scientifically arrange sensor positions/angles to fully cover key parts and collect accurate data, ensuring test reliability. Test personnel must strictly follow procedures, prioritize safety, and avoid errors/accidents from improper operations.

Post - test: Conduct in - depth data analysis, confirm/diagnose abnormal signals, and take targeted maintenance/repair measures to accurately determine equipment status and hidden faults.

3 Analysis of Technology Application Cases

3.1 Handover Test Case

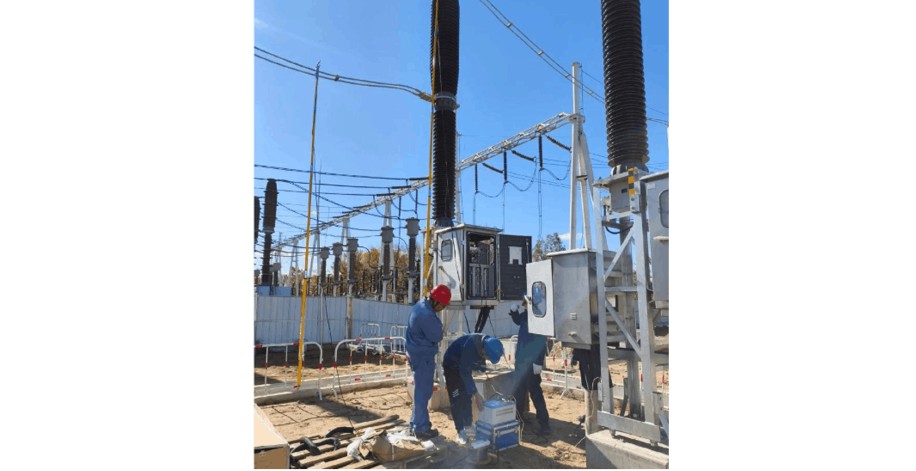

For a 220 kV surge arrester handover test, technical personnel performed comprehensive tests (electrical performance, insulation resistance, etc.) on newly installed arresters.

Electrical performance test: DC reference voltage results showed electrical characteristics met standards (smooth volt - ampere curves, no abnormal fluctuations).

Insulation resistance test: Arresters exhibited good insulation (resistance within specified ranges).

Impulse voltage test: A high - sensitivity detector confirmed no obvious internal insulation abnormalities.

During power frequency/impulse voltage tests, arresters withstood rated voltages and operated normally. Stable post - installation operation verified test accuracy, ensuring safe commissioning. Technical personnel optimized processes based on experience, improving efficiency/accuracy.

3.2 Live Testing Case

During a substation live test, technical personnel performed infrared detection and impulse voltage tests on operating 220 kV arresters:

Infrared detection: A thermal imager detected a ~10 °C abnormal temperature rise at an upper position.

Impulse voltage test: Further detection revealed stronger impulse voltage signals at this position, indicating an insulation defect—subsequently confirmed by lower - than - normal insulation resistance.

Targeted repairs restored normal operation. This test timely eliminated hidden dangers, providing valuable experience for future equipment monitoring/maintenance.

3.3 Experience Summary and Recommendations

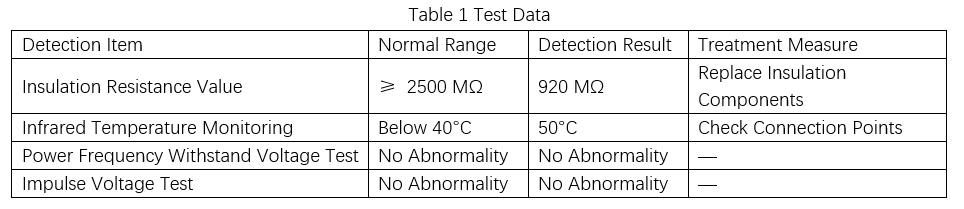

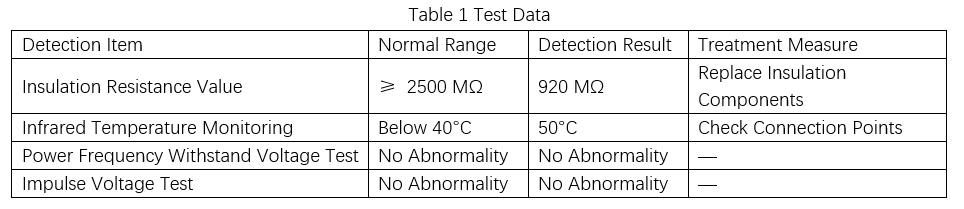

In the handover test of surge arresters, ensuring their electrical performance and insulation resistance meet the standards is the core prerequisite for reliable commissioning of the equipment. During actual operations, attention should be paid to the calibration and maintenance of test equipment. Regular maintenance ensures measurement accuracy and stability. Meanwhile, strengthen the analysis and management of detection data: establish equipment health records and build trend analysis models to realize real - time monitoring of equipment status and fault prediction. The test data of live tests in a certain substation are detailed in Table 1.

From Table 1, it can be seen that standardized live testing and timely maintenance are effective approaches to enhancing the operational reliability of equipment, ensuring the stable operation of the power system.

4. Conclusion

The handover test and live testing technologies for surge arresters below the 220 kV class are highly effective in ensuring the reliable operation of surge arresters. In the future, as detection technologies continue to innovate and develop, the intelligent management level of the power system will be further enhanced, thus providing a more solid technical guarantee for the safe and stable operation of the power grid.