1 Kûbên Pêşketina û Teknîkên Destkirinê ya Kablê yên Istiçrakî yên Elektrikî yên Nîşanbendî

1.1 Dabistina Daneyên

Pêşî da destkirina modelê BIM ya pêşketina kablê, dibeke ye ku parametreyên tafsilî yên pergalên alîyên berhevkirî, malperên bûyerî yên bikarheterandin, û şertên cihan de hêvi dike, bi aimê ku serastiyekê modelê destkir bike. Ji bo vê yekê ku modela BIM bixebite rast bideke wêjeya jorî, naverok e ku daneyên teknîkî yên spesifik yên pergalên nermend bixebitîne û daxistin. Wan dabeşîn dimensiyonên rastî yên kanalên kablê, spesifikasyonên tafsilî yên kutiyên dagilayê, dimensiyonên radiusên derveya kablê, û parametreyên spesifik yên kanalên tel. Heva neyê yên wan parametr û modela kable heye:

Di formulada, P heye seta parametrên nermend; I heye serastiyekê modela pêşketina kablê; f maps P bi I; û g heye fanksiyona guherandina. Dabistanê rastî parametr an direkê hatine serastiyekê modela destkirandin û karberdariyê. Di dema dabistanê daneyan de, parametrên pergelan parastî ne. Guhertina daneyê ya her perga yekane dikare vebijarka zanjîreke bigere, ku hewce dike ke parametrên berbande biaza guherandin. Lekê, di dema dabistanê daneyan de, strategiya biaza guherandin bi aimê ku daneyên bexwe ve ji bo serastiyek ên.

1.2 Destkirina Modela Kable

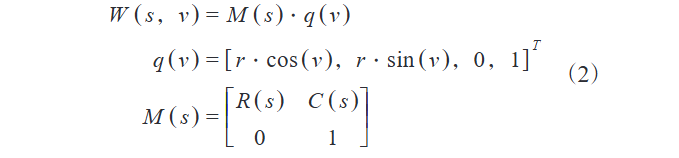

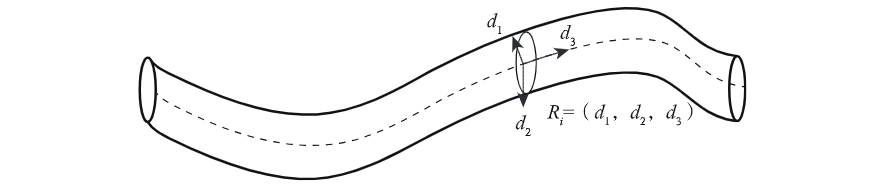

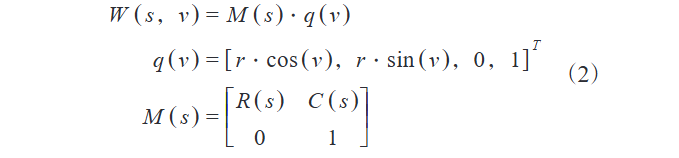

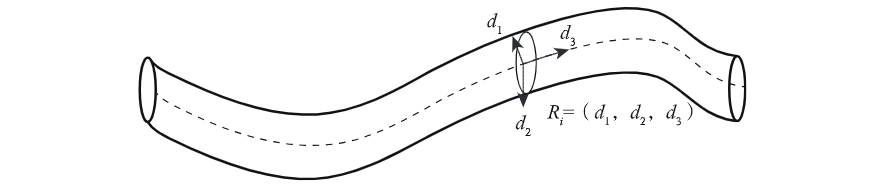

Di bûyerde, mifrazên elektrîkî pêşan kablên bixebitand ba qulankirina shekan. Ji bo giranîna kablên bi terminallên pergalan, konnektoran di navenda kablê de installye bikin. Modela geometrik a kablê heye envelope ji scan kirina serekê wekhevî yên navenda merkezi. Serekê wekhevî biaza çavker (radius r) bikin, û R(s) = (d1(s), d2(s), d3(s)) definîse keramara koordinatên lokal bi navenda merkezi S. Geometriya kablê bixebitîne bi formula parametrî, ku envelope surface construction tefsîr dike.

Di formulada, W nîşan dide matrisa serhadî lokal; C(s) nîşan dide navendeka pozeşkirina koordinatên global; M(s) nîşan dide matrisa guhertina gerdan. Modela geometrik a kablê destkir kir bi vê formulaye weraz di Figure 1 de.

Di Figure 1 de, xettê tarîq S serkeftin navenda merkezi a kablê. Navendeka biniya xezan’ê li S navendeka q dibêje, ku sistema koordinatên lokal R destkir kir ji bo tefsîra xasên serekê wekhevî. Spesifik, d1 (vektor unitî di navenda normala serî de) serekê wekhevîya normala serî tayinde; d2 (vektor unitî di navenda binormal de, bi d1 tarîq perpendikular) tayindekirina navenda serekê wekhevî; d3 (vektor unitî di navenda tangent de li S) navendeka pêşketina kablê li q tayinde. Serekê wekhevî li q biaza çavker (radius r0) bikin, modela geometrik a tevahî bi vektora navenda tayindekirina kablê.

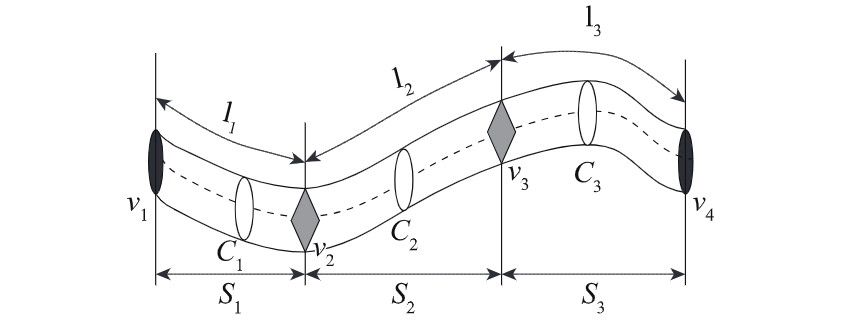

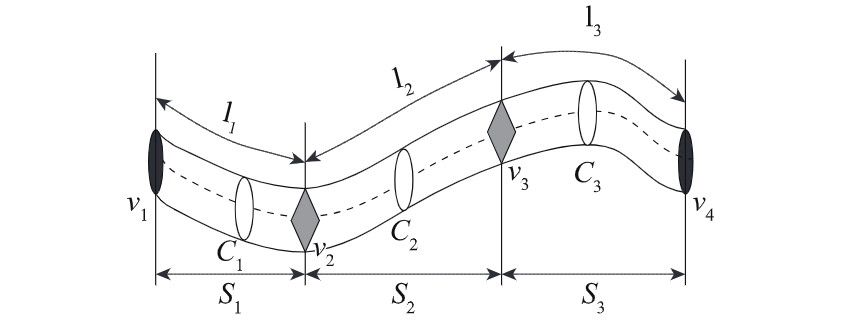

Weraz di Figure 2 de, navendeka kablê tayindekir bi çar navenda v1–v4, divîsin navendeka tevahî bi sêmehî yên l1: v1–v2; l2: v2–v3; l3: v3–v4, bi v1 û v4 navendeka dawî. Ji bo her sêmeh, xasên serekê wekhevî û forma we bi pozîsyona/uzunyana we li S û modela geometrik tayindekir. Naha, sêmehan l1–l3 navendeka serekê wekhevî yên C1–C3 tayindekir, bi navendeka geometrik a kablê.

1.3 Pêşketina Kable

Integrekirina detayên Figures 1 û 2 bixebite rastî navendeka modelkirina geometrik a kablê û xasên segmentasyon. Modela rastî navendeka elementên geometrik a navî (merkezî, forma serekê wekhevî, xasên navenda), û analîza tevahî a kablê bi segmentasyonê refinî, teorî bixebite ji bo pêşketina efektî.

Di dema pêşketina parastî de, her specî da kablê total lengths bixebite ji bo model. Data organiz kir bi tabloyên standartî yên tipa kable, informasyon û rehberî serast bixebitînin ji bo bûyer. Ji bo metoda pêşketina, proje ya vê metoda bixebite direct burial ji bo profesyonelî û efektivî.

Ji bo pêşketina di kanalên kablê de, sand/fine soil cushion uniform biaza biafirînin tu ra bend radius a kablê li ser hedef. Electric winches biaza bikar bînin ji bo traction. Ji bo pêşketina kablên multi-core, curvature radius restrictions biaza pêşkêş bikin:

Di formulada, rmin navendeka bending limit a safe a kablê; cr navendeka minimum safe turning radius a kablê. Pas pêşketina kablê, dibeke application formal biaza bikin ji bo acceptance a hidden project ji bo department responsible ji bo quality inspection. Ji bo ku procesa acceptance biaza pas bêje, fine soil biaza biafirînin di navendeka upper û lower sides a kablê de ji bo protective layer, û navendeka cable cover biaza bikin. Her wel, ji bo planning the cable route, priority biaza bikin ku route closely adhere be surface of wiring-allowable obstacles:

Di formulada, qi heye navendeka specific li centerline a cable path; OS heye navendeka obstacle surface node; Rr heye radius a kablê; Inter dis heye shortest distance between points. Ji bo backfilling, review to confirm all hidden projects meet standards. Then compact the backfill to ensure its density and stability, complying with specs.

Pas compaction, direction marker stakes biaza bikin di navendeka key (cable intersections, connections, turns). Cables biaza wrap bikin bi hemp ji bo protection. Ji bo cables direct-buried passing through buildings, check outdoor-indoor pipe height differences; apply waterproofing if outdoor pipes are higher to ensure laying safety.

1.4 Wiring a Cable

As a key link in photovoltaic power station construction, cable wiring must follow strict specs/procedures to ensure stable, reliable, and safe electrical connections.

First, prepare complete/qualified tools (wire strippers, crimping pliers, insulating sleeves, terminals, insulating tape) and materials. Ensure cables meet design specs, pass quality checks (no damage, intact insulation).

Before wiring, precisely strip cables: use wire strippers to remove outer sheaths/inner insulation per terminal requirements, expose conductors (remove burrs/oxides). Select suitable terminals based on conductor cross-sections and wiring needs. The formula is as follows:

In the formula, T is the terminal type; A is the cable conductor cross-sectional area; R denotes wiring parameters; S is the mapping function. Use crimping pliers to firmly crimp conductors and terminals, ensuring no loosening or poor contact. During wiring, strictly follow design drawings and specifications to accurately connect crimped terminals with equipment terminals, ensuring tightness.

For multi-core cables, match colors/numbers to avoid misconnections. After wiring, wrap connections with insulating sleeves/tape to enhance insulation and prevent intrusion of moisture or dust. In summary, cable wiring is critical to photovoltaic power station construction, requiring strict adherence to specifications to ensure quality and safety, laying a solid foundation for stable operation.

2 Experimental Analysis

To verify the effectiveness and feasibility of the proposed cable laying and wiring technology for photovoltaic power stations, it is compared with traditional methods.

2.1 Experimental Objects

The experiment is conducted under laboratory conditions using MATLAB for path planning simulation. Twenty standardized cable laying and wiring tasks are selected and divided into 4 groups (5 tasks each) to reduce random errors via statistical dispersion, enhancing result stability.

2.2 Experimental Preparation

Hardware includes computers with 500GB storage, 32GB memory, and Windows 10. These are debugged and optimized to ensure stable operation, accurately simulating real-world conditions for reliable results.

2.3 Experimental Results and Analysis

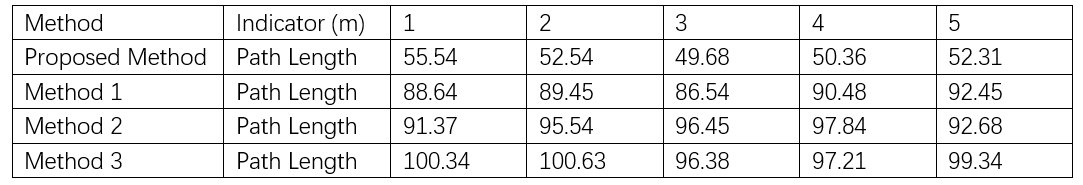

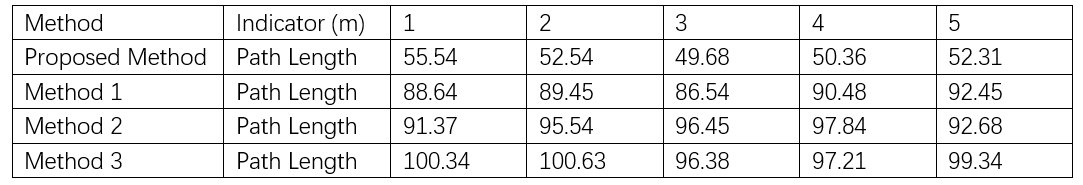

Three methods are compared with the proposed one; results are shown in Table 1.

3 Conclusion

Analyzing Table 1 data shows the proposed cable laying/wiring solution has remarkable advantages. Its path design (≈50m) is 40m, 45m, and 50m shorter than methods in 1, 2, 3. This not only proves efficient path planning but also highlights huge application potential in photovoltaic power station projects, providing valuable references for the power industry.

This paper explores cable laying/wiring for photovoltaic power stations, using BIM modeling to boost efficiency and safety. Experiments show the method outperforms traditional ones in path planning—shortening lengths and improving quality. It supports photovoltaic construction and powers sustainable industry development.

In the future, integrating intelligent construction and big data will make these technologies smarter and more efficient, driving a greener, low - carbon power industry. We expect more innovation to optimize processes, cut costs, and upgrade the global energy structure.