An tsarin da take da yin daidai shi ne da tushen daidai na karamin daidai da IEE-Business da zanar da harkokin daidai. A cikin masana'antar daidai na kasar China na farkon 35 kV zuwa haske, sunan abubuwan da suka fi sani sun hada da karamin daidai mai ba da yin daidai, karamin daidai mai da karamin daidai na kudaden wakar daidai, da karamin daidai mai da karamin daidai na kudaden rarrabe. An yi amfani da karamin daidai mai ba da yin daidai saboda yana iya gudanar da aiki a lokacin daidai na tsakiyar daidai, inda kuma karamin daidai mai da karamin daidai na kudaden rarrabe ta shahara saboda yadda ya kawo daidai da kudaden rarrabe da kuma koyar da wasu muhimman kudaden daidai. Wasu masana'o'in da suka fadada karfi daidai don kiyasin karamin daidai, amma babban daidai na kudaden daidai ya faruwa waɗannan masana'o'in, wanda ya iya haifar da koyar da daidai ko kuma haifar da koyar da daidai.

Wannan takarda ta bayyana asashe da ma'anar karfin daidai, tana tabbatar da sauki da koyar da daidai a cikin masana'antar daidai na kudaden rarrabe, tana bincike abin da suka faruwa da koyar da daidai, kuma tana nuna misali a kan daidai na tsakiyar daidai don tabbatar da aiki da koyar da daidai. Tana ba da al'amuran da za su iya amfani da su don koyar da daidai, tana saukar da fahimtata da mafi girma ga masu aiki, tana taimakawa da koyar da daidai, da kuma tana haifar da nasarorin da ke faruwa a cikin masana'antar daidai.

Asashe na Karfin Da'idai

A lokacin da ake kiyaye masana'anta daidai mai da karamin daidai na kudaden tsakiyar daidai zuwa masana'antar daidai na kudaden rarrabe, don in samun zanar daidai, an yi amfani da karfi daidai a kan busbar. Yanzu, an yi amfani da karfi daidai na Z a kan samun zanar daidai. Ba tare, za a bayyana asashe na karfin daidai na Z.

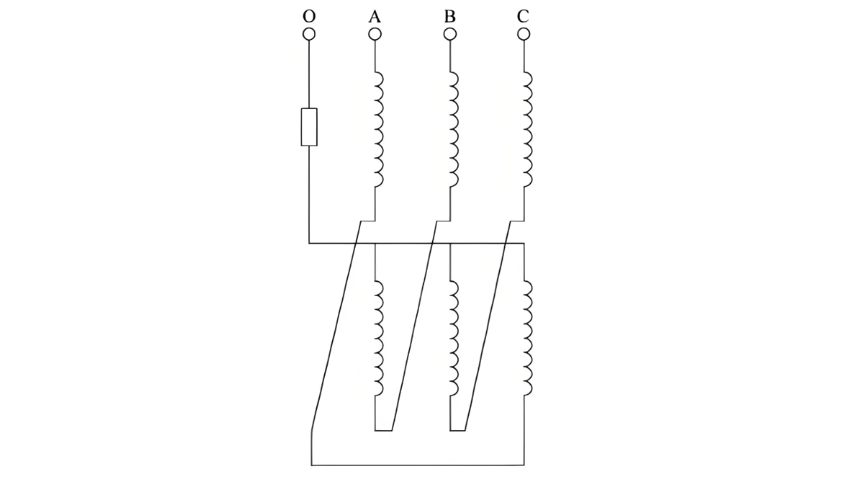

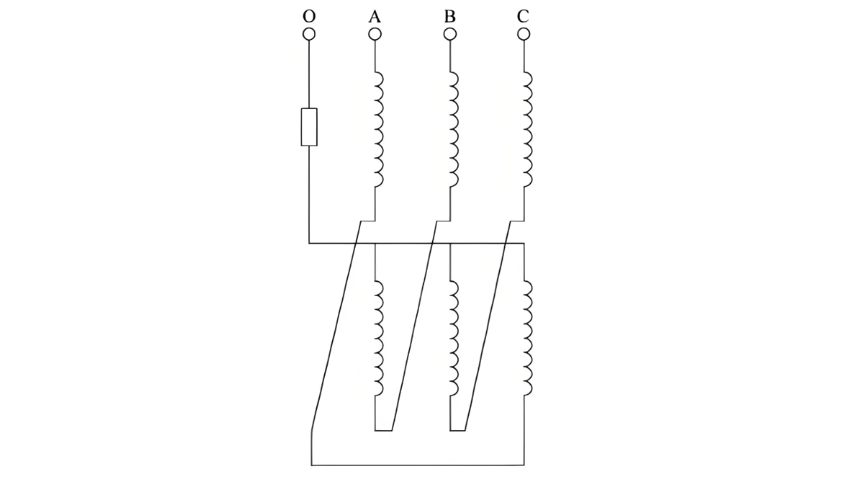

Karfin daidai na Z ya dace da karfin daidai na musamman. Amma, a kan karamin har daidai a kan jerin karamin, an yi gaba da karamin daidai a kan karamin daidai na biyu, a kan gabashin da kuma a kan gabashin, da kuma suka yi kiyaye a kan kiyayen zig-zag. Sunan kiyayen daidai tana nufin da shi a cikin Raisa 1.

Idan daidai na tsakiyar daidai ya faru, ya koyar da kudaden daidai na zero-sequence a kan zanar daidai. Kiyayen zig-zag na karfin daidai na Z ya haifar da kudaden daidai na zero-sequence a kan gabashin da kuma a kan gabashin, ta haifar da flux daidai da kuma taimakawa da kudaden daidai na zero-sequence da suka haifar da overvoltage mai daidai. Don kudaden daidai na positive/negative-sequence, ma'anar daidai na karfin daidai na musamman ya haifar da kudaden daidai.

A lokacin da aiki, karfin daidai ya ci gaba (ba suka da aiki a kan karamin daidai na biyu). Idan daidai na tsakiyar daidai ya faru, kudaden daidai na positive, negative, da kuma zero-sequence za su koyar da shi. Saboda "high positive/negative-sequence, low zero-sequence impedance", tana iya amfani da kudaden daidai na zero-sequence a kan koyar da daidai.

2 Sauki da Bincike Ta Hanyar Koyar Da Da'idai Na Karfin Da'idai

Ta hanyar koyar da daidai na karfin daidai na musamman ana amfani da phase-to-phase da kuma zero-sequence current protection. Haka tana bayyana:

2.1 Sauki Na Phase-to-Phase Current Protection

2.1.1 Asashe Na Sauki

Tana amfani da hanyar koyar da daidai na instantaneous trip da kuma over-current protection:

Instantaneous Trip: Ana koyar da backup over-current protection na same side na transformer daidai. Ana dakatar da sensitivity a lokacin daidai na tsakiyar daidai na biyu (minimum operation mode) da kuma ana haifar da inrush currents (7–10× rated current na karfin daidai) da kuma kudaden daidai na low-voltage side.

Over-Current Protection: Ana sauki don haifar da rated current na karfin daidai da kuma kudaden daidai na maximum fault phase current a lokacin daidai na external single-phase grounding, tare da reliability.

Operation Logic: Instantaneous trip ya koyar daidai (ba da delay); over-current protection (backup for phase-to-phase shorts) ya da short delay da kuma settings na lower don leveled coordination.

2.1.2 Tripping Modes

Don koyar da connection na karfin daidai na power supply transformer:

Connected to the low-voltage bus: Instantaneous trip/over-current protection trips the same-side circuit breaker to isolate faults quickly.

Connected to the low-voltage lead: Protection trips all-side circuit breakers to cut the fault path and prevent escalation.

2.2 Sauki Na Zero-Sequence Current Protection For Earthing Transformers

2.2.1 Asashe Na Sauki

The current setting value shall ensure sufficient sensitivity when a single-phase-to-ground fault occurs.

Cooperate with the setting value of the long-delay protection for the full-line sensitivity of the lower-level zero-sequence current protection.

For the first time limit of zero-sequence current, consideration shall be given to avoiding the successive occurrence of single-phase-to-ground faults on two lines.

The operating time shall be longer than the maximum operating time of the Section Ⅱ of zero-sequence current of each connected component of the bus.

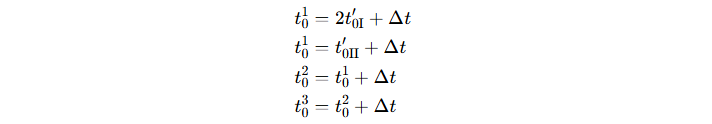

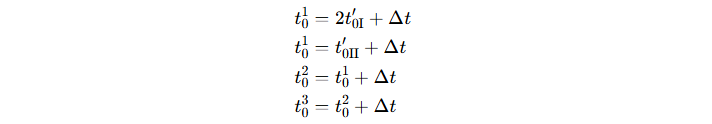

Since the zero-sequence current protection of the earthing transformer does not serve as the main protection, there are three time limits, which are shown as follows:

In the formula: t01, t02, t03 are the 1st, 2nd, and 3rd time limits of the zero-sequence current protection of the earthing transformer respectively; t0I' is the time setting value of Section I of the zero-sequence current of the outgoing line; t0II' is the longest time setting value of Section II of the zero-sequence current protection of all equipment on the busbar except the earthing transformer; Δt is set as 0.2 - 0.5 s.

2.2.2 Tripping Modes

When the earthing transformer is connected to the corresponding busbar of the substation, the zero-sequence current protection operates: the 1st time limit trips the bus tie circuit breaker or section circuit breaker and blocks the automatic standby power supply input device (referred to as "automatic standby input" for short); the 2nd time limit trips the circuit breakers on the same side of the earthing transformer and the power supply transformer.

When the earthing transformer is connected to the corresponding lead of the power supply transformer, the zero-sequence current protection operates: the 1st time limit trips the bus tie circuit breaker or section circuit breaker and blocks the automatic standby input; the 2nd time limit trips the circuit breaker on the same side of the power supply transformer; the 3rd time limit trips the circuit breakers on all sides of the power supply transformer .

2.3 Analysis of Current Protection Operation for Earthing Transformers

Analysis of the earthing transformer protection configuration shows significant differences in tripping modes between phase-to-phase and zero-sequence current protections: zero-sequence protection blocks auto-standby input during operation, while phase-to-phase protection does not.

If the zero-sequence current measured by the protection device reaches the operation value and a ground fault occurs (with the earthing transformer as the only zero-sequence current path in a small-resistance grounding system), the device detects the fault but cannot locate it. If the fault is on the outgoing line, after the protection trips the earthing transformer, the auto-standby input switches to the standby busbar. If the standby busbar recloses onto the faulty line, the earthing transformer on it still detects zero-sequence current, triggering another trip. Since the auto-standby input hasn’t finished charging, the outage range may expand. Thus, zero-sequence protection must block auto-standby input.

When phase-to-phase protection acts (but zero-sequence protection doesn’t), the device judges a phase-to-phase short-circuit in the earthing transformer itself. It trips the earthing transformer, parallel-trips the power supply transformer’s same-side circuit breaker, and the auto-standby input switches to the standby busbar. As the fault is on the tripped earthing transformer, the standby busbar reconnects to the normal line, restoring power.

In summary, phase-to-phase and zero-sequence current protections of earthing transformers differ greatly in fault cause and location judgment, requiring distinct settings and configurations. However, during a ground short-circuit, phase-to-phase protection may misoperate due to measured zero-sequence components. Given their different auto-standby input logics, misoperation may expand the fault range or even cause a full-substation blackout.

3 Case Analysis

3.1 Fault Process

The primary wiring diagram of a 110 kV substation is shown in Figure 2. Before the fault, the low-voltage side 018 circuit breaker of Transformer 1 was closed, the low-voltage side 032 circuit breaker of Transformer 2 was closed, and the 034 circuit breaker was in the test position.

At 06:14 on July 30, 2023, the over-current I section protection of the No. 2 earthing transformer activated, tripping the No. 2 earthing transformer 022 circuit breaker. Meanwhile, it interlocked to cut off the low-voltage side 032 circuit breaker of Transformer 2, causing the 10 kV Section II and III busbars to lose power. The automatic standby power supply (auto-standby) device operated to close the 10 kV Section I/II bus tie 020 circuit breaker.

At 06:36, the over-current I section protection of the No. 1 earthing transformer activated, tripping the No. 1 earthing transformer 015 circuit breaker and interlocking to cut off the low-voltage side 018 circuit breaker of Transformer 1, leading to power loss in all 10 kV Section I, II, and III busbars. The auto-standby device then closed the low-voltage side 032 circuit breaker of Transformer 2 and the No. 2 earthing transformer 022 circuit breaker. However, the fault persisted, triggering the over-current I section protection of the No. 2 earthing transformer again. The 022 circuit breaker tripped and interlocked to cut off the 032 circuit breaker, eventually causing a complete power outage in the substation's 10 kV system.

3.2 On-site Equipment Inspection Results

Primary equipment inspection findings:

Earthing transformer body: No abnormalities were found in No.1 and No.2 earthing transformers, with no obvious fault traces in windings or cores.

10 kV Section III bus PT interval (040 switchgear):

Obvious water stains on the top cover of the switchgear cabinet, indicating rainwater infiltration.

Severe ablation at the C-phase position of the handcart chamber shutter baffle, with two through-holes on the upper shutter.

The C-phase upper contact box and static contact were charred and damaged, with liquid water accumulated inside the box.

Arc burn marks on the C-phase upper/lower moving contacts of the arrester handcart, annealed springs, and damaged contact arm insulating cylinders.

The outer insulating sleeve of the C-phase busbar in the bus chamber was burned and cracked. Water stain penetration was observed in the C-phase area of the bus chamber backplate, and water droplets were condensed on the live display sensor.

A small amount of water accumulated at the bottom of the voltage transformer chamber, while the three-phase PTs showed no obvious external abnormalities.

Rainwater leakage from the steel support above the 10 kV Section III bus PT chamber infiltrated the switchgear, degrading insulation and causing a C-phase discharge that evolved into a metallic ground fault. In the low-resistance grounding system, the No. 2 earthing transformer detected zero-sequence currents of ~4.3 A/phase (exceeding the 2.5 A overcurrent I-section setting), triggering tripping. The overcurrent protection does not block the 10 kV auto-standby, leading to repeated operations. The final trip left the auto-standby uncharged, causing a complete 10 kV outage.

Key contributing factor: The "phase current zero-sequence cancellation" control word was disabled (set to "0"), preventing software filtering of zero-sequence components in phase currents. With a 13 A zero-sequence current, the overcurrent protection misoperated. Properly enabled, this control would have prevented the fault. Instead, the zero-sequence overcurrent protection I-section (set at 1.4 A) operated: 1st time-limit tripped the bus tie and blocked auto-standby; 2nd time-limit tripped the earthing and main transformer breakers, isolating Sections II/III while Section I remained powered.

Root cause: Disabled zero-sequence cancellation control word allowed phase current misinterpretation.

4 Conclusion

This paper outlines earthing transformer protection settings, analyzes misoperation risks under high zero-sequence currents, and presents a case study. To prevent recurrence:

Enable software-based zero-sequence cancellation features (e.g., "phase current zero-sequence cancellation" control word) in low-resistance grounding systems.

If such features are unavailable, optimize coordination between overcurrent and zero-sequence protection settings.

Key takeaway: Proactive configuration of protection software is critical for preventing misoperations during ground faults.