1. Overview of Surge Arrester Handover Test Technology

1.1 Necessity of Handover Test

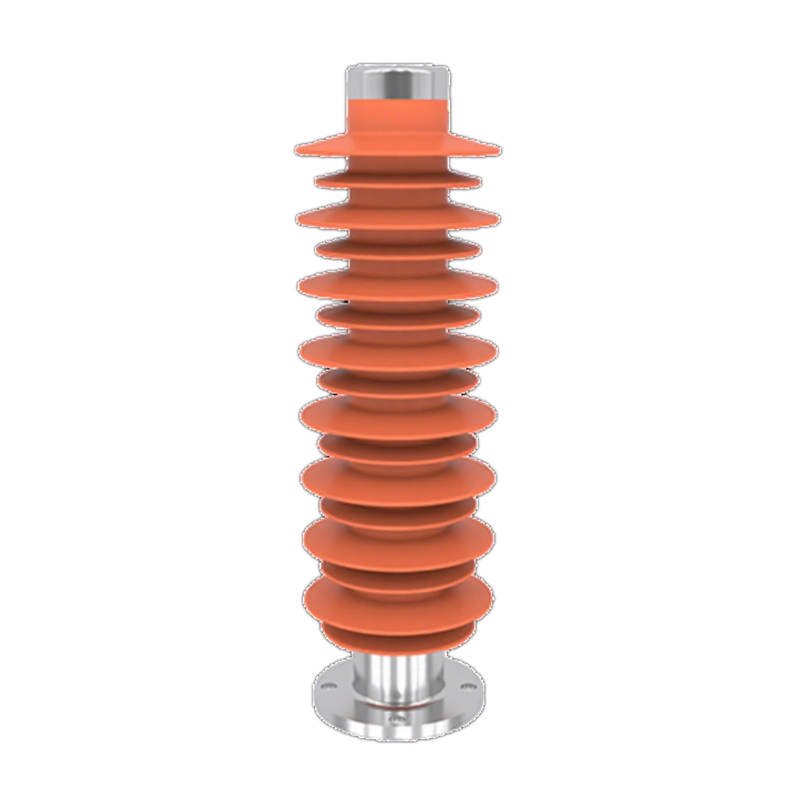

The handover test is a crucial step in ensuring the performance and safe operation of surge arresters within power systems. For power systems with voltage levels at 220 kV and below, surge arresters play a core role in protecting electrical equipment from damage caused by overvoltages and lightning strikes. However, during the process from the arrester leaving the factory to its actual operation after installation, environmental factors or operational oversights during transportation, storage, and installation may impact its performance. Through the handover test, manufacturing defects, transportation damages, and installation issues can be promptly identified, ensuring the arrester is in optimal condition before being put into operation and avoiding fault risks during operation, thus maintaining the stability and reliability of the power grid.

1.2 Main Contents of Handover Test

The handover test focuses on two core aspects:

Electrical Performance Testing: Verifies whether the electrical characteristics of the surge arrester meet the design requirements under specific conditions, ensuring its protective function during overvoltages and lightning strikes. Actual tests cover items such as DC reference voltage (reflecting volt-ampere and nonlinear characteristics), leakage current testing, as well as power frequency reference voltage, leakage current at 0.75 times the DC reference voltage, discharge counter operation, residual voltage, power frequency withstand voltage, and impulse voltage tests, comprehensively evaluating electrical performance.

Insulation Resistance Testing: Detects the insulation status of the surge arrester, identifying hidden dangers such as insulation damage and excessive leakage current during operation. By measuring the insulation resistance, it determines whether the insulation performance meets the standards, preventing system problems caused by insulation faults.

1.3 Standards and Specifications for Handover Test

The handover test must strictly adhere to domestic and international standards and specifications to ensure accurate and reliable testing. Standards clearly define test methods and technical requirements for the electrical characteristics and environmental adaptability of surge arresters. Combined with the actual situation of China’s power system, they refine requirements for test equipment, environment, and procedures, ensuring the standardization of the testing process and the credibility of results. During testing, equipment and instruments meeting precision requirements should be used, operated by professional personnel in accordance with standard procedures. Meanwhile, attention should be paid to environmental temperature, humidity, and electromagnetic interference to simulate the actual operating environment and obtain accurate data.

2. Overview of Live Testing Technology

2.1 Significance of Live Testing

Live testing is widely applied in power systems, featuring the advantages of non-intrusiveness and real-time monitoring:

Avoid losses from power outages: Detection can be carried out without power interruption, ensuring power supply continuity and reducing economic and social impacts.

Real-time status monitoring: Dynamically detects the insulation, conductivity, and thermal status of surge arresters without interfering with normal operation, promptly identifying potential fault hazards and facilitating planned maintenance, preventing large-scale power outages and equipment damage.

Whole-life cycle management: By detecting the electrical performance and insulation status of surge arresters, it assesses their health conditions, ensuring proper operation during lightning strikes and overvoltages. Analyzing test data enables the formulation of targeted maintenance strategies, extending equipment service life and reducing fault risks, providing a basis for condition-based maintenance and preventive maintenance.

Promote smart grid development: Improve the operational reliability of electrical equipment, ensure the safe production and economic benefits of power enterprises, and facilitate the intelligent and modernized management upgrade of power systems.

2.2 Technical Principles of Live Testing

The technical principle of live testing is mainly based on multiple physical phenomena such as electromagnetism, thermodynamics, and acoustics. By measuring and analyzing parameters like the electromagnetic field, temperature field, and sound waves of equipment in a live state, it judges the operation status and health condition of the equipment.

Common methods for live testing include:

Infrared Detection: Using infrared thermal imaging technology to detect the surface temperature distribution and heat transfer of the equipment, identify abnormal high - temperature areas, and diagnose issues such as overheating, poor contact, or insulation aging in the equipment.

Ultrasonic Detection: Capture ultrasonic signals generated inside and on the surface of the equipment to evaluate the insulation status of the equipment.

Impulse Voltage Detection: Measure the impulse voltage signals inside the equipment to determine the location and severity of insulation defects, and simultaneously analyze characteristics such as the signal intensity, frequency, and voltage waveform.

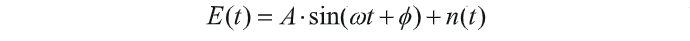

The basic principle of live testing can be summarized as:

In the formula, E(t) is the detected signal, A is the amplitude of the signal, φ is the angular frequency, ω is the phase angle, and (n(t) is the noise signal.

2.3 Implementation of Live Testing

When conducting live testing, select and configure equipment/instruments based on the test object type and operating environment, matching appropriate sensors and detectors. For surge arrester live testing, common tools include infrared thermal imagers, ultrasonic detectors, impulse voltage detectors, and live testers—these offer high sensitivity/resolution for accurate detection in complex electromagnetic environments.

Pre - test: Calibrate instruments to ensure measurement accuracy/stability.

During test: Scientifically arrange sensor positions/angles to fully cover key parts and collect accurate data, ensuring test reliability. Test personnel must strictly follow procedures, prioritize safety, and avoid errors/accidents from improper operations.

Post - test: Conduct in - depth data analysis, confirm/diagnose abnormal signals, and take targeted maintenance/repair measures to accurately determine equipment status and hidden faults.

3 Analysis of Technology Application Cases

3.1 Handover Test Case

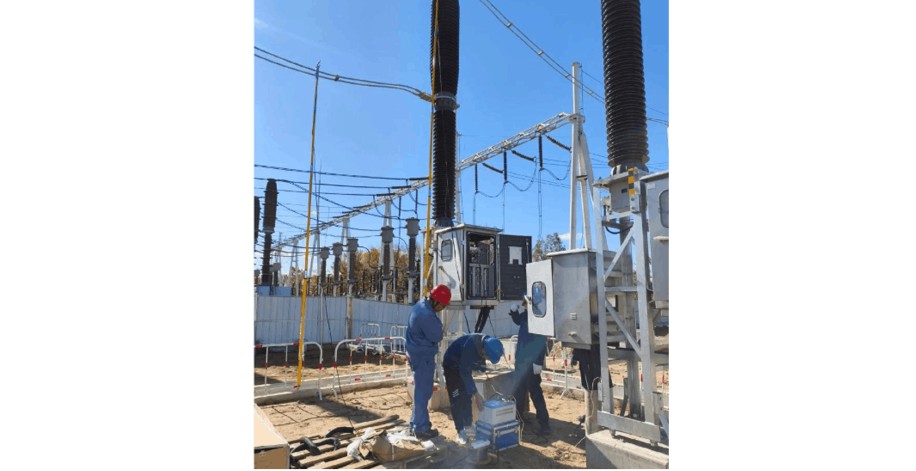

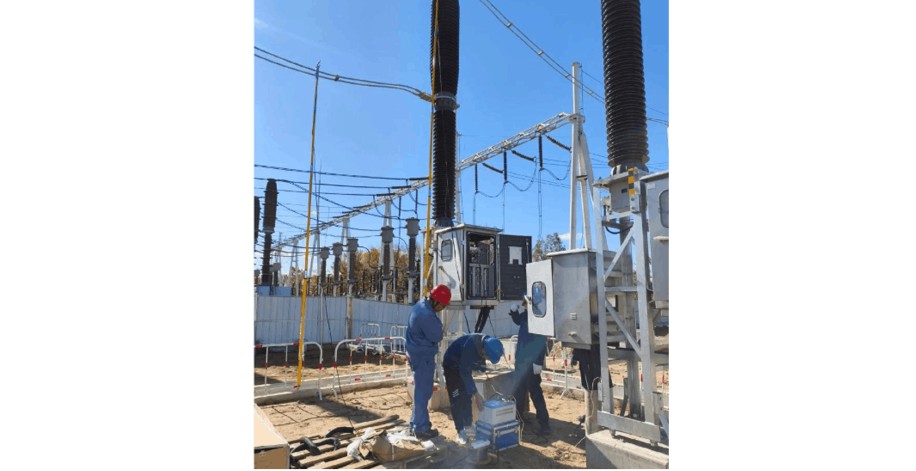

For a 220 kV surge arrester handover test, technical personnel performed comprehensive tests (electrical performance, insulation resistance, etc.) on newly installed arresters.

Electrical performance test: DC reference voltage results showed electrical characteristics met standards (smooth volt - ampere curves, no abnormal fluctuations).

Insulation resistance test: Arresters exhibited good insulation (resistance within specified ranges).

Impulse voltage test: A high - sensitivity detector confirmed no obvious internal insulation abnormalities.

During power frequency/impulse voltage tests, arresters withstood rated voltages and operated normally. Stable post - installation operation verified test accuracy, ensuring safe commissioning. Technical personnel optimized processes based on experience, improving efficiency/accuracy.

3.2 Live Testing Case

During a substation live test, technical personnel performed infrared detection and impulse voltage tests on operating 220 kV arresters:

Infrared detection: A thermal imager detected a ~10 °C abnormal temperature rise at an upper position.

Impulse voltage test: Further detection revealed stronger impulse voltage signals at this position, indicating an insulation defect—subsequently confirmed by lower - than - normal insulation resistance.

Targeted repairs restored normal operation. This test timely eliminated hidden dangers, providing valuable experience for future equipment monitoring/maintenance.

3.3 Experience Summary and Recommendations

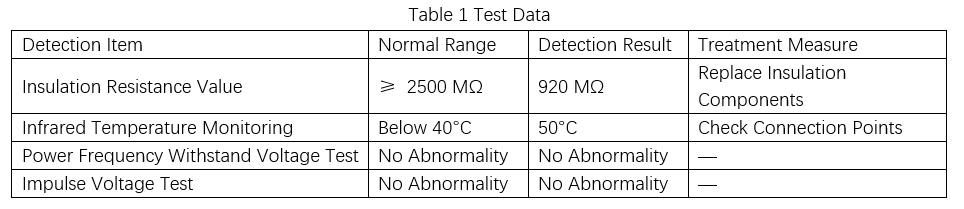

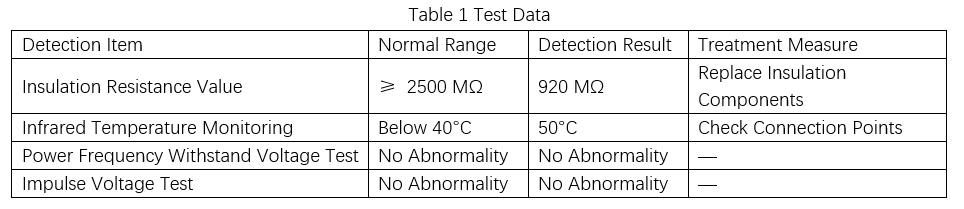

In the handover test of surge arresters, ensuring their electrical performance and insulation resistance meet the standards is the core prerequisite for reliable commissioning of the equipment. During actual operations, attention should be paid to the calibration and maintenance of test equipment. Regular maintenance ensures measurement accuracy and stability. Meanwhile, strengthen the analysis and management of detection data: establish equipment health records and build trend analysis models to realize real - time monitoring of equipment status and fault prediction. The test data of live tests in a certain substation are detailed in Table 1.

From Table 1, it can be seen that standardized live testing and timely maintenance are effective approaches to enhancing the operational reliability of equipment, ensuring the stable operation of the power system.

4. Conclusion

The handover test and live testing technologies for surge arresters below the 220 kV class are highly effective in ensuring the reliable operation of surge arresters. In the future, as detection technologies continue to innovate and develop, the intelligent management level of the power system will be further enhanced, thus providing a more solid technical guarantee for the safe and stable operation of the power grid.